Maintenance Manual 14P

Meritor Tire Inflation System (MTIS™)

Standard MTIS™

MTIS™ with the ThermALERT™ System

Revised 10-19

Service Notes

Information contained in this publication was in effect at the time the publication was

approved for printing and is subject to change without notice or liability. Meritor Heavy

Vehicle Systems, LLC, reserves the right to revise the information presented or to

discontinue the production of parts described at any time.

Meritor Maintenance Manual 14P (Revised 10-19)

About This Manual

This manual provides installation and maintenance procedures for

the Meritor Tire Inflation System (MTIS™). Use the procedures in

this manual to install the standard tire inflation system and the tire

inflation system with ThermALERT™ on either new trailer axles at

original equipment manufacturers or in-service trailer axles at fleets.

NOTE: ThermALERT became a standard feature in all MTIS kits

starting October 1, 2017.

Before You Begin

1. Read and understand all instructions and procedures before

you begin to service components.

2. Read and observe all Warning and Caution hazard alert

messages in this publication. They provide information that can

help prevent serious personal injury, damage to components,

or both.

3. Follow your company’s maintenance and service, installation,

and diagnostics guidelines.

4. Use special tools when required to help avoid serious personal

injury and damage to components.

Hazard Alert Messages and Torque

Symbols

WARNING

A Warning alerts you to an instruction or procedure that you

must follow exactly to avoid serious personal injury and

damage to components.

CAUTION

A Caution alerts you to an instruction or procedure that you

must follow exactly to avoid damage to components.

@This symbol alerts you to tighten fasteners to a specified torque

value.

How to Obtain Additional Maintenance,

Service and Product Information

Visit Literature on Demand at meritor.com to access and order

additional information.

Contact the Meritor OnTrac™ Customer Call Center at

866-668-7221 (United States and Canada); 001-800-889-1834

(Mexico); or email OnTrac@meritor.com.

If Tools and Supplies are Specified in

This Manual

Contact Meritor’s Commercial Vehicle Aftermarket at

888-725-9355 to obtain Meritor tools and supplies.

For Grainger tools, visit their website at www.grainger.com to locate

a branch near you.

pg. pg.

Contents

1 Section 1: Introduction

Overview

2 The Standard Meritor Tire Inflation System (MTIS)

The MTIS with the ThermALERT System

If the MTIS Warning Light Comes ON When the Air System

is Charging

If the MTIS Warning Light Comes ON During Operation

3 Warning Light

Wheel-End Assembly

Controls

4 Installation and Maintenance Information

6

Section 2: Assembly and Installation

Installation on Non-Prepped Axles

Sequence for Installing a Standard MTIS System and an

MTIS System with a ThermALERT System

Axle Air Fitting

7 Prepare a Hollow Spindle Axle to Install the Standard MTIS

and MTIS with the ThermALERT System

12 Prepare a Solid Spindle Axle to Install Standard MTIS

Without the ThermALERT System

16 Stator

Wheel-End Components

19 Air Components

23 Electrical Components

26 Wheel-End Oil

Standard MTIS and ThermALERT System Decals

28

Section 3: Check System Operation

Check System Operation

30 Control Box Adjustment Procedures

34 MTIS Allowable Leak Rate and Test

35 Check the Hose Connections for Leaks

37 Check the Wheel End for Air Leaks

39

Section 4: Pre-Service Check

Pre-Service Check

41

Section 5: Inspection and Maintenance

Tire Inflation System Inspection Interval Guidelines

42 Inspection

Warning Light

Tires

43 Component Removal and Installation

Turn the System OFF

44 Remove and Replace the Tires

45 Hose Check Valves

Remove the Thru-Tee Before Installing a Hubcap

47

Section 6: Troubleshooting

Diagnostics

49

Section 7: Special Tools

Special Tools

Tire Inflation System

1 Introduction

1

Meritor Maintenance Manual MM-14P (Revised 10-19)

1 Introduction

Overview

Figure 1.1

Figure 1.1

SHORT

HOSE

HUBCAP

HUBCAP

RELIEF

VALVE

THRU-TEE

STATOR

LONG

HOSE

DEFLECTOR SHIELD

WHEEL-END ASSEMBLY

TRAILER

AIR TANK

AIR SUPPLY

LINE

PRESSURE

PROTECTION VALVE

(PPV)

