Operating Instructions

Radar sensor for continuous level

measurement of liquids

VEGAPULS 64

Two-wire 4 … 20 mA/HART

Document ID: 51141

2

Contents

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use ................................................................................................................ 5

2.3 Warning about incorrect use ............................................................................................. 5

2.4 General safety instructions ............................................................................................... 5

2.5 EU conformity ................................................................................................................... 6

2.6 NAMUR recommendations .............................................................................................. 6

2.7 Radio license for Europe .................................................................................................. 6

2.8 Radio license for USA ...................................................................................................... 7

2.9 Radio license for Canada ................................................................................................. 7

2.10 Installation and operation in the USA and Canada ........................................................... 9

2.11 Environmental instructions ............................................................................................... 9

3 Product description ............................................................................................................... 10

3.1 Conguration .................................................................................................................. 10

3.2 Principle of operation...................................................................................................... 11

3.3 Packaging, transport and storage ................................................................................... 11

3.4 Accessories.................................................................................................................... 12

4 Mounting ................................................................................................................................. 14

4.1 General instructions ....................................................................................................... 14

4.2 Mounting versions, plastic horn antenna ........................................................................ 14

4.3 Mounting preparations, mounting strap .......................................................................... 17

4.4 Mounting instructions ..................................................................................................... 18

4.5 Measurement setup - Flow ............................................................................................. 26

5 Connecting to power supply ................................................................................................. 29

5.1 Preparing the connection ............................................................................................... 29

5.2 Connecting ..................................................................................................................... 30

5.3 Wiring plan, single chamber housing.............................................................................. 31

5.4 Wiring plan, double chamber housing ............................................................................ 32

5.5 Wiring plan - version IP66/IP68, 1 bar ............................................................................ 34

5.6 Switch-on phase............................................................................................................. 35

6 Set up with the display and adjustment module ................................................................ 36

6.1 Insert display and adjustment module ............................................................................ 36

6.2 Adjustment system ......................................................................................................... 37

6.3 Measured value indication - Selection of national language ........................................... 38

6.4 Parameter adjustment - Quick setup .............................................................................. 39

6.5 Parameter adjustment - Extended adjustment................................................................ 39

6.6 Saving the parameterisation data ................................................................................... 55

7 Setup with PACTware ............................................................................................................. 56

7.1 Connect the PC .............................................................................................................. 56

7.2 Parameter adjustment with PACTware ............................................................................ 56

7.3 Saving the parameterisation data ................................................................................... 58

3

Contents

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

8 Set up with other systems .................................................................................................... 59

8.1 DD adjustment programs ............................................................................................... 59

8.2 Field Communicator 375, 475 ........................................................................................ 59

9 Diagnosis, asset management and service ........................................................................ 60

9.1 Maintenance .................................................................................................................. 60

9.2 Measured value and event memory ............................................................................... 60

9.3 Asset Management function ........................................................................................... 61

9.4 Rectify faults ................................................................................................................... 64

9.5 Exchanging the electronics module ................................................................................ 68

9.6 Software update ............................................................................................................. 68

9.7 How to proceed if a repair is necessary .......................................................................... 69

10 Dismount................................................................................................................................. 70

10.1 Dismounting steps.......................................................................................................... 70

10.2 Disposal ......................................................................................................................... 70

11 Supplement ............................................................................................................................ 71

11.1 Technical data ................................................................................................................ 71

11.2 Radio astronomy stations ............................................................................................... 84

11.3 Dimensions .................................................................................................................... 84

11.4 Industrial property rights ................................................................................................. 97

11.5 Trademark ...................................................................................................................... 97

Safety instructions for Ex areas

TakenoteoftheExspecicsafetyinstructionsforExapplications.

These instructions are attached as documents to each instrument

with Ex approval and are part of the operating instructions.

Editing status: 2021-02-17

4

1 About this document

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

1 About this document

1.1 Function

This instruction provides all the information you need for mounting,

connection and setup as well as important instructions for mainte-

nance,faultrectication,theexchangeofpartsandthesafetyofthe

user. Please read this information before putting the instrument into

operation and keep this manual accessible in the immediate vicinity

of the device.

1.2 Target group

This operating instructions manual is directed to trained personnel.

Thecontentsofthismanualmustbemadeavailabletothequalied

personnel and implemented.

1.3 Symbols used

Document ID

This symbol on the front page of this instruction refers to the Docu-

ment ID. By entering the Document ID on www.vega.com you will

reach the document download.

Information, note, tip: This symbol indicates helpful additional infor-

mation and tips for successful work.

Note: This symbol indicates notes to prevent failures, malfunctions,

damage to devices or plants.

Caution: Non-observance of the information marked with this symbol

may result in personal injury.

Warning: Non-observance of the information marked with this symbol

may result in serious or fatal personal injury.

Danger: Non-observance of the information marked with this symbol

results in serious or fatal personal injury.

Ex applications

This symbol indicates special instructions for Ex applications.

•

List

The dot set in front indicates a list with no implied sequence.

1 Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of bat-

teries and accumulators.

5

2 For your safety

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

2 For your safety

2.1 Authorised personnel

All operations described in this documentation must be carried out

onlybytrained,qualiedpersonnelauthorisedbytheplantoperator.

During work on and with the device, the required personal protective

equipment must always be worn.

2.2 Appropriate use

VEGAPULS 64 is a sensor for continuous level measurement.

Youcannddetailedinformationabouttheareaofapplicationin

chapter " Product description".

Operational reliability is ensured only if the instrument is properly

usedaccordingtothespecicationsintheoperatinginstructions

manual as well as possible supplementary instructions.

2.3 Warning about incorrect use

Inappropriate or incorrect use of this product can give rise to applica-

tion-specichazards,e.g.vesseloverllthroughincorrectmounting

or adjustment. Damage to property and persons or environmental

contamination can result. Also, the protective characteristics of the

instrument can be impaired.

2.4 General safety instructions

This is a state-of-the-art instrument complying with all prevailing

regulations and directives. The instrument must only be operated in a

technicallyawlessandreliablecondition.Theoperatorisresponsi-

ble for the trouble-free operation of the instrument. When measuring

aggressive or corrosive media that can cause a dangerous situation

if the instrument malfunctions, the operator has to implement suitable

measures to make sure the instrument is functioning properly.

The safety instructions in this operating instructions manual, the na-

tional installation standards as well as the valid safety regulations and

accident prevention rules must be observed by the user.

For safety and warranty reasons, any invasive work on the device

beyond that described in the operating instructions manual may be

carried out only by personnel authorised by the manufacturer. Arbi-

traryconversionsormodicationsareexplicitlyforbidden.Forsafety

reasons,onlytheaccessoryspeciedbythemanufacturermustbe

used.

To avoid any danger, the safety approval markings and safety tips on

the device must also be observed.

The low transmitting power of the radar sensor is far below the inter-

nationally approved limits. No health impairments are to be expected

with intended use. The band range of the measuring frequency can

be found in chapter " Technical data".

6

2 For your safety

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

2.5 EU conformity

ThedevicefullsthelegalrequirementsoftheapplicableEUdirec-

tives.ByaxingtheCEmarking,weconrmtheconformityofthe

instrument with these directives.

The EU conformity declaration can be found on our homepage.

2.6 NAMUR recommendations

NAMUR is the automation technology user association in the process

industry in Germany. The published NAMUR recommendations are

acceptedasthestandardineldinstrumentation.

ThedevicefullstherequirementsofthefollowingNAMURrecom-

mendations:

•

NE 21 – Electromagnetic compatibility of equipment

•

NE 43 – Signal level for fault information from measuring transduc-

ers

•

NE53–Compatibilityofelddevicesanddisplay/adjustment

components

•

NE107–Self-monitoringanddiagnosisofelddevices

For further information see www.namur.de.

