WORK STUDY TO REVIEW

THE STAFF STRENGTH OF

SSE/ELEC/POWER/CGL

CHENNAI DIVISION

SOUTHERN RAILWAY

SOUTHERN RAILWAY

PLANNING BRANCH

G. 275 / WSSR-051718 / 2017-18

STUDIED BY

WORK STUDY TEAM

OF

PLANNING BRANCH

FEBRUARY 2018

WORK STUDY TO REVIEW

THE STAFF STRENGTH OF

SSE/ELEC/POWER/CGL

CHENNAI DIVISION

SOUTHERN RAILWAY

INDEX

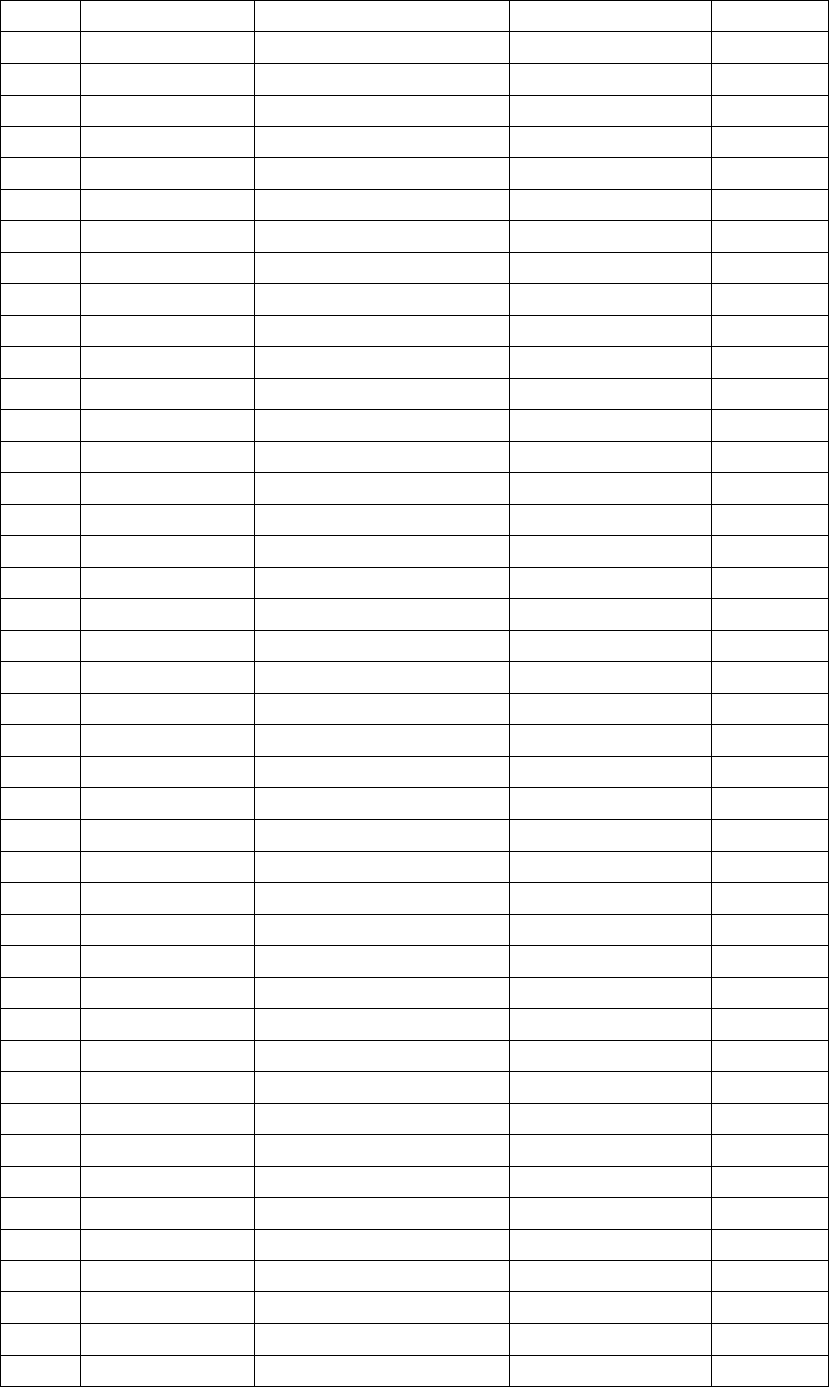

SERIAL

NUMBER

CONTENTS

PAGE

NUMBER

(i)

ACKNOWLEDGEMENT

1

(ii)

AUTHORITY

(iii)

TERMS OF REFERENCE

(iv)

METHODOLOGY

(v)

SUMMARY OF RECOMMENDATIONS

2

CHAPTERS

I

INTRODUCTION

3 - 4

II

PRESENT SCENARIO

5 - 46

III

CRITICAL ANALYSIS

47 - 52

IV

PLANNING BRANCH’S REMARKS ON CO-

ORDINATING OFFICER’S VIEWS

53-55

V

FINANCIAL SAVINGS

56

ANNEXURES

I

S.A.V.E. STATEMENT OF SSE/ELEC/POWER/CGL

57

II

SUMMARY OF ENERGY CONSUMPTION

58-59

III

BENCHMARKING ISSUED BY RAILWAY BOARD FOR

THE MONTH OF OCTOBER 2017

60

IV

CO-ORDINATING OFFICER’S VIEWS

61

V

INDEX OF TABLES AND CHARTS

62

1

(i)

ACKNOWLEDGEMENT

The work study team acknowledges its gratitude to Sr.DEE/MAS, ADEE/MAS

(Co-ordinating Officer), SSE/POWER/CGL (Co-ordinating Supervisor) and all the

signal staff of under SSE/POWER/CGL for their valuable inputs and guidance in

conducting and completing the study in time.

(ii)

AUTHORITY

Annual programme of work studies, approved by SDGM for the year 2017-18.

(iii)

TERMS OF REFERENCE

To review the staff strength of SSE/POWER/CGL section in Chennai

Division/S.Rly.

(iv)

METHODOLOGY

The following methodology has been adopted while conducting the study:

1) Collection of data

2) Discussion and interaction with officers of the Division and supervisors

and staff of the unit.

3) Observation at Field Unit.

4) Working out the requirements on need base duly considering

benchmarking, need basis, quantum of outsourcing and

modernization.

2

(V)

SUMMARY OF RECOMMENDATIONS

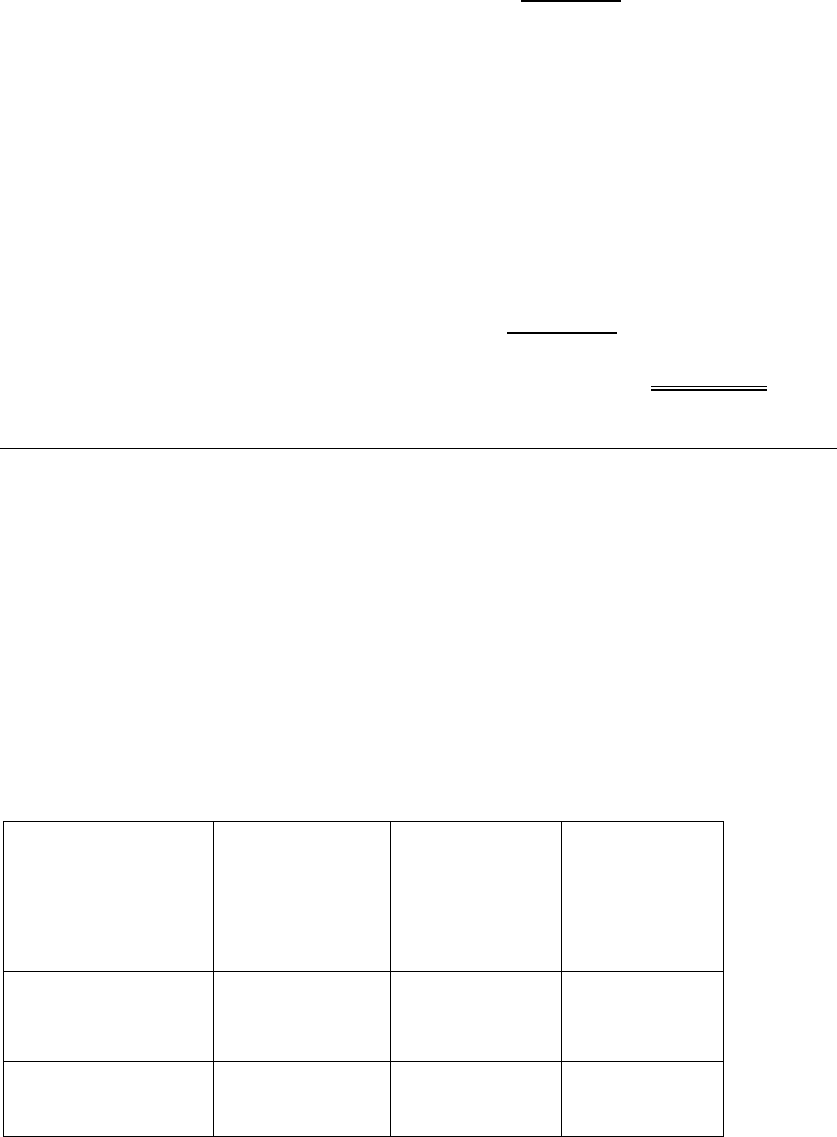

The following posts in respect to SSE/ELEC/POWER/CGL section are

identified as surplus to the requirement and these posts may be

surrendered and credited to the vacancy bank.

Sl.No

Category

Grade in Rs

No. of posts

1

Helper/P

Rs.1800/-

2

TOTAL

2

Table 1: Posts recommended for surrender

Total Two (2) posts.

