84

SUBCHAPTER C—HAZARDOUS MATERIALS REGULATIONS

PART 171—GENERAL INFORMA-

TION, REGULATIONS, AND DEFI-

NITIONS

Sec.

Subpart A—Applicability, General Require-

ments, and North American Shipments

171.1 Applicability of Hazardous Materials

Regulations (HMR) to persons and func-

tions.

171.2 General requirements.

171.3 Hazardous waste.

171.4 Marine pollutants.

171.6 Control numbers under the Paperwork

Reduction Act.

171.7 Reference material.

171.8 Definitions and abbreviations.

171.9 Rules of construction.

171.10 Units of measure.

171.11 [Reserved]

171.12 North American Shipments.

171.12a [Reserved]

171.14 [Reserved]

Subpart B—Incident Reporting, Notification,

BOE Approvals and Authorization

171.15 Immediate notice of certain haz-

ardous materials incidents.

171.16 Detailed hazardous materials inci-

dent reports.

171.17–171.18 [Reserved]

171.19 Approvals or authorizations issued by

the Bureau of Explosives.

171.20 Submission of Examination Reports.

171.21 Assistance in investigations and spe-

cial studies.

Subpart C—Authorization and Require-

ments for the Use of International

Transport Standards and Regulations

171.22 Authorization and conditions for the

use of international standards and regu-

lations.

171.23 Requirements for specific materials

and packagings transported under the

ICAO Technical Instructions, IMDG

Code, Transport Canada TDG Regula-

tions, or the IAEA Regulations.

171.24 Additional requirements for the use

of the ICAO Technical Instructions.

171.25 Additional requirements for the use

of the IMDG Code.

171.26 Additional requirements for the use

of the IAEA Regulations.

A

UTHORITY

: 49 U.S.C. 5101–5128, 44701; 49

CFR 1.45 and 1.53; Pub. L. 101–410 section 4 (28

U.S.C. 2461 note); Pub. L. 104–134 section

31001.

E

DITORIAL

N

OTE

: Nomenclature changes to

part 171 appear at 70 FR 56090, Sept. 23, 2005.

Subpart A—Applicability, General

Requirements, and North

American Shipments

§ 171.1 Applicability of Hazardous Ma-

terials Regulations (HMR) to per-

sons and functions.

Federal hazardous materials trans-

portation law (49 U.S.C. 5101 et seq.) di-

rects the Secretary of Transportation

to establish regulations for the safe

and secure transportation of hazardous

materials in commerce, as the Sec-

retary considers appropriate. The Sec-

retary is authorized to apply these reg-

ulations to persons who transport haz-

ardous materials in commerce. In addi-

tion, the law authorizes the Secretary

to apply these regulations to persons

who cause hazardous materials to be

transported in commerce. The law also

authorizes the Secretary to apply these

regulations to persons who manufac-

ture or maintain a packaging or a com-

ponent of a packaging that is rep-

resented, marked, certified, or sold as

qualified for use in the transportation

of a hazardous material in commerce.

Federal hazardous material transpor-

tation law also applies to anyone who

indicates by marking or other means

that a hazardous material being trans-

ported in commerce is present in a

package or transport conveyance when

it is not, and to anyone who tampers

with a package or transport convey-

ance used to transport hazardous mate-

rials in commerce or a required mark-

ing, label, placard, or shipping descrip-

tion. Regulations prescribed in accord-

ance with Federal hazardous materials

transportation law shall govern safety

aspects, including security, of the

transportation of hazardous materials

that the Secretary considers appro-

priate. In 49 CFR 1.53, the Secretary

delegated authority to issue regula-

tions for the safe and secure transpor-

tation of hazardous materials in com-

merce to the Pipeline and Hazardous

Materials Safety Administrator. The

Administrator issues the Hazardous

Materials Regulations (HMR; 49 CFR

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00094 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

85

Pipeline and Hazardous Materials Safety Admin., DOT § 171.1

Parts 171 through 180) under that dele-

gated authority. This section addresses

the applicability of the HMR to pack-

agings represented as qualified for use

in the transportation of hazardous ma-

terials in commerce and to pre-trans-

portation and transportation func-

tions.

(a) Packagings. Requirements in the

HMR apply to each person who manu-

factures, fabricates, marks, maintains,

reconditions, repairs, or tests a pack-

aging or a component of a packaging

that is represented, marked, certified,

or sold as qualified for use in the trans-

portation of a hazardous material in

commerce, including each person under

contract with any department, agency,

or instrumentality of the executive,

legislative, or judicial branch of the

Federal government who manufac-

tures, fabricates, marks, maintains, re-

conditions, repairs, or tests a pack-

aging or a component of a packaging

that is represented, marked, certified,

or sold as qualified for use in the trans-

portation of a hazardous material in

commerce.

(b) Pre-transportation functions. Re-

quirements in the HMR apply to each

person who offers a hazardous material

for transportation in commerce, causes

a hazardous material to be transported

in commerce, or transports a hazardous

material in commerce and who per-

forms or is responsible for performing a

pre-transportation function, including

each person performing pre-transpor-

tation functions under contract with

any department, agency, or instrumen-

tality of the executive, legislative, or

judicial branch of the Federal govern-

ment. Pre-transportation functions in-

clude, but are not limited to, the fol-

lowing:

(1) Determining the hazard class of a

hazardous material.

(2) Selecting a hazardous materials

packaging.

(3) Filling a hazardous materials

packaging, including a bulk packaging.

(4) Securing a closure on a filled or

partially filled hazardous materials

package or container or on a package

or container containing a residue of a

hazardous material.

(5) Marking a package to indicate

that it contains a hazardous material.

(6) Labeling a package to indicate

that it contains a hazardous material.

(7) Preparing a shipping paper.

(8) Providing and maintaining emer-

gency response information.

(9) Reviewing a shipping paper to

verify compliance with the HMR or

international equivalents.

(10) For each person importing a haz-

ardous material into the United States,

providing the shipper with timely and

complete information as to the HMR

requirements that will apply to the

transportation of the material within

the United States.

(11) Certifying that a hazardous ma-

terial is in proper condition for trans-

portation in conformance with the re-

quirements of the HMR.

(12) Loading, blocking, and bracing a

hazardous materials package in a

freight container or transport vehicle.

(13) Segregating a hazardous mate-

rials package in a freight container or

transport vehicle from incompatible

cargo.

(14) Selecting, providing, or affixing

placards for a freight container or

transport vehicle to indicate that it

contains a hazardous material.

(c) Transportation functions. Require-

ments in the HMR apply to transpor-

tation of a hazardous material in com-

merce and to each person who trans-

ports a hazardous material in com-

merce, including each person under

contract with any department, agency,

or instrumentality of the executive,

legislative, or judicial branch of the

Federal government who transports a

hazardous material in commerce.

Transportation of a hazardous material

in commerce begins when a carrier

takes physical possession of the haz-

ardous material for the purpose of

transporting it and continues until the

package containing the hazardous ma-

terial is delivered to the destination

indicated on a shipping document,

package marking, or other medium, or,

in the case of a rail car, until the car

is delivered to a private track or sid-

ing. For a private motor carrier, trans-

portation of a hazardous material in

commerce begins when a motor vehicle

driver takes possession of a hazardous

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00095 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

86

49 CFR Ch. I (10–1–12 Edition) § 171.1

material for the purpose of trans-

porting it and continues until the driv-

er relinquishes possession of the pack-

age containing the hazardous material

at its destination and is no longer re-

sponsible for performing functions sub-

ject to the HMR with respect to that

particular package. Transportation of

a hazardous material in commerce in-

cludes the following:

(1) Movement. Movement of a haz-

ardous material by rail car, aircraft,

motor vehicle, or vessel (except as del-

egated by Department of Homeland Se-

curity Delegation No. 0170 at 2(103)).

(2) Loading incidental to movement of a

hazardous material. Loading of pack-

aged or containerized hazardous mate-

rial onto a transport vehicle, aircraft,

or vessel for the purpose of trans-

porting it, including blocking and brac-

ing a hazardous materials package in a

freight container or transport vehicle,

and segregating a hazardous materials

package in a freight container or trans-

port vehicle from incompatible cargo,

when performed by carrier personnel or

in the presence of carrier personnel.

For a bulk packaging, loading inci-

dental to movement is filling the pack-

aging with a hazardous material for

the purpose of transporting it when

performed by carrier personnel or in

the presence of carrier personnel (ex-

cept as delegated by Department of

Homeland Security Delegation No. 0170

at 2(103)), including transloading.

(3) Unloading incidental to movement of

a hazardous material. Removing a pack-

age or containerized hazardous mate-

rial from a transport vehicle, aircraft,

or vessel; or for a bulk packaging,

emptying a hazardous material from

the bulk packaging after the hazardous

material has been delivered to the con-

signee when performed by carrier per-

sonnel or in the presence of carrier per-

sonnel or, in the case of a private

motor carrier, while the driver of the

motor vehicle from which the haz-

ardous material is being unloaded im-

mediately after movement is com-

pleted is present during the unloading

operation. (Emptying a hazardous ma-

terial from a bulk packaging while the

packaging is on board a vessel is sub-

ject to separate regulations as dele-

gated by Department of Homeland Se-

curity Delegation No. 0170 at 2(103).)

Unloading incidental to movement in-

cludes transloading.

(4) Storage incidental to movement of a

hazardous material. Storage of a trans-

port vehicle, freight container, or

package containing a hazardous mate-

rial by any person between the time

that a carrier takes physical possession

of the hazardous material for the pur-

pose of transporting it until the pack-

age containing the hazardous material

has been delivered to the destination

indicated on a shipping document,

package marking, or other medium, or,

in the case of a private motor carrier,

between the time that a motor vehicle

driver takes physical possession of the

hazardous material for the purpose of

transporting it until the driver relin-

quishes possession of the package at its

destination and is no longer respon-

sible for performing functions subject

to the HMR with respect to that par-

ticular package.

(i) Storage incidental to movement

includes—

(A) Storage at the destination shown

on a shipping document, including

storage at a transloading facility, pro-

vided the original shipping documenta-

tion identifies the shipment as a

through-shipment and identifies the

final destination or destinations of the

hazardous material; and

(B) A rail car containing a hazardous

material that is stored on track that

does not meet the definition of ‘‘pri-

vate track or siding’’ in § 171.8, even if

the car has been delivered to the des-

tination shown on the shipping docu-

ment.

(ii) Storage incidental to movement

does not include storage of a hazardous

material at its final destination as

shown on a shipping document.

(d) Functions not subject to the require-

ments of the HMR. The following are ex-

amples of activities to which the HMR

do not apply:

(1) Storage of a freight container,

transport vehicle, or package con-

taining a hazardous material at an of-

feror facility prior to a carrier taking

possession of the hazardous material

for movement in transportation in

commerce or, for a private motor car-

rier, prior to a motor vehicle driver

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00096 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

87

Pipeline and Hazardous Materials Safety Admin., DOT § 171.1

taking physical possession of the haz-

ardous material for movement in

transportation in commerce.

(2) Unloading of a hazardous material

from a transport vehicle or a bulk

packaging performed by a person em-

ployed by or working under contract to

the consignee following delivery of the

hazardous material by the carrier to

its destination and departure from the

consignee’s premises of the carrier’s

personnel or, in the case of a private

carrier, departure of the driver from

the unloading area.

(3) Storage of a freight container,

transport vehicle, or package con-

taining a hazardous material after its

delivery by a carrier to the destination

indicated on a shipping document,

package marking, or other medium, or,

in the case of a rail car, storage of a

rail car on private track.

(4) Rail and motor vehicle move-

ments of a hazardous material exclu-

sively within a contiguous facility

boundary where public access is re-

stricted, except to the extent that the

movement is on or crosses a public

road or is on track that is part of the

general railroad system of transpor-

tation, unless access to the public road

is restricted by signals, lights, gates,

or similar controls.

(5) Transportation of a hazardous ma-

terial in a motor vehicle, aircraft, or

vessel operated by a Federal, state, or

local government employee solely for

noncommercial Federal, state, or local

government purposes.

(6) Transportation of a hazardous ma-

terial by an individual for non-com-

mercial purposes in a private motor ve-

hicle, including a leased or rented

motor vehicle.

(7) Any matter subject to the postal

laws and regulations of the United

States.

(e) Requirements of other Federal agen-

cies. Each facility at which pre-trans-

portation or transportation functions

are performed in accordance with the

HMR may be subject to applicable

standards and regulations of other Fed-

eral agencies.