2.7 Radio license for Europe

The instrument was tested according to the latest issue of the follow-

ingharmonizedstandards:

•

EN 302372 - Tank Level Probing Radar

•

EN 302729 - Level Probing Radar

It is hence approved for use inside and outside closed vessels in

countries of the EU.

Use is also approved in EFTA countries, provided the respective

standards have been implemented.

For operation inside of closed vessels, points a to f in annex E of

EN302372mustbefullled.

For operation outside of closed vessels, the following conditions must

befullled:

•

The instrument must be stationary mounted and the antenna

directed vertically downward

•

The instrument may only be used outside closed vessels in the

version with G1½ or 1½ NPT thread with integrated horn antenna.

•

The mounting location must be at least 4 km away from radio

astronomy stations, unless special permission was granted by the

responsible national approval authority

•

When installed within 4 to 40 km of a radio astronomy station,

the instrument must not be mounted higher than 15 m above the

ground.

A list of the respective radio astronomy stations can be found in chap-

ter " Appendix" of the operating instructions.

7

2 For your safety

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

2.8 Radio license for USA

This approval is only valid for USA. Hence the following text is only

available in the English language:

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions:

•

This device may not cause interference, and

•

This device must accept any interference, including interference

that may cause undesired operation of the device

This device is approved for unrestricted use only inside closed, sta-

tionaryvesselsmadeofmetal,reinforcedberglassorconcrete.

For operation outside of closed vessels, the following conditions must

befullled:

•

This device shall be installed and maintained to ensure a verti-

cally downward orientation of the transmit antenna's main beam.

Furthermore, the use of any mechanism that does not allow the

main beam of the transmitter to be mounted vertically downward is

prohibited.

•

Operation of the instrument is only permitted with thread G1½ or

1½ NPT with integrated horn antenna.

•

Thisdeviceshallbeinstalledonlyatxedlocations.TheLPR

device shall not operate while being moved or while inside a mov-

ing container.

•

Hand-held applications are prohibited.

•

Marketing to residential consumers is prohibited.

Changesormodicationsnotexpresslyapprovedbythemanufac-

turer could void the user’s authority to operate this equipment.

2.9 Radio license for Canada

This approval is only valid for Canada. Hence the following texts are

only available in the English/French language:

This device complies with Industry Canada's license-exempt RSS

standard(s). Operation is subject to the following conditions:

•

This device may not cause interference, and

•

This device must accept any interference, including interference

that may cause undesired operation of the device

This device has been approved for both closed containers and open-

air environments with the following limitations:

•

ClosedContainers:Forinstallationsutilizingatiltduringinstalla-

tion: This device is limited to installation in a completely enclosed

containermadeofmetal,reinforcedberglassorconcretetopre-

vent RF emissions, which can otherwise interfere with aeronauti-

cal navigation, the maximum approved tilt angel is 10°.

•

Open Air Environment: For operation outside of closed vessels,

thefollowingconditionmustbefullled:Thisdeviceshallbe

installed and maintained to ensure a vertically downward orienta-

tion of the transmit antenna's main beam. Furthermore, the use of

8

2 For your safety

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

any mechanism that does not allow the main beam of the transmit-

ter to be mounted vertically downward is prohibited.

•

Operation of the instrument outside of closed vessels is only per-

mitted with G1½ or 1½ NPT with integrated horn antenna.

•

The installation of the LPR/TLPR device shall be done by trained

installers, in strict compliance with the manufacturer's instructions.

•

Thisdeviceshallbeinstalledonlyatxedlocations.TheLPR

device shall not operate while being moved or while inside a mov-

ing container.

•

Hand-held applications are prohibited.

•

Marketing to residential consumers is prohibited.

•

The use of this device is on a "no-interference, no-protection"

basis. That is, the user shall accept operations of high-powered

radar in the same frequency band which may interfere with or

damage this device.

•

However, devices found to interfere with primary licensing opera-

tions will be required to be removed at the user's expense.

•

The installer/user of this device shall ensure that it is at least 10 km

from the Dominion Astrophysical Radio Observatory (DRAO) near

Penticton, British Columbia. The coordinates of the DRAO are

latitude49°19′15″Nandlongitude119°37′12″W.Fordevicesnot

meeting this 10 km separation (e.g., those in the Okanagan Valley,

British Columbia,) the installer/user must coordinate with, and

obtain the written concurrence of, the Director of the DRAO before

the equipment can be installed or operated. The Director of the

DRAO may be contacted at 250-497-2300 (tel.)or 250-497-2355

(fax). (Alternatively, the Manager, Regulatory Standards, Industry

Canada, may be contacted.)

Le présent appareil est conforme aux CNR d’Industrie Canada ap-

plicables aux appareils radio exempts de licence. L’exploitation est

autorisée aux conditions suivantes :

•

L’appareil ne doit pas produire de brouillage; et

•

L’utilisateur de l’appareil doit accepter tout brouillage radioélect-

rique subi, même si le brouillage est susceptible d’en compromet-

tre le fonctionnement.

Cet appareil est homologué pour une utilisation dans les cuves fer-

mées et les environnements ouverts avec les restrictions suivantes :

•

Cuves fermées : Pour les installations impliquant une inclinaison

lors de l'installation : cet appareil ne doit être installé que dans une

cuve totalement fermée en métal ou en béton, pour empêcher les

émissions RF susceptibles d'interférer avec la navigation aéronau-

tique. L'angle d'inclinaison maximum autorisé est de 10°.

•

Environnement ouvert : Pour l'utilisation hors des cuves fermées,

la condition suivante doit être remplie : L'appareil doit être installé

et entretenu de manière à garantir une orientation verticale vers

le bas du faisceau principal de l’antenne émettrice. De plus,

l’utilisation de tout mécanisme ne permettant pas l’orientation ver-

ticale vers le bas du faisceau principal de l’émetteur est interdite

•

Il est uniquement autorisé d'utiliser la version d'appareil avec le

letageG1½ou1½NPTenenvironnementsouvertes.

9

2 For your safety

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

•

L’installationd’undispositifLPRouTLPRdoitêtreeectuée

pardesinstallateursqualiés,enpleineconformitéavecles

instructions du fabricant.

•

Cetappareilnedoitêtreinstalléqu'àdesemplacementsxes.

L’appareil LPR ne doit pas être utilisé pendant qu’il est en train

d’être déplacé ou se trouve dans un conteneur en mouvement.

•

Les applications portables sont interdites.

•

La vente à des particuliers est interdite

•

Ce dispositif ne peut être exploité qu'en régime de non-brouillage

et de non-protection, c'est-à-dire que l'utilisateur doit accepter que

des radars de haute puissance de la même bande de fréquences

puissent brouiller ce dispositif ou même l'endommager.

•

D'autre part, les capteurs de niveau qui perturbent une exploita-

tion autorisée par licence de fonctionnement principal doivent être

enlevés aux frais de leur utilisateur.

•

La personne qui installe/utilise ce capteur de niveau doit s'assurer

qu'il se trouve à au moins 10 km de l'Observatoire fédéral de

radioastrophysique (OFR) de Penticton en Colombie-Britannique.

Lescoordonnéesdel'OFRsont:latitudeN49°19′15″,longitude

O119°37′12″.Lapersonnequiinstalle/utiliseundispositifne

pouvant respecter cette distance de 10 km (p. ex. dans la vallée

de l'Okanagan [Colombie-Britannique]) doit se concerter avec le

directeurdel'OFRand’obtenirdesapartuneautorisationécrite

avant que l'équipement ne puisse être installé ou mis en marche.

Le directeur de l'OFR peut être contacté au 250-497-2300 (tél.) ou

au 250-497-2355 (fax). (Le Directeur des Normes réglementaires

d'Industrie Canada peut également être contacté).

2.10 Installation and operation in the USA and

Canada

This information is only valid for USA and Canada. Hence the follow-

ing text is only available in the English language.