3

CHAPTER I

1.0 INTRODUCTION

1.1 Electrical Department:

Electrical Department of Indian Railways is responsible for the operation

and maintenance of the Electrical Assets, as well as construction activities

involving electrical installations.

Electrical Rolling Stock:

Operation and maintenance of Electrical

Locomotives, Electrical multiple units and Mainline electrical multiple

units.

Electrical Traction Distribution Installations:

Operation and Maintenance

of Traction Sub-Stations, Switching stations and Traction overhead power

supply systems and supervisory control and data acquisition systems.

Electrical General Services:

Operation and maintenance of Train Lighting

and Air-Conditioning equipment in coaches- Operation and maintenance

of HT & LT Power Distribution, standby generators power backup

systems, lighting, ventilation, Air-Conditioning, Lifts, Escalators and

Pumping in stations, Offices, Workshops, Railway Colonies, Railway

Hospitals, Passenger Reservation Systems, Level Crossings Gates etc.,

In Southern Railway, power supply for Railway Electric Traction is availed

from State Electricity Boards of Tamil Nadu (TANGEDCO), Kerala (KSEB),

Andhra Pradesh (APTRANSCO) and the power supply for General Services

is availed from State Electricity Board of Karnataka (KPTL) also in addition

to the three other State Electricity Boards indicated above.

1.2 One of the main departments of the Indian Railways, Electrical

department shoulders lot of responsibility in proper operation of railway

services. With Railway Electrification on the rise, Electric traction hauls

almost 60% of freight traffic and 48% of passenger traffic.

1.3 The Electrical department is headed Member/Electrical (

ex officio

Secretary to the Govt. of India

) at the Railway Board level. At the Zonal

Level, Principal Chief Electrical Engineer (PCEE) is the Principal Officer of

the Electrical Department. Sr.Divisional Electrical Engineer (Sr.DEE)

heads the organization at the Divisional Level. He is assisted by DEEs

4

(General, Traction Operation, Traction Distribution & Electrical Loco shed)

and ADEEs.

1.4 The department, at the Divisional level is divided into a number of

functional units vested with one or more of the functions of the

department elaborated in the previous paragraphs.

1.5 The unit considered for this study, SSE/P/CGL of Chennai Division, takes

care of General Services maintenance of the assets under its jurisdiction

and Train Lighting maintenance activities for the trains.

1.6 This section comes under heavy pressure during the various festival

Seasons esp.

Melmaruvathur

Adiparasakthi Amman Festival in the month

of December & January and devotees’ pilgrimages to Murugan Temple in

Mailam

& world famous temples of

Kanchipuram

.

1.7 The term Benchmark originates from the chiseled horizonal marks that

surveyors made into which an angle iron could be placed to bracket

(bench) and leveling rod, thus ensuring that the leveling rod can be

repositioned in exactly the same location in future. Bench Marking is also

a point of reference for a measurement. It is the process used in

management in which organization evaluates various aspects of their

process in relation to the best practice usually within their own sector.

1.8 Keeping the above aspects in view, the work study team has made an

attempt to study the present system of working at SSE/POWER/CGL

Section, through Benchmarking and need basis as means of reducing cost

and right sizing the work force. With increased activity of Outsourcing

and further growth of Technology, the work load vs requirement of staff

is critically examined in the ensuing chapters.

5

CHAPTER II

2.0 PRESENT SCENARIO

2.1 Southern Railway has six (6) Divisions namely MAS, MDU, TPJ, PGT, TVC

& SA. Electrical Department of MAS Division is functioning under the

overall control of Sr.DEE/MAS who is assisted by DEEs/MAS, ADEEs/MAS,

SSEs and Supervisors in extending Co-operation for smooth and efficient

functioning of the Department with sub units/sections. Among the six

Divisions, Chennai Division comes under the category of Divisions

consuming more than 23,00,000 Units.

SSE/ELEC/POWER/CGL is In-charge SSE for this section.

2.2 LOCATION OF THE OFFICE OF SSE/ELEC/POWER/CGL:

Office of the SSE/ELEC/POWER/CGL is located in the UP-end direction of

the Platform No.1, adjacent to the Office of the IPF/CGL within in the

Chengalpattu Station.

2.3 STAFF STRENGTH:

The details of the Sanction, Actual, Vacancy and Excess are given in Page

No.57 as Annexure I. The total sanction is shown as 28 including SSEs

and JE. Actual is 32 as per Sr.DPO/MAS’s list. Actual staff strength

according to list of staff position issued by SSE/ELEC/POWER/CGL dated

17.10.2017, is 32 against sanctioned strength of 28. Work Study team

reviews the staff strength based upon the S.A.V.E statement issued by

Sr.DPO/MAS only. Hence Sanctioned strength is taken as 28.

2.4 ORGNISATIONAL SETUP:

Sr.DEE/G/MAS

DEE/MAS

ADEE/MAS

SSE/ELEC/POWER/CGL

Sr.Tech/Power

Tech I/P & Tech I/TL

Tech II/P & Tech II/TL

Tech III/P & Tech III/TL

Helpers

Table 2: Organizational Structure

6

2.5 DUTY HOURS & DEPLOYMENT OF STAFF AT VARIOUS PLACES IN

THIS SECTION:

It is evident from the below tabular data of Duty Hours that staff are not

posted for duty during 06.00 Hrs – 08.00 Hrs in this section.

Station Location Working Hours No.of Staff

11KV Sub Station 22.00-06.00 Hrs 1

07.00-11.00 Hrs 1

21.00-07.00 Hrs 1

11.00-21.00 Hrs 1

10

08.00-17.00 Hrs 2

14.00-22.00 Hrs 2

22.00-06.00 Hrs 2

08.00-17.00 Hrs 4

08.00-17.00 Hrs 4

28

CJ NEW

TMV

CGL

PALAR Pump House

08.00-17.00 Hrs

PWU-MLMR Stations LC-

52 -- LC 74 Gate Lodges

Train Lighting

ACK-MYP Stations & LC

75-LC 120Gate Lodges

RDY-TMLP Station & LC

6-LC 37 Gate Lodges

Table 3: Duty Hours & Deployment of Staff

2.6 JURISDICTION AND SUB-SECTIONS OF THE

SSE/ELEC/POWER/CGL:

Jurisdiction of SSE/P/CGL is between PWU-MYP and CGL-TMLP.

2.7 JURISDICTION: ROUTE KILOMETRES OF THE SECTION:

This section covers total route kilometers of 155.03. Sub-section wise

route kms is as shown below:

Sub-section

Kms. Covered

PWU-MYP

106.44

CGL-TMLP

48.59

Total Section (Kms.)

155.03

Table 4: Route Kilometres of the Section

7

2.8 STATIONS IN THE SSE/ELEC/P/CGL’S JURISDICTION:

There are

Twenty Four (24)

stations in this Section.

Station Name

Station

Code

At Km.

Inter Distance

in Km.

Paranur

PWU

55.16

-

Chengalpattu

CGL

59.84

4.68

Ottivakkam

OV

68.37

8.53

Padalam

PTM

73.08

4.71

Karunguzhi

KGZ

80.83

7.75

Madhurantakam

MMK

84.48

3.65

Melmaruvathur

MLMR

95.52

11.04

Acharapakkam

ACK

98.21

2.69

Tozhupedu

TZD

104.27

6.06

Olakur

OLA

113.86

9.59

Tindivanam

TMV

125.48

11.62

Mailam

MTL

134.84

9.36

Perani

PEI

143.44

8.60

Vikravandi

VVN

149.92

6.48

Mundiayambakkam

MYP

161.60

11.68

Sub-Section PWU-MYP Total

106.44

Chengalpattu

CGL

0

---

Reddipalayam

RDY

4.83

4.83

Villiyambakkam

VB

8.00

8.00

Palur

PALR

11.49

11.49

Palayasivaram

PYV

14.95

14.95

Walazabad

WJ

21.84

21.84

Nathapettai

NTT

29.26

29.26

Kanchipuram East

CJ/E

34.62

34.62

Kanchipuram New

CJ/N

35.94

35.94

Tirumalpur

TMLP

48.59

48.59

Sub-Section CGL-TMLP Total

48.59

Total Section

155.03

Table 5: List of Stations in the SSE/P/CGL Section

8

2.9 JURISDICTION: TYPES OF STATIONS IN THIS SECTION:

Type

BG

Under GC

Total

Block

16- CGL, OV, KGZ, MMK, MLMR, TZD,

LA, TMV, MTL, PEI, VVN, MYP

PALR, WJ, CJ & TMLP

-

16

CNC

-

-

-

Halt

07- PTM, ACK, RDY, VB, PYV, NTT,

CJ/E

01

PWU

08

Total

23

1

24

Table 6: Types of Stations-SSE/P/CGL Section

2.10 ASSETS AND INSTALLATIONS:

1. No. of stations - 24

2. No. of Level crossing gates - 56

3. No. of power line crossings - 93

4. No. of service connections - 88

5. No. of staff Quarters - 275

6. No. of service buildings - 22

7. No. of sub-station - 01

8. No. of pumps - 44

9. No. of UPS - 40

10. No. of generators - 09 (4 Port Gen)

11. No. of Retiring Room - 15

12. No. of ORH - 01

13. No. of Running Room - 03

14. No. of Rail kalyana mandapam - --

15. No. of Transformers - 02

16. No. of HT earths - 15

17. No. of LT earths - 496

18. No. of Lights - 3174

19. No. of ceiling fans - 867

20. No. of Air Circulator Fans - 46

21. No. of Pre-Cooling Charging Points - 12

22. No. of Pvt. Stalls - 06

23. No. of PRS - 05

24. No. of UTS - 16

9

2.11 MACHINERIES AND PLANTS:

S.No.