(f) Requirements of state and local gov-

ernment agencies. (1) Under 49 U.S.C.

5125, a requirement of a state, political

subdivision of a state, or an Indian

tribe is preempted, unless otherwise

authorized by another Federal statute

or DOT issues a waiver of preemption,

if—

(i) Complying with both the non-Fed-

eral requirement and Federal haz-

ardous materials transportation law,

the regulations issued under Federal

hazardous material transportation law

or a hazardous material transportation

security regulation or directive issued

by the Secretary of Homeland Security

is not possible;

(ii) The non-Federal requirement, as

applied or enforced, is an obstacle to

accomplishing and carrying out Fed-

eral hazardous materials transpor-

tation law, the regulations issued

under Federal hazardous material

transportation law, or a hazardous ma-

terial transportation security regula-

tion or directive issued by the Sec-

retary of Homeland Security;

(iii) The non-Federal requirement is

not substantively the same as a provi-

sion of Federal hazardous materials

transportation law, the regulations

issued under Federal hazardous mate-

rial transportation law, or a hazardous

material transportation security regu-

lation or directive issued by the Sec-

retary of Homeland Security with re-

spect to—

(A) The designation, description, and

classification of hazardous material;

(B) The packing, repacking, handling,

labeling, marking, and placarding of

hazardous material;

(C) The preparation, execution, and

use of shipping documents related to

hazardous material and requirements

related to the number, contents, and

placement of those documents;

(D) The written notification, record-

ing, and reporting of the unintentional

release of hazardous material; or

(E) The design, manufacturing, fabri-

cating, marking, maintenance, recon-

ditioning, repairing, or testing of a

package or container represented,

marked, certified, or sold as qualified

for use in transporting hazardous ma-

terial.

(iv) A non-Federal designation, limi-

tation or requirement on highway

routes over which hazardous material

may or may not be transported does

not comply with the regulations in

subparts C and D of part 397 of this

title; or

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00097 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

88

49 CFR Ch. I (10–1–12 Edition) § 171.2

(v) A fee related to the transpor-

tation of a hazardous material is not

fair or is used for a purpose that is not

related to transporting hazardous ma-

terial, including enforcement and plan-

ning, developing, and maintaining a ca-

pability for emergency response.

(2) Subject to the limitations in para-

graph (f)(1) of this section, each facil-

ity at which functions regulated under

the HMR are performed may be subject

to applicable laws and regulations of

state and local governments and Indian

tribes.

(3) The procedures for DOT to make

administrative determinations of pre-

emption are set forth in subpart E of

part 397 of this title with respect to

non-Federal requirements on highway

routing (paragraph (f)(1)(iv) of this sec-

tion) and in subpart C of part 107 of

this chapter with respect to all other

non-Federal requirements.

(g) Penalties for noncompliance. Each

person who knowingly violates a re-

quirement of the Federal hazardous

material transportation law, an order

issued under Federal hazardous mate-

rial transportation law, subchapter A

of this chapter, or a special permit or

approval issued under subchapter A or

C of this chapter is liable for a civil

penalty of not more than $55,000 and

not less than $250 for each violation,

except the maximum civil penalty is

$110,000 if the violation results in

death, serious illness or severe injury

to any person or substantial destruc-

tion of property, and a minimum $495

civil penalty applies to a violation re-

lating to training. When a violation is

a continuing one and involves trans-

porting of hazardous material or caus-

ing them to be transported, each day of

the violation is a separate offense.

Each person who knowingly violates

§ 171.2(l) or willfully or recklessly vio-

lates a provision of the Federal haz-

ardous material transportation law, an

order issued under Federal hazardous

material transportation law, sub-

chapter A of this chapter, or a special

permit or approval issued under sub-

chapter A or C of this chapter, shall be

fined under title 18, United States

Code, or imprisoned for not more than

5 years, or both, except the maximum

amount of imprisonment shall be 10

years in any case in which a violation

involves the release of a hazardous ma-

terial which results in death or bodily

injury to any person.

[68 FR 61937, Oct. 30, 2003; 70 FR 20031, Apr.

15, 2005, as amended at 70 FR 73162, Dec. 9,

2005; 71 FR 8488, Feb. 17, 2006; 71 FR 44931,

Aug. 8, 2006; 74 FR 68702, Dec. 29, 2009; 75 FR

53596, Sept. 1, 2010]

§ 171.2 General requirements.

(a) Each person who performs a func-

tion covered by this subchapter must

perform that function in accordance

with this subchapter.

(b) Each person who offers a haz-

ardous material for transportation in

commerce must comply with all appli-

cable requirements of this subchapter,

or an exemption or special permit, ap-

proval, or registration issued under

this subchapter or under subchapter A

of this chapter. There may be more

than one offeror of a shipment of haz-

ardous materials. Each offeror is re-

sponsible for complying with the re-

quirements of this subchapter, or an

exemption or special permit, approval,

or registration issued under this sub-

chapter or subchapter A of this chap-

ter, with respect to any pre-transpor-

tation function that it performs or is

required to perform; however, each of-

feror is responsible only for the specific

pre-transportation functions that it

performs or is required to perform, and

each offeror may rely on information

provided by another offeror, unless

that offeror knows or, a reasonable per-

son, acting in the circumstances and

exercising reasonable care, would have

knowledge that the information pro-

vided by the other offeror is incorrect.

(c) Each person who performs a func-

tion covered by or having an effect on

a specification or activity prescribed in

part 178, 179, or 180 of this subchapter,

an approval issued under this sub-

chapter, or an exemption or special

permit issued under subchapter A of

this chapter, must perform the func-

tion in accordance with that specifica-

tion, approval, an exemption or special

permit, as appropriate.

(d) No person may offer or accept a

hazardous material for transportation

in commerce or transport a hazardous

material in commerce unless that per-

son is registered in conformance with

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00098 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

89

Pipeline and Hazardous Materials Safety Admin., DOT § 171.2

subpart G of part 107 of this chapter, if

applicable.

(e) No person may offer or accept a

hazardous material for transportation

in commerce unless the hazardous ma-

terial is properly classed, described,

packaged, marked, labeled, and in con-

dition for shipment as required or au-

thorized by applicable requirements of

this subchapter or an exemption or spe-

cial permit, approval, or registration

issued under this subchapter or sub-

chapter A of this chapter.

(f) No person may transport a haz-

ardous material in commerce unless

the hazardous material is transported

in accordance with applicable require-

ments of this subchapter, or an exemp-

tion or special permit, approval, or reg-

istration issued under this subchapter

or subchapter A of this chapter. Each

carrier who transports a hazardous ma-

terial in commerce may rely on infor-

mation provided by the offeror of the

hazardous material or a prior carrier,

unless the carrier knows or, a reason-

able person, acting in the cir-

cumstances and exercising reasonable

care, would have knowledge that the

information provided by the offeror or

prior carrier is incorrect.

(g) No person may represent, mark,

certify, sell, or offer a packaging or

container as meeting the requirements

of this subchapter governing its use in

the transportation of a hazardous ma-

terial in commerce unless the pack-

aging or container is manufactured,

fabricated, marked, maintained, recon-

ditioned, repaired, and retested in ac-

cordance with the applicable require-

ments of this subchapter. No person

may represent, mark, certify, sell, or

offer a packaging or container as meet-

ing the requirements of an exemption,

a special permit, approval, or registra-

tion issued under this subchapter or

subchapter A of this chapter unless the

packaging or container is manufac-

tured, fabricated, marked, maintained,

reconditioned, repaired, and retested in

accordance with the applicable require-

ments of the exemption, special per-

mit, approval, or registration issued

under this subchapter or subchapter A

of this chapter. The requirements of

this paragraph apply whether or not

the packaging or container is used or

to be used for the transportation of a

hazardous material.

(h) The representations, markings,

and certifications subject to the prohi-

bitions of paragraph (g) of this section

include:

(1) Specification identifications that

include the letters ‘‘ICC’’, ‘‘DOT’’,

‘‘CTC’’, ‘‘MC’’, or ‘‘UN’’;

(2) Exemption, special permit, ap-

proval, and registration numbers that

include the letters ‘‘DOT’’, ‘‘EX’’, ‘‘M’’,

or ‘‘R’’; and

(3) Test dates associated with speci-

fication, registration, approval, retest,

exemption, or special permit markings

indicating compliance with a test or

retest requirement of the HMR, or an

exemption, special permit, approval, or

registration issued under the HMR or

under subchapter A of this chapter.

(i) No person may certify that a haz-

ardous material is offered for transpor-

tation in commerce in accordance with

the requirements of this subchapter

unless the hazardous material is prop-

erly classed, described, packaged,

marked, labeled, and in condition for

shipment as required or authorized by

applicable requirements of this sub-

chapter or an exemption or special per-

mit, approval, or registration issued

under this subchapter or subchapter A

of this chapter. Each person who offers

a package containing a hazardous ma-

terial for transportation in commerce

in accordance with the requirements of

this subchapter or an exemption or spe-

cial permit, approval, or registration

issued under this subchapter or sub-

chapter A of this chapter, must assure

that the package remains in condition

for shipment until it is in the posses-

sion of the carrier.

(j) No person may, by marking or

otherwise, represent that a container

or package for transportation of a haz-

ardous material is safe, certified, or in

compliance with the requirements of

this chapter unless it meets the re-

quirements of all applicable regula-

tions issued under Federal hazardous

material transportation law.

(k) No person may, by marking or

otherwise, represent that a hazardous

material is present in a package, con-

tainer, motor vehicle, rail car, aircraft,

or vessel if the hazardous material is

not present.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00099 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

90

49 CFR Ch. I (10–1–12 Edition) § 171.3

(l) No person may alter, remove, de-

face, destroy, or otherwise unlawfully

tamper with any marking, label,

placard, or description on a document

required by Federal hazardous material

transportation law or the regulations

issued under Federal hazardous mate-

rial transportation law. No person may

alter, deface, destroy, or otherwise un-

lawfully tamper with a package, con-

tainer, motor vehicle, rail car, aircraft,

or vessel used for the transportation of

hazardous materials.

(m) No person may falsify or alter an

exemption or special permit, approval,

registration, or other grant of author-

ity issued under this subchapter or sub-

chapter A of this chapter. No person

may offer a hazardous material for

transportation or transport a haz-

ardous material in commerce under an

exemption or special permit, approval,

registration or other grant of author-

ity issued under this subchapter or sub-

chapter A of this chapter if such grant

of authority has been altered without

the consent of the issuing authority.

No person may represent, mark, cer-

tify, or sell a packaging or container

under an exemption or special permit,

approval, registration or other grant of

authority issued under this subchapter

or subchapter A of this chapter if such

grant of authority has been altered

without the consent of the issuing au-

thority.

[68 FR 61937, Oct. 30, 2003, as amended at 70

FR 43643, July 28, 2005; 70 FR 73162, Dec. 9,

2005]

§ 171.3 Hazardous waste.

(a) No person may offer for transpor-

tation or transport a hazardous waste

(as defined in § 171.8 of this subchapter)

in interstate or intrastate commerce

except in accordance with the require-

ments of this subchapter.

(b) No person may accept for trans-

portation, transport, or deliver a haz-

ardous waste for which a manifest is

required unless that person:

(1) Has marked each motor vehicle

used to transport hazardous waste in

accordance with § 390.21 of this title

even though placards may not be re-

quired;

(2) Complies with the requirements

for manifests set forth in § 172.205 of

this subchapter; and

(3) Delivers, as designated on the

manifest by the generator, the entire

quantity of the waste received from the

generator or a transporter to:

(i) The designated facility or, if not

possible, to the designated alternate fa-

cility;

(ii) The designated subsequent car-

rier; or

(iii) A designated place outside the

United States.

N

OTE

: Federal law specifies penalties up to

$250,000 fine for an individual and $500,000 for

a company and 5 years imprisonment for the

willful discharge of hazardous waste at other

than designated facilities. 49 U.S.C. 5124.

(c) If a discharge of hazardous waste

or other hazardous material occurs

during transportation, and an official

of a State or local government or a

Federal agency, acting within the

scope of his official responsibilities, de-

termines that immediate removal of

the waste is necessary to prevent fur-

ther consequence, that official may au-

thorize the removal of the waste with-

out the preparation of a manifest.

[N

OTE

: In such cases, EPA does not re-

quire carriers to have EPA identifica-

tion numbers.]

