NREL is a national laboratory of the U.S. Department of Energy

Office of Energy Efficiency & Renewable Energy

Operated by the Alliance for Sustainable Energy, LLC

This report is available at no cost from the National Renewable Energy

Laboratory (NREL) at www.nrel.gov/publications.

Contract No. DE-AC36-08GO28308

Technical Report

NREL/TP-5400-83795

December 2022

Florida Alternative Transportation Fuel

Resilience Plan

Caley Johnson

,

1

Jeff Cappellucci,

1

Lauren Spath Luhring,

1

Maria St. Louis

-Sanchez,

1

Fan Yang,

1

Abby Brown,

1

Austin Sipiora,

2

Alexander Kolpakov,

2

Xiaopeng Li,

2

Qianwen Li,

2

Sean White,

3

John Gonzales,

1

Erin Nobler,

1

and Eric Wood

1

1 National Renewable Energy Laboratory

2 University of South Florida

, Center for Urban Transportation

Research

3 Florida Department of Agriculture & Consumer Services

NREL is a national laboratory of the U.S. Department of Energy

Office of Energy Efficiency & Renewable Energy

Operated by the Alliance for Sustainable Energy, LLC

This report is available at no cost from the National Renewable Energy

Laboratory (NREL) at www.nrel.gov/publications.

Contract No. DE-AC36-08GO28308

National Renewable Energy Laboratory

15013 Denver West Parkway

Golden, CO 80401

303-275-3000 • www.nrel.gov

Technical Report

NREL/TP-5400-83795

December 2022

Florida Alternative Transportation Fuel

Resilience Plan

Caley Johnson,

1

Jeff Cappellucci,

1

Lauren Spath Luhring,

1

Maria St. Louis-Sanchez,

1

Fan Yang,

1

Abby Brown,

1

Austin Sipiora,

2

Alexander Kolpakov,

2

Xiaopeng Li,

2

Qianwen Li,

2

Sean White,

3

John Gonzales,

1

Erin Nobler,

1

and Eric Wood

1

1 National Renewable Energy Laboratory

2 University of South Florida, Center for Urban Transportation

Research

3 Florida Department of Agriculture & Consumer Services

Suggested Citation

Johnson, Caley, Jeff Cappellucci, Lauren Spath Luhring, Maria St. Louis-Sanchez, Fan

Yang, Abby Brown, Austin Sipiora, Alexander Kolpakov, Xiaopeng Li, Qianwen Li, Sean

White, John Gonzales, Erin Nobler, and Eric Wood. 2022. Florida Alternative

Transportation Fuel Resilience Plan. Golden, CO: National Renewable Energy

Laboratory. NREL/TP-5400-83795. https://www.nrel.gov/docs/fy23osti/83795.pdf

.

NOTICE

This work was authored in part by the National Renewable Energy Laboratory, operated by Alliance for

Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-

08GO28308. This material is based upon work supported by the U.S. Department of Energy’s Office of

Energy Efficiency and Renewable Energy (EERE) under the Energy Technology Development Program

“Statewide Alternative Fuel Resiliency Plan” Award Number DE-EE0008880. The principal investigator of

the award is the Florida Department of Agriculture and Consumer Services.

This report was prepared as an account of work sponsored by an agency of the United States Government.

Neither the United States Government nor any agency thereof, nor any of their employees, makes any

warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness,

or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would

not infringe privately owned rights. Reference herein to any specific commercial product, process, or service

by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its

endorsement, recommendation, or favoring by the United States Government or any agency thereof. The

views and opinions of authors expressed herein do not necessarily state or reflect those of the United States

Government or any agency thereof.

This report is available at no cost from the National

Renewable Energy Laboratory (NREL) at

www.nrel.gov/publications

.

U.S. Department of Energy (DOE) reports produced

after 1991 and a growing number of pre-1991

documents are available

free via www.OSTI.gov

.

Cover Photos by Dennis Schroeder: (clockwise, left to right) NREL 51934, NREL 45897, NREL 42160, NREL 45891, NREL 48097,

NREL 46526.

NREL prints on paper that contains recycled content.

iii

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Acknowledgments

The authors would like to thank the Department of Energy for funding this work. In particular,

they would like to thank Mark Smith and Trev Hall for project oversight. This project was

informed and guided by conversations with many fleet managers, vehicle mechanics, fuel station

operators, emergency response specialists, ChargePoint, the Florida Department of Emergency

Management, Port Tampa Bay, and others. The project would not have been possible without

these experts sharing their insight and data with us and we are very thankful.

iv

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

List of Acronyms

AFV alternative fuel vehicle

BCT Broward County Transit

BEB battery-electric bus

BRT bus rapid transit

CNG compressed natural gas

CUTR Center for Urban Transportation Research

DCFC DC fast charger

DEMP Diesel Emissions Mitigation Program

DOE U.S. Department of Energy

EOC emergency operations center

ESF-12 Emergency Support Function 12

EV electric vehicle

EVI-Pro Electric Vehicle Infrastructure – Projection

EVSE electric vehicle supply equipment

FDACS Florida Department of Agriculture and Consumer Services

FDEM Florida Division of Emergency Management

FDOT Florida Department of Transportation

FHWA Federal Highway Administration

GIS geographic information system

iREV Initiative for Resiliency in Energy through Vehicles

JTA Jacksonville Transportation Authority

L1 Level 1

L2 Level 2

LMTV Light Medium Tactical Vehicle

LNG liquefied natural gas

LPG liquefied petroleum gas

MCDA multi-criteria decision analysis

MUSC Medical University of South Carolina

NHTS National Household Travel Survey

NREL National Renewable Energy Laboratory

SAIDI System Average Interruption Duration Index

VBFD Virginia Beach Fire and Rescue Department

v

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Executive Summary

Many counties and cities in Florida are developing resilience plans to help them minimize

damage from hurricanes and accelerate recovery.

1

An Achilles’ heel of these plans is their

dependence on diesel fuel, which is particularly vulnerable to hurricane-related disruptions

because 90% of petroleum in Florida is imported via maritime tanker (EIA 2014). Fuel

diversification can add to Florida’s transportation resilience because if the supply of one fuel gets

disrupted during a hurricane, there is a good chance that the supplies of other fuels are still

available. As Figure ES-1 shows, the four main transportation fuels in Florida have different

means of distribution. If one means of transport (e.g., marine port) is removed, then other means

(e.g., pipeline, rail, cable) could then be relied upon to deliver transportation fuel. The Florida

Alternative Transportation Fuel Resilience Plan aims to address these factors and create a

strategy for how three alternative fuels (natural gas, propane, and electricity) can best be

employed to improve transportation resilience in Florida. It does this through a combination of

literature review and stakeholder engagement for best practices, vehicle technology

recommendations, the creation of three tools (with descriptions and brief guides included), and

charting how stakeholders coordinate to overcome these hurdles.

Figure ES-1. Origin, processing, and distribution of four transportation fuels in Florida.