Name of the Assets

Quantity

1

Transformers

02

2

Generator

05

3

Portable Generator

04

4

UPS

40

5

Posts

664

6

AC plants

14

7

Water coolers

17

8

Geysers

14

9

High masts

08

10

Tower light

02

10

HT Earths

15

11

LT Earths

496

Table 7: List of Machineries and Plants

2.11.1 LC GATES IN THE SSE/ELEC/P/CGL’s JURISDICTION:

There are Fifty Six (56) Level Crossing Gates in the Jurisdiction of

SSE/P/CGL section, as listed below:

DETAILS OF LEVEL CROSSING GATES- CGL Section

S.

No.

S.C.NO.

LC NO.

AT KM

Between

Station

T/E

1

514-013-389

LC-04

5/8-10

RDY-VB

E

2

514-004-165

LC--06

7/900-8/000

RDY-VB

E

3

327-004-65

LC--07

8/300-400

VB-PALR

E

4

327-001-730

LC--08

11/2-4

VB-PALR

T

5

327-003-270

LC--10

12/38-40

PALR- PYV

E

6

635-005-284

LC--11

14/10-12

PALR- PYV

E

7

NEW S.C.

LC-12

14/32-15/2

PYV-WJ

E

8

635-001-1006

LC--14

17/10-12

PYV- WJ

E

9

327-002-158

LC--15

18/36-38

PYV- WJ

E

10

328-008-532

LC--16

20/18-20

PYV- WJ

E

11

326-008-527

LC--18

21/12-14

PYV- WJ

T

12

328-001-2674

LC--19

22/700-800

WJ- NTT

E

13

328-001-813

LC--19/A

23/12-14

WJ- NTT

T

10

14

626-011-1081

LC--21

25/20-22

WJ- NTT

T

15

301-038-249

LC--28

35/400-500

CJ-TMLP

T

16

307-001-210

LC--30

38/300-400

CJ-TMLP

E

17

612-004-331

LC--32

41/900-42/000

CJ-TMLP

E

18

612-011-185

LC--33

43/19-21

CJ-TMLP

E

19

612-012-259

LC--34

44/400-500

CJ-TMLP

E

20

311-002-820

LC--35

45/5-7

CJ-TMLP

T

21

311-001-1307

LC--36

47/3-5

CJ-TMLP

E

22

311-001-955

LC--37

47/29-31

CJ-TMLP

E

23

501-030-51/old-

59

LC--52

58/34-36

PWU-CGL

E

24

513-014-70

LC--55

63/4-6

CGL- OV

T

25

513-005-728

LC--57

66/16-18

CGL- OV

E

26

513-005-1076

LC--60

69/12-14

OV-PTM

E

27

522-001-139

LC--63

78/22-24

PTM-KGZ

T

28

NEW S.C.

LC-64

81/2-4

KGZ YARD

T

29

525-011-299

LC--70

88/14-16

MMK-PQM

E

30

525-007-320

LC--71

89/16-18

MMK-PQM

T

31

525-007-272

LC--72

89/32-34

MMK-PQM

E

32

592-009-204

LC--73

92/4-6

PQM-MLMR

T

33

592-002-49

LC--74

94/30-32

PQM-MLMR

T

34

586-008-186

LC--75

97/30-32

ACK YARD

E

35

586-012-338

LC--76/A

99/32-34

ACK-TZD

E

36

586-012-335

LC--77

100/24-26

ACK-TZD

E

37

588-002-841

LC--79

102/18-20

ACK - TZD

T

38

591-011-391

LC--84

108/4-6

TZD - OLA

T

39

591-012-29

LC--85

109/18-20

TZD - OLA

T

40

470-001-1532

LC--87

113/20-22

TZD - OLA

E

41

470-001-1533

LC--88

114/4-6

OLA - TMV

E

42

470-027-701

LC--89

116/32-117/2

OLA - TMV

E

43

457-002-605

LC--94

124/36-125/2

TMV - MTL

E

44

458-011-319

LC--97

127/34-128/2

TMV - MTL

T

45

458-002413

LC-99

131/12-14

TMV-MTL

E

46

458-001-67

LC--100

132/26-28

MTL-PEI

E

47

472-011-155

LC--104

136/26-28

MTL-PEI

T

48

471-013-716

LC--106

139/38-40

MTL-PEI

E

49

476-012-103

LC--109

144/28-30

PEI- VVN

E

50

415-005-504

LC--110

146/30-32

PEI- VVN

E

51

415-001-1920

LC--111

150/12-14

VVN-

MYP(ROB)

E

52

415-001-1500

LC--113

151/32-152/2

VVN- MYP

E

53

418-001-1662

LC--115

154/36-155/2

VVN- MYP

E

54

418-001-715

LC--116

155/13-32

VVN- MYP

T

11

Table 8: List of Level Crossing Gates-SSE/P/CGL Section

2.11.2 DETAILS OF POWER LINE CROSSING IN SSE/P/CGL SECTION:

There are Ninty Three (93) Power Line Crossings in this Section, which

are enlisted below:

S.No.

BETWEEN

STATIONS

BETWEEN

TRACTION MAST

SYSTEM

VOLTAGE

OH/UG

1

CGL-RDY

0/12-14

11KV

UG

2

CGL-RDY

1/30-32

400V

UG

3

CGL-RDY

2/14-16

11KV

UG

4

CGL-RDY

2/22-24

400V

UG

5

CGL-RDY

3/8-10

11KV

UG

6

CGL-RDY

3/10-12

110KV

OH

7

CGL-RDY

3/22-24

110KV

OH

8

CGL-RDY

3/22-24

33KV

UG

9

CGL-RDY

4/2-4

110KV

OH

10

RDY-VB

5/4-6

400V

UG

11

RDY-VB

5/30-32

11KV

UG

12

VB-PALR

10/8-10

33KV

UG

13

PALR-PYV

12/22-24

400V

UG

14

PYV-WJ

15/16-18

11KV

UG

15

PYV-WJ

15/16-18

11KV

UG

15A

PYV-WJ

15/32-34

110KV

OH

16

PYV-WJ

16/10-12

400V

OH

17

PYV-WJ

16/12-14

33KV

UG

18

PYV-WJ

17/10-12

33KV

UG

19

PYV-WJ

21/6-8

11KV

UG

20

WJ-NTT

22/26-28

33KV

UG

21

WJ-NTT

23/8-10

110

OH

22

WJ-NTT

23/34-36

11KV

UG

23

WJ-NTT

25/24-26

11KV

UG

24

NTT-CJE

29/28-30

11KV

UG

25

NTT-CJE

33/28-30

11KV

UG

26

CJE -TMLP

36/32-34

11KV

UG

27

CJE- TMLP

36/32-34

110KV

OH

28

CJE -TMLP

36/36-38

33KV

UG

29

CJE -TMLP

36/38-40

33KV

UG

30

CJE- TMLP

36/40-42

11KV

OH

31

CJE -TMLP

36/46-48

110KV

OH

55

418-001-698

LC--117

156/10-12

VVN- MYP

E

56

418-004-1275

LC--119

157/20-22

MYP-VM

E

Total No. of LC Gates - 56

12

32

CJE -TMLP

36/46-48

33KV

UG

33

CJE- TMLP

37/12-14

33KV

UG

34

CJE -TMLP

38/28-30

110KV

OH

35

CJE- TMLP

39/15-17

110KV

OH

36

CJE -TMLP

42/29-31

400V

UG

37

CJE -TMLP

44/27-29

33KV

UG

38

CJE -TMLP

45/29-31

11KV

UG

39

CJE -TMLP

48/27-29

11KV

UG

40

CJE-TMLP

48/600-700

11KV

UG

41

CJ-TMLP

48/27-29

110KV DC

OH

42

CJ-TMLP

45/31-46/1

400KV DC

OH

43

VB-PALR

10/8-10

400V

UG

44

VB-PALR

10/12-14

11KV

UG

45

PWU-CGL

56/7-8

11KV

UG

46

PWU-CGL

58/34-36

400V

UG

47

CGL-OV

61/4--6

11KV

UG

48

CGL-OV

62/ 18--20

33Kv

UG

49

CGL-OV

62/ 24—26

11KV

UG

50

CGL-OV

67/22-24

230KV

OH

51

OV—PTM

69/ 4--6

11KV

UG

52

PTM—KGZ

73/ 34-36

11KV

UG

53

PTM—KGZ

74/ 12-14

230KV

OH

54

PTM-KGZ

76/30-32

230KV

OH

55

PTM—KGZ

78/ 26-28

11KV

UG

56

PTM—KGZ

81/16-18

11KV

UG NC

57

KGZ—MMK

83/ 18--20

33KV

UG

58

KGZ—MMK

83/ 24--26

11KV

UG

59

KGZ—MMK

83/ 24--26

11KV

UG

60

MMK-PQM

97/8-9

400KV DC

OH

61

PQM—MLMR

91/20-22

400KV

OH

62

PQM—MLMR

92/ 8—10

11KV

UG

63

PQM—MLMR

93/18-20

33KV

UG

64

PQM—MLMR

93/26-28

110KV

OH

65

MLMR-ACK

96/ 8--10

11KV

UG

66

MLMR-ACK

97/16-18

110KV

OH

67

MLMR-ACK

97/18--20

11KV

UG

68

ACK—TZD

99/ 30--32

11KV

UG

69

ACK—TZD

103/2-4

11KV

OH

70

ACK—TZD

103/12-14

33KV

UG

71

TZD—OLA

104/ 32—34

11KV

UG

72

TZD—OLA

106/ 12--14

400V

UG

73

TZD—OLA

109/ 30--32

400v

UG

74

TZD—OLA

109/ 30--32

11KV

UG

75

OLA-PCLM

114/ 16--18

11KV

UG

13

76

OLA-PCLM

116/ 10--12

400V

UG

77

PCLM—TMV

122/10--12

11KV

UG

78

PCLM—TMV

123/4-6

33KV

OH

79

PCLM—TMV

124/ 36--38

11KV

UG

80

TMV—MTL

125/ 16--18

11KV

UG

81

TMV—MTL

126/ 24--26

400V

UG

83

TMV—MTL

127/ 32,128/ 2

11KV

UG

84

TMV—MTL

127/ 34-128/ 2

11KV

UG

85

TMV—MTL

127/34

400V

UG

86

MTL—PEI

135/ 6--8

11KV

UG

87

MTL-PEI

137/32-34

110KV

OH

88

MTL—PEI

138/ 28--30

33KV

UG

89

MTL--PEI

142/ 34,143/ 2

11KV

UG

90

PEI—VVN

148/ 24--26

11KV

UG

91

VVN-MYP

152/12-14

230KV

OH

92

VVN-MYP

154/16-18

110KV

OH

93

MYP-VM

161/2-4

2x110KV

OH

Table 9: Details of Power Line Crossings: SSE/P/CGL Section.