WARNING

LIGHT

WARNING LIGHT

TRAILER AXLE

SPINDLE

AXLE

PRESS PLUG

DRAIN

PETCOCK

PARTICULATE

FILTER

FLOW SENSING

SWITCH

SYSTEM

ON/OFF

VALVE

SYSTEM PRESSURE

A DJU STMENT KNOB

PRESSURE

PROTECTION

VA LVE (PPV)

CONTROL BOX

(ORIGINAL DESIGN)

4016802c

TUBE

ThermALERT™ SYSTEM

DECAL

LIQUID TIGHT

FITTING

PARTICULATE

FILTER

SYSTEM

ON/OFF VALVE

REGULATED AIR

TO SUPPLY AXLES

AIR FROM PRESSURE

PROTECTION VALVE

CONTROL BOX

(MANIFOLD DESIGN)

MAINTENANCE

DRAIN VALVE

SYSTEM

PRESSURE

REGULATOR

FLOW SENSING

SWITCH

1 Introduction

2

Meritor Maintenance Manual MM-14P (Revised 10-19)

The Standard Meritor Tire Inflation System

(MTIS)

The Meritor Tire Inflation System (MTIS) uses compressed air from

the trailer to inflate any tire that falls below the system air pressure

setting during operation.

Air from the existing trailer air supply is routed to a control box, then

into each axle. Refer to Figure 1.1. The axles act as conduits to

distribute air through rotary union assemblies at the spindle ends,

which then distribute air to each tire as needed. If a tire is leaking,

check valves in the tire delivery lines prevent loss of pressure in the

remaining tires.

The MTIS warning light on the front of the trailer will come ON to

alert you if there is an excessive amount of air flow through the

system, which can be caused by a leaking tire or a loose

connection, or both. If the warning light comes ON during operation,

immediately find a safe place to bring the tractor and trailer to a

complete stop. You must repair components that caused the air leak

before returning the vehicle to service.

Standard MTIS does not eliminate the need to perform tire

inspections or wheel-end maintenance at regularly-scheduled

intervals.

The MTIS with the ThermALERT System

NOTE: ThermALERT became a standard feature in all MTIS kits

starting October 1, 2017.

The MTIS with the ThermALERT system detects when air is

escaping from the axle’s thermal plug and out through the hubcap

relief valve, which occurs if a wheel end is operating at an

abnormally high temperature. The MTIS warning light will come ON

to alert you to immediately find a safe place to bring the tractor and

trailer to a complete stop.

Air escaping from the hubcap relief valve produces an audible noise,

which helps you to identify the wheel end that is overheated. Do not

operate the trailer until the components are repaired.

The MTIS ThermALERT system does not eliminate the need to

perform tire inspections at regularly-scheduled intervals.

If the MTIS Warning Light Comes ON When

the Air System is Charging

When you start a vehicle, the MTIS warning light initially may come

ON while the air system is charging. However, if the warning light

stays ON for more than 10 minutes, a tire may be damaged and

losing air pressure. Inspect the tires for damage and air leaks.

Repair damaged or leaking tires before returning the vehicle to

service.

If the MTIS Warning Light Comes ON During

Operation

WARNING

If the ThermALERT system activates during vehicle operation,

you must repair or replace components that caused the wheel

end to overheat before returning the vehicle to service. Upon

activation, the thermal plug must be removed and replaced.

The thermal plug is not reusable. Otherwise, the warning light

will continue to remain ON during vehicle operation, even

though the wheel end has been repaired. If you ignore the

warning light, and another wheel end overheats during

operation, serious personal injury and damage to components

can result.

The MTIS with the ThermALERT system detects when air is

escaping from the axle’s thermal plug and out through the hubcap

relief valve, which occurs if a wheel end is operating at an

abnormally high temperature. The MTIS warning light will come ON

to alert you that air flow through the system is excessive.

1. Immediately find a safe place to bring the tractor and trailer to

a complete stop.