Source: National Renewable Energy Laboratory

In Florida, various stakeholders share responsibility for emergency preparedness and resilience,

and actions and decisions are made at multiple levels, including government, the private sector,

and communities. These stakeholders receive direction from the State of Florida Comprehensive

Emergency Management Plan (CEMP), which is administered by the Florida Division of

1

County and city resilience resources and plans listed in the Florida Resilience Tool, https://widgets-stage.tada-

stage.nrel.gov/tada/fl-resiliency/.

vi

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Emergency Management (FDEM). Stakeholders convened via webinar at the beginning of this

project and revisited numerous times so their wide variety of perspectives could help inform the

plan. Fleet partners helped develop a list of best practices for fleets, including vehicle

recommendations, fueling prioritization strategies, redundancies in fuel supply networks, and

fuel tanker logistics. Site visits also provided input that was incorporated into the plan. None of

the visited alternative fuel fleets experienced interruptions in fuel supply to their alternative fuel

vehicles (AFVs) during recent hurricanes (in the past ~7 years), even when diesel and gasoline

supplies were interrupted due to port closures. Fleets increased the resilience of their natural gas

and propane supplies by using mobile fueling units.

The supply chain of alternative fuels, as shown in Figure ES-1, is diverse in Florida. Natural gas

comes via four interstate pipelines. Propane is a byproduct of both natural gas and petroleum

processing facilities and is imported to the state via rail. Electricity in Florida is generated largely

from natural gas (with fuel oil as backup), two nuclear power plants, coal, solar, and biofuels.

Alternative fuels are then sold to vehicles through 28 electricity, 15 natural gas, 11 propane, 10

biofuel, and 3 hydrogen vendors.

Hurricanes can limit communication by knocking out cellphone towers and other

communications infrastructure while simultaneously increasing the need for fleet and vehicle

communications to facilitate evacuation and recovery operations. Surveyed fleets reported

communicating via radio, cellphones, and landlines during disaster situations. However, some of

the fleets that could be most beneficial during evacuation, such as propane school buses or

natural gas-fueled power line repair vehicles, are prioritized below first responders and might not

have access to their radio channels. Electric vehicle supply equipment (EVSE) normally

communicates with drivers through its network and mobile applications. EVSE is built to

withstand 18 inches of standing water (per the National Electrical Code), but if this threshold is

surpassed and the hardware is damaged, it cannot be brought back online until a technician

physically inspects it. ChargePoint (the largest EVSE network company in Florida) has mobile

fast chargers on skids/trucks with 4 feet of clearance that can be moved to strategic locations and

connected quickly to the grid.

To facilitate the use of alternative fuels before and during a hurricane, the National Renewable

Energy Laboratory (NREL) developed a Florida Resiliency Tool website to help facilitate

planning and communications. Available at https://widgets-stage.tada-stage.nrel.gov/tada/fl-

resiliency/, this website uses state-of-the-art technologies to provide useful maps, information,

connections, and other resources. A second tool developed as part of this plan is an electric

vehicle evacuation planning prototype web tool to prepare the state for using electric vehicles

(EVs) before and during an emergency event. This tool, developed by the University of South

Florida (USF), uses a novel algorithm to coordinate reservations for EVs to charge along

evacuation routes.

Resilience should be considered when planning and building out the nascent EVSE network in

Florida. Therefore, NREL projected the number of EVs in each Florida county in 2030 and 2050

and used the Electric Vehicle Infrastructure – Projection (EVI-Pro) tool to estimate how much

public EVSE will be needed to charge those vehicles. Florida is estimated to have 74,000 EVs in

2030, with 17% of them being plug-in hybrid EVs and 83% battery-electric vehicles. These EVs

will need 45,485 nonresidential EVSE chargers by 2030. To be specific, 54% are workplace

vii

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Level 2 chargers, 34% are public Level 2 chargers, and 12% are fast chargers. By 2030, Broward

County will have the most significant need for EVSE, whereas Lafayette County will require the

least EVSE.

NREL also developed a geographic information system (GIS) model for two purposes: (1) to

identify potential locations for new AFV stations to increase the connectivity of the road network

for AFVs evacuating or performing emergency response duties, and (2) to address future needs

for EVSE by comparing counts of current EVSE ports against future EVSE needs forecast by

EVI-Pro. This analysis considered flood zones, emergency shelters, evacuation routes, AFV

refueling infrastructure, garage locations of AFV fleets, and the EV and EVSE projections from

EVI-Pro. After removing stations that are at risk of flooding, the percentage of evacuation routes

covered by each AFV service area averaged 87.6%. However, after integrating proposed new

stations at emergency shelters, the coverage increased to an average of 99.0%. The tool was also

used to track progress toward meeting the required number of DC fast-charging ports in 2030.

Several of the more populated counties need more than 200 stations to meet their goals, and

other counties were already at or near their 2030 targets. The GIS-based Alternative Fuel

Resilience tool was made available to planners and analysts at

https://nrel.maps.arcgis.com/apps/mapviewer/index.html?webmap=70d980d59f39453387d8286f

cb505ae1, and a case study was developed for instruction using the tool. Finally, the

methodologies and findings of this analysis were compared to relevant portions of the Florida

Electric Vehicle Roadmap (Burk et al. 2020) and the EV Infrastructure Master Plan (FDOT

2021).

This plan must interact with other aspects of resilience planning in Florida, so relevant laws,

regulations, and organizations were described. The state’s 10 regional planning councils and the

Florida Division of Emergency Management were identified as particularly important to work

with.

A vehicle’s ability to drive through standing water can be crucial during a hurricane, so NREL

and USF conducted a literature review and held multiple interviews on this topic. Fleet managers

should try to purchase vehicles with high air intake or modify the air intake system to raise the

height. Fleet managers must ensure that electrical components are water-resistant or move them

to higher locations on the vehicle. It is also important to remotely mount vent tubes to the

transmission and differential at the highest points possible. Vehicle buoyancy is a key

consideration, and liftoff occurs later (deeper) in vehicles with higher clearance, greater mass,

smaller footprint, and better tire traction. Vehicles powered by propane or natural gas have

completely sealed fuel systems, reducing the likelihood of water infiltration. EVs do not need

oxygen to operate, and key components are often waterproofed (Evarts 2018). This has enabled

the EV company Rivian to claim in the specifications of their R1S and R1T that these vehicles

can drive through 43 inches of standing water.

2

Likewise, DD DANNAR claims that its electric

off-road work vehicles can operate in up to 4 feet of water.

3

However, 11 EVs from other

manufacturers auto-ignited after Hurricane Ian (Weise 2022), accelerating research into the

impact that extended periods of saltwater submersion has on EVs.