Installations in the US shall comply with the relevant requirements of

the National Electrical Code (ANSI/NFPA 70).

Installations in Canada shall comply with the relevant requirements of

the Canadian Electrical Code

A Class 2 power supply unit has to be used for the installation in the

USA and Canada.

2.11 Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system

with the goal of continuously improving company environmental pro-

tection.Theenvironmentmanagementsystemiscertiedaccording

to DIN EN ISO 14001.

Pleasehelpusfullthisobligationbyobservingtheenvironmental

instructions in this manual:

•

Chapter " Packaging, transport and storage"

•

Chapter " Disposal"

10

3 Product description

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

3 Product description

3.1 Conguration

The scope of delivery encompasses:

•

VEGAPULS 64 radar sensor

•

Discsprings(angeversionwithencapsulatedantennasystem)

1)

•

Optional accessory

The further scope of delivery encompasses:

•

Documentation

– Quick setup guide VEGAPULS 64

– Instructions for optional instrument features

– Ex-specic"Safety instructions" (with Ex versions)

– Ifnecessary,furthercerticates

Information:

Optional instrument features are also described in this operating

instructions manual. The respective scope of delivery results from the

orderspecication.

This operating instructions manual applies to the following instrument

versions:

•

Hardware version from 1.0.3

•

Software version from 1.3.3

Thetypelabelcontainsthemostimportantdataforidenticationand

use of the instrument:

6

5

4

3

2

1

Fig. 1: Layout of the type label (example)

1 Instrument type, product code

2 Field for approvals

3 Technical data

4 Data matrix code for VEGA Tools app

5 Reminder to observe the instrument documentation

The type label contains the serial number of the instrument. With it

youcanndthefollowinginstrumentdataonourhomepage:

Scope of delivery

Scope of this operating

instructions

Type label

Serial number - Instru-

ment search

1)

Use see chapter "Mounting instructions, sealing to the process"

11

3 Product description

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

•

Product code (HTML)

•

Delivery date (HTML)

•

Order-specicinstrumentfeatures(HTML)

•

Operating instructions and quick setup guide at the time of ship-

ment (PDF)

•

Order-specicsensordataforanelectronicsexchange(XML)

•

Testcerticate(PDF)-optional

Move to " www.vega.com"andenterinthesearcheldtheserial

number of your instrument.

Alternatively, you can access the data via your smartphone:

•

Download the VEGA Tools app from the " Apple App Store" or the

" Google Play Store"

•

Scan the DataMatrix code on the type label of the instrument or

•

Enter the serial number manually in the app

3.2 Principle of operation

VEGAPULS 64 is a radar sensor for continuous level measurement of

liquids.

Thesmallprocessttingsoerparticularadvantagesinsmalltanksor

tight mounting spaces. The very good signal focusing ensures the use

in vessels with many installations such as stirrers and heating spirals.

TheVEGAPULS64isavailablewithdierentantennasystems:

1 2 3

Fig. 2: Antenna systems VEGAPULS 64

1 Thread with integrated horn antenna

2 Plastic horn antenna

3 Flange with encapsulated antenna system

The instrument emits a continuous, frequency-modulated radar signal

throughitsantenna.Theemittedsignalisreectedbythemedium

andreceivedbytheantennaasanechowithmodiedfrequency.The

frequency change is proportional to the distance and is converted into

the level.

3.3 Packaging, transport and storage

Your instrument was protected by packaging during transport. Its

capacity to handle normal loads during transport is assured by a test

based on ISO 4180.

Application area

Functional principle

Packaging

12

3 Product description

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

The packaging consists of environment-friendly, recyclable card-

board. For special versions, PE foam or PE foil is also used. Dispose

of the packaging material via specialised recycling companies.

Transport must be carried out in due consideration of the notes on the

transport packaging. Nonobservance of these instructions can cause

damage to the device.

The delivery must be checked for completeness and possible transit

damage immediately at receipt. Ascertained transit damage or con-

cealed defects must be appropriately dealt with.

Up to the time of installation, the packages must be left closed and

stored according to the orientation and storage markings on the

outside.

Unless otherwise indicated, the packages must be stored only under

the following conditions:

•

Not in the open

•

Dry and dust free

•

Not exposed to corrosive media

•

Protected against solar radiation

•

Avoiding mechanical shock and vibration

•

Storage and transport temperature see chapter " Supplement -

Technical data - Ambient conditions"

•

Relative humidity 20 … 85 %

With instrument weights of more than 18 kg (39.68 lbs) suitable and

approved equipment must be used for lifting and carrying.

3.4 Accessories

The instructions for the listed accessories can be found in the down-

load area on our homepage.

The display and adjustment module is used for measured value indi-

cation, adjustment and diagnosis.

The integrated Bluetooth module (optional) enables wireless adjust-

ment via standard adjustment devices.

The interface adapter VEGACONNECT enables the connection of

communication-capable instruments to the USB interface of a PC.

The VEGADIS 81 is an external display and adjustment unit for VEGA

plics

®

sensors.

The VEGADIS adapter is an accessory part for sensors with double

chamber housings. It enables the connection of VEGADIS 81 to the

sensor housing via an M12 x 1 plug.

Transport

Transport inspection

Storage

Storage and transport

temperature

Lifting and carrying

PLICSCOM

VEGACONNECT

VEGADIS 81

VEGADIS adapter

13

3 Product description

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

VEGADIS 82 is suitable for measured value indication and adjustment

of sensors with HART protocol. It is looped into the 4 … 20 mA/HART

signal cable.

The PLICSMOBILE T81 is an external GSM/GPRS/UMTS radio unit

for transmission of measured values and for remote parameter adjust-

ment of HART sensors.

PLICSMOBILE 81 is an internal GSM/GPRS/UMTS radio unit for

HART sensors for transmitting measured values and for remote

parameterization.

The protective cover protects the sensor housing against soiling and

intense heat from solar radiation.

Screwedangesareavailableindierentversionsaccordingtothe

following standards: DIN 2501, EN 1092-1, BS 10, ASME B 16.5,

JIS B 2210-1984, GOST 12821-80.

Welded sockets are used to connect the sensors to the process.

Threaded adapters are used for adaptation of the sensor with

threadedttingG¾orG1½toexistingweldedsockets.

VEGADIS 82

PLICSMOBILE T81

PLICSMOBILE 81

Protective cover

Flanges

Welded sockets and

adapters

14

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

4 Mounting

4.1 General instructions

Protect your instrument against moisture ingress through the following

measures:

•

Use a suitable connection cable (see chapter " Connecting to

power supply")

•

Tighten the cable gland or plug connector

•

Lead the connection cable downward in front of the cable entry or

plug connector

This applies mainly to outdoor installations, in areas where high

humidity is expected (e.g. through cleaning processes) and on cooled

or heated vessels.

Note:

Make sure that during installation or maintenance no moisture or dirt

can get inside the instrument.

To maintain the housing protection, make sure that the housing lid is

closed during operation and locked, if necessary.

Note:

For safety reasons, the instrument must only be operated within the

permissibleprocessconditions.Youcannddetailedinformationon

the process conditions in chapter " Technical data" of the operating

instructions or on the type label.

Hence make sure before mounting that all parts of the instrument ex-

posed to the process are suitable for the existing process conditions.

These are mainly:

•

Active measuring component

•

Processtting

•

Process seal

Process conditions in particular are:

•

Process pressure

•

Process temperature

•

Chemical properties of the medium

•

Abrasionandmechanicalinuences

As a standard feature, the VEGAPULS 64 is separate from the pro-

cess through its plastic antenna encapsulation.

Optionally, the instrument is available with a Second Line of Defense

(SLOD), a second process separation. It is located as gas-tight

leadthrough between the process component and the electronics.

This means additional safety against penetration of the medium fron

the process into the instrument.