N

OTE

1: EPA requires shippers (generators)

and carriers (transporters) of hazardous

wastes to have identification numbers which

must be displayed on hazardous waste mani-

fests. See 40 CFR parts 262 and 263. (Identi-

fication number application forms may be

obtained from EPA regional offices.)

N

OTE

2: In 40 CFR part 263, the EPA sets

forth requirements for the cleanup of re-

leases of hazardous wastes.

[Amdt. 171–53, 45 FR 34586, May 22, 1980, as

amended by Amdt. 171–53, 45 FR 74648, Nov.

10, 1980; Amdt. 171–78, 49 FR 10510, Mar. 20,

1984; Amdt. 171–107, 54 FR 40068, Sept. 29, 1989;

Amdt. 171–111, 55 FR 52466, Dec. 21, 1990; 56

FR 66157, Dec. 20, 1991; Amdt. 171–2, 59 FR

49132, Sept. 26, 1994; Amdt. 171–141, 61 FR

21102, May 9, 1996; 73 FR 57004, Oct. 1, 2008]

§ 171.4 Marine pollutants.

(a) Except as provided in paragraph

(c) of this section, no person may offer

for transportation or transport a ma-

rine pollutant, as defined in § 171.8, in

intrastate or interstate commerce ex-

cept in accordance with the require-

ments of this subchapter.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00100 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

91

Pipeline and Hazardous Materials Safety Admin., DOT § 171.6

(b) The requirements of this sub-

chapter for the transportation of ma-

rine pollutants are based on the provi-

sions of Annex III of the 1973 Inter-

national Convention for Prevention of

Pollution from Ships, as modified by

the Protocol of 1978 (MARPOL 73/78).

(c) Exceptions. Except when all or

part of the transportation is by vessel,

the requirements of this subchapter

specific to marine pollutants do not

apply to non-bulk packagings trans-

ported by motor vehicle, rail car or air-

craft.

[Amdt. 171–116, 57 FR 52934, Nov. 5, 1993, as

amended by Amdt. 107–39, 61 FR 51337, Oct. 1,

1996; 73 FR 4712, Jan. 28, 2008]

§ 171.6 Control numbers under the Pa-

perwork Reduction Act.

(a) Purpose and scope. This section

collects and displays the control num-

bers assigned to the HMR collections of

information by the Office of Manage-

ment and Budget (OMB) under the Pa-

perwork Reduction Act of 1995. This

section complies with the requirements

of 5 CFR 1320.7(f), 1320.12, 1320.13 and

1320.14 (OMB regulations implementing

the Paperwork Reduction Act of 1995)

for the display of control numbers as-

signed by OMB to collections of infor-

mation of the HMR.

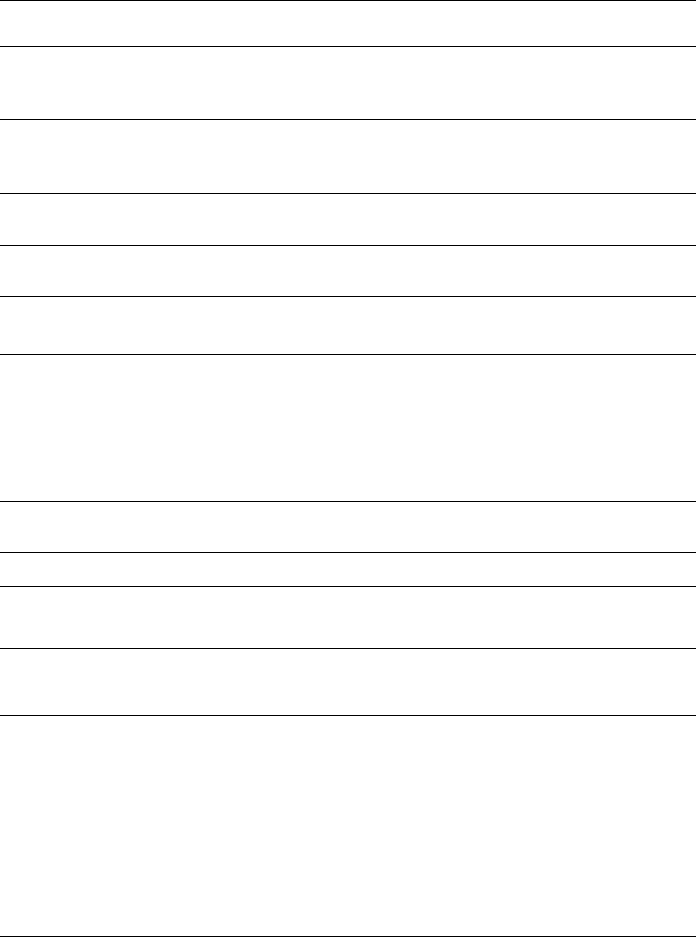

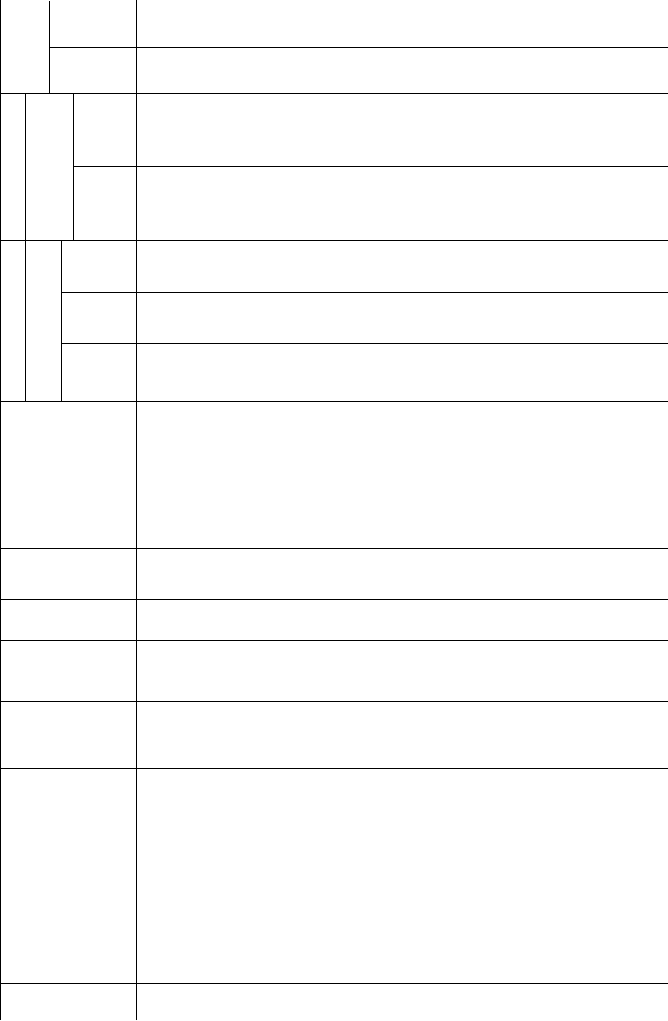

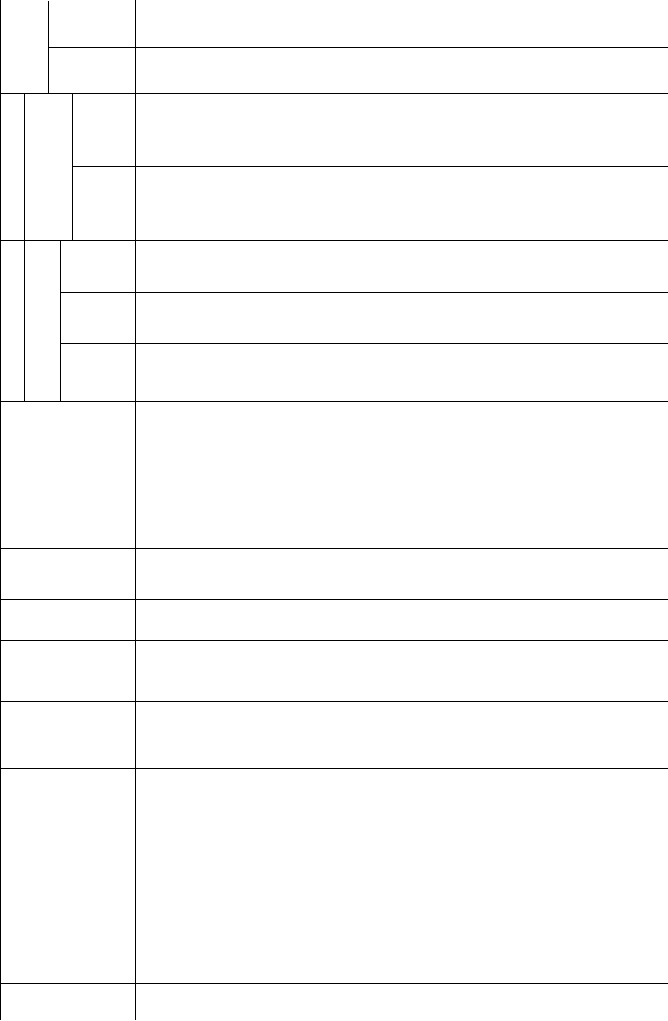

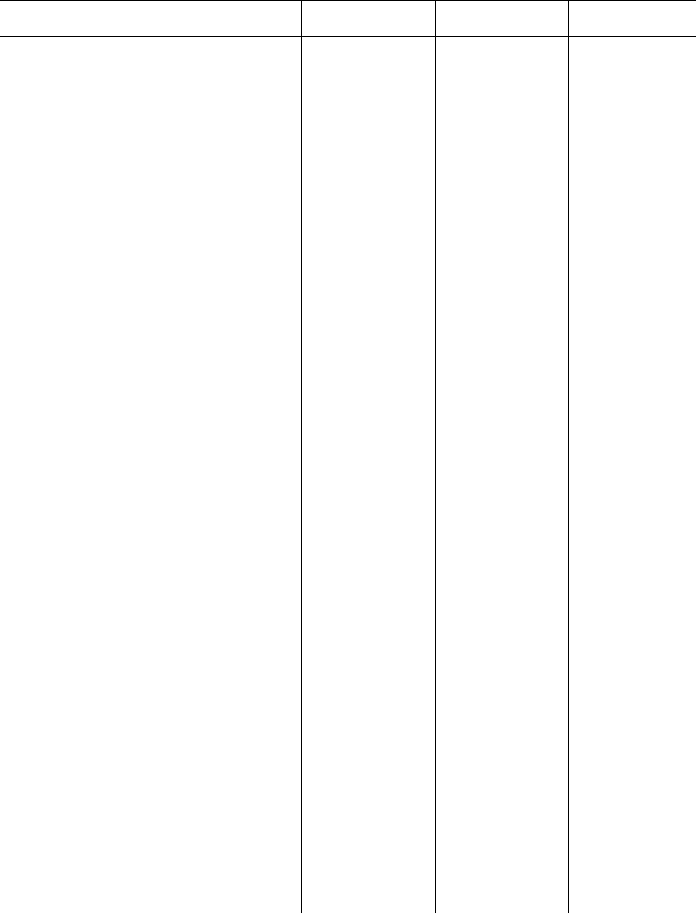

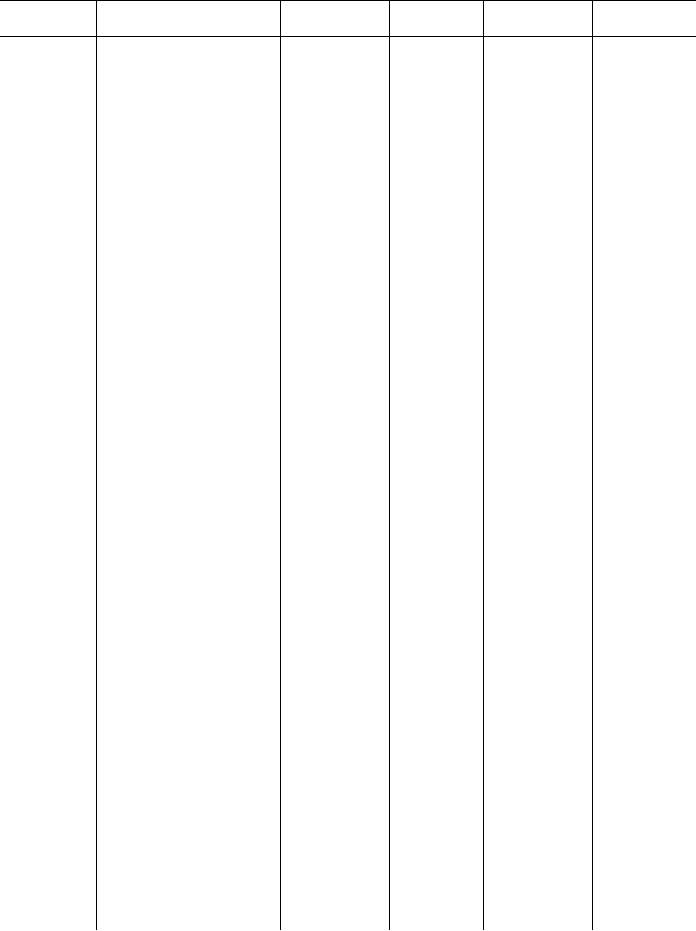

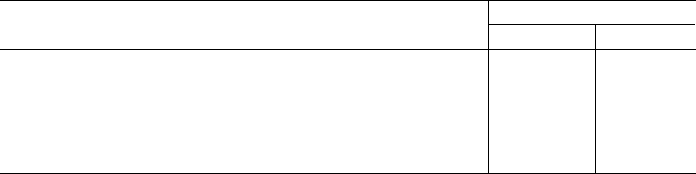

(b) OMB control numbers. The table in

paragraph (b)(2) of this section sets

forth the control numbers assigned to

collection of information in the HMR

by the Office of Management and Budg-

et (OMB) under the Paperwork Reduc-

tion Act of 1995.