2

https://rivian.com/support/article/what-is-the-water-fording-height

3

https://www.dannar.us.com/

viii

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Table of Contents

1 Introduction ........................................................................................................................................... 1

2 Background ........................................................................................................................................... 3

3 Stakeholders and Involvement ............................................................................................................ 4

Fuel Resilience Stakeholders .................................................................................................................. 4

Stakeholder Kickoff Meeting ................................................................................................................. 6

Fuel Resilience Best Practices for Fleets ................................................................................................ 6

Site Visits ............................................................................................................................................... 8

4 Supply Chain of Natural Gas, Propane, and Electricity in Florida .................................................. 9

Upstream Sources of Alternative Fuels .................................................................................................. 9

Alternative Fuel Vendors ..................................................................................................................... 11

5 Communications Practices and Protocols ...................................................................................... 13

Current Status and Shortcomings of Communications During Hurricanes .......................................... 13

Solution 1: New Website to Facilitate Planning ................................................................................... 15

Solution 2: EVSE Communications Algorithms and Web Tool .......................................................... 18

6 Long-Term Planning for Electric Vehicle Infrastructure Expansion ............................................. 24

Electric Vehicle Infrastructure Projections Method Overview ............................................................ 24

Vehicle and Infrastructure Attribute Assumptions ............................................................................... 25

Florida County-Level Travel Demand Assumptions ............................................................................ 26

EVI-Pro Simulation Analysis and Results ........................................................................................... 27

7 GIS-Based Preparation for Hurricanes ............................................................................................. 34

Utilizing Current Infrastructure Data ................................................................................................... 35

Future Infrastructure Identification Methods ....................................................................................... 37

Key Findings of GIS Analysis .............................................................................................................. 40

Florida Alternative Fuel Resilience Web Map Local Usage Example ................................................. 44

Comparison to Florida’s EV Roadmap and EV Master Plan ............................................................... 47

GIS Summary ....................................................................................................................................... 48

8 Laws, Regulations and Organizations Relevant to Resilience Planning ...................................... 49

Relevant Laws and Regulations ........................................................................................................... 49

Re

gional Planning Councils ................................................................................................................. 49

Resilient Florida ................................................................................................................................... 50

Functions of the Florida Department of Agriculture and Consumer Services ..................................... 50

9 Vehicles in Standing Water ............................................................................................................... 51

Important Components of High-Water-Capable Vehicles ................................................................... 51

Electric Vehicles and Flooding ............................................................................................................ 53

High-Water Fleet Experiences ............................................................................................................. 53

High-Water Vehicle Conclusions and Recommendations ................................................................... 55

10 Conclusions and Recommendations ............................................................................................... 56

References ................................................................................................................................................. 57

Appendix A. SAIDI Zone Data Provided to NREL .................................................................................. 62

Appendix B. Site Visit Summaries .......................................................................................................... 63

Waste Pro Facility and CNG Fueling Site ............................................................................................ 63

Seminole County Schools..................................................................................................................... 66

City Furniture ....................................................................................................................................... 68

Broward County Transit – Paratransit Division ................................................................................... 72

Jacksonville Transportation Authority ................................................................................................. 76

Appendix C. Alternative Fuel Vendors .................................................................................................... 82

Appendix D. MCDA Algorithm for Potential New Fuel Station Identification ..................................... 88

Appendix E. Workflow for Future EVSE Needs Mapping ...................................................................... 89

Appendix F: Literature Review for Vehicles in Standing Water ........................................................... 90

Background and Purpose ...................................................................................................................... 90

ix

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Vehicle Water Damage......................................................................................................................... 90

Preventing Water Damage........................................................................................................... 90

Common Vehicle Damage and How To Assess and Repair It .................................................... 91

Assessing and Repairing Common Damage ............................................................................... 91

Engine and Transmission ............................................................................................................ 92

Electrical Components ................................................................................................................ 93

Interior Considerations ................................................................................................................ 93

Case Study: Virginia Beach Fire and Rescue ....................................................................................... 93

Equipment Used and Damage Found .......................................................................................... 94

Potential Vehicle Modifications To Avoid Damage ................................................................... 94

Driver Training ............................................................................................................................ 95

Results 95

Preparing Fleets for Hurricanes and Flooding ...................................................................................... 95

Emergency Operating Plans ........................................................................................................ 96

Vehicle Planning and Repositioning ........................................................................................... 97

Driver Training ............................................................................................................................ 98

Other Considerations ................................................................................................................... 98

Preferred Vehicles for Driving Through Floodwaters .......................................................................... 98

Conclusion ............................................................................................................................................ 98

x

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

List of Figures

Figure ES-1. Origin, processing, and distribution of four transportation fuels in Florida. ........................... v

Figure 1. Origin, processing, and distribution of four transportation fuels in Florida. ................................. 2

Figure 2. Categories of fuel resilience stakeholders ..................................................................................... 5

Figure 3. Alternative Transportation Fuel Resilience Plan design and implementation model .................... 6

Figure 4. Florida’s Four Interstate Natural Gas Pipelines ........................................................................... 10

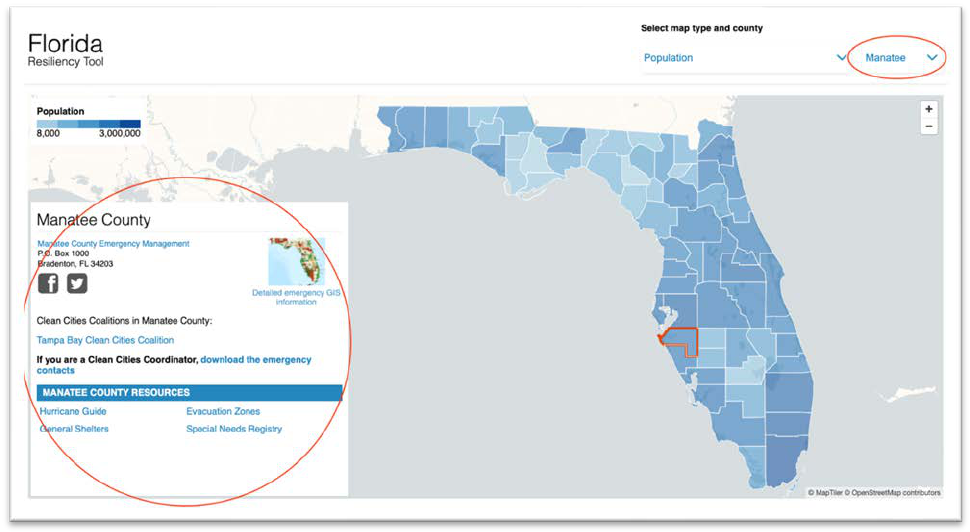

Figure 5. Florida Resilience Tool homepage .............................................................................................. 15

Figure 6. County-specific resources appear when a county is selected. ..................................................... 16

Figure 7. Florida Resilience Tool map layers ............................................................................................. 17

Figure 8. Accessing fuel-specific station location by county ..................................................................... 17

Figure 9. Station-specific information provides detail ................................................................................ 18

Figure 10. Detailed emergency GIS information accessible in the Florida Resilience Tool ...................... 18

Figure 11. EV Evacuation Tool homepage ................................................................................................. 20

Figure 12. Signup and login to the EV Evacuation Tool ............................................................................ 20

Figure 13. Evacuation reservation in the EV Evacuation Tool ................................................................... 21

Figure 14. Back-end evacuation planning algorithm structure ................................................................... 22

Figure 15. Evacuation route ........................................................................................................................ 23

Figure 16. EVI-Pro model structure and data flow ..................................................................................... 25

Figure 17. Florida county-level population density and EV fleets ............................................................. 27

Figure 18. EV charging load profiles in 2030, n = 80,000 ......................................................................... 28

Figure 19. Comparison of 2030 and 2050 EV charging infrastructure ....................................................... 32

Figure 20. Summary of the two geospatial Florida AFV flood resilience analyses .................................... 34