4.2 Mounting versions, plastic horn antenna

The optional mounting strap allows simple mounting of the instrument

on a wall, ceiling or boom. Especially in the case of open vessels, this

Protection against mois-

ture

Process conditions

Second Line of Defense

Mounting strap

15

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

isasimpleandeectivewaytoalignthesensortothesurfaceofthe

bulk solid material.

The following versions are available:

•

Length 300 mm

•

Length 170 mm

The instrument is normally mounted vertically with a bracket on the

ceiling.

This allows swivelling the sensor up to 180° for optimal orientation

and rotating for optimal connection.

Fig. 3: Ceiling mounting via the mounting strap with length 300 mm

Asanalternativethestrapmountingiscarriedouthorizontallyor

obliquely.

> 200 mm

(7.87")

Fig. 4: Wall mounting horizontally via the mounting strap with length 170 mm

Mounting strap - Ceiling

mounting

Mounting strap - Wall

mounting

16

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Fig. 5: Wall mounting with inclined wall via the mounting strap with length

300 mm

Twoversionsareavailableformountingtheinstrumentonanozzle:

•

Combicompressionange

•

Adapterange

Combicompressionange

Thecombicompressionangeissuitablefordierentvesselanges

DN 80, ASME 3" and JIS 80. It comes not sealed against the radar

sensorandcanthusonlybeusedunpressurized.Itcanberetrotted

oninstrumentswithsinglechamberhousing,retrottingtoadouble

chamber housing is not possible.

1

Fig. 6: Combi compression ange

1 Combi compression ange

Adapterange

TheadapterangeisavailablefromDN100,ASME4"andJIS100.It

is permanently connected with the radar sensor and sealed.

Flange

17

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

3

1

2

Fig. 7: Adapter ange

1 Connection screw

2 Adapter ange

3 Process seal

4.3 Mounting preparations, mounting strap

The mounting strap is supplied unassembled (optionally) and must be

screwed to the sensor before setup with three hexagon socket screws

M5 x 10 and spring washers. Max. torque, see chapter " Technical

data".Requiredtools:Allenwrenchsize4.

Therearetwodierentvariantsofscrewingthestraptothesensor,

see following illustration:

1 2

Fig. 8: Mounting strap for screwing to the sensor

1 For angle of inclination in steps

2 For angle of inclination, innitely variable

Depending on the selected variant, the sensor can be rotated in the

strap:

•

Single chamber housing

– Angle of inclination in three steps 0°, 90° and 180°

– Angleofinclination180°,innitelyvariable

•

Double chamber housing

– Angle of inclination in two steps 0° and 90°

– Angleofinclination90°,innitelyvariable

18

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Fig. 9: Adjustment of the angle of inclination

Fig. 10: Turning by fastening in the centre

4.4 Mounting instructions

Radar sensors for level measurement emit electromagnetic waves.

Thepolarizationisthedirectionoftheelectricalcomponentofthese

waves.

Thepolarizationdirectionismarkedbyanoseonthehousing,see

following drawing:

1

Fig. 11: Position of the polarisation

1 Nose for marking the direction of polarisation

Note:

Whenthehousingisrotated,thedirectionofpolarizationchanges

andhencetheinuenceofthefalseechoonthemeasuredvalue.

Please keep this in mind when mounting or making changes later.

When mounting the device, keep a distance of at least 200 mm

(7.874 in) from the vessel wall. If the device is installed in the center

of dished or round vessel tops, multiple echoes can arise. However,

Polarisation

Installation position

19

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

these can be suppressed by an appropriate adjustment (see chapter

" Setup").

If you cannot maintain this distance, you should carry out a false

signal suppression during setup. This applies particularly if buildup on

the vessel wall is expected. In such cases, we recommend repeating

the false signal suppression at a later date with existing buildup.

> 200 mm

(7.87

")

Fig. 12: Mounting of the radar sensor on round vessel tops

In vessels with conical bottom it can be advantageous to mount the

device in the centre of the vessel, as measurement is then possible

down to the bottom.

Fig. 13: Mounting of the radar sensor on vessels with conical bottom

The measuring range of VEGAPULS 64 begins physically at the end

of the antenna. The min./max. adjustment, however, begins at the

referenceplane.Thereferenceplaneisdierentdependingonthe

sensor version.

•

Plastic horn antenna: The reference plane is the sealing surface

on the lower edge

•

Thread with integrated horn antenna: The reference plane is

the sealing surface at the bottom of the hexagon

•

Flange with encapsulated antenna system: The reference

planeistheloweredgeoftheangeplating

•

Hygienicttings: The reference plane is the highest contact point

betweensensorprocessttingandweldedsocket

Reference plane

20

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

The following graphic shows the position of the reference plane with

dierentsensorversions.

2

1

1

1

1

3

4 5

Fig. 14: Position of the reference plane

1 Reference plane

2 Plastic horn antenna

3 Threaded ttings

4 Flange connections

5 Hygienic ttings

Donotmounttheinstrumentsinorabovethellingstream.Makesure

thatyoudetectthemediumsurface,nottheinowingproduct.

Fig. 15: Mounting of the radar sensor with inowing medium

Fornozzlemounting,thenozzleshouldbeasshortaspossibleand

itsendrounded.Thisreducesfalsereectionsfromthenozzle.

With threaded connection, the antenna end should protrude at least

5mm(0.2in)outofthenozzle.

ca. 5 mm

1 2 3

Fig. 16: Recommended socket mounting with dierent versions of VEGAPULS

64

1 Thread with integrated horn antenna

2 Plastic horn antenna

3 Flange with encapsulated antenna system

Inowingmedium

Nozzle

21

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Ifthereectivepropertiesofthemediumaregood,youcanmount

VEGAPULS 64 on sockets longer than the antenna. The socket end

should be smooth and burr-free, if possible also rounded.

Note:

Whenmountingonlongernozzles,werecommendcarryingouta

false signal suppression (see chapter " Parameter adjustment").

Youwillndrecommendedvaluesforsocketheightsinthefollowing

illustration or the tables. The values come from typical applications.

Deviating from the proposed dimensions, also longer sockets are

possible, however the local conditions must be taken into account.

1 2 3

d

h

d

h

d

h

Fig. 17: Socket mounting with deviating socket dimensions with dierent ver-

sions of VEGAPULS 64

1 Thread with integrated horn antenna

2 Plastic horn antenna

3 Flange with encapsulated antenna system

Thread with integrated horn antenna

Socket diameter d Socket length h

40 mm 1½" ≤150mm ≤5.9in

50 mm 2" ≤200mm ≤7.9in

80 mm 3" ≤300mm ≤11.8in

100 mm 4" ≤400mm ≤15.8in

150 mm 6" ≤600mm ≤23.6in

Plastic horn antenna

Socket diameter d Socket length h

80 mm 3" ≤400mm ≤15.8in

100 mm 4" ≤500mm ≤19.7in

150 mm 6" ≤800mm ≤31.5in

22

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Flange with encapsulated antenna system

Socket diameter d Socket length h

50 mm 2" ≤200mm ≤7.9in

80 mm 3" ≤400mm ≤15.8in

100 mm 4" ≤500mm ≤19.7in

150 mm 6" ≤800mm ≤31.5in

TheVEGAPULS64withangeandencapsulatedantennasystem,

the PTFE washer of the antenna encapsulation serves also as pro-

cess seal.

2

1

Fig. 18: VEGAPULS 64 with ange and encapsulated antenna system

1 PTFE washer

2 Antenna encapsulation

However,PTFE-platedangeshaveapreloadlossovertimeathigh

temperature changes.

Note:

Therefore, use disc springs to compensate for this preload loss during

mounting. They are included in the scope of delivery of the instrument

andareintendedfortheangescrews.