2. Inspect the trailer hubs for air leaks.

3. Listen for the ThermALERT system’s audible sound at the

wheel end. If you hear the sound, the wheel end is overheated.

Do not operate the trailer until the wheel-end components are

repaired. If a wheel end overheats during operation, it can

separate from the vehicle. Serious personal injury and damage

to components can result.

4. If you do not hear the ThermALERT system’s audible sound at

the wheel end, inspect the tires for damage. Repair damaged

or leaking tires before returning the vehicle to service.

1 Introduction

3

Meritor Maintenance Manual MM-14P (Revised 10-19)

Warning Light

A warning light mounted to the trailer comes ON when the system

delivers an excessive amount of air due to a leaking tire, tire inflation

system component, or if equipped with a ThermALERT system, a

wheel end operating at an abnormally high temperature.

An MTIS system with a ThermALERT system will also have a

ThermALERT system decal installed at the warning light on the

trailer.

Wheel-End Assembly

Stator and Thru-Tee

The stator is located inside the axle spindle and the thru-tee is

attached to the hubcap. Pressurized air passes from the stationary

axle interior to the rotating hub through a tube extending from the

thru-tee into the stator. Dynamic seals, located in the thru-tee and

stator, allow rotation without loss of air pressure.

Hoses

A hose is a flexible valve stem extension which mechanically opens

the tire valve core and allows air to pass into a tire. A check valve

located at the knurled end of a hose allows air to flow in only one

direction-towards the tire. This protects each tire from loss of air

pressure if the tire inflation system, or any tire, loses air pressure

during operation.

Deflector Shield

The deflector shield helps prevent any contaminants such as dirt

and water from entering the wheel end.

Hubcaps

CAUTION

The Meritor Tire Inflation System (MTIS) that is equipped with

the ThermALERT system uses hubcaps with six vent tubes.

These hubcaps are not interchangeable with the three-vent

tubes. Damage to components can result if you install the

incorrect hubcaps.

The hubcaps for MTIS with and without the ThermALERT system use

vents to prevent pressure buildup in the wheel end, as well as a

deflector shield to help prevent contaminants from entering the

wheel end.

Hubcaps for oil-lubricated wheel ends typically have a fill plug for

adding lubricant.

Axle Press Plug

The axle press plug is used in axles with hollow spindles to seal off

the pressurized axle interior from the wheel end and provide a

means of holding and securing the stator.

Refer to Figure 1.2 for a comparison of the standard MTIS axle

press plug and the ThermALERT system axle press plug.

Figure 1.2

NOTE: ThermALERT became a standard feature in all MTIS kits

starting October 1, 2017.

Controls

Particulate Filter

The particulate filter removes contaminants from the air system.

Flow Sensing Switch

WARNING

The standard MTIS can have a control box with either a black

flow sensing switch or a grey flow sensing switch. Both

control boxes mount to the trailer in the same way. However,

MTIS equipped with a ThermALERT system must have a

control box with a grey flow sensing switch, which is more

sensitive to air flow than the black switch.

If a ThermALERT system has a control box with a black flow

sensing switch, replace it with a control box that has a grey

switch. Otherwise, the warning light may not come ON if a

wheel end overheats. Serious personal injury and damage to

components can result.

Figure 1.2

4006188d

THERMAL

PLUG

A

XLE PRESS PLUG

AXLE PRESS PLUG

MTIS with

ThermALERT

MTIS without

ThermALERT

1 Introduction

4

Meritor Maintenance Manual MM-14P (Revised 10-19)

The flow sensing switch illuminates the warning light when the

system delivers an excessive amount of air to either a leaking tire, a

leaking tire inflation system component; or if equipped with the

ThermALERT system, a wheel end operating at an abnormally high

temperature.

The control box for the standard MTIS can include a flow sensing

switch that is either black or grey. The control box for the MTIS with

the ThermALERT system must include a grey flow sensing switch.

Both control boxes mount to the trailer in the same way.

Drain Petcock

The drain petcock is used to manually exhaust pressure from the

tire inflation system. This enables you to perform maintenance on

either the trailer axle components or the tire inflation system.