Figure 21. FHWA alternative fuel corridor requirements. .......................................................................... 35

Figure 22. Florida flood risk, emergency shelters, and evacuation routes. ................................................. 36

Figure 23. Level 2 EVSE and related 50-mile radius EV service map ....................................................... 38

Figure 24. Propane vehicle vulnerability map ............................................................................................ 39

Figure 25. Best new CNG station locations identified by the analysis ....................................................... 41

Figure 26. Number of DCFC Ports Required to Meet 2030 Goals ............................................................. 42

Figure 27. Resilience web map features while planning EV resilience in Dixie County ........................... 45

Figure 28. Example of the ability to add new data to the resilience web map ............................................ 46

Figure 29. Example use case after adding gasoline station data to the resilience web map ....................... 47

Figure 30. Medium-duty vehicle and its points of vulnerability to standing water. ................................... 53

Fi

gure B-1. Gauge above 400 psi at WastePro. .......................................................................................... 64

Figure B-2. Natural gas line service inlet at 100 psi. .................................................................................. 65

Figure B-3. 400-kW genset at Seminole County Schools. .......................................................................... 67

Figure B-4. Diesel storage at Seminole County Schools (2,877 gallons). .................................................. 67

Figure B-5. CNG fleet using time-fill. ........................................................................................................ 69

Figure B-6. City Furniture electric Kalmar Ottawa yard truck. .................................................................. 70

Figure B-7. City Furniture CNG station. .................................................................................................... 71

Figure B-8. City Furniture CNG delivery fleet. .......................................................................................... 72

Figure B-9. BCT paratransit bus fueling with propane. .............................................................................. 73

Figure B-10. BCT propane paratransit buses. ............................................................................................. 74

Figure B-11. BCT propane fueling facility. ................................................................................................ 75

Figure B-12. JTA battery-electric bus. ........................................................................................................ 77

Figure B-13. JTA CNG fueling station. ...................................................................................................... 78

Figure B-14. JTA on-site diesel fuel storage. ............................................................................................. 78

Figure B-15. Electric bus charging station installation. .............................................................................. 79

xi

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

List of Tables

Table 1. Alternative Fuel Vendors in the State of Florida .......................................................................... 11

Table 2. EV Charging Infrastructure Technology Specifications ............................................................... 26

Table 3. 2030 EV Nonresidential Charging Infrastructure Projection ........................................................ 28

Table 4. 2050 EV Nonresidential Charging Infrastructure Projection ........................................................ 30

Table 5. AFV Corridor Coverage Change With Proposed New Stations ................................................... 40

Table 6. Current and Modeled DCFC Port Counts by Florida County ....................................................... 42

1

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

1 Introduction

Hurricanes are increasing in frequency, intensity, and duration and are projected to continue

increasing (Knutson 2022; Kossin 2018). Many counties and cities in Florida are developing

resilience plans to help them minimize damage from hurricanes and accelerate recovery.

4

The

transportation portions of these plans tend to focus on bolstering road infrastructure, stockpiling

diesel for strategic fleets, purchasing high-water vehicles, and placing evacuation shelters in safe

areas. An Achilles’ heel of these plans is their dependence on diesel fuel, which is particularly

vulnerable to hurricane-related disruptions because 90% of petroleum in Florida needs to be

imported via maritime tanker (EIA 2014). These tankers are restricted from accessing Florida

ports before and during hurricanes because the risks of damage to the port facilities and tanker

are too high. Therefore, transportation resilience can be fortified by diversifying the

transportation fuels utilized in a hurricane.

Fuel diversification can add to the transportation resilience of Florida because if the supply of

one fuel gets disrupted during a hurricane, there is a good chance that the supplies of other fuels

have not. As Figure 1 shows, the four main transportation fuels in Florida have very different

means of distribution, and if one means (e.g., marine port) is removed, then other means (e.g.,

pipeline, rail, cable) could then be relied upon to deliver transportation fuel.

Fuel diversification is complicated by a few factors. First, there must be vehicles available that

can use an alternative fuel, be useful for hurricane evacuation or recovery purposes, and also be

useful outside of hurricane operations. These vehicles are discussed in Section 4. Second,

alternative fuels have fewer and less standardized refueling stations, so fleets must be able to

communicate with the stations to know their operating status and compatibility with their

vehicles (Section 5), and new stations need to be added strategically (Sections 6 and 7). Third,

alternative fuel vehicles (AFVs) and conventional vehicles need to be assessed for their

capabilities in driving through standing water, which would likely be required during hurricane

recovery operations (Section 9). The Florida Alternative Transportation Fuel Resilience Plan

aims to address these factors and create a plan for how alternative fuels can best be used to

improve transportation resilience in Florida. It does this through a combination of literature

review and stakeholder engagement for best practices, vehicle technology recommendations, the

creation of three tools (with descriptions and brief guides included), and charting how

stakeholders coordinate to best overcome these hurdles.

4

County and city resilience resources and plans listed in the Florida Resilience Tool, https://widgets-stage.tada-

stage.nrel.gov/tada/fl-resiliency/.

2

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 1. Origin, processing, and distribution of four transportation fuels in Florida.

Source: National Renewable Energy Laboratory

This plan follows a framework used for numerous supplies during natural disasters, including

water, food, and medical supplies. The first step is to add redundancy to the supply. This is done

through fuel diversification, as mentioned previously and discussed throughout the majority of

this report. The second step is to have adequate storage. State and local resilience plans address

this for petroleum used by essential fleets, and this plan addresses this for alternative fuels. The

third step is to ensure access to supplies. This plan does this for alternative fuels through a

geographic information system (GIS) analysis that estimates which fueling locations are likely to

remain accessible and by setting up a communication system so alternative fuel fleets can ensure

that a station can accommodate them during a hurricane. It goes further for electric vehicles

(EVs), where a reservation system and coordinating algorithms is proposed to coordinate the

charging of numerous evacuating EVs. The fourth step is to resupply as quickly as possible; the

plan discusses the rates at which various fuels are likely to be resupplied after a hurricane. The

fifth step is to improve the efficiency with which a given amount of fuel is used, so that a

maximum amount of transportation services might be rendered per a given amount of fuel. The

plan discusses the relative efficiency of evacuation and emergency vehicles and compares

efficiency between fuels.

3

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

2 Background

State departments of transportation have a long history of supporting transportation resilience,

but they are mainly focused on infrastructure rather than fuel supplies.

5

Likewise, local resilience

planning agencies have a history of focusing on transportation infrastructure and storing diesel

reserves for strategic yet conventional vehicles. The U.S. Department of Energy (DOE) assessed

the resilience of various fuels in their seminal 2014 three-part report United States Fuel

Resilience: U.S. Fuels Supply Infrastructure (DOE 2014). These reports set a useful definition of

resilience as “the ability to withstand small to moderate disturbances without loss of service, to

maintain minimum service during severe disturbances, and to quickly return to normal service

after a disturbance.” This is the definition that we use in this plan. The DOE report highlighted

numerous chokepoints in the petroleum supply, transportation, storage, and distribution

infrastructure and the relative resilience of the natural gas and propane infrastructure. In doing

so, they discussed the relative fragility of the electric grid (largely due to lack of storage

capacity), but their focus was on the interactions between the electric grid and the supply of other

fuels rather than electricity as an end-use fuel. For example, electricity is needed to pump diesel

out of underground storage tanks or to compress natural gas. In general, the focus of the 2014

report was upstream of the fuel dispensers and vehicles.