2.11.3 STAFF QUARTERS: SSE/E/CGL has been entrusted to maintain and

service of two hundred and seventy five (275) staff quarters.

S.No. Station Type-I Type-II Type-III Type-IV Type-V TOTAL

1 CGL 101 63 12 2 1 179

2 MMK 0 4 0 0 0 4

3 ACK 4 19 1 0 0 24

4 TMV 19 21 1 0 0 41

5 MTL 1 3 0 0 0 4

6 PEI 3 0 0 0 0 3

7 VVN 0 8 0 0 0 8

8 CJ/E 8 2 0 0 0 10

9 TMLP 2 0 0 0 0 2

138 120 14 2 1 275

TOTAL STAFF QUARTERS: 275

Table 10: Staff Quarters- SSE/P/CGL Section

2.11.4 SUB-STATION DETAILS:

There is a 11 KV Sub-Station catering to the needs of CGL area. It is

functioning with 2 transformers, each one’s capacity being 160 KVA and

connected load is 250 KW. Details of the Transformers are tabled below:

Transformer

I

II

Location

CGL

CGL

Date of energization

29.12.2003

29.12.2003

14

Make

KEL

KEL

Capacity

160 KVA

160 KVA

Phase

3 PHASE

3 PHASE

Cycle

50

50

Voltage primary

11KV

11KV

Voltage secondary

433V

433V

Vector group

Dyn11

Dyn11

HT tapping’s at

5

5

Amper HT

8.4 A

8.4A

Amper LT

213.3A

213.3A

Impedance voltage

4.43 V

4.43 V

Nett. Weight with oil

883 Kg

883 Kg

Thermometer

01

01

Type of cooling

ON AN

ON AN

Makers serial No

47703

47704

Year of manufacturing

2003

2003

Maximum temperature

45

.

C

45

.

C

Table 11: Details of Sub-Station & Transformers

2.11.5 PUMP DETAILS:

There are Forty Four (44) pumps in this section, maintained by

SSE/E/CGL.

S.

No.

STATION-LOCATION

CPTY.

(in

HP)

TYPE

QTY

1.

CGL-GLR

5

OPEN WELL SUB.

2

2.

CGL- PF-7&8

10

OPEN WELL SUB

2

3.

CGL- EAST COLONY

5

OPEN WELL SUB

1

4.

CGL- EAST COLONY

1

BORE WELL SUB.

1

5.

CGL- PALAR PH (GLR)

10

OPEN WELL SUB.

1

6.

CGL -PALAR PUMP HPUSE

1

BORE WELL SUB.

3

7.

CGL- PALAR PUMP HPUSE

3

BORE WELL SUB.

2

8.

CGL -PWI OFFICE

1

OPEN WELL SUB

1

9.

OV- PF-1

1

BORE WELL SUB

1

10.

PTM- PF-1

1

BORE WELL SUB.

1

15

11.

KGZ- PF-1

1.5

BORE WELL SUB.

1

12.

MMK- CIRCULATING AREA

1.5

OPEN WELL SUB.

1

13.

MLMR- GLR

5

OPEN WELL SUB.

1

14.

MLMR- CIRCULATING AREA

1

BORE WELL SUB.

1

15.

MLMR- CIRCULATING AREA

3

BORE WELL SUB.

1

16.

MLMR- PF-3&4

7.5

OPEN WELL SUB.

1

17.

ACK- TRACK MACHINE ROOM

1

BORE WELL SUB.

1

18.

ACK- LC-75

1

BORE WELL SUB.

1

19.

ACK- TRACTION SUBSTATION

1

BORE WELL SUB.

1

20.

ACK- PF-1(CGL END)

1.5

OPEN WELL SUB.

1

21.

TZD- PF-1

1.5

BORE WELL SUB.

1

22.

OLA- PF-1

1

OPEN WELL SUB.

1

23.

TMV- PUMP HOUSE

5

OPEN WELL SUB.

2

24.

TMV- PUMP HOUSE

3

BORE WELL SUB.

2

25.

TMV- GLR

5

OPEN WELL SUB.

1

26.

MTL- APPROACH ROAD

1.5

BORE WELL SUB.

1

27.

PEI- QRS AREA

1.5

BORE WELL SUB.

1

28.

VVN- QRS AREA

1.5

BORE WELL SUB.

1

29.

MYP- PF-1

1.5

BORE WELL SUB.

1

30.

MYP- GOODS YARD

1.5

BORE WELL SUB.

1

31.

PALR- APPROACH ROAD

1.5

BORE WELL SUB.

1

32.

WJ- PF-1

1.5

BORE WELL SUB.

1

33.

WJ- PF-1

3

OPEN WELL SUB.

1

34.

CJ/E- QRS AREA

3

OPEN WELL SUB.

1

35.

CJ- CIRCULATING AREA

3

BORE WELL SUB.

1

36.

TMLP- QRS AREA

1

BORE WELL SUB.

2

TOTAL

44

Table 12: Details of Pumps: SSE/P/CGL Section

16

2.11.6 BOREWELLS: There are 21 wells in the Jurisdiction of SSE/E/CGL.

Sl.No Location BW/OL

Capacity

(HP)

Tank

Capacity

(HLT)

BL/OL

Depth

(M)

1 CGL PLR PH BW 3 50000 110

2 CGL PLR PH BW 3 50000 80

3 CGL PLR PH BW 3 50000 140

4 CGL PLR PH BW 3 50000 180

5 OV BW 1 2000 180

6 PTM BW 0.75 1000 250

7 KGZ BW 1 2000 200

8 MMK OL 1.5 15000 28

9 MLMR BW 3 90000 180

10 ACK BW 3 75000 170

11 TZD BW 1 2000 140

12 OLA OL 1.5 3000 70

13 MTL BW 1 2000 130

14 PEI BW 0.75 3000 140

15 VVN BW 1 3000 110

16 MYP BW 1 1000 140

17 PALR GLR 1 5000 35

18 WJ GLR 1.5 5000 35

19 CJE OL 3 5000 110

20 CJ NEW BW 3 5000 120

21 TMLP BW 1 2000 110

Table 13: Details of Bore wells: SSE/P/CGL Section

2.11.7 UPS@UTS LOCATIONS:

UPS is provided for at the following 16 locations in this section.

Sl.

No

Stn.

Code

Station Name

C

A

t

UPS No.

Back

up

Time

(Mts)

DOI

1

TMLP

Tirmalpur

E

N1091503230

PO 2011205425

60

02.04.11

2

CJ

Kanchipuram

D

PO20110205424

PO20110205423

120

02.04.11

3

WJ

Walajahbad

E

N1091903231

PO20110205390

60

02.04.11

4

PALR

Palur

E

N1092305635

PO20110205390

60

02.04.20

11

5

CGL

Chengalpattu

A

N1092305635

PO20110205435

60

02.04.20

11

17

6

OV

Ottivakkam

E

PO20110205429

PO20110205388

60

17.12.11

7

KGZ

Karunguzhi

E

N11100907231

PO20110205394

60

17.12.11

8

MMK

Madurantakam

E

PO20110205385

N1092305701

60

13.12.08

9

MLM

R

Melmaruvathur

B

---

60

03.12.08

10

TZD

Tozhupedu

E

N1092305641

PO20110205386

60

15.12.11

11

OLA

Olakur

E

N1092305643

PO20110205363

60

20.04.11

12

TMV

Tindivanam

D

PO20110205391

PO20110205417

60

04.08.14

13

MTL

Mailam

D

PO2011012173

N1092305629

60

20.4.201

1

14

PEI

Perani

E

N1092305651

60

02.09.08

15

VVN

Vikravandi

E

PO201101271

N1092305720

60

02.09.08

16

MYP

Mundiyabakkam

E

PO2011012187

N1092405057

60

15.12.11

Table 14: Details of UPS @ UTS Locations: SSE/P/CGL Section

2.11.8 UPS@PRS LOCATIONS:

UPS is provided for at the following 5 locations in this section.

Sl.

No

Locat-

ion

Code

Location

Name

C

A

t

UPS No.

Backup

Time

(Mts)

DOI

1

CJ

Kanchipuram

D

PO20110205424

PO20110205423

120

02.04.11

2

CGL

Chengalpattu

A

N1092305635

PO20110205435

60

02.04.11

3

MLMR

Melmaruvathur

B

-----

60

03.12.08

4

TMV

Tindivanam

D

PO20110205391

PO20110205417

60

04.08.14

5

MBPM

Mahabalipuram

-

N1091302836

PO20110205407

60

24.08.11

Table 15: Details of UPS @ PRS Locations: SSE/P/CGL Section

18

2.11.9 DIESEL GENERATORS:

There are 5 (five) Diesel Generators under the jurisdiction of SSE/E/CGL.