Tosealeectively,thefollowingrequirementsmustbefullled:

1. Makesurethenumberofangescrewscorrespondstothenum-

berofangeholes

2. Use of disc springs as previously described

1

2

Fig. 19: Use of disc springs

1 Disc spring

2 Sealing surface

Sealing to the process

23

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

3. Tighten screws with the necessary torque (see chapter " Techni-

cal data", " Torques")

2)

Note:

We recommend re-tightening the screws at regular intervals, depend-

ing on process pressure and temperature. Recommended torque, see

chapter " Technical data", " Torques".

The PTFE washer in 8 mm version can be exchanged by the user in

case of wear or damage.

Proceed as follows while dismounting:

1. Dismount and clean the instrument, note chapters " Dismounting

steps" and " Maintenance"

2. Unscrew and remove the PTFE disc by hand, protecting the

thread against dirt.

Fig. 20: VEGAPULS 64 - Loosening the PTFE washer

3. Remove the sealing and clean the sealing groove

4. Insert the supplied new sealing, place the PTFE washer onto the

thread and tighten it manually

5. Mountthesensor,tightentheangescrews(torqueseechapter"

Technical data", " Torques")

Note:

We recommend re-tightening the screws at regular intervals, depend-

ing on process pressure and temperature. Recommended torque, see

chapter " Technical data", " Torques".

PTFE threaded adapters are available for VEGAPULS 64 with thread

G1½ or 1½ NPT. Due to this, only PTFE is in contact with the medium.

Mount the PTFE threaded adapter in the following way:

Exchange,angeplating

Mounting, PTFE threaded

adapter

2)

Thetorquesspeciedinthetechnicaldataonlyapplytotheplatingshown

here in the area of the sealing surface. For plating up to the outer diameter,

the values are for orientation only; the torque values actually required are

application-specic.

24

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

1

3

2

4

5

*$

*

*$

*

6:

6:

Fig. 21: VEGAPULS 64 with PTFE threaded adapter

1 Sensor

2 O-ring seal (sensor side)

3 PTFE threaded adapter

4 Flat seal (process side)

5 Welded socket

1. RemoveexistingKlingersilatsealonthethreadofVEGAPULS

64

2. Insert the supplied O-ring seal (1) into the threaded adapter

3. Placethesuppliedatseal(4)ontothethreadoftheadapter

Note:

ForthethreadedadapterinNPTversion,thereisnoatsealrequired

on the process side.

4. Screw the threaded adapter on the hexagon into the welded

socket. Torque see chapter " Technical data"

5. Screw VEGAPULS 64 on the hexagon into the threaded adapter.

Torque see chapter " Technical data"

Instruments for a temperature range up to 200 °C have a spacer

fortemperaturedecouplingbetweenprocessttingandelectronics

housing.

Note:

The spacer may only be incorporated up to a maximum of 40 mm into

the vessel insulation. Only then is a reliable temperature decoupling

guaranteed.

Mounting in the vessel

insulation

25

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

max. 40 mm

(1.57")

1

2

3

Fig. 22: Mounting the instrument on insulated vessels.

1 Electronics housing

2 Spacer

3 Vessel insulation

The mounting location of the radar sensor should be a place where no

otherequipmentorxturescrossthepathoftheradarsignals.

Vessel installations, such as e.g. ladders, limit switches, heating spi-

rals, struts, etc., can cause false echoes and impair the useful echo.

Make sure when planning your measuring point that the radar sensor

has a " clear view" to the measured product.

In case of existing vessel installations, a false signal suppression

should be carried out during setup.

If large vessel installations such as struts or supports cause false

echoes, these can be attenuated through supplementary measures.

Small,inclinedsheetmetalbaesabovetheinstallations"scatter"

theradarsignalsandpreventdirectinterferingreections.

Fig. 23: Cover at, large-area proles with deectors

In liquids, direct the device as perpendicular as possible to the me-

dium surface to achieve optimum measurement results.

Vessel installations

Orientation

26

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Fig. 24: Alignment in liquids

If there are agitators in the vessel, a false signal suppression should

be carried out with the agitators in motion. This ensures that the

interferingreectionsfromtheagitatorsaresavedwiththebladesin

dierentpositions.

Fig. 25: Agitators

Throughtheactionoflling,stirringandotherprocessesinthevessel,

compact foams which considerably damp the emitted signals may

form on the medium surface.

If foams lead to measurement errors, you should use the biggest pos-

sible radar antennas or sensors with guided radar.

4.5 Measurement setup - Flow

In general, the following must be observed while mounting the device:

•

Mounting the sensor on the upstream or inlet side

•

Installationinthecentreoftheumeandverticaltotheliquid

surface

•

DistancetotheoverfalloriceorVenturiume

•

Min. distance to the max. height of damming for optimum accu-

racy: 250 mm (9.843 in)

3)

Agitators

Foam generation

Mounting

3)

At smaller distances the measuring accuracy is reduced, see "Technical

data".

27

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Everyumegeneratesadierentlevelofbackwaterdependingonits

typeandversion.Thespecicationsofthefollowingumesareavail-

able in the instrument:

Predenedcurves

Aowmeasurementwiththesestandardcurvesisveryeasytoset

up,asnodimensionalinformationoftheumeisrequired.

•

Palmer-Bowlusume(Q=kxh

1.86

)

•

Venturi,trapezoidalweir,rectangularume(Q=kxh

1.5

)

•

V-Notch,triangularoverfall(Q=kxh

2.5

)

Dimensions (ISO standard)

Whenselectingthesecurves,thedimensionsoftheumemustbe

known and entered via the assistant. As a result, the accuracy of the

owmeasurementishigherthanwiththespeciedcurves.

•

Rectangularume(ISO4359)

•

Trapezoidalume(ISO4359)

•

U-shapedume(ISO4359)

•

Triangular overfall thin-walled (ISO 1438)

•

Rectangularumethin-walled(ISO1438)

•

Rectangular weir broad crown (ISO 3846)

Flow formula

Iftheowformulaofyourumeisknown,youshouldselectthisop-

tion,astheaccuracyoftheowmeasurementishighesthere.

•

Flowformula:Q=kxh

exp

Manufacturerdenition

IfyouuseaParshallumefromthemanufacturerISCO,thisoption

mustbeselected.Thisgivesyouahighaccuracyofowmeasure-

mentwitheasyconguration.

Alternatively, you can also take over Q/h table values provided by the

manufacturer here.

•

ISCOParshallume

•

Q/htable(assignmentofheightwithcorrespondingowinatable)

Detailed project planning data can be found at the channel manufac-

turers and in the technical literature.

Thefollowingexamplesserveasanoverviewforowmeasurement.

Flume

28

4 Mounting

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

h

max

≥ 2 x h

max

90°

4

3 ... 4 h

max

90°

2 3

1

Fig. 26: Flow measurement with rectangular ume: h

max.

= max. lling of the

rectangular ume

1 Overfall orice (side view)

2 Upstream water

3 Tailwater

4 Overfall orice (view from tailwater)

2

3 ... 4 x h

max

90°

h

max

1

B

Fig. 27: Flow measurement with Khafagi-Venturi ume: h

max.

= max. lling of the

ume; B = tightest constriction in the ume

1 Position sensor

2 Venturi ume

Rectangular overfall

Khafagi-Venturiume

29

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

5 Connecting to power supply

5.1 Preparing the connection

Always keep in mind the following safety instructions:

•

Carryoutelectricalconnectionbytrained,qualiedpersonnel

authorised by the plant operator

•

If overvoltage surges are expected, overvoltage arresters should

be installed

Warning:

Onlyconnectordisconnectinde-energizedstate.

Power supply and current signal are carried on the same two-wire

cable.Theoperatingvoltagecandierdependingontheinstrument

version.

Thedataforpowersupplyarespeciedinchapter"Technical data".

Provide a reliable separation between the supply circuit and the

mains circuits according to DIN EN 61140 VDE 0140-1.