System Pressure Adjustment Knob

The system pressure adjustment knob is used to adjust system air

pressure. The system air pressure should be adjusted to the

customer’s recommended tire pressure.

System On/Off Valve

The system on/off valve allows air delivery to the system and also

stops air delivery to the system.

Pressure Protection Valve (PPV)

CAUTION

Only use the pressure protection valve (PPV) provided in the

Meritor Tire Inflation System (MTIS) kit during installation. Do

not install any other PPV, which will void Meritor’s warranty

and can damage components.

The pressure protection valve (PPV) ensures that air is available for

other trailer functions and maintains air tank pressure if a tire or a

tire inflation system component is damaged. During the installation

process, only use the PPV provided in the Meritor Tire Inflation

System (MTIS) kit.

Installation and Maintenance Information

Use the procedures in this manual to install the tire inflation system

on either new trailer axles at original equipment manufacturers or

in-service axles at fleets.

The tire inflation system can be installed onto trailer axles

manufactured either by Meritor, Holland, Hendrickson, Ingersoll,

Dana, Eaton, Sudisa, Fuwa or AXN. When installing the system,

follow the maintenance instructions provided by these various

manufacturers. For trailer axles manufactured by Meritor, refer to

Maintenance Manual 14, Trailer Axles. To obtain this publication,

refer to the Service Notes page on the front inside cover of this

manual.

Trailer axles may be manufactured with either hollow or solid

spindles. The system installation sequence is different depending on

the axle type. Please refer to the information in the following

sections.

NOTE: Up until September 30, 2017, Meritor provided axle models

prepped for installation of the standard tire inflation and the

ThermALERT system. As of October 1, 2017, Meritor only provides

axle models prepped for installation of MTIS with the ThermALERT

system. The system installation sequence is different depending on

the axle type. Refer to the information in the following sections.

Hollow Spindle Axle

Most hollow spindle trailer axles have a spindle that’s integrally

formed out of axle tube material. A welsh plug is pressed into a

machined recess in the end of the spindle. If you’re unsure of the

axle type, contact the axle manufacturer. Figure 1.3.

Figure 1.3

Solid Spindle Axle

Most solid spindle trailer axles have a forged spindle welded to the

axle tube. If you’re unsure of the axle type, contact the axle

manufacturer. Figure 1.4.

Figure 1.3

PRESS

PLUG

HOLLOW SPINDLE

4000407a

1 Introduction

5

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 1.4

Prepped Axle

A trailer axle that has been prepped by Meritor has the following

provisions. Other axle manufacturers’ prep may vary.

앫 Debris has been cleaned from the axle interior.

앫 The standard tire inflation system axle press plug and stator are

installed into the axle spindle. Figure 1.5.

앫 If equipped with the ThermALERT system, the axle press plug

with the thermal plug and stator are installed into the axle

spindle. The thermal plug must be installed at the 12 o’clock

position when the axle is sitting in the running position.

Figure 1.6.

앫 The axle top-center hole is tapped to accept the tire inflation

system axle air fitting, and a plug is installed into this hole. Some

axle manufacturers may select an alternate location for this hole.

Figure 1.7.

Figure 1.5

Figure 1.6

Figure 1.7

Figure 1.4

Figure 1.5

AVAILABLE ON PREPPED AXLES PRIOR TO OCTOBER 1, 2017.

SOLID SPINDLE

4000408a

AXLE

PRESS PLUG

STATOR

4000410a

STANDARD MTIS

Figure 1.6

AVAILABLE ON PREPPED AXLES AS OF OCTOBER 1, 2017.

Figure 1.7

AXLE

PRESS PLUG

4006189a

MTIS with ThermALERT

THERMAL

PLUG

STATOR

TAPPED TOP-CENTER HOLE

PLUG

4000409a

6

Meritor Maintenance Manual MM-14P (Revised 10-19)

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury and

damage to components can result.

Installation on Non-Prepped Axles

Sequence for Installing a Standard MTIS

System and an MTIS System with a

ThermALERT System

1. Install the axle air fitting.

2. Prepare the axle.

3. Install the stator.

4. Install the wheel-end components.

5. Follow the remaining sections in the manual for the air and

electrical components.