The first initiative to assess and utilize alternative fuels to improve transportation resilience was

the Initiative for Resiliency in Energy through Vehicles (iREV) program. This was a joint project

with DOE’s Clean Cities program and the National Association of State Energy Officials

(NASEO). iREV began by documenting the role of natural gas minibuses helping New Jersey

recover from Hurricane Sandy when diesel was in short supply.

6

Throughout 2015 and 2016,

iREV published a series of case studies of using alternative fuels in emergency response

vehicles.

7

In 2017, a GIS-based iREV-Tracking tool was created to help coordinate alternative

fuel stations and national-level critical infrastructure when planning for emergencies.

8

In addition to iREV case studies, the utilization of alternative fuels during natural disasters has

also been documented. During Japan’s 2011 tsunami, oil refineries were destroyed but electricity

was still available in some areas. Therefore, EVs were an asset in transporting small items like

medicines and transporting doctors and building inspectors so that buildings could be safely

reopened (Belson 2011). This event inspired Nissan’s “Leaf to Home” power exporter. Wildfires

in California proved another value for EVs when the Pacific Gas and Electric Company began

using their Class 5 plug-in hybrid electric vehicle utility trucks with exportable power modules to

provide power to evacuation shelters (Morris 2015). Compressed natural gas (CNG) was

documented fueling buses in the face of diesel shortages during Hurricane Sandy (Atlantic City

9

)

and Hurricane Harvey (Houston

10

). Propane-fueled school buses transported medical personnel

to hospitals during Hurricane Sandy (New York) and evacuated residents of Tampa during

5

As reflected by the agendas of the Transportation Research Board’s Transportation Resilience Innovations Summit

and Exchange annual meetings, www.trb.org.

6

https://www.naseo.org/irev

7

https://www.naseo.org/irev

8

https://irev.ctc.com/Account/Login

9

https://afdc.energy.gov/case/1323

10

https://afdc.energy.gov/case/3078

4

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Hurricane Irma (Thompson 2017). These disasters were the proving grounds for the potential of

alternative fuels during natural disasters.

Of the three alternative fuels utilized by this resilience plan, electric vehicle stock is projected to

grow the most (EIA 2021). Therefore, Florida has published two documents outlining the state‘s

strategy for building out infrastructure. These are the Florida Electric Vehicle Roadmap (Burk et

al. 2020) and EV Infrastructure Master Plan (Florida Department of Transportation [FDOT],

2021). Both of these plans focus on electric vehicle supply equipment (EVSE) needs during

nonemergency times, briefly addressing hurricane evacuation routes. Comparisons between these

EV infrastructure development plans and this plan are included in our GIS analysis in Section 7.

3 Stakeholders and Involvement

The researchers integrated input from a wide variety of stakeholders from various geographic

areas of the state representing organizations that are involved in resilience planning or providing

critical transportation functions during emergencies. Over 240 stakeholders were identified for

this study from which to potentially seek input, including representatives from airports, ports,

local governments, county school districts, conventional and alternative fuel suppliers, transit

agencies, local and regional planning agencies, state agencies, vehicle manufacturers, and

utilities, as well as universities, research institutions, Clean Cities coalitions, advocacy groups,

and other stakeholders.

Fuel Resilience Stakeholders

Responsibility for emergency preparedness, response, and resilience is shared among various

stakeholders, and actions and decisions are made at multiple levels, including government,

private sector, and communities. See Figure 2 for responsible stakeholders, which include

emergency managers, planners, and public agencies responsible for decision-making during

emergency conditions. To plan and implement fuel resilience strategies, there is a need for cross-

collaboration among both public and private entities and to engage both responsible and

impacted stakeholders. Fuel resilience involves stakeholders across jurisdictions and requires

intergovernmental coordination, collaboration, and planning given that vulnerabilities are

embedded across stakeholder groups and government jurisdictions.

5

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 2. Categories of fuel resilience stakeholders

In the state of Florida, emergency response is dictated by the State of Florida Comprehensive

Emergency Management Plan (CEMP), which is administered by the Florida Division of

Emergency Management (FDEM). The plan provides a unified framework for all levels of

government within the state to respond to emergencies that is in accordance with federal

guidelines (FDEM 2020). It contains strategies, objectives, and means of mobilizing resources

and guidance for local governments to coordinate all stages of emergency management,

including emergency preparedness, response, recovery, and mitigation.

Within the State of Florida Comprehensive Emergency Management Plan, the state has

designated the Emergency Support Function 12 (ESF-12) as the function responsible for

ensuring that policies and procedures that are used by the Public Service Commission, and others

engaged in responding to and recovering from power disruptions. Recently, Florida has split the

roles of ESF 12, creating ESF 19 – Fuels to assist with all transportation fuel and propane

response in the state. ESF 19 is housed at FDEM in the Infrastructure Branch, and FDEM is the

primary agency tasked with coordinating with fuel suppliers to ensure adequate supplies of fuel

are available. Response actions are coordinated and communicated with the public and

governmental agencies with support from additional agencies and organizations, such as the

Florida Department of Agriculture and Consumer Services, Florida Department of

Environmental Protection, Florida Department of Health, Florida Department of Transportation,

Florida National Guard, Florida Petroleum Council, American Petroleum Institute, Florida

Trucking Association, Florida Petroleum Marketers Association, and Florida Propane Gas

Association, as well as various industry trade groups and associations. ESF-12 is responsible for

coordinating agencies and organizations with identifying response and recovery needs,

maintaining communications with fuel and energy providers, supporting the State Emergency

Response Team and local emergency operations centers to determine emergency fuel needs,

aiding local government agencies with identifying fuel providers, and maintaining

communications with electric utilities and support agencies responsible for recovery and

response of electric generating capacities and outages (FDEM 2020).

6

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Stakeholder Kickoff Meeting

A stakeholder webinar—held in September 2020 by the Florida Energy Office in partnership

with the Tampa Bay Clean Cities Coalition, University of South Florida, National Renewable

Energy Laboratory (NREL), and Florida Solar Energy Center—informed stakeholders on the

state resilience initiative work plan and solicited stakeholder input. The goal of the workshop

was to gain insight from stakeholders to inform the development of the Alternative

Transportation Fuel Resilience Plan following the implementation model (see Figure 3).

Figure 3. Alternative Transportation Fuel Resilience Plan design and implementation model

Over 80 people attended the stakeholder workshop, representing local governments, state

governments, EVSE suppliers, airports/ports, nonprofit organizations, utilities, and other

organizations. A poll of the attendees revealed that the majority of participating fleets have

emergency fueling plans for hurricanes and other emergency events. The majority of participants

indicated that their fleets play a critical role for transporting people and/or goods before, during,

and after hurricanes, while a few others can also use their vehicles for critical roles if needed.

Participants noted that a lack of fueling infrastructure and costs of AFVs and infrastructure

remain the biggest obstacles for using alternative fuels. Following the stakeholder webinar, the

Florida Solar Energy Center published a “Resilient Florida Buildings” brochure (FSEC 2021).