Details of which are tabled below:

Sl.No. I II III IV V

Location 11 KV SS 11 KV SS CGL Pump MLMR Stn CJ Stn

Capacity (KVA) 125 62.5 62.5 30 30

Make-Engine R&H (I) Ltd Kirlos Kirlos Kirlos Kirlos

Make-Alternator Kirlos Crompt Crompt Crompt Crompt

Engine SL No. 34220620562 RB66/845D RB66845D PA 494 3R1040

Alternator SL No. 9207AC-87 77019AG11 GADI130 GIS160MB G2R30-43

Date of Installation 27.01.2016 17.03.2017 1995 Aug-08 Jun-03

Remarks - -

Table 16: Details of Diesel Generators: SSE/P/CGL Section

Working Details of 63 KVA DG Set & 125 KVA DG Set till Oct’17

Month

Working

Hrs.

Fuel cons.in

Ltr

Units

Generated

Units

Gen/ltr.

JAN-15

11.20

90

560

6.22

FEB-15

00.45

7

23

3.29

MAR-15

09.00

72

450

6.25

APR-15

15.30

124

765

6.17

MAY-15

06.10

50

305

6.10

JUNE-15

01.45

16

73

4.56

JULY-15

12.15

96

608

6.33

AUG-15

12.05

96

603

6.28

SEP-15

12.75

96

615

6.41

OCT-15

11.50

90

567

6.30

NOV-15

01.15

8

25

3.13

DEC-15

31.05

250

1553

6.21

JAN-16

13.45

112

673

6.01

FEB-16

5.40

45

270

6.00

MAR-16

4.50

40

225

5.63

APR-16

2.50

24

125

5.21

MAY-16

8.30

71

415

5.85

JUNE-16

4.40

38

220

5.79

JULY-16

8.35

72

418

5.81

AUG-16

12.27

98

614

6.27

SEP-16

6.30

49

315

6.43

125 KVA DG Set working at HT SC No. 28 from Oct-2016

OCT-16

8.22

69

801

11.61

NOV-16

6.75

55

602

10.95

DEC-16

6.20

50

598

11.96

JAN-17

5.25

45

525

11.67

FEB-17

2.15

24

215

8.96

19

MAR-17

5.25

43

525

12.21

APR-17

8.35

69

835

12.10

MAY-17

6.10

48

610

12.70

JUNE-17

6.15

50

615

12.30

JULY-17

18.35

147

1835

12.48

AUG-17

15.10

121

1510

12.48

SEP-17

8.20

67

820

12.24

OCT-17

3

24

300

12.50

Total

288.96

2356

19213

274.41

Table 17: Working Details of Diesel Generators: SSE/P/CGL Section

2.11.10 POWER SERVICE CONNECTION TO OUTSIDERS:

Thirty two (32) Outsiders within Railway Premises are provided with

Service Connection from Railway Power Service, details of which are

tabulated below:

S.

N

o

S.C.

CGL

No.

Name of Outsider

Stn.

Auth

ority

Avbl.

Period

of

Service

Consum

ption

Units

Sep 17.

1

CGL-

001

Amman Koil

CGL

NA

NA

125

2

002

SRMU

CGL

NA

NA

40

3

005

GRP

CGL

NA

NA

611

4

006

RMS

CGL

NA

NA

1745

5

009

Anthoniar Koil

CGL

NA

NA

76

6

027

TATA Tele

CGL

NA

NA

3359

7

032

RAILTEL

CGL

NA

NA

5939

8

035

Book stall

CGL

NA

NA

30

9

048

ATM Indian Bank

CGL

NA

NA

1628

10

051

ATM canara Bank

CGL

NA

NA

280

11

054

SRMU/OL Branch PF 1

CGL

NA

NA

4

12

066

Catering Stall PF 5 &6

MAS S 14

CGL

NA

NA

239

13

079

Catering Stall PF 5 &6

SMU 15

CGL

AVBL

NA

628

14

088

Catering Stall PF 1 &2

GMU 15

CGL

AVBL

5 Yrs.

251

15

085

Water Vending PF 3 &

4

CGL

AVBL

5 Yrs.

174

16

086

Water Vending PF 5 &

6

CGL

AVBL

5 Yrs.

25

17

087

AIOBC

CGL

NA

NA

32

18

092

Cycle Stand

CGL

AVBL

3 Yrs.

33

20

19

---

Cycle Stand

CGL

AVBL

3 Months

20

022

SRMU

CJ

NA. SRMU

Branch Office Area

demolished on

19.09.2017

11

21

049

ATM Indian Bank

CJ

NA

NA

626

22

050

ATM Union Bank

CJ

NA

NA

41

23

090

Cycle Stand-

Sri.AT.Thirumurthy

CJ

AVBL

3 Yrs.

120

24

010

Amman Koil

ACK

NA

NA

136

25

011

Vinayagar Koil

TMV

NA

NA

185

26

013

RMS

TMV

NA

NA

1574

27

019

SRMU

TMV

NA

NA

151

28

028

TATA Tele

TMV

NA

NA

1280

29

033

RAIL TEL

TMV

NA

NA

2512

30

080

Cycle Stand

(Sri.S.MALIS RAJ)

MLMR

AVBL

3 Yrs.

78

31

082

Catering Stall (SMU

13)

MLMR

AVBL

5 Yrs.

424

32

089

Water Vending

MLMR

AVBL

5 Yrs.

0

Total Consumption by Outsiders

22357

Table 18: List of Outsiders availing Power Supply: SSE/P/CGL Section

2.11.11 TEMPORARY POWER SUPPLY:

Power supply to private parties or contractors, in connection with Railway

Works is being provided based upon instructions by the Divisional

Authorities. Details of such temporary power supply from

July’17 to

August’17

are listed below:

S.

No.

Name of the

Contractor

Supply

@

Phase

Related Work

1

M/s.Malathy

Construction,Nellore

ACK

Single

Provision of Fibre

reinforced CC Blocks@

MSB-VM section

2

Sri.VM.Prabhakar,AJJ

CGL

Three

To repair compound wall

and back yard roofing of

staff quarters MS-VM sec.

3

Sri.V.Balakoteeswara

Rao, SPE

TMV

Single

Reconstruction of 7 Type

III- Staff Quarters @TMV

4

Sri.V.Balakoteeswara

Rao, SPE

CGL &

MMK

Single

Reconstruction of 4 & 3

Type III- Staff Quarters

@CGL & MMK

21

5

M/s.Aarthi

Enterprises, Chennai

CGL

Single

Repair door & ceiling of

staff quarters DEN/CGL

Sub-Sec.

6

M/s.Sree

Construction, HYB

ACK

Single

Doubling of BG track

CGL-VM etc.,

Table 19: Details of Contractors availing Temporary connection: SSE/P/CGL Section

2.11.12 AC PLANTS:

There are Fourteen (14) AC Plants functioning in this Section. Details are

enlisted below:

S.No.

Station

Location

Capacity

(Ton)

Type

Quantity

1

CGL

VIP Room

1.5

Split AC

1

2

CGL

RRI Cabin (EI

Room)

1.5

Window

AC

2

3

CGL

Electronic Weigh

Bridge Room (PF

7 & 8)

1

4

CGL

Exchange

1.5

WAC

1

5

CGL

Health Unit

1.5

WAC

1

6

CGL

ORH

1.5

WAC

1

7

MLMR

AC Dormitory

1.5

Split AC

2

8

TMV

VIP Room

1.5

WAC

1

9

CJ/NEW

VIP Room

1.5

WAC

1

10

CJ/NEW

AC Dormitory

1.5

WAC

2

11

CJ/NEW

SUITE A

1.5

WAC

1

12

CJ/NEW

SUITE B

1.5

WAC

1

Total no. of AC Plants

14

Table 20: Details of AC Plants: SSE/P/CGL Section

22

2.11.13 WATER COOLERS IN THIS SECTION:

Seventeen (17) Water Coolers of SIDWAL (listed as below) make are

being maintained by the SSE/P/CGL, which are installed for the use by

the General Public.

S.No.

Station

PF No.

Capacity (Ltrs)

Quantity

1

CGL

1A

150

1

2

CGL

2

150

2

3

CGL

3,4

150

2

4

CGL

5,6

150

2

5

CGL

7,8

150

2

6

MMK

1

150

1

7

MLMR

1

150

1

8

MLMR

2

150

2

9

MLMR

3,4

150

2

10

TMV

1

150

1

11

CJ

1

150

1

Total No. of Water Coolers

17

Table 21: Details of Water Coolers: SSE/P/CGL Section

2.11.14 DETAILS OF GEYSERS OF THIS SECTION:

In this section, Fourteen (14) Geysers are maintained by SSE/P/CGL.

S.No.

Station

PF No.

Quantity

1

CGL

ORH

1

2

CGL

RETIRING ROOM 1,2 & 3

3

3

CGL

RUNNING ROOM

1

4

MLMR

AC RETIRING ROOM

2

23

5

MLMR

NON-AC RETIRING ROOM

2

6

CJ

AC RETIRING ROOM SUIT 1 & 2

2

7

CJ

RUNNING ROOM

1

8

CJ

NON-AC RETIRING ROOM

1

9

TMLP

RUNNING ROOM

1

Total No. of Geysers: 14

Table 22: Details of Geysers: SSE/P/CGL Section

2.11.15 FIRE EXTINGUISHERS:

There are Ten (10) Fire Extinguishers are available in this section under

the control of SSE/P/CGL, to be used in case of Fires, Fire related

accidents.

S.

No.

Station

Location

No. of

FEs

Due Date of

Refilling

1

CGL

PUMP ROOM OF PALAR PUMP

HOUSE

1

17.02.2018

2

CGL

DG ROOM OF PALAR PUMP

HOUSE

1

17.02.2018

3

CGL

11KV SUB STATION

2

17.02.2018

4

CGL

ADEN OFFICE MDB

1

17.02.2018

5

CGL

SSE/E/CGL OFFICE MDB ROOM

1

17.02.2018

6

CGL

TL ROOM

1

17.02.2018

7

TMV

MAIN SWITCH ROOM

1

17.02.2018

8

CJ

MAIN SWITCH ROOM

1

17.02.2018

9

CJ

DG ROOM

1

17.02.2018

Total

10

Table 23: Details of Fire Extinguishers: SSE/P/CGL Section

24

2.11.16 ROLLING INSPECTION LIGHT DETAILS:

Rolling Inspection lights are provided for Train Lighting staff at CGL and

maintained by SSE/P/CGL.