Axle Air Fitting

1. Wear safe eye protection.

2. Park the vehicle on a level surface. Block the wheels to prevent

the vehicle from moving.

3. On Meritor axles, locate the top-center of the axle, which is the

preferred location for the axle air fitting. For other axle

manufacturers, this location may vary. If the axle manufacturer

has installed a top-center hole in the axle, use this hole as a

pilot when you drill for the air fitting. Figure 2.1.

Figure 2.1

4. Use drilling lubricant and a variable speed electrical drill to drill

an 11/32-inch diameter hole STRAIGHT into the top-center of

the axle. Figure 2.2.

Figure 2.2

5. Use tapping fluid and a 1/8-27 inch NPT tap to thread the

drilled hole STRAIGHT into the axle. Do not run the tap

completely through the hole. Leave 1/4- to 3/8-inch of the tap

threads exposed. Figure 2.3.

Figure 2.1

Figure 2.2

AXLE

TOP-CENTER

4000411a

DRILL

4000412a

7

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.3

6. Hand-tighten the axle air fitting into the tapped hole. Then use

a wrench to tighten the fitting 2-1/2 additional turns to obtain

an air tight seal. Continue to tighten until the fitting faces

TOWARD the side of the trailer where you’ll install the system

control box. Figure 2.4. It is not necessary to apply a sealer

when the axle air fitting is first installed if current production

fittings have sealant pre-applied to the threads. If the part is

removed, however, apply a sealant tape to the threads prior to

reinstalling. Figure 2.5.

Figure 2.4

Figure 2.5

Prepare a Hollow Spindle Axle to Install the

Standard MTIS and MTIS with the

ThermALERT System

CAUTION

Cover the wheel ends at both ends of the axle during system

installation to prevent contaminants from entering the wheel

end. Damage to the bearings and seals can result.

1. Wear safe eye protection.

2. Park the vehicle on a level surface. Block the wheels to prevent

the vehicle from moving.

3. Place a container under the hubcap to receive the draining oil.

Then, remove the hubcap and hubcap gasket from both ends

of the axle. Figure 2.6. Do not reuse either the hubcap gasket

or the oil.

Figure 2.6

Figure 2.3

Figure 2.4

TAP

1/4"-3/8"

4000413a

4005324a

AXLE

AIR

FITTING

AXLE

AIR FITTING

Figure 2.5

Figure 2.6

SEALANT

TAPE

NEW FITTING

PRE-APPLIED

SEALANT

REINSTALLING FITTING

4006111a

1003654b

8

Meritor Maintenance Manual MM-14P (Revised 10-19)

4. Cover the wheel ends at both ends of the axle with a clean

towel. Figure 2.7.

Figure 2.7

5. Use a slide hammer fitted with the welsh plug removal spear to

remove the spindle welsh plugs from both ends of the axle. Use

care not to score the inside diameter of the spindle bore.

Figure 2.8. A slide hammer and welsh plug removal spear are

available from Meritor to help remove these plugs. Refer to

Section 7 for part numbers of special tools and supplies.

Figure 2.8

CAUTION

Use a bore polisher to remove all old adhesive from the spindle

bore before you apply retaining compound to install the axle

press plug. Retaining compound must contact a bare metal

surface or it will not harden. Damage to components can

result.

6. Choose the correct sized bore polisher by matching the axle

manufacturer and model to the bore polishing tools listed in

Section 7. Figure 2.9.

Figure 2.9

7. Polish the spindle bore to remove all adhesive residue left from

the old spindle plug and any metal burrs or sharp edges from

the spindle bore surface. Figure 2.10.

앫 If the axle spindle is equipped with cotter pin holes:

Use a round abrasive tool to remove all metal burrs and

sharp edges from the spindle bore side of the cotter pin

holes. Figure 2.11.

Figure 2.10

Figure 2.7

Figure 2.8

4000436a

Cover both

ends of the

axle with a

clean towel.