Fuel Resilience Best Practices for Fleets

In addition to the workshop, researchers also reached out to individual fleets to seek input

regarding best practices in resilience initiatives. Finally, some of the preliminary findings from

the Tampa Resilience study (Kolpakov et al. 2021) also informed the development of this plan.

Lessons learned from previous hurricane events in Florida include:

• Asset staging prior to hurricane landfall is a key step for public fleets to preserve critical

transportation assets by moving them from low-lying areas to higher elevations.

• Navigating flooded streets and performing recovery operations after a hurricane may

require high-water-capable vehicles. The capability of the vehicle to operate in standing

7

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

water conditions is typically determined by the vehicle clearance and the position of air

intake at the highest possible point aboveground.

• Off-road equipment (e.g., loaders, dump trucks, claw trucks) is often required to remove

debris from roadways after a hurricane to restore critical transportation functions.

• Fuel strategy is critical to fleet preparation during an emergency event. Critical public

fleets are encouraged to maintain adequate fuel storage on-site (underground or

aboveground) that can sustain fleet operation for at least a week in case of fuel shortage.

Fueling prioritization strategies can be implemented to determine which vehicles fuel

first during a shortage.

• Accurately predicting fuel burn rate under emergency conditions is challenging but an

essential calculation for estimating fuel supply needs, particularly for public agencies

responsible for fueling generators. It is not uncommon for fleets to consume 2–3 times

more fuel under emergency conditions than during normal operations.

• Fuel diversification is an important resilience strategy, which may include diversifying

fuel supply channels (e.g., receiving fuel from different geographic areas, by different

delivery methods) and diversifying types of fuel used (e.g., use AFVs, flex-fuel vehicles,

and solar-powered EV charging stations).

• It is necessary to plan for redundancies in fuel supply networks to ensure the resilience of

fuel supply.

• Investing in backup electricity generators, including generators powered by alternative

fuels, is a wise strategy for fleets and facilities responsible for providing critical services

before, during, or after natural disasters.

• Sharing fuel resources between critical public fleets is a resilience strategy already

employed through the use of formal and informal agreements between local governments.

This practice can also be expanded to include better collaboration between public and

private fleets.

• Police escorts for fuel tankers may be needed to ensure timely delivery on congested

roads impacted by evacuation efforts.

• Electricity outages can contribute to fuel shortages caused by the disruption of fuel

supply channels resulting from natural disasters. Even if fuel is available, electricity is

often required to dispense it. Therefore, quick restoration of power to fueling sites after a

hurricane is crucial for ensuring that critical services will be provided.

A variety of different vehicles can be used for emergency response and recovery operations.

Transit vehicles (including large and small buses) and school buses are often used for evacuating

people and/or transporting work crews to impacted sites. Despite relatively high clearance,

transit and school buses do have limitations regarding the level of standing water in which they

can safely operate. Usually, the safe water level for a transit or school bus is just a few inches (5–

8 inches of water). Operating in higher water levels can be harmful for the bus undercarriage

components, including the rear differential, air brake system, and many grease-lubricated parts

that can be damaged if submerged in water. See section 9 for more details. Both transit and

school buses can be powered by various alternative fuels, including propane, CNG, and

electricity.

Fleets can employ high-water-capable tactical vehicles (often former military vehicles),

including Humvees and 5-ton trucks with high clearance, to transport equipment and personnel

8

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

during flooding events. Such vehicles are rarely designed to run on alternative fuels but can be

converted to run on propane or CNG.

Finally, there is a variety of off-road equipment that can be used for recovery operation and can

withstand high-water conditions, at least for some time. While most off-road equipment

brands/models are currently powered by conventional petroleum fuels, some of those vehicles

can operate on alternative fuels. For example, available models/brands currently on the market

include battery-electric mobile power stations that can use changeable attachments for

performing various tasks, have high clearance, are rated to operate in 3–4 feet of standing water,

and can be operated by a remote control from a significant distance. The ability to withstand

standing water and remote-control capability provide great potential for using such vehicles for

recovery operations after hurricanes/floods without placing the operator in danger.

The capability of such vehicles to remain operational while being submerged in standing water

for a prolonged period of time is questionable. Furthermore, saltwater presents additional

challenges since it is significantly more corrosive than fresh water. Even completely sealed

vehicle components can get damaged by being submerged in salt water for a prolonged period of

time, so even high-water-capable vehicles may need evaluation and repairs after encountering

salt water.

Site Visits

This plan incorporates best practices and lessons learned from site visits to five alternative fuel

fleets throughout Florida, including both public and private fleets. The site visits that informed

the development of the current plan include the following fleets: WastePro (Samford), Seminole

County Schools (Winter Springs), City Furniture (Tamarac), Broward County Transit

(Plantation), and Jacksonville Transportation Authority (Jacksonville). Reviewed technologies

included CNG, propane, and battery-electric.

Despite differences in visited fleets and types of reviewed alternative fuel technologies, some

similarities in resilience practices were noted. The common takeaways from these site visits

included:

• None of the visited alternative fuel fleets experienced interruptions in fuel supply to their

AFVs (natural gas, propane, or EVs) during recent hurricanes (in the past ~7 years). Even

when diesel and gasoline supply were interrupted due to port closures during past

hurricanes, alternative fuel remained available to the reviewed fleets.

• None of the visited fleets encountered standing water conditions during previous

hurricane events. At the same time, some of the vehicles in the visited properties are

capable of handling high standing water (e.g., refuse trucks).

• Fleets that use CNG and propane have access to mobile fueling systems that can be used

to deliver fuel in case of interruptions during natural disasters. This includes both their

own mobile fueling vehicles and vehicles owned by fuel suppliers.

• Most visited fleets rely on diesel-powered generators to provide emergency power in case

of power outages. Fleets typically maintain adequate supply of diesel for diesel-powered

generators. Few fleets also employ alternative fuel-powered generators to provide backup

power (e.g., CNG).

9

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

• Several visited fleets (both public and private) received and accommodated requests in

the past to share fuel with other essential fleets (mainly government fleets) in the

aftermath of hurricanes. Such requests were typically coordinated through the emergency

operations center (EOC).

• During the times of fuel shortage, such as during or after a hurricane, it is common

practice for fleets to ration fuel depending on the routes and ranges required for vehicles

to perform essential tasks.

• Fueling all vehicles (including AFVs) prior to a hurricane is a common strategy used by

fleets to prepare for the upcoming impact.

• Several visited fleets experienced severe accidents involving AFVs (including rollover

accidents and vehicle fire), none of which caused fuel tank rapture, demonstrating the

safety of AFVs.

Summaries of all the site visits are provided in Appendix B.

4 Supply Chain of Natural Gas, Propane, and

Electricity in Florida

The diversity of supply chains for alternative fuels is a large part of why they add to the

resilience of transportation systems in Florida. This section assesses the upstream supply chains

of alternative fuels and lists vendors of alternative fuels to enable fleets and refueling stations to

access the fuels.