(1) Column 1 lists the OMB control

number assigned to the HMR collec-

tions of information. Column 2 con-

tains the Report Title of the approved

collection of information. Column 3

lists the part(s) or section(s) in 49 CFR

identified or described in the collection

of information.

(2) Table.

Current OMB

control No.

Title

Title 49 CFR part or section where identified

and described

2137–0014 ......................... Cargo Tank Specification Requirements ............ §§107.503, 107.504, 178.320, 178.337,

178.338, 178.345, 180.407, 180.409,

180.413, 180.417.

2137–0018 ......................... Inspection and Testing of Portable Tanks and

Intermediate Bulk Containers.

§§ 173.24, 173.32, 178.3, 178.255, 178.273,

178.274, 178.703, 178.801, 180.352,

180.605.

2137–0022 ......................... Testing, Inspection, and Marking Requirements

for Cylinders.

§§ 173.5b, 173.302a, 173.303, 173.304,

173.309, 178.2, 178.3, 178.35, 178.44,

178.45, 178.46, 178.57, 178.59, 178.60,

178.61, 178.68, 180.205, 180.207, 180.209,

180.211, 180.213, 180.215, 180.217, Appen-

dix C to Part 180.

2137–0034 ......................... Hazardous Materials Shipping Papers and

Emergency Response Information.

§§ 172.200, 172.201, 172.202, 172.203,

172.204, 172.505, 172.600, 172.602,

172.604, 172.606, 173.6, 173.7, 173.22,

173.56, 174.24, 174.26, 174.114, 175.30,

175.31, 175.33, 176.24, 176.27, 176.30,

176.36, 176.89, 177.817.

2137–0039 ......................... Hazardous Materials Incidents Reports .............. §§171.15, 171.16, 171.21.

2137–0051 ......................... Rulemaking and Special Permit Petitions ........... §§ 105.30, 105.40, 106.95, 106.110, 107.105,

107.107, 107.109, 107.113, 107.117,

107.121, 107.123, 107.125, 107.205,

107.211, 107.215, 107.217, 107.219,

107.221, 107.223.

2137–0510 ......................... RAM Transportation Requirements ..................... Part 173, Subpart I, §§ 173.22, 173.411,

173.415, 173.416, 173.417, 173.457,

173.471, 173.472, 173.473, 173.476.

2137–0542 ......................... Flammable Cryogenic Liquids ............................. §§ 173.318, 177.816, 177.840, 180.405.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00101 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

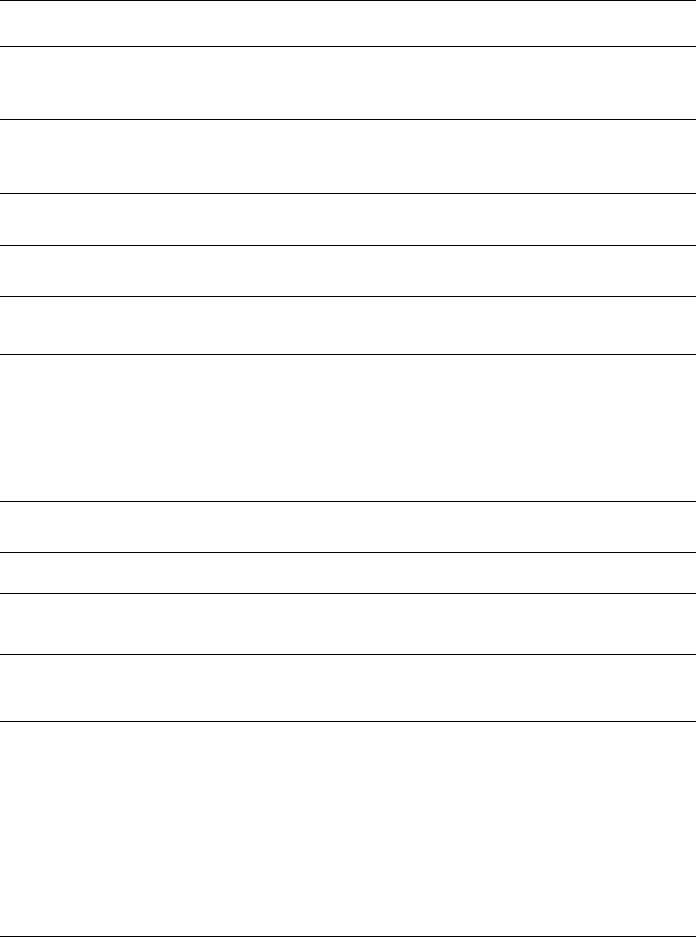

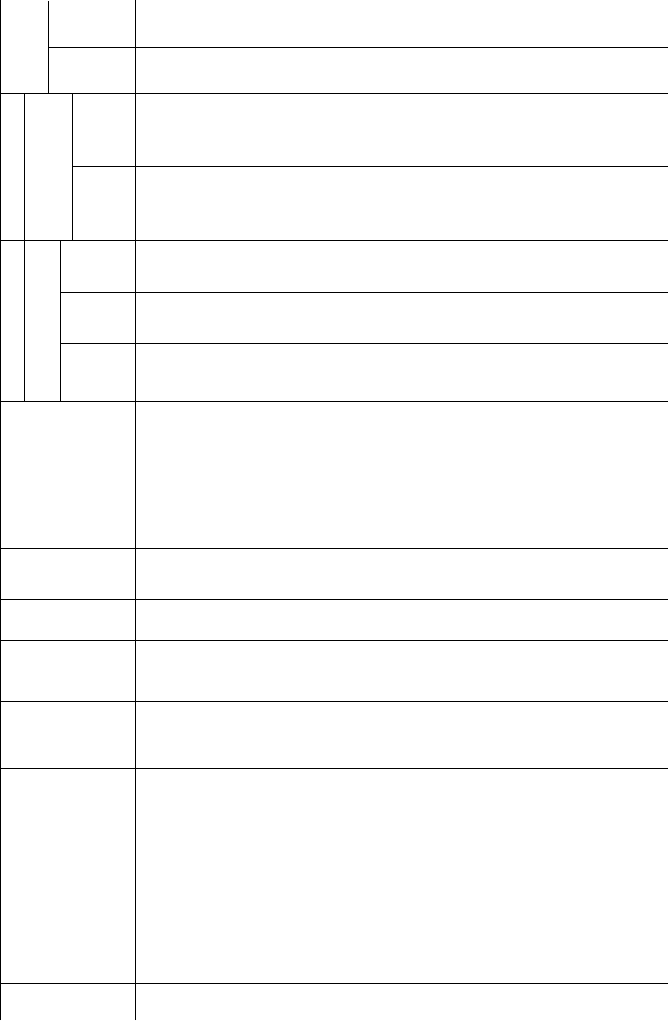

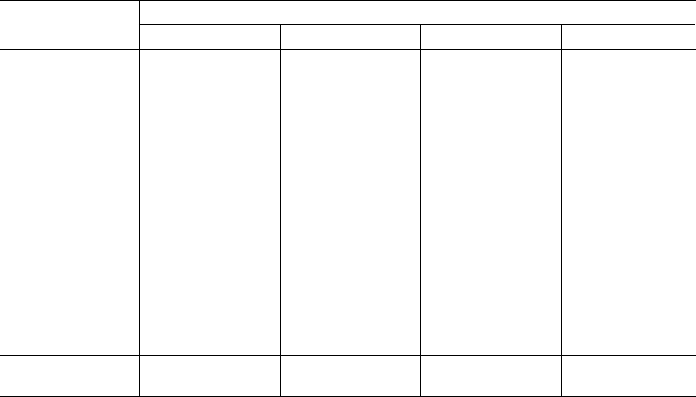

92

49 CFR Ch. I (10–1–12 Edition) § 171.7

Current OMB

control No.

Title

Title 49 CFR part or section where identified

and described

2137–0557 ......................... Approvals for Hazardous Materials §§ 107.402, 107.403, 107.405, 107.502,

107.503, 107.705, 107.713, 107.715,

107.717, 107.803, 107.805, 107.807, 110.30,

172.101, 172.102, Special Provisions 19, 26,

53, 55, 60, 105, 118, 121, 125, 129, 131,

133, 136, B45, B55, B61, B69, B77, B81,

N10, N72, 173.2a, 173.4, 173.7, 173.21,

173.22, 173.24, 173.31, 173.38, 173.51,

173.56, 173.58, 173.59, 173.124, 173.128,

173.159, 173.166, 173.171, 173.214,

173.222, 173.224, 173.225, 173.245,

173.301, 173.305, 173.306, 173.314,

173.315, 173.316, 173.318, 173.334,

173.340, 173.411, 173.433, 173.457,

173.471, 173.472, 173.476, 174.50, 174.63,

175.8, 175.85, 175.701, 175.703, 176.168,

176.340, 176.704, 178.3, 178.35, 178.47,

178.53, 178.273, 178.274, 178.503, 178.509,

178.605, 178.606, 178.608, 178.801,

178.813, 180.213.

2137–0559 ......................... (Rail Carriers and Tank Car Tank Require-

ments) Requirements for Rail Tank Car

Tanks—Transportation of Hazardous Mate-

rials by Rail..

§§ 172.102, Special provisions: B45, B46, B55,

B61, B69, B77, B78, B81; 173.10, 173.31,

174.20, 174.50, 174.63, 174.104, 174.114,

174.204, 179.3, 179.4, 179.5, 179.6, 179.7,

179.11, 179.18, 179.22, 179.100–9, 179.100–

12, 179.100–13, 179.100–16, 179.100–17,

179.102–4, 179.102–17, 179.103–1, 179.103–

2, 179.103–3, 179.103–5, 179.200–10,

179.200–14, 179.200–15, 179.200–16,

179.200–17, 179.200–19, 179.201–3,

179.201–8, 179.201–9, 179.220–4, 179.220–

7, 179.220–8, 179.220–13, 179.220–15,

179.220–17, 179.220–18, 179.220–20,

179.220–22, 179.300–3, 179.300–7, 179.300–

9, 179.300–12, 179.300–13, 179.300–15,

179.300–20, 179.400–3, 179.400–4, 179.400–

11, 179.400–13, 179.400–16, 179.400–17,

179.400–19, 179.400–20, 179.500–5,

179.500–8, 179.500–12, 179.500–18,

180.505, 180.509, 180.515, 180.517.

2137–0572 ......................... Testing requirements for non-bulk packages ...... §§ 173.168, 178.2, 178.601, Appendix C to Part

178, Appendix D to Part 178.

2137–0582 ......................... Container Certification Statement ....................... §§ 176.27, 176.172.

2137–0586 ......................... Hazardous Materials Public Sector Training and

Planning Grants.

Part 110.

2137–0591 ......................... Response Plans for Shipments of Oil ................. Part 130.

2137–0595 ......................... Cargo Tank Motor Vehicles in Liquefied Com-

pressed Gas Service.

§§ 173.315, 178.337–8, 178.337–9, 180.405,

180.416.

2137–0612 ......................... Hazardous Materials Security Plans ................... Part 172, Subpart I, §§ 172.800, 172.802,

172.804.

2137–0613 ......................... Subsidiary Hazard Class and Number/Type of

Packagings.