S.No.

Location

Capacity

No.of

Fittings

Type of

Fittings

1

PF 3

500 W

1

Holagen

2

PF 4

500 W

1

Holagen

3

PF 5

500 W

2

Holagen

4

PF 6

500 W

1

Holagen

5

PF 7 & 8

500 W

2

Holagen

Total

7

Table 24: Details of Rolling Inspection Lights: SSE/P/CGL Section

2.11.17 ELECTRICAL ASSETS Like Lights, Fans, Water Coolers, Lifts &

_Escalators:

Station

No. of

Lights

No. of

Fans

No. of

water coolers

PARANUR

101

5

-

CHEGALPATTU

579

353

10

OTIVAKKAM

117

21

-

PADALAM

48

3

-

KARUNGUZHI

92

9

-

MADURANTAKKAM

82

5

1

MELAMARUVATHUR

308

63

4

ACHARAPAKKAM

56

5

-

TOZHUPEDU

55

6

-

OLAKUR

46

11

-

TINDIVANAM

262

40

1

MAILAM

55

11

-

PERANI

44

9

-

VIKRAVANDI

72

12

-

MUNDIYAMBAKKAM

153

18

-

REDYPALAYAM

17

02

-

VILLIYAMBAKKAM

16

01

-

25

PALUR

27

12

-

PALAYASIVARAM

19

01

-

WALAZABAD

42

09

-

NATHAPETTAI

14

02

-

KANCHIPURAM/EAST

18

04

-

KANCHIPURAM

134

31

1

TIRUMALPUR

49

17

TOTAL

2406

650

17

Table 25: List of Electric Assets at Each Station: SSE/P/CGL Section

2.11.18 LAMP POST POPULATION IN THIS SECTION:

Station

No.of

Meter

box

No.of

Rail

post

No.of stay

insulators

No.of

tubular

posts

No.of

high

Masts

No.of

Poles

45/75

feet

tower

PARANUR

2

-

-

19

-

-

-

CHEGALPATTU

26

14

14

78

02

12

02

OTIVAKKAM

2

-

-

37

-

-

-

PADALAM

1

-

-

40

-

-

-

KARUNGUZHI

2

6

6

24

-

05

-

MADURANTAKKA

M

6

2

2

41

-

-

-

MELAMARUVATHU

R

2

-

-

49

01

-

-

ACHARAPAKKAM

2

8

8

24

-

07

-

TOZHUPEDU

4

-

-

32

-

-

-

OLAKUR

5

1

1

27

-

-

-

TINDIVANAM

4

12

12

49

-

14

-

MAILAM

8

5

5

24

-

04

-

PERANI

4

8

8

27

-

04

-

VIKRAVANDI

9

3

3

32

-

-

-

MUNDIYAMBAKKA

M

3

1

1

27

04

-

-

REDYPALAYAM

1

-

-

9

-

-

-

VILLIYAMBAKKAM

3

07

-

02

-

-

-

PALUR

3

-

-

17

-

-

-

PALAYASIVARAM

3

1

1

9

-

-

-

WALAZABAD

5

-

-

21

01

-

-

26

NATHAPETTAI

4

-

-

10

-

-

-

KANCHIPURAM/EA

ST

3

5

5

9

-

4

-

KANCHIPURAM

3

4

4

30

-

04

-

TIRUMALPUR

9

-

-

18

-

-

-

TOTAL

114

77

70

655

8

54

2

Table 26: Details of Lamp Post Population: SSE/P/CGL

2.12 PASSENGER TRAFFIC:

The details of the trains that pass through CGL Section are as below:

26 Express Trains Daily in both directions

06 Passenger Trains in both directions

02 Originating Express Train in both directions

15 Weekly Express Trains in both directions.

2.13 DETAILS OF ANNUAL MAINTAINENCE CONTRACT (AMC):

2.13.1 LIST OF DG-SET FOR AMC:

Section

Station/Location

Capacity in

KVA

AMC effect

from

CGL

CGL/11KV SUB STATION

125

NIL

CGL

CGL/11KV SUB STATION

62.5

NIL

CGL

CGL/ PALR PUMP HOUSE

62.5

NIL

CGL

MLMR STATION/PF-1

30

NIL

CGL

CJ STATION/PF-1

30

NIL

Table 27: List of DG-Set for AMC

2.13.2 LIST OF UPS FOR AMC:

Sl. No.

Capacity of UPS

AMC effect from

1.

1KVA & 5KVA

NIL

Table 28: List of UPS for AMC

27

2.14 ACTIVITIES OF SSE/POWER/CGL SECTION:

2.14.1 11 KV/433V SUB-STATION/CGL

One staff is available for duty at Sub-Station during night hours to attend

in case of emergency failures. Operation of 125 & 62.5 KVA DG Set and

maintenance work e.g. filling of HSD Oil, water for Radiator & water for

batteries and cleaning of DG Set. The quarterly, half yearly, annual

maintenance of 4 Pole HT Structure and 160 KVA Transformer I & II is

carried out. Cleaning of MDB’s, Panels, batteries, surrounding areas of

transformers, HT earth Pits (15 no.s) and checking of Earth resistance

values duly marking them.

2.14.2 PALAR PUMP HOUSE:

This Pump House is at a distance of around 3.5 Kms. From CGL Station

and manned round the clock. Water supply for CGL Station is met through

this Pump House. Operation and Observation of 7 no.s of bore well

submersible pump motor for filing the GLR having capacity of 2*100000

lakhs ltrs. Operation and Observation of 2*10 HP Mono Blocks

submersible Pump Motor is done. The staff are maintaining a record of

hourly energy consumption of pumps and failure cum generator register.

2.14.3 STATION BUILDINGS AND PLATFORMS:

There are Fifty Seven (57) number of platforms in the Twenty Four (24)

number of Stations, where following activities are performed to upkeep

the assets:

• Based upon complaints received failure maintenance is attended

for lamp posts (664), lights (1138), ceiling fans (811), Air circulator

fans (16) and water coolers (16).

• Operation and Maintenance of sub-pumps (43).

• Periodical cleaning of 496 - LT earth pits, checking of earth

resistance values and duly marking on them.

• Attention of Power Line Crossings (93).

• Monitoring of Power generation at 10 Kwp Solar Power Panel Plants

(2) installed at Roof Tops of station buildings of CGL & MLMR.

• Power supply maintenance of AC Plants (13).

2.14.4 ACTIVITIES AT LC GATES:

The following work activities are performed by the staff at the Level

Crossing Gates (56) in this section.

28

• Failure maintenance acting upon the complaints received from

Gatemen or Station Master of the concerned station.

• Failure maintenance of lights (336) and fans (56) acting upon the

complaints received from Gatemen or Station Master of the

concerned station.

2.14.5 PRS CENTRE:

There are Eight (8) UPS with batteries installed at PRS Centers (5) & 1

KVA DG Set installed at each PRS Centre in this section. Activities at PRS

Centers are enlisted below:

• Regular & Failure maintenance of UPS with batteries- periodical

cleaning, checking & greasing of battery terminals and periodical

changeover of UPS etc.

• Regular and Failure maintenance of 1 KVA DG Set- filling of Lube

Oil and Rope Cut Failure etc.

2.14.6 UTS CENTRE:

There are Thirty Two (32) UPS with batteries installed at UTS Centers

(16) & 1 KVA DG Set installed at each UTS Centre in this section. Activities

at UTS Centers are as below:

• Regular & Failure maintenance of UPS with batteries- periodical

cleaning, checking & greasing of battery terminals and periodical

changeover of UPS etc.

• Regular and Failure maintenance of 1 KVA DG Set- filling of Lube

Oil and Rope Cut Failure etc.

2.14.7 ACTIVITIES CONCERNED WITH AT/CLS PANEL:

• Ensuring EB supply to AUTO TRANSFORMER (AT) Panels.

• Ensuring of 1 FL and 1 Fan in working condition through AT supply

at Station Master’s Room/Office.

• Ensuring of AT supply to UTS counters.

• Ensuring emergency lights in FOB and Shelter (AT Supply) station.

• Ensuring of EB supply to CLS Panels.

29

2.14.8 PRE-COOLING CHARGING OF AC COACHES:

There are twelve (12) pre-cooling charging points provided for pre-

cooling the AC Coaches maintained by Power wing staff. These are

required for the two (2) trains- Kacheguga Exp & Circar Exp and

special trains whenever notified to start from CGL station.

2.14.9 HIGH MAST LIGHTS AT GOODS SHED, STATION

CIRCULATING AND APPROACH ROAD AREA:

In this section seven (7) high mast lights having thirty (30) LED fittings

of 200/400W MH in Goods Sheds of CGL, MYP & WJ stations, enabling

them to load and unload freight effectively and also SSE/P/CGL is

ensuring power supply to goods shed stacking area. In addition to

this, three (3) high mast lights having ten (10) LED fittings of 200w &

lighting arrangement in the circulating area of CGL and MLMR stations.

Lighting arrangement is installed for all approach road areas of

seventeen (17) stations.

2.14.10 ACTIVITIES RELATING TO STAFF QUARTERS:

Occupation:

On production of proper requisition/ allotment orders

from the competent authority, occupation of quarters is recorded in

the registers maintained for the purpose; duly extending the power

supply to that quarters. Handing over of electrical assets e.g. Meter

Board, FL Fittings, Ceiling Fans, Switch Boards and Wirings.

Maintenance:

Assets and installations in the Quarters, Quarters area

and Colony areas are maintained as per maintenance schedule.