Upstream Sources of Alternative Fuels

This subsection tracks the source and upstream pathways of alternative fuels in Florida in order

to assessing their resilience. Florida receives its natural gas supplies from four interstate

pipelines, as shown in Figure 4 and described below:

10

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 4. Florida’s Four Interstate Natural Gas Pipelines

Source: EIA

• The Florida Gas Transmission line runs from Texas through the Florida Panhandle to

Miami;

• The Gulfstream Gas System is an underwater pipeline running under the Gulf of Mexico

from Mississippi and Alabama to Central Florida;

• The Sabal Trail pipeline runs from Alabama to Orange County; and

• The Cypress Pipeline supplies liquified natural gas to the Jacksonville area from Elba

Island, Georgia.

Propane stocks are abundant nationally, with nearly 78 million barrels of supply available as of

September 9, 2022 (EIA 2022). As a byproduct of domestic natural gas processing and

petroleum refining, they come from similar locations as natural gas and petroleum. However,

they are generally delivered via rail to Florida instead of pipeline. Florida belongs to the

Petroleum Administration for Defense Districts (PADD) Subdistrict 1C, which includes the

Lower Atlantic States. The PADD is the Federal classification used for organizing the allocation

of fuels derived from petroleum products.

Florida is one of the largest generators of electricity in the nation, second only to Texas.

Florida’s primary fuel source (fueling ¾ of all electricity) is natural gas, but 2/3 of these power

plants can use fuel oil as a backup fuel source. The remaining ¼ of Florida’s electricity is fueled

by a diverse set of two nuclear power plants, coal-fired power plants, solar and biofuels, listed

from largest to smallest contributors (EIA 2021).

11

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Alternative Fuel Vendors

All Clean Cities coalitions in the state of Florida, including Tampa Bay Clean Cities, Southeast

Florida Clean Cities, Central Florida Clean Cities, and North Florida Clean Fuels, collaborated to

compile a list of alternative fuel vendors in Florida. Identified organizations include vendors of

various alternative fuels (CNG, propane, ethanol, biodiesel), utilities, infrastructure providers,

stationary and mobile generator suppliers, and other types of organizations that may be useful for

providing redundancy in service during emergency events.

Table 1 provides an inventory of 62 alternative fuel vendors. These include 28 electricity, 15

natural gas, 11 propane, 10 biofuel, and 3 hydrogen vendors (some vendors offer more than one

fuel). While most listed vendors are headquartered in Florida, some are not. Instead, they have a

presence in Florida or provide their products/services in the state.

Table 1. Alternative Fuel Vendors in the State of Florida

Organization Name Fuel/Infrastructure Type Location

All in One Propane Propane Leesburg, FL

American Homegrown Fuel

Corporation

Hydrogen, biofuels

American Natural Gas CNG

Amerigas Pr

opane Jacksonville, FL

AmeriGas Propane Propane Tampa, FL

ampCNG Nat

ural gas Chicago, IL

Be-Ev.Com EVSE infrastructure

BioDiesel Las Americas (BDLA) Bi

odiesel production Miami, FL

Blink EVSE infrastructure Miami, FL

Blossman Gas Pr

opane Jacksonville, FL

Brickell Energy EVSE infrastructure Miami, FL

ChargePoint, Inc. EVSE

infrastructure

City of Orlando Electric Orlando, FL

Clean Energy CNG Station Orlando

Ai

rport

CNG Orlando, FL

Clean Energy Fuels Natural gas Dallas, TX

Clearwater Gas System Nat

ural gas Clearwater, FL

Commercial Aviation AF Initiative

(CAAFI)

Aviation fuel

Dannar

Of

froad EV/mobile power

station

Muncie, IN

Duke Energy Electric Charlotte, NC

Efacec USA EVSE

infrastructure

Endera EVSE infrastructure

12

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Organization Name Fuel/Infrastructure Type Location

Ferrell Gas - Pinellas Park Service

Center

Propane Pinellas Park, FL

Fleetwing Corporation Biodiesel, ethanol Lakeland, FL

Florida City Gas CNG Dor

al, FL

Florida Power & Light Company Electric Juno Beach, FL

Florida Public Utilities Nat

ural gas, propane, electric West Palm Beach, FL

Florida Public Utilities Electric, CNG Fernandina Beach, FL

GAIN Clean Fuel CNG Kis

simmee, FL

Gate Petroleum Ethanol, CNG, electric Jacksonville, FL

Glover Oil Bi

odiesel 20 Melbourne, FL

GoSpace EVSE infrastructure

Heritage Propane Pr

opane Tampa, FL

Jacksonville Transportation Authority CNG Jacksonville, FL

JEA Ele

ctric Jacksonville, FL

NASA/KSC Electric/B20/E85/hydrogen Kennedy Space Center, FL

Nopetro Nat

ural gas Coral Gables, FL

NoPetro CNG (LYNX) CNG Orlando, FL

Northside Propane Inc. Pr

opane Lutz, FL

NovaCharge EVSE infrastructure Oldsmar, FL

OBE Power Networks EVSE

infrastructure Miami, FL

Orlando Utilities Commission Electric Orlando, FL

Palatka Gas CNG

Pioneer Critical Power Generators/mobile Miami, FL

Pioneer Power Mobility Mobi

le EVSE/propane Champlin, MN

Pivotal LNG Liquefied natural gas (LNG)

Port Canaveral Ele

ctric/LNG Cape Canaveral, FL

Protec Fuel Management LLC Ethanol Boca Raton, FL

Rack Electric EVSE

infrastructure Boca Raton, FL

Ross Plumbing CNG Leesburg, Fl

St. Johns County CNG

Suburban Propane Propane Tampa, FL

Superior Energy Systems Pr

opane infrastructure Columbia Station, OH

Targray Biodiesel, ethanol Kirkland, Quebec

TECO Energy Ele

ctric Tampa, FL

TECO Peoples Gas CNG Tampa, FL

Tesla Ele

ctric Palo Alto, CA

13

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Organization Name Fuel/Infrastructure Type Location

Thorntons Inc. Ethanol Louisville, KY

TruStar Energy Natural gas Rancho Cucamonga, CA

University of Central Florida Electric/propane Orlando, FL

VISTRA Ele

ctric, natural gas Tampa, FL

Waste Pro CNG Bunnell, FL

Withlacoochee Electric Cooperative Ele

ctric Dade City, FL

Appendix C provides a more detailed list of alternative fuel vendors that includes company

names and contact information.

5 Communications Practices and Protocols

Hurricanes limit communication by knocking out cellphone towers and other communications

infrastructure. At the same time, they increase the need for fleet and vehicle communications to

facilitate evacuation and recovery operations. This section assesses the current fleet

communication strategies during hurricanes, with a focus on areas in need of improvement. It

then introduces two solutions to some of the communications problems that currently limit the

usefulness of alternative fuels before, during, and after a hurricane. The first solution is a website

and GIS mapping tool that NREL created to facilitate emergency planning and ensure that fleets

have the right contacts and information beforehand to minimize the last-minute communication

needs during a hurricane. This website also ensures that fleet managers know the likelihood of

their home station being shut down and the best areas to refuel if their station is no longer

operable. The second solution is a series of algorithms developed by the University of South

Florida’s Center for Urban Transportation Research (CUTR) that maximizes the evacuation

potential of EVSE in a given area by directing vehicles to available EVSE and charging them the

appropriate amount to make it to safety.