4006112a

WELSH

PLUG

REMOVAL

SPEAR

WELSH

PLUG

REMOVAL

SPEAR

SLIDE

HAMMER

SLIDE

HAMMER

Figure 2.9

Figure 2.10

STRAIGHT

DIE GRINDER

BORE

POLISHER

MANDREL

4000418a

BORE POLISHING

4000419a

9

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.11

CAUTION

Use a cleaning wand and high-volume air to clean debris from

the axle interior before you install the tire inflation system axle

press plugs. Check that the axle is clear of debris, including

loose rust, scale, liquid and machining residue. A

contaminated axle can damage the tire inflation system and

void the warranty.

8. Connect a cleaning wand to a high-volume air supply. Refer to

Section 7 for information on building a cleaning wand.

Figure 2.12. Slowly push the wand through the axle until it

exits the opposite end. During this operation, a steady stream

of air will be blowing from the axle spindle. Figure 2.13.

Figure 2.12

Figure 2.13

9. Check the inside of the axle tube with a flashlight by shining

the light into one end of the spindle and looking through the

opposite end. Confirm that all debris, including loose rust,

scale, liquid and machining residue has been removed.

Figure 2.14.

앫 If necessary: Repeat the cleaning procedure until the axle

is clear of debris. For debris that’s difficult to remove, it may

be helpful to push the cleaning wand through the axle from

the opposite end.

Figure 2.14

10. Choose the correct axle press plug drive adapter by matching

the axle manufacturer and model to the axle press plug drive

adapters. Refer to Section 7. Figure 2.15. Current production

axle press plug drive adapters are identified with a number

stamped on the part. Some early adapters were not marked.

Figure 2.11

Figure 2.12

ABRASIVE

TOOL

COTTER

PIN HOLE

4000420a

Build from 1/2"

galvanized pipe.

Overall

length must

exceed the

interior

length of the

trailer axle.

Drill pipe

cap with

3/32" drill

positioned

as shown.

45

6 HOLES

CLEANING

WAND

ON-OFF VALVE

4000489a

45°

Figure 2.13

Figure 2.14

CLEANING

WAND

AIR

SUPPLY

CLEANING

WAND

4000422b

FLASHLIGHT

SPINDLE

END

4000695a

10

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.15

11. Install the axle press plug drive adapter onto the drive handle.

Figure 2.16.

Figure 2.16

12. Clean the exposed O-ring surface and outside diameter surface

of one axle press plug using a towelette provided in the

installation kit. Use a new towelette for each wheel end. Protect

the cleaned plug from additional contaminants. Figure 2.17.

Figure 2.17

13. Use the same towelette to clean one spindle bore of

contaminants such as grinding dust, dirt and wheel-end

lubricant. Protect the cleaned bore from additional

contaminants. Figure 2.18.

Figure 2.18

CAUTION

Only use the retaining compound supplied in the installation

kit when you install the axle press plug. Only apply retaining

compound to the OUTSIDE diameter of the axle press plug. Do

not apply it to the inside diameter of the spindle bore, axle

press plug stator threads or axle spindle threads. Damage to

components can result.

14. Put on a new pair of latex gloves. Apply only the approved

retaining compound included in the installation kit evenly to the

OUTSIDE diameter of the axle press plug. The installation kit

contains enough retaining compound for four wheel ends.

Divide the material equally among the wheel ends. The axle

press plug must be installed within 10 minutes of applying the

retaining compound to ensure that the compound hardens

correctly. Loctite

620, 3M RT20 and PermaBond HH 0040

are all approved retaining compounds. Figure 2.19.

Figure 2.19

Figure 2.15

Figure 2.16

Figure 2.17

DRIVE HANDLE

AXLE PRESS PLUG DRIVE ADAPTERS

-01 -02 -03 -04

4000423a

AXLE PRESS PLUG

DRIVE ADAPTER

DRIVE HANDLE

4000424a

AXLE

PRESS PLUG

TOWELETTE

4000425a

Figure 2.18

Figure 2.19

TOWELETTE

4000426a

Apply retaining compound

to this surface.

AXLE

PRESS

PLUG

4000427a

11

Meritor Maintenance Manual MM-14P (Revised 10-19)

15. If you are installing an axle press plug fitted with a thermal plug

for a ThermALERT system, install the axle press plug with the

thermal plug positioned at 12 o’clock ( 15 degrees).

Figure 2.20.