§§ 172.202, 172.203

2137–0620 ......................... Inspection and Testing of Meter Provers ............ Part 173, Subpart A, § 173.5a.

2137–0621 ......................... Requirements for United Nations (UN) Cylinders §§ 173.301, 173.304, 173.304b, 178.69, 178.70,

178.74, 178.75, 180.207, 180.209, 180.212,

180.215, 180.217.

[Amdt. 171–111, 56 FR 66157]

E

DITORIAL

N

OTE

: For F

EDERAL

R

EGISTER

citations affecting § 171.6, see the List of CFR Sec-

tions Affected, which appears in the Finding Aids section of the printed volume and at

www.fdsys.gov.

§ 171.7 Reference material.

(a) Matter incorporated by reference—

(1) General. There is incorporated, by

reference in parts 170–189 of this sub-

chapter, matter referred to that is not

specifically set forth. This matter is

hereby made a part of the regulations

in parts 170–189 of this subchapter. The

matter subject to change is incor-

porated only as it is in effect on the

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00102 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

93

Pipeline and Hazardous Materials Safety Admin., DOT § 171.7

date of issuance of the regulation refer-

ring to that matter. The material list-

ed in paragraph (a)(3) has been ap-

proved for incorporation by reference

by the Director of the Federal Register

in accordance with 5 U.S.C 552(a) and 1

CFR part 51. Material is incorporated

as it exists on the date of the approval

and a notice of any change in the mate-

rial will be published in the F

EDERAL

R

EGISTER

. Matters referenced by foot-

note are included as part of the regula-

tions of this subchapter.

(2) Accessibility of materials. All incor-

porated matter is available for inspec-

tion at:

(i) The Office of Hazardous Materials

Safety, Office of Hazardous Materials

Standards, East Building, PHH–10, 1200

New Jersey Avenue, SE., Washington,

DC 20590–0001. For information on the

availability of this material at PHH–10,

call 1–800–467–4922, or go to: http://

www.phmsa.dot.gov; and

(ii) The National Archives and

Records Administration (NARA). For

information on the availability of this

material at NARA, call 202–741–6030, or

go to: http://www.archives.gov/

federallregister/

codeloflfederallregulations/

ibrllocations.html.

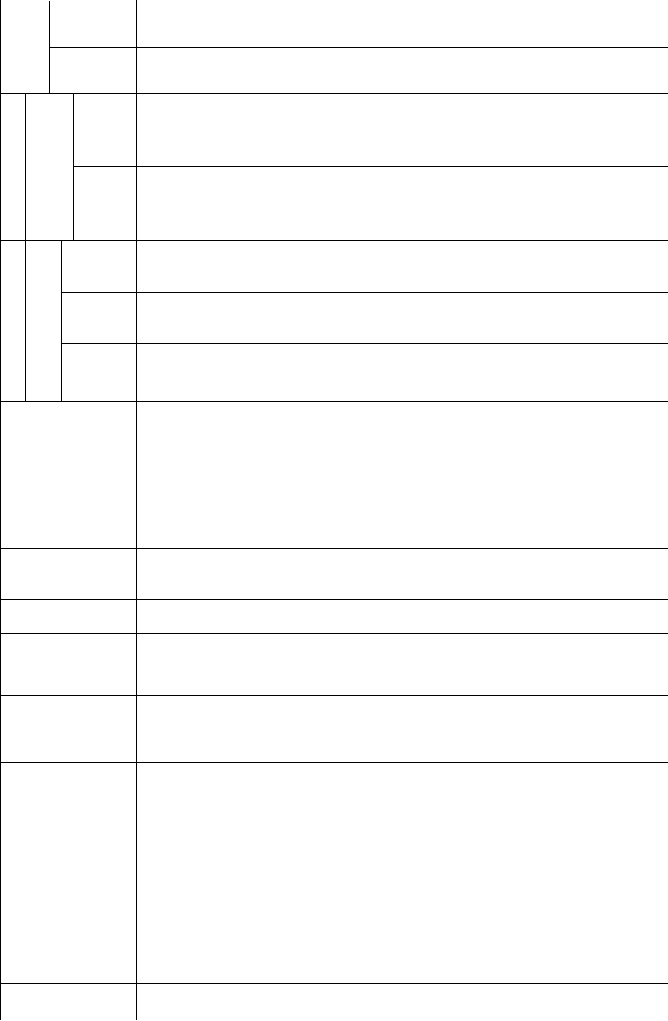

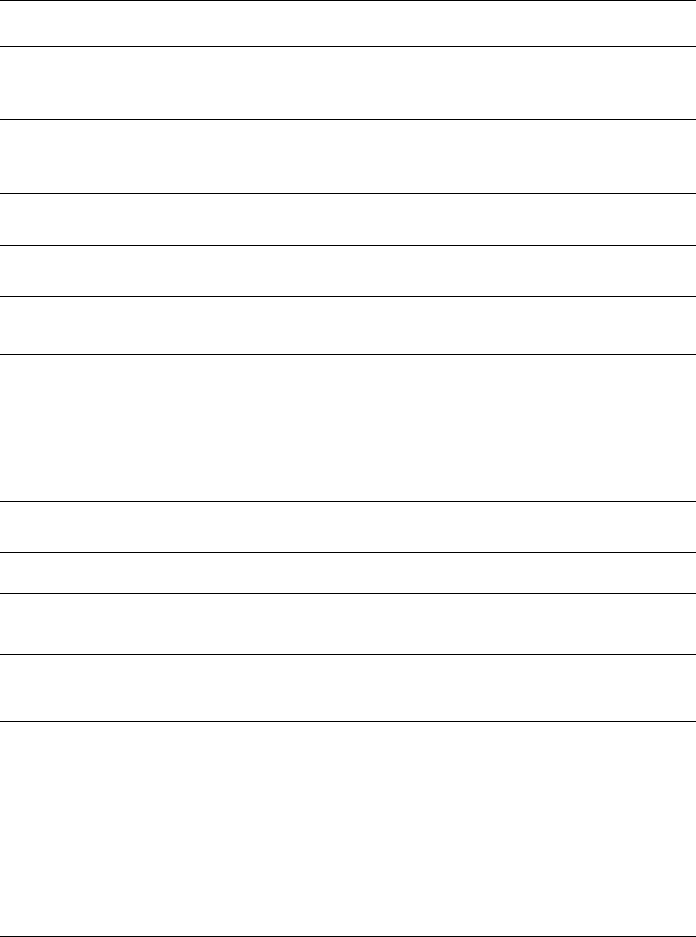

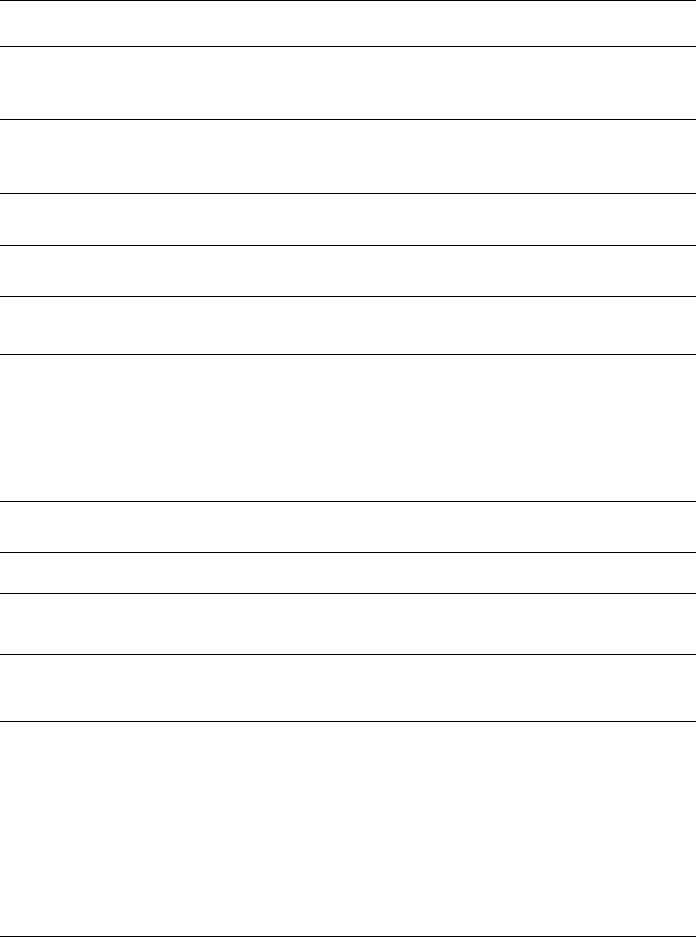

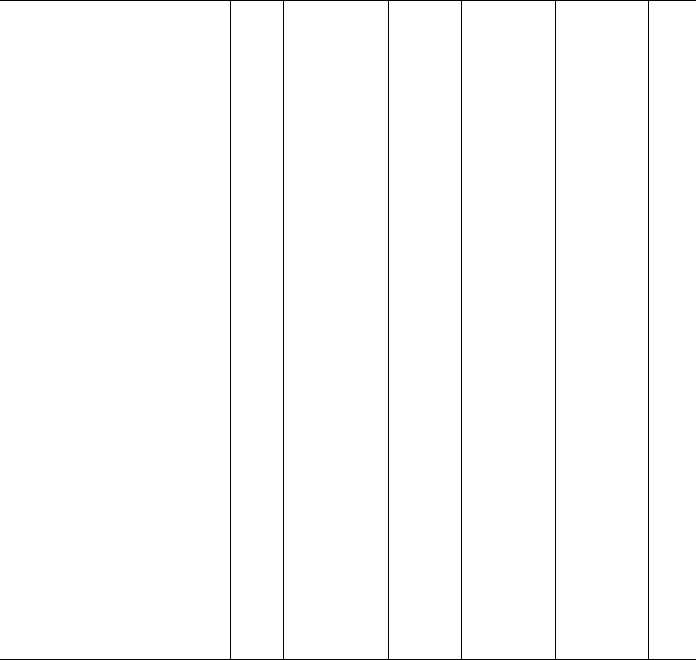

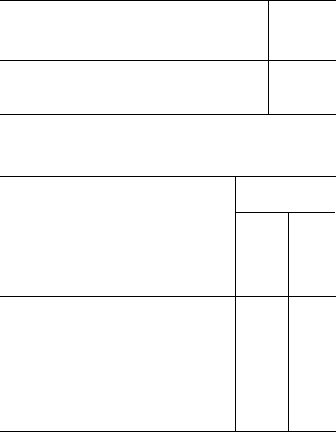

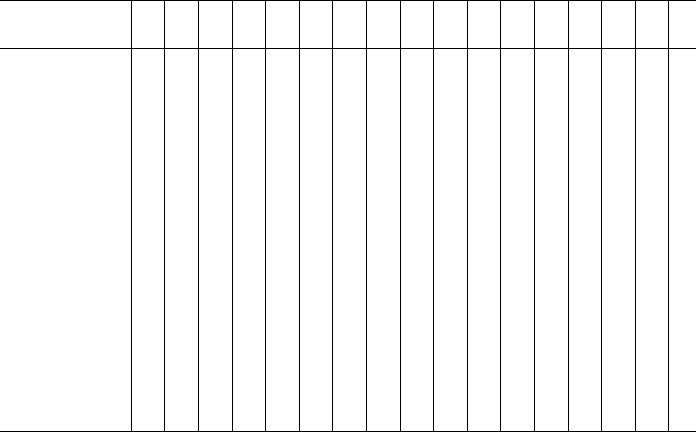

(3) Table of material incorporated by

reference. The following table sets forth

material incorporated by reference.

The first column lists the name and ad-

dress of the organization from which

the material is available and the name

of the material. The second column

lists the section(s) of this subchapter,

other than § 171.7, in which the matter

is referenced. The second column is

presented for information only and

may not be all inclusive.

Source and name of material 49 CFR reference

Air Transport Association of America, 1301 Pennsylvania Avenue, N.W., Washington, DC 20004–1707:

ATA Specification No. 300 Packaging of Airline Supplies, Revision 19, July 31, 1996 .................. 172.102.

The Aluminum Association, 1525 Wilson Blvd, Suite 6000, Arlington, VA 22209, telephone 703–358–

2960, http://www.aluminum.org.

Aluminum Standards and Data, Seventh Edition, June 1982 .......................................................... 172.102; 178.65.