Current Status and Shortcomings of Communications During

Hurricanes

At a September 2020 webinar hosted by the FDACS Office of Energy and project partners

Tampa Bay Clean Cities Coalition, University of South Florida, NREL, and the Florida Solar

Energy Center, stakeholders from Florida municipalities were asked about how fleets

communicate with dispatch during hurricanes and other disaster situations.

In preparation for hurricanes, EOC communications are tested, and radios are staged at

accessible locations, including in high-clearance vehicles. Local governments are primarily

responsible for developing and managing local communications plans in coordination with the

state. EOCs have a designated list of where fleet vehicles can refuel, which does not currently

include alternative fuels.

Participants reported that their fleets communicate via radio, cellphones, and landlines during

actual disaster situations. Cell phone outages have not been a problem in recent events, and

communication that occurs from EOCs and backup EOCs also includes email correspondence,

which has remained largely intact in recent events.

14

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

During or after a hurricane, public safety is the priority, and first responders have exclusive

access to public emergency radio channels. According to interviews with the Florida Division of

Emergency Management, many school districts have their own designated channels and

dispatchers, and utilities often have their own systems. School bus channels are not prioritized

during emergencies, despite the fact that these high-clearance, high-capacity, often propane-

fueled vehicles could serve as a means of getting people without their own vehicles to

emergency shelters (which are often located in elementary schools) prior to hurricane impacts.

Utilities and telecommunications services have their own radio channels and are given second

priority by the Division of Emergency Management after first responders. This covers many of

the utility-owned, CNG-fueled vehicles used to repair power lines.

Along with the commercial-grade radio, amateur radio network (ham), satellite phones, business

band radio, and mobile cellular towers are sometimes used by fleets to communicate. Private

companies are responsible for their own communication redundancies, and some choose to pay a

retainer to third parties for access to equipment (e.g., mobile cellular towers) during hurricanes

or other emergency events.

Most of the emergency planning and coordination is handled at the county level, although some

cities have dedicated emergency coordinators. When overwhelmed, these local governments

request “missions” from the state, who can subsequently request a mission to the Federal

Emergency Management Agency (FEMA). When possible, FDEM sets up camps and mobile

fueling depots for first responders. These fueling depots typically provide diesel and unleaded

fuel but no alternative fuels.

EVSE Communications Systems

To assess the communications capabilities and needs of EV charging infrastructure, NREL

interviewed a variety of researchers and managers at ChargePoint. ChargePoint was chosen

because it is the largest charging network provider in Florida. All of ChargePoint’s public EVSE

are networked (i.e., connected to the internet), and therefore allow for communication between

the EV charging infrastructure and the ChargePoint mobile app. This allows drivers to see in real

time the available ChargePoint networked EV chargers in their area. In addition, the app shows

the availability of “roaming partners” outside the ChargePoint network that ChargePoint

members could use. If connectivity were to go down, ChargePoint members could still charge on

ChargePoint equipment, but nonmembers would no longer be able to.

Individual EVSE are built to withstand 18 inches of standing water (per the National Electrical

Code), but if this threshold is surpassed and the hardware is damaged, it cannot be brought back

online until it is physically inspected by a technician. ChargePoint also has mobile DC fast

chargers (DCFCs) on skids/trucks (with 4 feet of clearance) that can be brought to appropriate

locations and connected quickly to the grid, which could be critical to deploy along major

evacuation routes before a hurricane. It should be noted that there are skids with DCFCs and

propane-powered generators available on the market (Pioneer Power Solutions, Inc. 2022). Some

features of ChargePoint’s communication system that could help coordinate charging during an

emergency include reservations and waitlists, but they fear that using these features in an

emergency situation could lead to the chargers going unused for valuable minutes. Another

feature that could help encourage people not to idle at an EV charger is the capability for hosts to

raise their prices quickly in response to demand. However, the raises need to be limited so as to

15

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

not be considered “price gouging,” which is illegal. The limitations to the network’s

communications systems and remote features are addressed in Solution 2.

Solution 1: New Website to Facilitate Planning

To facilitate the use of alternative fuels before and during a hurricane, NREL developed a

Florida Resilience Tool website to help facilitate planning and communications. Available at

https://widgets-stage.tada-stage.nrel.gov/tada/fl-resiliency/, this website uses state-of-the-art

technologies to provide useful maps, information, connections, and other resources. Here, users

are presented with state-level information, including links to Clean Cities coalitions and the

FDEM’s website, Facebook, and Twitter pages. It is intended for use by resilience planners, fleet

managers, individuals planning their evacuation, and alternative fuel station operators.

Dropdown menus provided at the top of the page allow users to adjust information displayed by

choosing from various map layers and counties. When changed, the website automatically

refreshes to present the information selected.

Figure 5. Florida Resilience Tool homepage

To obtain local information, users can select a county from a drop-down menu at the top right-

hand side of the page or click the appropriate county on the map.

16

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 6. County-specific resources appear when a county is selected.

Where available, the following information is presented:

• Emergency management department

name.

• Link to emergency management

website.

• Link to emergency management

Twitter.

• Link to emergency management

Facebook.

• Emergency management department

address.

• Link to county hurricane guide.

• Link to county evacuation zone

information.

• Link to county evacuation route

information.

• Shelter location information.

• Special needs shelter location

information.

• County special needs registry.

• Link to county notification system.

• Link to county emergency

management app.

• Community Emergency Response

Team (CERT) information.

• Link to county YouTube station.

• County 311 app.

• Links to partner organizations.

• County population.

• Clean City coalition information.

A second drop-down menu allows users to select a map layer with the following options:

• Population (default).

• Percent of population with no

vehicles.

• Median income (to ensure equitable

preparation).

• Electric station locations.

• CNG station locations.

• Propane (liquefied petroleum gas

[LPG]) station locations.

• Biodiesel (B20 and above) station

locations.

• Ethanol (E85) station locations.

• LNG station locations.

17

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 7. Florida Resilience Tool map layers

Users may select from one or both drop-down menus to view detailed information. Clicking on a

county on the map also selects that county and updates the information displayed.

Figure 8. Accessing fuel-specific station location by county

When both a fuel type and county are selected, users can see fuel station details in the info box

that help fleet managers determine if the station would be compatible with their vehicles and the

likelihood that the station could remain in operation during a power outage. Clicking “SEE

MORE” displays more detailed station location information such as fill type, fill pressure, fill

rate, vehicle accessibility, electric generator existence, and fuel, as well as change to station

capacity with a generator, if applicable.

18

This report is available at no cost from the National Renewable Energy Laboratory at www.nrel.gov/publications.

Figure 9. Station-specific information provides detail

A link to download emergency contact information for fueling stations is provided, but this

information is considered private and therefore only accessible by Clean Cities coordinators.

Please contact your local coordinator via the Clean Cities link in order for them to download this

information from the coordinator toolbox (via the state-level link showed in Figure 9).

From any view of the Florida Resilience Tool, users can click the small map image to see

detailed emergency GIS information. This information is elaborated in the GIS analysis in

Section 7.

Figure 10. Detailed emergency GIS information accessible from any view in the Florida Resilience

Tool

Solution 2: EVSE Communications Algorithms and Web Tool