Failures are duly attended as per complaints of the occupant.

Vacation of Staff Quarters: Based upon the proper requisition

/Vacation Order from the competent authority, process of vacation is

initiated. Power Supply is disconnected for the quarters and all the

Assets and Installations handed over to occupant are removed from

the quarters and Entry is made in the registers concerned.

2.15 ATTENTION OF FAILURES/COMPALINTS BY THE STAFF OF

SSE/P/CGL:

30

2.15.1 LIST OF COMPLAINTS ATTENDED BY TL STAFF:

The following is the list of various complaints attended by Train

Lighting staff of CGL from 2015 to 2017.

Table 29:Complaint attention- Train Lighting Side: SSE/P/CGL

2.15.2 FAILURE ATTENTION POWER SIDE-DETAILS:

Failure attention is one of the major activity of SSE/P/CGL. Number of

failures attended Power Staff year wise are tabled below:

SNo.

Nature of failures

2015

2016

2017

1

Fan failure

236

223

242

2

No of light failure in staff quarters

217

251

291

3

No of failure in service buildings

256

319

271

4

Fan checking

482

134

124

5

No of light failure in platform

143

203

318

6

Structure maintenance

15

13

11

7

Yard light failures

15

21

27

8

Earth checking

1

1

1

9

Outstations complaints

29

33

27

S.No.

Nature of failures

2015

2016

2017

1

Fan failure

136

98

124

2

No light failure in passing trains

117

151

171

3

Power failure in passing trains

126

119

144

4

Fan & lights circuit Rotary swiching on

102

94

111

5

Belt cut compliants

12

8

4

6

Battery box open compliants in passing trains

7

5

4

TOTAL

500

475

558

TOTAL COMPLAINTS ATTENDED FOR 3 YEARS

1533

AVERAGE COMPLAINTS ATTENTION PER YEAR

511

AVERAGE COMPLAINTS ATTENTION PER MONTH

42.58

AVERAGE COMPLAINTS ATTENTION PER DAY

1.42

31

10

LC gate complaints

212

178

185

11

Solar water heaters failures and

attentions

7

6

8

12

Pump house maintenance

55

64

34

13

LT board maintenance

12

24

24

14

Lights and fans cleaning

17

14

21

15

Emergency light failure attention

24

34

28

16

AT panel maintenance

3

5

4

17

UPS maintenance

29

26

33

18

Additional wirings and light provision

54

78

69

19

High mast lights failures

7

5

12

20

Outstation staff quarters attentions

310

295

338

21

Private stalls and other services

maintenance

19

28

45

22

Cable failures and attentions

27

18

17

23

Additional light and fan provisions

58

74

89

24

pit line pre-cooling & battery chargers

7

11

13

25

ICM shed maintenance

0

0

0

26

Capacitors KVA rh checking

4

4

4

27

Pit line lights gantry and cat walk

0

0

0

28

LVT & Battery chargers checking

7

5

10

29

Temporary & advertisement electrical

supply connections

4

5

4

TOTAL

2250

2072

2250

TOTAL FAILURES 2015-17

6572

AVERAGE FAILURE ATTENTION PER MONTH

182.56

AVERAGE FAILURE ATTENTION PER DAY

6.09

Table 30: Failure Attention- Power Side: SSE/P/CGL

32

2.16 CONSUMPTION OF ELECTRICAL UNITS IN SSE/POWER/CGL:

Summary of Energy Consumption:

TOTAL ENERGY CONSUMPTION

SERVICES/MONTH

LC GATES-LT

QUARTERS-LT

PUMPS-LT

STATIONS-LT

PCLM SSP- (LT)NEW

SERVICE FROM APRIL

PRS/MBPM+GOOD

SHED- (LT)

HT/CGL-STN

HT/CGL-QRS.

MONTHLY TOTAL

Jan-15

46964

22310

16800

27670

-

400

26958

21570

162672

Feb-15

6680

6211

7230

30158

-

590

29706

24060

104635

Mar-

15

3499

21250

15080

25258

-

410

28934

23790

118221

Apr-15

4740

6780

11050

29320

150

930

33408

26640

113018

May-

15

4380

27010

16610

32860

-

460

38515

22530

142365

Jun-15

5218

6440

9000

32120

290

800

47259

15240

116367

Jul-15

4052

23640

15700

33450

-

440

62395

16410

156087

Aug-15

5230

7030

9520

28723

90

520

24582

20760

96455

Sep-15

4290

24269

11670

35130

-

470

67090

17790

160709

Oct-15

5131

1400

10080

29332

90

640

13480

24968

85121

Nov-15

4050

23390

11510

30830

-

430

29918

24968

125096

Dec-15

4811

1390

8050

28114

60

660

24556

21614

89255

Jan-16

2941

19743

10920

26100

-

320

30105

22829

112958

Feb-16

4001

3280

10755

27544

220

810

30191

22756

99557

Mar-

16

3310

22470

10430

31410

-

570

29428

22934

120552

Apr-16

4639

6200

9650

26470

60

480

35532

23630

106661

May-

16

3910

23747

11480

37900

-

670

34624

26123

138454

Jun-16

4816

6100

11740

29830

70

1910

34982

28317

117765

Jul-16

3890

22030

11920

34490

-

600

31976

25630

130536

Aug-16

5300

6080

0

19250

70

1810

31614

26630

90754

Sep-16

3720

20850

12530

37540

-

450

29602

24931

129623

Oct-16

6915

6390

18820

17270

0

580

31444

24556

105975

Nov-16

3040

23780

11600

35750

-

450

32922

24582

132124

Dec-16

5057

5510

11690

26560

10

1390

23802

16522

90541

Jan-17

4400

19800

12120

25660

-

360

28461

18895

109696

Feb-17

4130

4660

9340

29930

10

10

28446

19042

95568

Mar-

17

3200

20390

11280

31320

-

370

29134

19046

114740

Apr-17

4570

5830

9080

19994

0

1950

36228

24704

102356

May-

17

4070

21710

11330

33590

-

420

37434

26194

134748

33

Jun-17

4742

6110

9550

29242

0

780

40638

28718

119780

Jul-17

4113

21670

22970

35020

-

410

35674

25906

145763

Aug-17

4318

13110

9100

27544

0

2150

51425

11983

119630

Sep-17

2130

23250

1660

29282

-

-

60452

0

116774

Sub-

Total

186257

473830

370265

974666

1120

23240

1150915

724268

3904556

TOTAL ENERGY CONSUMPTION for 33 Months (Jan’15-Sep’17): 3904556 Units.

TOTAL ENERGY CONSUMPTION/Month: 118319.88 Units.

Table 31: Summary of Electrical Units consumed jan’15 to Sep’17: SSE/P/CGL

2.17 DUTIES PERFORMED IN THIS SECTION:

2.17.1 DUTIES PERFORMED BY THE STAFF OF SSE/P/CGL:

▪ Maintaining and attending to petty complaints of Quarters.

▪ Maintaining and attending to Quarters street lights.

▪ Attending to Electrical works when Vacation and Occupation of

Quarters.

▪ Maintaining and attending fuse calls in co-ordination with EB.

▪ Maintaining and attending to Service Building failures.

▪ Maintaining and attending to Platform lighting including Passenger

Amenities, Yard lighting, approach road lighting and LC Gates.

▪ Maintaining and attending to water pumping facilities in case of

emergencies.

▪ Maintaining and attending to UPS and generators at all the PRS/UTS

stations.

▪ Maintaining and attending to AT CLS panels for uninterrupted and its

premises.

▪ Handing over bill receipts and collecting acknowledgements for the

same.

▪ Initiating penalty for late payment of the Power Bills.

▪ Fan OH work.

34

▪ Monthly meter reading in Staff Quarters, Outsider supply and private

stalls, every month between 25

th

to 30

th

and providing details to Hqrs.

Every month between 1

st

to 5

th

, enabling them to post in EMIS

module for recovery.

▪ Replacing of Silica Gel, Breather Oil and Cleaning of Transformers

and its premises.

▪ Tree pruning in the whole jurisdiction.

▪ Cleaning of water coolers.

▪ Cleaning of earth pits, recording of earth resistant values and painting

of pits.

▪ Painting all the structures of poles in the whole jurisdiction.

▪ Collection of materials from stores and firms. Stocked items are

collected once in three (3) months from GSD/PER.

▪ Frequently used items e.g. FL, Choke, PVC Tape, HSD Oil and Lube

Oil are procured from imprest cash duly obtaining special sanction

from Sr.DEE/G/MAS.

2.17.2 DUTIES OF SSE/ELECTRICAL:

• Observation of the rules and circulars issued by the CEE from time to

time and ensuring that all the staffs under his charge updated with

relevant rules and working method and efficiently performing their

allotted duties.

• Inspection notes of higher authorities are duly received and

immediate action to be initiated.

• Looking after the day to day maintenance activities of all electrical

items in CGL section.

• Looking after the maintenance, operation and utilization of all

electrical assets related to electrical energy in their area of

jurisdiction.

• Maintaining all the stores activities like as indenting the indents,

collection of materials for section, attention of purchase order (P.O.),

challan.

35

• Attention of daily positions of all parameters which is installed in the

section.

• Attending major complaints like pump, transformer failure etc.

• Regular inspection of ongoing departmental work and contractors

work in the section.

• Conducting Inspection periodically-routine, night and surprise

inspection.

• Welfare measures to the staff- Issuance of PASS/PTO, other

Forms/Applications etc.

• Regular maintenance of Registers and Files.

• Deployment of staff for lookout duties as and when necessary.

• Updating section assets records.

• Preparation of monthly statements, preparation of outsider and

temporary supply meter reading statement.

• Conducting of Safety Check Drive of Ceiling Fans in all quarters,

Stations Service Buildings and Shelter Areas once in a year.