Welding Aluminum: Theory and Practice, 2002 Fourth Edition ........................................................ 178.68

American National Standards Institute, Inc., 25 West 43rd Street, New York, NY 10036:

ANSI/ASHRAE 15–94, Safety Code for Mechanical Refrigeration ................................................... 173.306; 173.307.

ANSI B16.5–77, Steel Pipe Flanges, Flanged Fittings ..................................................................... 178.360–4.

ANSI N14.1 Uranium Hexafluoride—Packaging for Transport, 1971, 1982, 1987, 1990, 1995 and

2001 Editions.

173.417; 173.420.

American Petroleum Institute, 1220 L Street, NW, Washington, D.C. 20005–4070:

API Recommended Practice Closures of Underground Petroleum Storage Tanks, 3rd Edition,

March 1996.

172.102.

American Pyrotechnics Association (APA), P.O. Box 30438, Bethesda, MD 20824, (301) 907–8181,

www.americanpyro.com:

APA Standard 87–1, Standard for Construction and Approval for Transportation of Fireworks,

Novelties, and Theatrical Pyrotechnics, December 1, 2001 version.

173.56.

American Society of Mechanical Engineers, ASME International, 22 Law Drive, P.O. Box 2900, Fairfield,

NJ 07007–2900, telephone 1–800–843–2763 or 1–973–882–1170, http://www.asme.org:

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00103 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

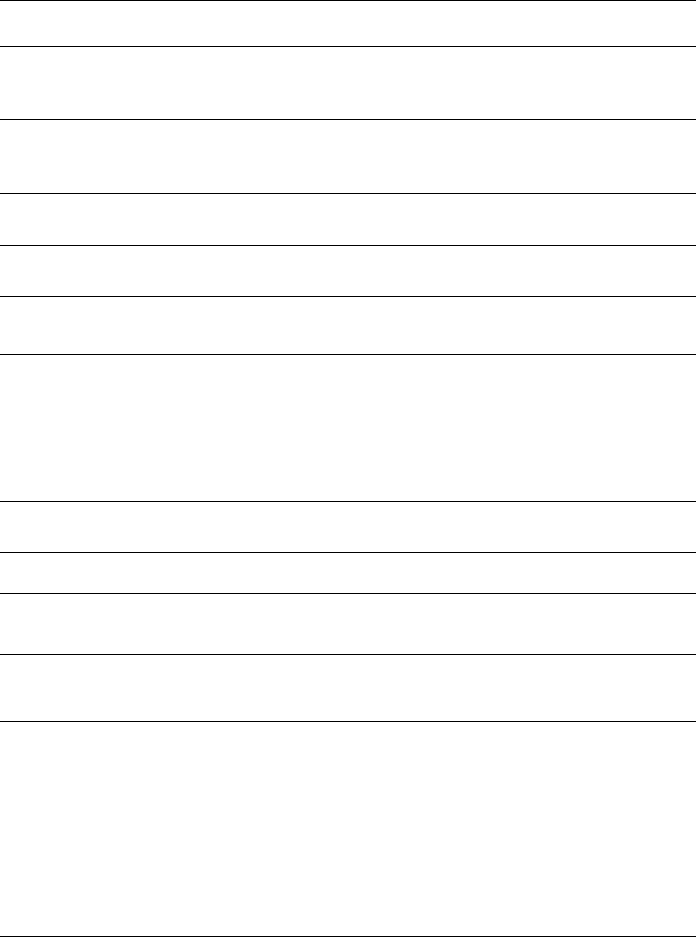

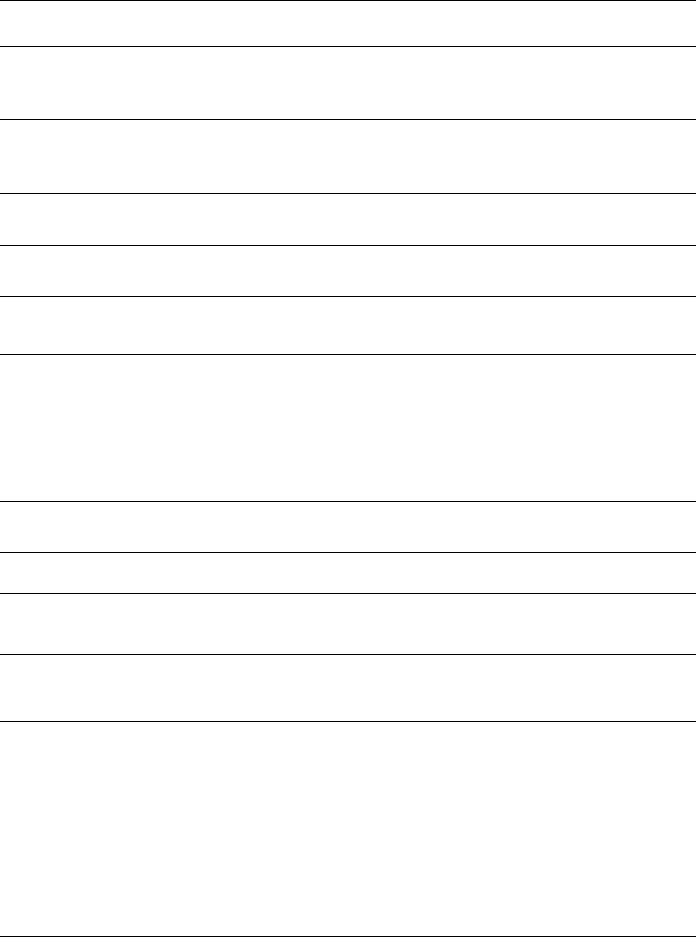

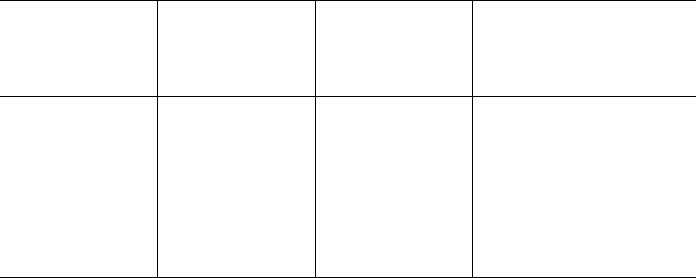

94

49 CFR Ch. I (10–1–12 Edition) § 171.7

Source and name of material 49 CFR reference

‘ASME Code’; ASME Code, Sections II (Parts A and B), V, VIII (Division 1), and IX of 1998 Edi-

tion of American Society of Mechanical Engineers Boiler and Pressure Vessel Code.

172.102; 173.5b;

173.24b; 173.32;

173.306; 173.315;

173.318; 173.420;

178.245–1;

178.245–3;

178.245–4;

178.245–6;

178.245–7;

178.255–1;

178.255–2;

178.255–14;

178.255–15;

178.270–2;

178.270–3;

178.270–7;

178.270–9;

178.270–11;

178.270–12;

178.271–1;

178.272–1;

178.273; 178.274;

178.276; 178.277;

178.320; 178.337–

1; 178.337–2;

178.337–3;

178.337–4;

178.337–6;

178.337–16;

178.337–18;

178.338–1;

178.338–2;

178.338–3;

178.338–4;

178.338–5;

178.338–6;

178.338–13;

178.338–16;

178.338–18;

178.338–19;

178.345–1;

178.345–2;

178.345–3;

178.345–4;

178.345–7;

178.345–14;

178.345–15;

178.346–1;

178.347–1;

178.348–1;

179.400–3;

180.407.

Pipeline Transportation Systems for Liquid Hydrocarbons and other Liquids, Chapters II, III, IV,

V and VI, ASME B31.4–1998 Edition.

173.5a.

American Society for Testing and Materials, 100 Barr Harbor Drive, West Conshohocken, PA 1942, tele-

phone (610) 832–9585, http://www.astm.org:

Noncurrent ASTM Standards are available from: Engineering Societies Library, 354 East 47th

Street, New York, NY 10017

ASTM A 20/A 20M–93a Standard Specification for General Requirements for Steel Plates for

Pressure Vessels.

178.337–2;

179.102–4;

179.102–1;

179.102–17.

ASTM A 47–68 Malleable Iron Castings ........................................................................................... 179.200–15.

ASTM A 53, ASTM A 53/A 53M–06a Standard Specification for Pipe, Steel, Black and Hot-

Dipped, Zinc-Coated, Welded and Seamless.

173.5b.

ASTM A 106, ASTM A 106/A 106M–06a Standard Specification for Seamless Carbon Steel Pipe

for High-Temperature Service.

173.5b.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00104 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

95

Pipeline and Hazardous Materials Safety Admin., DOT § 171.7

Source and name of material 49 CFR reference

ASTM A 240/A 240M–99b Standard Specification for Heat-Resisting Chromium and Chromium-

Nickel Stainless Steel Plate, Sheet and Strip for Pressure Vessels.

178.57; 178.358–5;

179.100–7;

179.100–10;

179.102–1;

179.102–4;

179.102–17;

179.200–7;

179.201–5;

179.220–7;

179.300–7;

179.400–5.

ASTM A 242–81 Standard Specification for High-Strength Low-Alloy Structural Steel ................... 178.338–2.

ASTM A 262–93a Standard Practices for Detecting Susceptibility to Intergranular Attack in Aus-

tenitic Stainless Steels.

179.100–7;

179.200–7;

179.201–4.

ASTM A 285–78 Pressure Vessel Plates, Carbon Steel, Low- and Intermediate-Tensile Strength 179.300–7.

ASTM A 300–58 Steel Plates for Pressure Vessels for Service at Low Temperatures .................. 178.337–2.

ASTM A 302/A 302M–93 Standard Specification for Pressure Vessel Plates, Alloy Steel, Man-

ganese-Molybdenum and Manganese-Molybdenum Nickel.

179.100–7;

179.200–7;

179.220–7.

ASTM A 333–67 Seamless and Welded Steel Pipe for Low-Temperature Service ........................ 178.45.

ASTM A 370–94 Standard Test 179.102–1; 179.102–4; Methods and Definitions for Mechanical

Testing of Steel Products.

179.102–17.

ASTM A 441–81 Standard Specification for High-Strength Low-Alloy Structural Manganese Va-

nadium Steel.

178.338–2.

ASTM A 514–81 Standard Specification for High-Yield Strength Quenched and Tempered Alloy

Steel Plate, Suitable for Welding.

178.338–2.

ASTM A 515/A 515M–03 Standard Specification for Pressure Vessel Plates, Carbon Steel, for

Intermediate- and Higher-Temperature Service.

179.300–7.

ASTM A 516/A 516M–90 Standard Specification for Pressure Vessel Plates, Carbon Steel, for

Moderate and Lower-Temperature Service.

178.337–2;

179.100–7;

179.102–1;

179.102–2;

179.102–4;

179.102–17;

179.200–7;

179.220–7;

179.300–7.

ASTM A 537/A 537M–91 Standard Specification for Pressure Vessel Plates, Heat-Treated, Car-

bon-Manganese-Silicon Steel.

179.100–7;

179.102–4;

179.102–17.

ASTM A 572–82 Standard Specification for High-Strength Low-Alloy Columbian-Vanadium

Steels of Structural Quality.

178.338–2.

ASTM A 588–81 Standard Specification for High-Strength Low-Alloy Structural Steel with 50 Ksi

Minimum Yield Point to 4 in. Thick.

178.338–2.

ASTM A 606–75 Standard Specification for Steel Sheet and Strip Hot- Rolled and Cold-Rolled,

High-Strength, Low-Alloy, with Improved Atmospheric Corrosion Resistance, 1975 (Re-

approved 1981).

178.338–2.

ASTM A 607–98 Standard Specification for Steel, Sheet and Strip, High-Strength, Low-Alloy,

Columbium or Vanadium, or Both, Hot-Rolled and Cold-Rolled.

178.338–2.

ASTM A 612–72a High Strength Steel Plates for Pressure Vessels for Moderate and Lower

Temperature Service.

178.337–2.

ASTM A 633–79a Standard Specification for Normalized High-Strength Low-Alloy Structural

Steel, 1979 Edition.

178.338–2.

ASTM A 715–81 Standard Specification for Steel Sheet and Strip, Hot-Rolled, High-Strength,

Low-Alloy with Improved Formability, 1981.

178.338–2.

ASTM A 1008/A 1008M—03 Standard Specification for Steel, Sheet, Cold-Rolled, Carbon,

Structural, High-Strength Low-Alloy and High Strength Low-Alloy with Improved Formability.