Power the instrument via an energy-limited circuit acc. to IEC 61010-

1, e.g. via Class 2 power supply unit.

Keepinmindthefollowingadditionalfactorsthatinuencetheoperat-

ing voltage:

•

Lower output voltage of the power supply unit under nominal load

(e.g. with a sensor current of 20.5 mA or 22 mA in case of fault)

•

Inuenceofadditionalinstrumentsinthecircuit(seeloadvaluesin

chapter " Technical data")

The instrument is connected with standard two-wire cable without

shielding. If electromagnetic interference is expected which is above

the test values of EN 61326-1 for industrial areas, shielded cable

should be used.

Use cable with round cross section for instruments with housing and

cable gland. Use a cable gland suitable for the cable diameter to

ensurethesealeectofthecablegland(IPprotectionrating).

Shielded cable generally necessary in HART multidrop mode.

Metric threads

In the case of instrument housings with metric thread, the cable

glands are screwed in at the factory. They are sealed with plastic

plugs as transport protection.

Note:

You have to remove these plugs before electrical connection.

NPT thread

In the case of instrument housings with self-sealing NPT threads, it is

not possible to have the cable entries screwed in at the factory. The

free openings for the cable glands are therefore covered with red dust

protection caps as transport protection.

Safety instructions

Voltage supply

Connection cable

Cable glands

30

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Note:

Prior to setup you have to replace these protective caps with ap-

proved cable glands or close the openings with suitable blind plugs.

On plastic housings, the NPT cable gland or the Conduit steel tube

must be screwed into the threaded insert without grease.

Max. torque for all housings, see chapter " Technical data".

If shielded cable is required, the cable screening must be connected

on both ends to ground potential. In the sensor, the cable screening

is connected directly to the internal ground terminal. The ground ter-

minal on the outside of the housing must be connected to the ground

potential (low impedance).

In Ex systems, the grounding is carried out according to the installa-

tion regulations.

In electroplating plants as well as plants for cathodic corrosion protec-

tionitmustbetakenintoaccountthatsignicantpotentialdierences

exist. This can lead to unacceptably high currents in the cable screen

if it is grounded at both ends.

Information:

Themetallicpartsoftheinstrument(processtting,sensor,concen-

tric tube, etc.) are connected with the internal and external ground

terminal on the housing. This connection exists either directly via

the conductive metallic parts or, in case of instruments with external

electronics, via the screen of the special connection cable.

Youcanndspecicationsonthepotentialconnectionsinsidethe

instrument in chapter " Technical data".

5.2 Connecting

The voltage supply and signal output are connected via the spring-

loaded terminals in the housing.

Connection to the display and adjustment module or to the interface

adapter is carried out via contact pins in the housing.

Information:

The terminal block is pluggable and can be removed from the

electronics. To do this, lift the terminal block with a small screwdriver

and pull it out. When reinserting the terminal block, you should hear it

snap in.

Proceed as follows:

1. Unscrew the housing lid

2. If a display and adjustment module is installed, remove it by turn-

ing it slightly to the left

3. Loosen compression nut of the cable gland and remove blind

plug

4. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

5. Insert the cable into the sensor through the cable entry

Cable screening and

grounding

Connection technology

Connection procedure

31

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

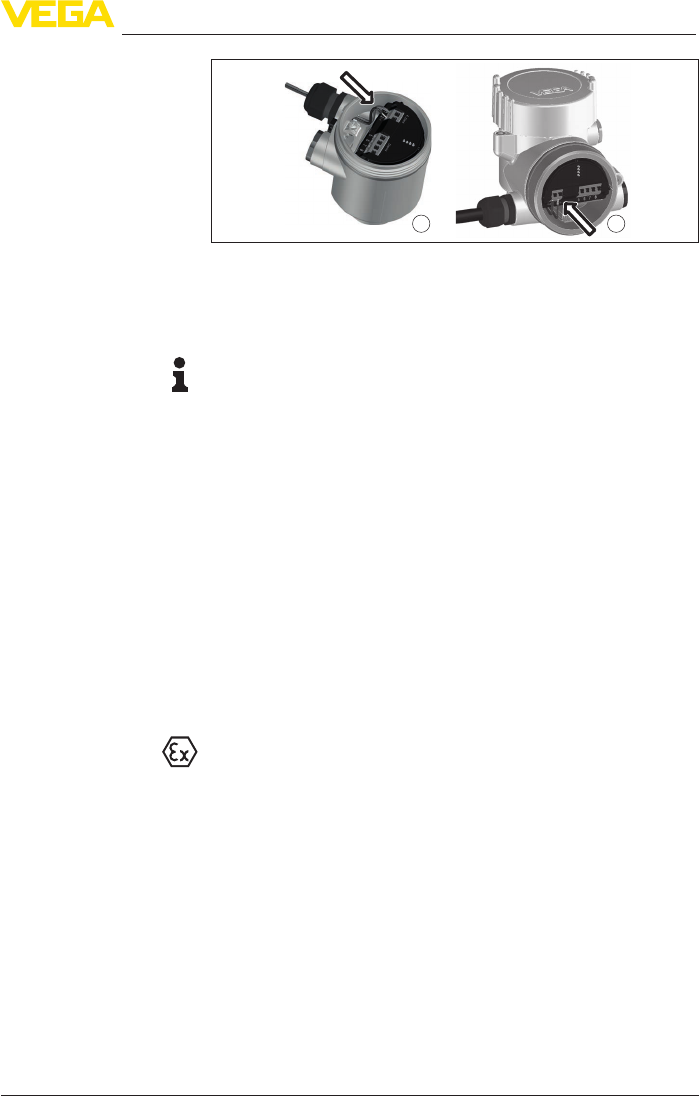

1 2

Fig. 28: Connection steps 5 and 6

1 Single chamber housing

2 Double chamber housing

6. Insert the wire ends into the terminals according to the wiring plan

Note:

Solidcoresaswellasexiblecoreswithwireendsleevesareinsert-

eddirectlyintotheterminalopenings.Incaseofexiblecoreswithout

end sleeves, press the terminal from above with a small screwdriver,

the terminal opening is then free. When the screwdriver is released,

the terminal closes again.

7. Check the hold of the wires in the terminals by lightly pulling on

them

8. Connect the shielding to the internal ground terminal, connect the

external ground terminal to potential equalisation

9. Tighten the compression nut of the cable entry gland. The seal

ring must completely encircle the cable

10. Reinsert the display and adjustment module, if one was installed

11. Screw the housing lid back on

Theelectricalconnectionisnished.

5.3 Wiring plan, single chamber housing

The following illustration applies to the non-Ex as well as to the Ex-ia

version.

32

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

5

1

2

+

( )

(-)

678

4...20mA

2

3

4

1

Fig. 29: Electronics and connection compartment - single chamber housing

1 Voltage supply, signal output

2 For display and adjustment module or interface adapter

3 For external display and adjustment unit

4 Ground terminal for connection of the cable screening

5.4 Wiring plan, double chamber housing

The following illustrations apply to the non-Ex as well as to the Ex-ia

version.

567

8

4...20mA

1

2

+

( )

(-)

2

1 1

Fig. 30: Electronics compartment - double chamber housing

1 Internal connection to the connection compartment

2 For display and adjustment module or interface adapter

Electronics and connec-

tion compartment

Electronics compartment

33

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

5

1

2

+

( )

(-)

678

4...20mADisplay

2

3

4

1

Fig. 31: Connection compartment - double chamber housing

1 Voltage supply, signal output

2 For display and adjustment module or interface adapter

3 For external display and adjustment unit

4 Ground terminal for connection of the cable screening

1

SIM

Status

Send

Off On

1

2

3

+

-

Fig. 32: Connection compartment - Radio module PLICSMOBILE 81

1 Voltage supply

Youcannddetailedinformationforconnectionintheoperating

instructions " PLICSMOBILE".