Joint inspection

▪ Joint inspection of CLS Panel with SSE/Signal, once in a year.

▪ Joint inspection of CLS Panel with SSE/Tele, once in a year.

▪ Joint inspection of CLS Panel with SSE/PSI, once in a year.

▪ Joint inspection with SSE/Works- Qrs. New Buildings, once in a

year.

▪ Joint Inspection with CCI & TI in regard to their departmental

assets requiring power supply & UPS.

▪ Joint Inspection of the Station Premises of CGL, with SIG Group:

SS, SSE/Works, TI, SSE/SIG, RPF, CCI.

▪ Joint Inspection with CCI- Cycle stands, Private stalls, Commercial

offices, Advertisements & Hoardings which require Power, Sign

Boards etc.

Staff matters

▪ Preparing details for payment of staff.

▪ Verification of diary and TA journals of staff & Preparation of TA

statement of staff.

▪ Verification of night duty allowance sheet of staff & Preparation of

NDA statement.

36

▪ Verification of national holiday allowance of staff & Preparation of

NHA statement.

▪ Arranging special training and counseling for staff at office.

▪ Preparation and issue of privilege pass for staff.

▪ Maintaining leave records of staff.

▪ Maintain daily work details of staff.

Stores

▪ Preparation of indent and collection of materials for maintenance

purpose.

▪ Preparation of indents as pre-section requirement.

▪ Certification of bills and returns of supplied materials.

▪ Updating of Daily Book of Receipt (DBR) and Daily Book of Issues

(DBI).

▪ Updating Revenue, Consumable, released and T&P ledgers.

▪ Preparation of returns of stores for T&P, Revenue, consumables

and released ledgers.

▪ Preparation of DS8 to dispose scrap & DS8 of materials

▪ Sending letters regarding sectional requirements to divisional

office.

▪ Issue of materials to staff for maintenance.

▪ Managing and coordinating with various inspecting officials from

stores, personnel, accounts, audit etc.

▪ Preparation of challans for materials issued.

▪ Self-stock verification.

2.17.3 DUTIES OF TECHNICIAN/POWER:

(Specific) Looking after the Efficient maintenance of all the existing

installations is in good and working condition and also ensures that all

the safety appliances related to the works spot is in good and working

condition and they work on site with 2 or 3 nos. of Helpers according

to the distribution of work/failure which is distributed by the SSE/JE.

2.17.4 DUTIES OF TECH/TRAIN LIGHTING: (Specific) Looking after the

duty in shift wise (3 Shifts 24x7) and attend the CGL station passing

train failure according to complaints given by on duty station

masters/CGL or Electrical controllers through telephonic message and

37

also recording the passing train timings and train numbers with nature

of failures in register.

2.18 SPECIAL WORKS ATTENDED BY SSE/P/CGL AND HIS STAFF:

The following special works are carried in this section from January’17 to

December’17. (Special works enlisted below, reproduced as submitted by

the SSE/P/CGL).

JANUARY - 2017

CGL running room 13 Nos. of 28w T5 replaced with 18w LED.

At CGL station old FOB and New FOB 39 Nos. of T5 (28w) replaced with 18w

LED.

At CJ station 6 Nos. of 4x14w FL replaced with 4 Nos. of 36w LED.

At MMK waiting Hall 2 Nos. of FL (36w) replaced with 18w LED.

At CJ/E five star rated 3 HP submersible pump provided

At CGL station PF 3&4 two Nos. of precooling charging point provided with

100 mtrs. of 70sqm cable.

At CGL good shed new supply cable of 70sqmm, 63mtrs provided and supply

shifted from VM end tower to CGL end tower.

At CGL PF 5&6 68 Nos. of T5 (28w) fitting replaced with 18W LED.

LC gate 59, 60.63 and 64 10 Nos. of T5 (28) replaced with 18W LED.

At CGL IOW office staff room 5 point wiring done.

At CGL substation 3 Nos. of 36W FL fitting replaced with 18w LED.

At CGL PWI office computer point wiring done.

On 23.01.2017, DS-8 item loaded through DS-8 special train and it will be

disposed after reaching GSD/PER.

MARCH-2017

At CGL station portico and main verandah 10nos. of 36w (2x2) LED panel

light replaced with 2 x 14w CFL fitting.

At CGL station retiring room 1, 2, & 3, 6nos of 36w (2x2) LED panel lights

replaced with 2 x 14w CFL fitting.

At CGL station PF 2, 11nos ceiling fans newly provided in place of old one.

At CGL station 11kv/433v substation 2nos of 160 KVA Transformer and its

structure painting done.

At CGL station retiring room verandah area 10 nos. of new point wiring done.

At CGL station Health Unit new supply cable of 4 core 30 sqmm 55mtrs

provided in place of damaged old supply cable.

At CGL station 10kw solar panel (capacity 10 kW) cleaning done.

38

At CGL & MLMR station totally 28/36w light fitting converted into LED light

fittings.

APRIL - 2017

At KGZ station PF 1 & 2 , FOB and service building all T5 28W FL fittings are

fully converted into 18W/20W LED lights

At KGZ station AN/PN wiring work done.

At PWU station PF 1 & 2 , FOB and service building all T5 28W FL fittings are

fully converted into 18W/20W LED lights in CSR project by Mahindra world

city company.

Energy saving point of view 3nos. of Key tag switch provided at CGL Retiring

room.

MAY - 2017

At CGL station PF 3 & 4 and 7 & 8 for pre- cooling purpose 4 nos of pre cooling

plug socket newly provided with 160mtrs of 70sq.mm cable arrangements.

At CGL station approach road area 8 nos of 45w LED fittings provided in place

of 85w CFL fittings.

At MLMR station 5 HP open well type sub pump motor commissioned for

water pumping purpose.

At CJ station PF 1 shelter area 5 no of ceiling fan newly provided.

At CJ station approach road area 7 nos of 45w LED fittings provided in place

of 85w CFL fittings.

CJ station PF- 1 time switch provided for water cooler.

At PALR station gang rest room 5 point new wiring done.

At PALR pump house 25sq. mm 160 mtr. New cable replaced in place of faulty

cable.

At VB station 25 sq. mm 40 mtrs. New cable laid for PF 1 & booking office

supply.

JUNE - 2017

At CGL in RRI cabin 1 nos. and BG SM room 2 nos. of new plug point wiring

done for water purifier.

As per Dy.CEE/PRS advice at CGL station in PRS and Booking office single

phase energy meter provided to monitor the consumption.

At CGL station platform 3&4 shelter cleaning purpose 4 nos of switches &

At CGL station in platform 3&4 for energy saving purpose 1no of time switch

provided for Air Circulating fans.

JULY - 2017

At CGL PF-2 (VM end) new toilet 8 points new wiring done with 4 nos. of LED

20W fittings and 2 nos. of bulkhead fittings.

39

East colony/CGL - 5 HP mono block sub pump set with 105 meters of 4 x 16

sq mm cabling arrangement done for water supply to Chennai through water

wagon.

At MLMR station - 5 HP bore well sub.pumpset lowered with 400 feet bore

well for water supply to station buildings.

At MLMR station PF-3 new water cooler supply wiring done.

At VB station for new LT service connection 40 meters of 4 core 16 sq.mm

cable lie down.

At LC 12 new lodge gate (CGL-TMLP section) 55 meters. 4 cores 16 sq.mm

new supply cable laying arrangement done with trench work.

DS-8 items sent to GSD/PER on 12.07.2017 with nonferrous metal weight of

460 kg.

AUGUST - 2017

At CGL station at PF 1A for water cooler 1 new point wiring done.

At palar pump house in GLR 10 HP open well submersible pump motor

provided in place of 15 HP for energy conservation point of view.

At TMV one 5HP submersible pump motor lowered in bore well and brought

into service.

At ACK TSS one 5HP bore well submersible pump motor lowered in newly

drilled bore well for meeting water scarcity.

At TMV station in circulating area (near PRS) 8 nos. of 150w MH lamp fittings

replaced with 90w LED fittings.

At SSE/E/O/CGL- New staff rest room 4nos of new point wiring done.

At CGL station booking office 6 nos of 35 watt energy efficient ceiling fans

replaced with conventional type of ceiling fans.

3 nos. of Technician Gr.-II/III sent for attending the competency certificate

training program at ETC/PER.

SEPTEMBER - 2017

At CGL station 2 nos. of pre-cooling charging point box newly provided at

PF-5&6 for pre-cooling purpose of Kachiguda express.

At CGL station 24 nos. of 35 watt energy efficient (Super fan) ceiling fans

newly provided in place of conventional type of ceiling fans at following

locations.

• Health unit = 12

• RRI cabin = 04

• I Class Waiting Hall = 03

• Retiring Room = 03

• Officer’s Rest House = 02

At CGL station I

st

& II

nd

class waiting hall new switch board provided in

place of old one with ELCB.

40

At CGL station II

nd

class waiting hall 1 nos. Of additional exhaust fan

(300mm) provided.

At CGL station on platform 7&8 2nos. Of new point wiring done for new

water coolers.

At CGL station on platform 2 in New Pay & Use Toilet 2 nos. of exhaust fans

newly provided.

At CGL station on platform 2 in shelter area 1no mobile charging point

wiring done.

At MLMR 10 KWp of solar panel brought in to service on 04.09.2017.

At TMV station GLR new 5 HP open well sub- pump set replaced with failed

the same.

At TMV station - Circulating area 4 nos. Of 50w LED flood light provided in

place of 150W MH fittings.

OCTOBER - 2017

On 27.09.2017 PAC (Passenger Amenities Committee) and all branch

officers inspected at CGL station.

In CGL section total 4 nos. of three phase KWH meter (Direct type) newly

provided in following locations:-

▪ Running Room/CGL – 01

▪ PF-2/CGL – 01

▪ PF-5&6/CGL – 01

▪ PF-1/MLMR – 01