178.338–2;

178.345–2

ASTM A 1011/A 1011M—03a Standard Specification for Steel, Sheet and Strip, Hot-Rolled, Car-

bon, Structural, High-Strength Low Alloy and High Strength Low-Alloy with Improved

Formability.

178.338–2;

178.345–2

ASTM B 162–93a Standard Specification for Nickel Plate, Sheet, and Strip .................................. 173.249; 179.200–7.

ASTM B 209–93 Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate ....... 179.100–7;

179.200–7;

179.220–7.

ASTM B 221–76 Aluminum Alloy Extruded Bars, Rods, Shapes, and Tubes ................................. 178.46.

ASTM B 557–84 Tension Testing Wrought and Cast Aluminum and Magnesium-Alloy Products .. 178.46.

ASTM B 580–79 Standard Specification for Anodic Oxide Coatings on Aluminum, (Re-approved

2000).

173.316; 173.318;

178.338–17.

ASTM D 56–05, Standard Test Method for Flash Point by Tag Closed Cup Tester, approved May 1, 2005 173.120

ASTM D 86–07a, Standard Test Method for Distillation of Petroleum Products at Atmospheric Pressure,

approved April 1, 2007.

173.121

ASTM D 93–08, Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester, approved

October 15, 2008.

173.120

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00105 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

96

49 CFR Ch. I (10–1–12 Edition) § 171.7

Source and name of material 49 CFR reference

ASTM D 1078–05, Standard Test Method for Distillation Range of Volatile Organic Liquids, approved May

15, 2005.

173.121

ASTM D 1238–90b Standard Test Method for Flow Rates of Thermoplastics for Extrusion Plas-

tometer.

173.225.

ASTM D 1709–01 Standard Text Methods for Impact Resistance of Plastic Film by the Free-Fall-

ing Dart Method.

173.197.

ASTM D 1835–97 Standard Specification for Liquefied Petroleum (LP) Gases .............................. 180.209.

ASTM D 1838–64 Copper Strip Corrosion by Liquefied Petroleum (LP) Gases ............................. 173.315.

ASTM D 1922–00a Standard Test Method for Propogation Tear Resistance of Plastic Film and

Thin Sheeting by Pendulum Method.

173.197.

ASTM D 3278–96 (Reapproved 2004) E

1

, Standard Test Methods for Flash Point of Liquids by Small

Scale Closed-Cup Apparatus, approved November 1, 2004.

173.120

ASTM D 3828–07a, Standard Test Methods for Flash Point by Small Scale Closed Cup Tester, approved

July 15, 2007.

173.120

ASTM D 4206–96 Standard Test Method for Sustained Burning of Liquid Mixtures Using the

Small Scale Open-Cup Apparatus.

173.120.

ASTM D 4359–90 Standard Test Method for Determining Whether a Material is a Liquid or a

Solid.

171.8.

ASTM E 8–99 Standard Test Methods for Tension Testing of Metallic Materials ........................... 178.36; 178.37;

178.38; 178.39;

178.44; 178.45;

178.50; 178.51;

178.53; 178.55;

178.56; 178.57;

178.58; 178.59;

178.60; 178.61;

178.68.

ASTM E 23–98 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials ...... 178.57.

ASTM E 112–88 Standard Test Methods for Determining Average Grain Size .............................. 178.44.

ASTM E 112–96 Standard Test Methods for Determining Average Grain Size, 1996 Edition ........ 178.274; Part 178,

appendix A.

ASTM E 114–95 Standard Practice for Ultrasonic Pulse-Echo Straight-Beam Examination by the

Contact Method.

178.45.

ASTM E 213–98 Standard Practice for Ultrasonic Examination of Metal Pipe and Tubing ............ 178.45.

ASTM E 290–97a Standard Test Methods for Bend Testing of Material for Ductility, published February

1998.

178.37.

American Water Works Association, 1010 Vermont Avenue, N.W., Suite 810, Washington, DC 20005:

AWWA Standard C207–55, Steel Pipe Flanges, 1955 ..................................................................... 178.360–4.

American Welding Society, 550 N.W. Le Jeune Road, Miami, Florida 33126:

AWS Code B 3.0; Standard Qualification Procedure; 1972 (FRB 3.0–41, rev. May 1973) ............. 178.356–2,

178.358–2.

AWS Code D 1.0; Code for Welding in Building Construction (FR D 1.0–66, 1966) ...................... 178.356–2;

178.358–2.

Association of American Railroads, American Railroads Building, 50 F Street, NW., Washington, DC

20001; telephone (877) 999–8824, http://www.aar.org/publications.com;

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00106 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

97

Pipeline and Hazardous Materials Safety Admin., DOT § 171.7

Source and name of material 49 CFR reference

AAR Manual of Standards and Recommended Practices, Section C—Part III, Specifications for

Tank Cars, Specification M–1002, (AAR Specifications for Tank Cars), December 2000.

173.31; 179.6;

179.7; 179.15;

179.16; 179.20;

179.22; 179.100–

9; 179.100–10;

179.100–12;

179.100–13;

179.100–14;

179.100–18;

179.101–1;

179.102–1;

179.102–4;

179.102–17;

179.103–5;

179.200–7;

179.200–9;

179.200–10;

179.200–11;

179.200–13;

179.200–17;

179.200–22;

179.201–6;

179.220–6;

179.220–7;

179.220–10;

179.220–11;

179.220–14;

179.220–18;

179.220–26;

179.300–9;

179.300–10;

179.300–15;

179.300–17;

179.400–5;

179.400–6;

179.400–8;

179.400–11;

179.400–12;

179.400–15;

179.400–18;

179.400–20;

179.400–25;

180.509; 180.513;

180.515; 180.517.

AAR Manual of Standards and Recommended Practices, Section I, Specially Equipped Freight

Car and Intermodal Equipment, 1988.

174.55; 174.63.

AAR Specifications for Design, Fabrication and Construction of Freight Cars, Volume 1, 1988 .... 179.16.

Chlorine Institute, Inc., 1300 Wilson Boulevard, Arlington, VA 22209

AAR Standard 286; AAR Manual of Standards and Recommended Practices, Section C, Car

Construction Fundamentals and Details, Standard S–286, Free/Unrestricted Interchange for

286,000 lb Gross Rail Load Cars (Adopted 2002; Revised: 2003, 2005, 2006).

179.13

Chlorine Institute Emergency Kit ‘‘A’’ for 100-lb. & 150 lb. Chlorine Cylinders (with the exception

of repair method using Device 8 for side leaks), Edition 10, June 2003.

173.3

Chlorine Institute Emergency Kit ‘‘B’’ for Chlorine Ton Containers (with the exception of repair

method using Device 9 for side leaks), Edition 9, June 2003.

173.3

Type 1

1

⁄

2

JQ 225, Dwg., H51970, Revision F, November 1996; or Type 1

1

⁄

2

JQ 225, Dwg.

H50155, Revision H, November 1996.

173.315.

Section 3, Pamphlet 57, Emergency Shut-Off Systems for Bulk Transfer of Chlorine, Edition 4,

October 2003.

177.840.

Section 3, Pamphlet 166, Angle Valve Guidelines for Chlorine Bulk Transportation, 1st Edition,

October 2002.

178.337–9.

Standard Chlorine Angle Valve Assembly, Dwg. 104–8, July 1993 ................................................. 178.337–9.

Excess Flow Valve with Removable Seat, Dwg. 101–7, July 1993 ................................................. 178.337–8.

Excess Flow Valve with Removable Basket, Dwg. 106–6, July 1993 .............................................. 178.337–8.

Standards for Housing and Manway Covers for Steel Cargo Tanks, Dwgs. 137–1 and 137–2,

September 1, 1982.

178.337–10.

Typical Manway Arrangement Chlorine Cargo Tank, Dwg 137–5, November 1996 ....................... 178.337–10.

Canadian General Standards Board, Place du Portage III, 6B1 11 ............................................................... 171.12

Laurier Street, Gatineau, Quebec, Canada K1A 1G6

National Standard of Canada (CAN/CGSB 43.147—2005) Construction, Modification, Qualifica-

tion, Maintenance, and Selection and Use of Means of Containment for the Handling, Offering

for Transport, or Transportation of Dangerous Goods by Rail.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00107 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

98

49 CFR Ch. I (10–1–12 Edition) § 171.7

Source and name of material 49 CFR reference

CGA Pamphlet C–3, Standards for Welding on Thin-Walled Steel Cylinders, 1994 ....................... 178.47; 178.50;

178.51; 178.53;

178.55; 178.56;

178.57; 178.58;

178.59; 178.60;

178.61; 178.65;

178.68; 180.211.

CGA C–5, Cylinder Service Life—Seamless Steel High Pressure Cylinders, 1991 (reaffirmed

1995).

173.302a.

CGA Pamphlet C–6, Standards for Visual Inspection of Steel Compressed Gas Cylinders, 1993 173.3, 173.198,

180.205, 180.209,

180.211, 180.411,

180.519.

CGA Pamphlet C–6.1, Standards for Visual Inspection of High Pressure Aluminum Compressed

Gas Cylinders, 2002, Fourth Edition.

180.205; 180.209

CGA Pamphlet C–6.2, Guidelines for Visual Inspection and Requalification of Fiber Reinforced

High Pressure Cylinders, 1996, Third Edition.

180.205.

CGA Pamphlet C–6.3, Guidelines for Visual Inspection and Requalification of Low Pressure Alu-

minum Compressed Gas Cylinders, 1991.

180.205; 180.209.

CGA C–7, Guide to Preparation of Precautionary Labeling and Marking of Compressed Gas

Containers, Appendix A, issued 2004 (8th Edition).

172.400a.

CGA Pamphlet C–8, Standard for Requalification of DOT-3HT Cylinder Design, 1985 .................. 180.205; 180.209.

CGA Pamphlet C–11, Recommended Practices for Inspection of Compressed Gas Cylinders at

Time of Manufacture, 2001, Third Edition.

178.35.

CGA Pamphlet C–12, Qualification Procedure for Acetylene Cylinder Design, 1994 ...................... 173.301; 173.303;

178.59; 178.60.

CGA Pamphlet C–13, Guidelines for Periodic Visual Inspection and Requalification of Acetylene

Cylinders, 2000, Fourth Edition.

173.303; 180.205;

180.209.

CGA Pamphlet C–14, Procedures for Fire Testing of DOT Cylinder Pressure Relief Device Sys-

tems, 1979.

173.301; 173.323.

CGA Pamphlet G–2.2, Guideline Method for Determining Minimum of 0.2% Water in Anhydrous

Ammonia, 1985, Second Edition, Reaffirmed 1997.

173.315.

CGA Pamphlet G–4.1, Cleaning Equipment for Oxygen Service, 1985 .......................................... 178.338–15.

CGA Pamphlet P–20, Standard for the Classification of Toxic Gas Mixtures, 2003, Third Edition ............... 173.115.

CGA Pamphlet P–20, Standard for the Classification of Toxic Gas Mixtures, 1995 ....................... 173.115.

CGA S–1.1, Pressure Relief Device Standards—Part 1—Cylinders for Compressed Gases, 2005

(with the exception of paragraph 9.1.1.1), Twelfth Edition.

173.301, 173.304a

178.75.

CGA Pamphlet S–1.2, Safety Relief Device Standards Part 2—Cargo and Portable Tanks for

Compressed Gases, 1980.

173.315; 173.318;

178.276; 178.277.

CGA S–7, Method for Selecting Pressure Relief Devices for Compressed Gas Mixtures in Cyl-

inders, 2005.

173.301.

CGA Technical Bulletin TB–2, Guidelines for Inspection and Repair of MC–330 and MC–331

Cargo Tanks, 1980.

180.407; 180.413.

CGA Technical Bulletin TB–25, Design Considerations for Tube Trailers, 2008 Edition ................. 173.301.

Department of Defense (DOD), 2461 Eisenhower Avenue, Alexandria, VA 22331:

DOD TB 700–2; NAVSEAINST 8020.8B; AFTO 11A–1–47; DLAR 8220.1: Explosives Hazard

Classification Procedures, January 1998.

173.56.

Packaging of Hazardous Material, DLAD 4145.41/ AR 700–143/AFJI 24–210/NAVSUPINST

4030.55B/MCO 4030.40B, January 14, 2000.

173.7

Department of Energy (USDOE), 100 Independence Avenue SW., Washington, DC 20545:

USDOE publications available from: Superintendent of Documents, Government Printing Office

(GPO) or The National Technical Information Service (NTIS).