Inthisconguration,anothersensorisconnectedviatheM12x1

plug and also powered via PLICSMOBILE. The sensors must be

operated in HART multidrop.

1

SIM

Status

Send

Off On

1

2

3

+

-

Fig. 33: Sensor with radio module PLICSMOBILE 81 and M12 x 1 plug

1 M12 x 1 plug connector for connection of another sensor

Connection compartment

Connection compart-

ment - Radio module

PLICSMOBILE 81

Connection compart-

ment - Radio module

PLICSMOBILE 81 and

M12 x 1 plug

34

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

41

2

3

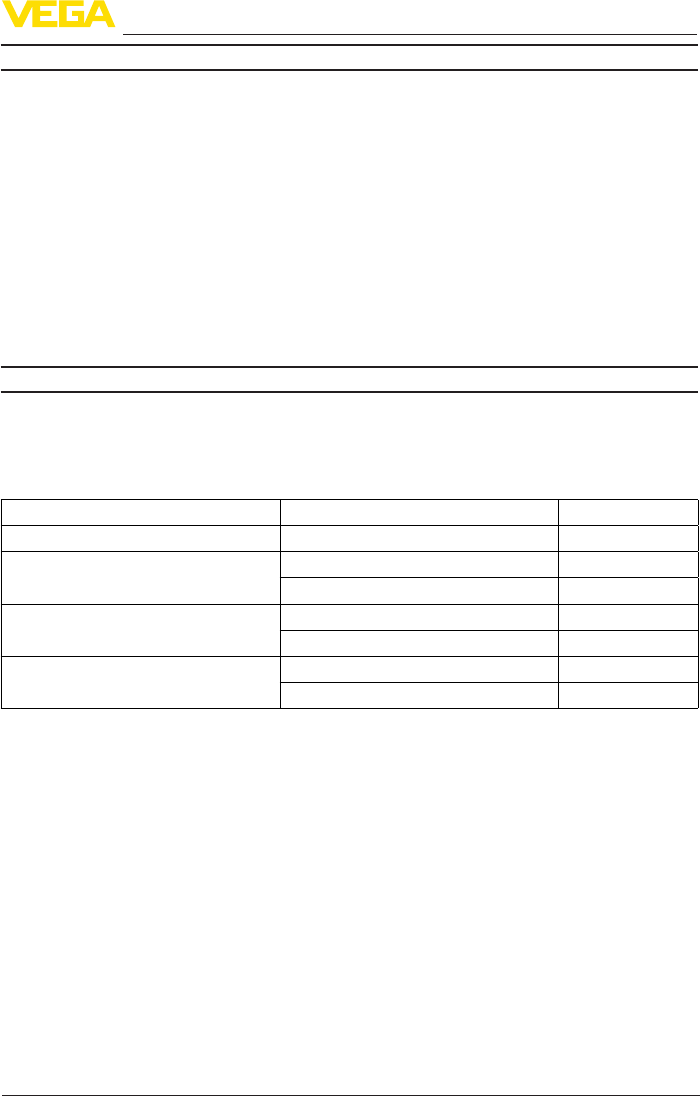

Fig. 34: Top view of the plug connector

Contact pin Terminal electronics mod-

ule additional sensor

Function/Polarity

1 Terminal 1 Power supply/Plus (+)

2 - Do not use

3 Terminal 2 Power supply/Minus (-)

4 - Do not use

1

4 5

6

2

7

3

5

1

2

+

-

678

4...20mA

SIM

Status

Send

Off On

1

23

+-

Fig. 35: Connection voltage supply and plics

®

sensor

1 Power supply PLICSMOBILE T81 and connected sensors

2 Sensor connection cable

3 HART sensor from the plics

®

series

4 Brown cable (+) for sensor power supply/HART communication

5 Blue cable (-) for sensor power supply/HART communication

6 Connection of additional HART sensors

7 Unused wires that must be insulated (not present on Ex version)

5.5 Wiring plan - version IP66/IP68, 1 bar

1

2

Fig. 36: Wire assignment in permanently connected connection cable

1 Brown (+) and blue (-) to power supply or to the processing system

2 Shielding

Wiring plan - Radio mod-

ule PLICSMOBILE 81 and

M12 x 1 plug

Connection exam-

ple - Radio module

PLICSMOBILE 81 and

plics

®

sensor via VEGA

sensor connection cable

Wire assignment, con-

nection cable

35

5 Connecting to power supply

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

5.6 Switch-on phase

Afterconnectionofthedevicetopowersupply,thedevicerstcarries

out a self-test:

•

Internal check of the electronics

•

Indication of the status message " F 105 Determine measured

value" on the display or PC

•

Theoutputsignaljumpsbrieytothesetfaultcurrent

Then the actual measured value is output to the signal cable. The

value takes into account settings that have already been carried out,

e.g. default setting.

36

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

6 Set up with the display and adjustment

module

6.1 Insert display and adjustment module

The display and adjustment module can be inserted into the sensor

andremovedagainatanytime.Youcanchooseanyoneoffourdier-

ent positions - each displaced by 90°. It is not necessary to interrupt

the power supply.

Proceed as follows:

1. Unscrew the housing lid

2. Place the display and adjustment module on the electronics in the

desired position and turn it to the right until it snaps in.

3. Screw housing lid with inspection window tightly back on

Disassembly is carried out in reverse order.

The display and adjustment module is powered by the sensor, an ad-

ditional connection is not necessary.

Fig. 37: Installing the display and adjustment module in the electronics compart-

ment of the single chamber housing

37

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

1 2

Fig. 38: Installing the display and adjustment module in the double chamber

housing

1 In the electronics compartment

2 In the connection compartment

Note:

Ifyouintendtoretrottheinstrumentwithadisplayandadjustment

module for continuous measured value indication, a higher lid with an

inspection glass is required.

6.2 Adjustment system

1

2

Fig. 39: Display and adjustment elements

1 LC display

2 Adjustment keys

•

[OK] key:

– Move to the menu overview

– Conrmselectedmenu

– Edit parameter

– Save value

•

[->] key:

– Change measured value presentation

– Select list entry

– Select menu items

– Select editing position

•

[+] key:

Key functions

38

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

– Change value of the parameter

•

[ESC] key:

– Interrupt input

– Jump to next higher menu

The instrument is operated via the four keys of the display and

adjustment module. The individual menu items are shown on the LC

display.Youcanndthefunctionoftheindividualkeysintheprevious

illustration.

With the Bluetooth version of the display and adjustment module you

can also adjust the instrument with the magnetic pen. The pen oper-

ates the four keys of the display and adjustment module right through

the closed lid (with inspection window) of the sensor housing.

1

2

4

3

Fig. 40: Display and adjustment elements - with adjustment via magnetic pen

1 LC display

2 Magnetic pen

3 Adjustment keys

4 Lid with inspection window

When the [+] and [->] keys are pressed quickly, the edited value,

or the cursor, changes one value or position at a time. If the key is

pressed longer than 1 s, the value or position changes continuously.

When the [OK] and [ESC] keys are pressed simultaneously for more

than 5 s, the display returns to the main menu. The menu language is

then switched over to " English".

Approx. 60 minutes after the last pressing of a key, an automatic reset

tomeasuredvalueindicationistriggered.Anyvaluesnotconrmed

with [OK] will not be saved.

6.3 Measured value indication - Selection of

national language

With the [->]keyyoumovebetweenthreedierentindicationmodes.

Intherstview,theselectedmeasuredvalueisdisplayedinlarge

digits.

In the second view, the selected measured value and a respective

bargraph presentation are displayed.

Operating system - Keys

direct

Adjustment system - keys

via magnetic pen

Time functions

Measured value indica-

tion

39

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

In the third view, the selected measured value as well as a second se-

lectable value, e.g. the temperature of the electronics, are displayed.