USDOE, CAPE–1662, Revision 1, and Supplement 1, Civilian Application Program Engineering

Drawings, April 6, 1988.

178.356–1;

178.356–2;

178.358–1;

178.358–2;

178.358–3;

178.358–4.

USDOE, Material and Equipment Specification No. SP–9, Rev. 1, and Supplement—Fire Resist-

ant Phenolic Foam, March 28, 1968.

178.356–2;

178.358–2.

USDOE, KSS–471, November 30, 1986—Proposal for Modifications to U.S. Department of

Transportation Specification 21PF–1, Fire and Shock Resistant Phenolic Foam—Insulated

Metal Overpack.

178.358–1;

178.358–3.

General Services Administration, Specification Office, Room 6662, 7th and D Street, S.W., Washington,

DC 20407:

Federal Specification RR-C–901D, Cylinders, Compressed Gas: Seamless Shatterproof, High

Pressure DOT 3AA Steel, and 3AL Aluminum, February 21, 2003 (Superseding RR-C–901C,

1981).

173.302; 173.336;

173.337.

Institute of Makers of Explosives, 1120 19th Street NW., Suite 310, Washington, DC 20036–3605:

IME Safety Library Publication No. 22 (IME Standard 22), Recommendations for the Safe Transportation

of Detonators in a Vehicle with Certain Other Explosive Materials, February 2007.

173.63; 177.835

International Atomic Energy Agency (IAEA), P.O. Box 100, Wagramer Strasse 5, A–1400 Vienna, Austria:

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00108 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

99

Pipeline and Hazardous Materials Safety Admin., DOT § 171.7

Source and name of material 49 CFR reference

Also available from: Bernan Associates, 4611–F Assembly Drive, Lanham, MD 20706–4391,

USA; or Renouf Publishing Company, Ltd., 812 Proctor Avenue, Ogdensburg, New York

13669, USA.

IAEA, Regulations for the Safe Transport of Radioactive Material, (IAEA Regulations), 1996 Edi-

tion (Revised), No. TS-R-1 (ST-1, Revised).

171.22; 171.23;

171.26, 173.415,

173.416, 173.417,

173.473

International Civil Aviation Organization (‘‘ICAO’’), 999 University Street, Montre

´

al, Quebec H3C 5H7,

Canada, 1–514–954–8219, http://www.icao.int:

ICAO Technical Instructions available from: INTEREG, International Regulations, Publishing and

Distribution Organization, P.O. Box 60105, Chicago, IL 60660.

Technical Instructions for the Safe Transport of Dangerous Goods by Air (ICAO Technical Instructions),

2011–2012 Edition.

171.8; 171.22;

171.23; 171.24;

172.101; 172.202;

172.401; 172.512;

172.519; 172.602;

172.704; 173.1;

173.56; 173.320;

175.33; 178.3.

International Electrotechnical Commission (IEC) 3, rue de Varembe

´

, P.O. Box 131, CH—1211, GENEVA

20, Switzerland:

Fuel cell technologies—Part 6–1: Micro fuel cell power systems—Safety, IEC/PAS 62282–6–

1:2006(E), First Edition 2006–02, with Corrigendum 1, First Edition 2007–04.

§ 175.10.

International Maritime Organization (‘‘IMO’’), 4 Albert Embankment, London, SE1 7SR, United Kingdom

or New York Nautical Instrument & Service Corporation, 140 West Broadway, New York, NY 10013,

+44 (0) 20 7735 7611, http://www.imo.org:

International Convention for the Safety of Life at Sea, 1974, as amended (SOLAS), Chapter II–2, Con-

struction—Fire protection, fire detection and fire extinction, Regulation 19, Carriage of dangerous

goods, Consolidated Edition 2009.

176.63, 176.84

International Maritime Dangerous Goods Code (IMDG Code), 2010 Edition, Incorporating Amendment

35–10 (English Edition), Volumes 1 and 2.

171.22; 171.23;

171.25; 172.101

172.202; 172.203

172.401; 172.502;

172.519; 172.602;

172.704; 173.1;

173.21; 173.56;

173.320; 176.2;

176.5; 176.11;

176.27; 176.30;

176.83; 176.84;

176.140; 176.720;

178.3; 178.274.

International Organization for Standardization, Case Postale 56, CH–1211, Geneve 20, Switzerland,

http://www.iso.org:

Also available from: ANSI 25, West 43rd Street, New York, NY 10036, 1–212–642–4900, http://

www.ansi.org.

ISO 535–1991(E) Paper and board—Determination of water absorptiveness—Cobb method ....... 178.516; 178.707;

178.708.

ISO 1496–1: 1990 (E)—Series 1 freight containers—Specification and testing, Part 1: General

cargo containers. Fifth Edition, (August 15, 1990).

173.411

ISO 1496–3—Series 1 freight containers—Specification and testing—Part 3: Tank containers for

liquids, gases and pressurized dry bulk, Fourth edition, March 1995, (E).

178.74; 178.75;

178.274.

ISO 1516:2002(E), Determination of flash/no flash—Closed cup equilibrium method, Third Edition, 2002–

03–01.

173.120.

ISO 1523:2002(E), Determination of flash point—Closed cup equilibrium method, Third Edition, 2002–03–

01.

173.120.

ISO 2431–1984(E) Standard Cup Method ........................................................................................ 173.121.

ISO 2592:2000(E), Determination of flash and fire points—Cleveland open cup method, Second Edition,

2000–09–15.

173.120.

ISO 2719:2002(E), Determination of flash point—Pensky-Martens closed cup method, Third Edition,

2002–11–15.

173.120.

ISO 2919–1980(E) Sealed radioactive sources—Classification ....................................................... 173.469.

ISO 3036–1975(E) Board—Determination of puncture resistance ................................................... 178.708.

ISO 3405:2000(E), Petroleum products—Determination of distillation characteristics at atmospheric pres-

sure, Third Edition, 2000–03–01.

173.121.

ISO 3574–1986(E) Cold-reduced carbon steel sheet of commercial and drawing qualities ............ 178.503; Part 178,

appendix C.

ISO 3679:2004(E), Determination of flash point—Rapid equilibrium closed cup method, Third Edition,

2004–04–01.

173.120.

ISO 3680:2004(E), Determination of flash/no flash—Rapid equilibrium closed cup method, Fourth Edition,

2004–04–01.

173.120.

ISO 3807–2, Cylinders for acetylene—Basic requirements—Part 2: Cylinders with fusible plugs,

First edition, March 2000, (E).

173.303; 178.71.

VerDate Mar<15>2010 14:52 Nov 15, 2012 Jkt 226218 PO 00000 Frm 00109 Fmt 8010 Sfmt 8010 Q:\49\49V2.TXT ofr150 PsN: PC150

100

49 CFR Ch. I (10–1–12 Edition) § 171.7

Source and name of material 49 CFR reference

ISO 3924:1999(E), Petroleum products—Determination of boiling range distribution—Gas chroma-

tography method, Second Edition, 1999–08–01.

173.121.

ISO 4126–1 Safety valves—Part 1: General Requirements, December 15, 1991, First Edition ..... 178.274.

ISO 4626:1980(E), Volatile organic liquids—Determination of boiling range of organic solvents used as

raw materials, First Edition, 1980–03–01.

173.121.

ISO 4706:2008(E), Gas cylinders—Refillable welded steel cylinders—Test pressure 60 bar and below,

First Edition, 2008–04–15, Corrected Version, 2008–07–01.

178.71.

ISO 6406, Gas cylinders—Seamless steel gas cylinders—Periodic inspection and testing, Sec-

ond edition, February 2005, (E).

180.207.

ISO 6892 Metallic materials—Tensile testing, July 15, 1984, First Edition ...................................... 178.274.

ISO 7225, Gas cylinders—Precautionary labels, Second Edition, July 2005, (E) ........................... 178.71.

ISO 7866, Gas cylinders—Refillable seamless aluminum alloy gas cylinders—Design, construc-

tion and testing, First edition, June 1999, (E).

178.71.

ISO 8115 Cotton bales—Dimensions and density, 1986 Edition ..................................................... 172.102.

ISO 9809–1: Gas cylinders—Refillable seamless steel gas cylinders—Design, construction and

testing—Part 1: Quenched and tempered steel cylinders with tensile strength less than 1 100

MPa., First edition, June 1999, (E).

178.37; 178.71;

178.75.

ISO 9809–2: Gas cylinders—Refillable seamless steel gas cylinders—Design, construction and

testing—Part 2: Quenched and tempered steel cylinders with tensile strength greater than or

equal to 1 100 MPa., First edition, June 2000, (E).

178.71; 178.75.

ISO 9809–3: Gas cylinders—Refillable seamless steel gas cylinders—Design, construction and

testing—Part 3: Normalized steel cylinders, First edition, December 2000, (E).

178.71; 178.75.

ISO 9978:1992(E)—Radiation protection—Sealed radioactive sources—Leakage test methods.

First Edition, (February 15, 1992).

173.469.

ISO 10156:1996, Gases and Gas Mixtures—Determination of fire potential and oxidizing ability for the se-

lection of cylinder valve outlets, Second edition, February 1996 (E).

173.115.

ISO 10156–2:2005, Gas cylinders—Gases and gas mixtures—Part 2: Determination of oxidizing ability of

toxic and corrosive gases and gas mixtures, First edition, August 2005, (E).

173.115.

ISO 10297:2006(E), Transportable gas cylinders—Cylinder valves—Specification and type testing, Sec-

ond Edition, 2006–01–15.

173.301b; 178.71.

ISO 10461:2005(E), Gas cylinders—Seamless aluminum-alloy gas cylinders—Periodic inspection and

testing, Second Edition, 2005–02–15 and Amendment 1, 2006–07–15.

180.207.

ISO 10462, Gas cylinders—Transportable cylinders for dissolved acetylene—Periodic inspection

and maintenance, Second edition, February 2005, (E).

180.207.

ISO 10692–2:2001(E), Gas cylinders—Gas cylinder valve connections for use in the micro-electronics in-

dustry—Part 2: Specification and type testing for valve to cylinder connections, First Edition, 2001–08–

01.

173.40.

ISO 11114–1, Transportable gas cylinders—Compatibility of cylinder and valve materials with

gas contents—Part 1: Metallic materials, First edition, October 1997, (E).

173.301b; 178.71.

ISO 11114–2, Transportable gas cylinders—Compatibility of cylinder and valve materials with

gas contents—Part 2: Non-metallic materials, First edition, December 2000, (E).

173.301b; 178.71.

ISO 11117, Gas cylinders—Valve protection caps and valve guards for industrial and medical

gas cylinders—Design, construction and tests, First edition, August 1998, (E).

173.301b.

ISO 11118, Gas cylinders—Non-refillable metallic gas cylinders—Specification and test methods,

First edition, October 1999, (E).

178.71.

ISO 11119–1, Gas cylinders—Gas cylinders of composite construction—Specification and test

methods—Part 1: Hoop-wrapped composite gas cylinders, First edition, May 2002, (E).

178.71.

ISO 11119–2, Gas cylinders—Gas cylinders of composite construction—Specification and test

methods—Part 2: Fully wrapped fibre reinforced composite gas cylinders with load-sharing

metal liners, First edition, May 2002, (E).

178.71.

ISO 11119–3, Gas cylinders of composite construction—Specification and test methods—Part 3:

Fully wrapped fibre reinforced composite gas cylinders with non-load-sharing metallic or non-

metallic liners, First edition, September 2002, (E).

178.71.

ISO 11120, Gas cylinders—Refillable seamless steel tubes of water capacity between 150 L and

3000 L—Design, construction and testing, First edition, March 1999, (E).

178.71; 178.75.

ISO 11621, Gas cylinders—Procedures for change of gas service, First edition, April 1997, (E) .. 173.302, 173.336,

173.337.

ISO 11623, Transportable gas cylinders—Periodic inspection and testing of composite gas cyl-

inders, First edition, March 2002, (E).

180.207.

ISO 13736:2008(E), Determination of flash point—Abel closed-cup method, Second Edition, 2008–09–15 173.120.

ISO 16111:2008(E), Transportable gas storage devices—Hydrogen absorbed in reversible metal hydride,

First Edition, 2008–11–15.

173.301b; 173.311;

178.71.

ISO 18172–1:2007(E), Gas cylinders—Refillable welded stainless steel cylinders—Part 1: Test pressure 6

MPa and below, First Edition, 2007–03–01.

178.71.

ISO 20703:2006(E), Gas cylinders—Refillable welded aluminum-alloy cylinders—Design, construction and