During the initial setup of an instrument shipped with factory settings,

use the " OK" key to get to the menu " National language".

This menu item is used to select the national language for further pa-

rameter adjustment. You can change the selection via the menu item "

Setup - Display, Menu language".

With the " OK" key you move to the main menu.

6.4 Parameter adjustment - Quick setup

To quickly and easily adapt the sensor to the application, select the

menu item " Quick setup" in the start graphic on the display and

adjustment module.

Select the individual steps with the [->] key.

After the last step, " Quick setup terminated successfully" is displayed

briey.

Information:

The echo curve of setup is stored automatically during the quick

setup.

The return to the measured value indication is carried out through the

[->] or [ESC] keys or automatically after 3 s

Youcannd"Extended adjustment" in the next sub-chapter.

6.5 Parameter adjustment - Extended adjustment

Themainmenuisdividedintovesectionswiththefollowingfunc-

tions:

Setup: Settings, e.g., for measurement loop name, units, application,

adjustment, signal output

Display: Settings, e.g., for language, measured value display, lighting

Selection of national

language

Main menu

40

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Diagnosis: Information, for example, on device status, peak value,

simulation, echo curve

Additional adjustments: Date/Time, reset, copy function, scaling,

currentoutput,falsesignalsuppression,linearization,HARTmode,

special parameters

Info: Instrument name, hardware and software version, calibration

date, instrument features

In the main menu item " Setup", the individual submenu items should

be selected one after the other and provided with the correct param-

eters to ensure optimum setting of the measurement. The procedure

is described in the following.

Here you can assign a suitable measurement loop name. Push the "

OK" key to start the editing. With the " +" key you change the sign and

with the " ->" key you jump to the next position.

You can enter names with max. 19 characters. The character set

comprises:

•

Capital letters from A … Z

•

Numbers from 0 … 9

•

Special characters + - / _ blanks

In this menu item you select the distance unit and the temperature

unit.

For the distance units you can choose between m, in and ft and for

the temperature units °C, °F and K.

This menu item allows you to adapt the sensor to the measuring

conditions.

Medium

The following options are available:

Setup - Measurement

loop name

Setup - Units

Setup - Application

41

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Application

The following options are available:

The following features form the basis of the applications:

Storage tank

•

Vessel:

– Large volume

– Uprightcylindrical,horizontalround

•

Process/measurement conditions:

– Condensation

– Smooth medium surface

– High requirements on measurement accuracy

– Slowllingandemptying

•

Properties, sensor:

– Low sensitivity to sporadic false echoes

– Stable and reliable measured values through averaging

– High measurement accuracy

– No short reaction time of the sensor required

Storage tank with product circulation

•

Setup: large-volumed, upright cylindrical, spherical

•

Mediumspeed:slowllingandemptying

•

Installations: small, laterally mounted or large, top mounted stirrer

•

Process/measurement conditions:

– Relatively smooth medium surface

– High requirements on measurement accuracy

– Condensation

– Slight foam generation

– Overllingpossible

•

Properties, sensor:

– Low sensitivity to sporadic false echoes

– Stable and reliable measured values through averaging

– High measurement accuracy, because not set for max. speed

– False signal suppression recommended

Storage tank on ships (Cargo Tank)

•

Mediumspeed:slowllingandemptying

•

Vessel:

– Installations in the bottom section (bracers, heating spirals)

– Highnozzles200…500mm,alsowithlargediameters

•

Process/measurement conditions:

– Condensation, buildup by movement

– Max. requirement on measurement accuracy from 95 %

•

Properties, sensor:

– Low sensitivity to sporadic false echoes

– Stable and reliable measured values through averaging

– High measurement accuracy

– False signal suppression required

42

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Stirrer vessel (reactor)

•

Vessel:

– Nozzle

– Large agitator blades of metal

– Vortex breakers, heating spirals

•

Process/measurement conditions:

– Condensation, buildup by movement

– Strong vortex generation

– Very agitated surface, foam generation

– Fasttoslowllingandemptying

– Vesselislledandemptiedveryoften

•

Properties, sensor:

– Higher measurement speed through less averaging

– Sporadic false echoes are suppressed

Dosing vessel

•

Setup:allvesselsizespossible

•

Medium speed:

– Fastllingandemptying

– Vesselislledandemptiedveryoften

•

Vessel: tight installation situation

•

Process/measurement conditions:

– Condensation, buildup on the antenna

– Foam generation

•

Properties, sensor:

– Measurementspeedoptimizedbyvirtuallynoaveraging

– Sporadic false echoes are suppressed

– False signal suppression recommended

Plastic tank

•

Process/measurement conditions:

– Condensation on the plastic ceiling

– In outdoor facilities, water and snow on vessel top possible

– Measurement through the vessel top, if appropriate to the

application

•

Properties, sensor:

– False signals outside the vessel are not taken into consideration

– False signal suppression recommended

For operation of the instrument in plastic tanks, certain conditions

mustbefullled(seechapter"Radio licenses" for Europe, USA and

Canada).

Transportable plastic tank

•

Process/measurement conditions:

– Materialandthicknessdierent

– Measured value jump with vessel change

– Measurement through the vessel top, if appropriate to the

application

•

Properties, sensor:

– Quickadaptationtochangingreectionconditionsduetoves-

sel change required

– False signal suppression required

43

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

For operation of the instrument in plastic tanks, certain conditions

mustbefullled(seechapter"Radio licenses" for Europe, USA and

Canada).

Open water (gauge measurement)

•

Process/measurement conditions:

– Slow gauge change

– Extreme damping of output signal due to wave generation

– Ice and condensation on the antenna possible

– Floating debris sporadically on the water surface

•

Properties, sensor:

– Stable and reliable measured values through frequent averag-

ing

– Insensitive in the close range

Openume(owmeasurement)

•

Process/measurement conditions:

– Slow gauge change

– Ice and condensation on the antenna possible

– Smooth water surface

– Exact measurement result required

•

Properties, sensor:

– Stable and reliable measured values through frequent averag-

ing

– Insensitive in the close range

Rain water spillover (weir)

•

Rate of level change: slow level change

•

Process/measurement conditions:

– Ice and condensation on the antenna possible

– Spiders and insects build nests in the antennas

– Turbulent water surface

– Sensoroodingpossible

•

Properties, sensor:

– Stable and reliable measured values through frequent averag-

ing

– Insensitive in the close range

Demonstration

•

Setting for all applications which are not typically level measure-

ment

– Instrument demonstration

– Object recognition/monitoring (additional settings required)

•

Properties, sensor:

– Sensor accepts all measured value changes within the measur-

ing range immediately

– High sensitivity to interference, because virtually no averaging

Vessel shape

Apart from the medium and the application, the vessel form itself can

inuencethemeasurement.Toadaptthesensortothesemeasuring

conditions,thismenuitemoersdierentoptionsforvesselbottom

and ceiling for certain applications.

44

6 Set up with the display and adjustment module

VEGAPULS 64 • Two-wire 4 … 20 mA/HART

51141-EN-210219

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Vessel height/Measuring range

Through this selection the operating range of the sensor is adapted

to the vessel height, which considerably increases measurement reli-

abilityunderdierentbasicconditions.

The min. adjustment must be carried out independently of this.

Enter the requested parameters via the appropriate keys, save your

settings with [OK] and jump to the next menu item with the [ESC] and

the [->] key.

Caution:

Ifliquidswithdierentdielectricconstantsseparateinthevessel,for

example through condensation, the radar sensor can detect under

certain circumstances only the medium with the higher dielectric

constant. Keep in mind that layer interfaces can cause faulty meas-

urements.

If you want to measure the total height of both liquids reliably, please

contact our service department or use an instrument specially de-

signed for interface measurement.

Since the radar sensor is a distance measuring instrument, it is the

distance from the sensor to the medium surface that is measured. To

indicate the actual level, the measured distance must be assigned to