Figure 2.20

16. Insert the axle press plug into the spindle bore by hand until the

plug stops in the bore. Figure 2.21.

앫 For Holland Propar Axles Only: The axle press plug slots

must align with the spindle cotter pin holes. Figure 2.22.

Figure 2.21

Figure 2.22

17. Check that the axle press plug protrudes from 1/8-1/4-inch

(3.175-6.35 mm) from the end of the spindle. Figure 2.23.

앫 If the axle press plug protrudes outside this acceptable

range: Before proceeding, contact the Meritor OnTrac™

Customer Call Center at 866-OnTrac1 (668-7221).

앫 If the axle press plug is fitted with a thermal plug for a

ThermALERT system: Ensure that the thermal plug is

located UP at the 12 o’clock ( 15 degrees) position when

the axle is installed under the trailer. Figure 2.20.

Figure 2.23

18. Insert the axle press plug drive adapter into the axle press plug.

Figure 2.24.

Figure 2.20

Figure 2.21

4006190a

12 O’CLOCK

POSITION

(±15°)

THERMAL

PLUG

AXLE

AXLE

PRESS

PLUG

4000428a

Figure 2.22

Figure 2.23

AXLE

PRESS

PLUG

SLOT

SPINDLE

COTTER

PIN HOLE

HOLLAND PROPAR AXLES

4000429a

AXLE

PRESS

PLUG

1/8-1/4"

(3.175-6.35 MM)

4000430a

12

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.24

WARNING

Use a brass or synthetic mallet for assembly and disassembly

procedures. Do not hit steel parts with a steel hammer. Pieces

of a part can break off. Serious personal injury and damage to

components can result.

CAUTION

The installed axle press plug must be seated square to the end

of the spindle and inset at or below any chamfer in the axle

spindle bore. An axle press plug that is flush with the end of

the spindle is not seated correctly. Damage to components can

result.

19. Use a four-pound brass or synthetic mallet to drive the axle

press plug into the spindle bore, until the drive adapter bottoms

out squarely on the end of the spindle. The drive adapter sets

the axle press plug installation depth. There will be a definite

change in the sound and feel of the hammering when the drive

adapter bottoms out. The tire inflation system can be

pressurized 30 minutes after installation of the axle press plug.

Figure 2.25.

Figure 2.25

20. Wipe off all retaining compound residue from the spindle and

axle press plug drive adapter. Figure 2.26.

Figure 2.26

Prepare a Solid Spindle Axle to Install

Standard MTIS Without the ThermALERT

System

Important Note: The ThermALERT system cannot be installed onto

a solid spindle axle.

Only use Meritor’s drill jig (part number 81023-00) to drill a hole into

a solid spindle axle to install the tire inflation system. Refer to the

Service Notes page on the front inside cover of this manual to obtain

the drill jig.

1. Wear safe eye protection.

CAUTION

Use only Meritor’s solid spindle drill jig (part number

81023-00) to drill a hole into a solid spindle axle to install the

tire inflation system. Meritor’s drill jig helps to ensure that the

hole will be concentric to the spindle end circumference. Do

not drill a hole into the axle by hand. Do not use a drill jig from

another manufacturer, or install the drill jig as an assembly.

Damage to components can result.

2. Use a Meritor drill jig. Correctly support the Meritor drill jig with

at least two full spindle threads. If necessary, remove the trailer

axle outer spindle nut to expose at least two full threads.

Figure 2.27.

Figure 2.24

Figure 2.25

AXLE PRESS

PLUG

AXLE PRESS

PLUG DRIVE

ADAPTER

4000431a

AXLE PRESS PLUG

DRIVE

ADAPTER

BOTTOMS OUT HERE

4000432a

Figure 2.26

AXLE

PRESS PLUG

DRIVE

ADAPTER

4000433a

13

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.27

CAUTION

Cover the wheel ends at both ends of the axle during system

installation to prevent contaminants from entering the wheel

end. Damage to the bearings and seals can result.

3. Cover the wheel ends at both ends of the axle with a clean

towel. Figure 2.28.

Figure 2.28

4. Clean the drill jig spindle installation nut and the axle spindle

nut. This will allow the drill jig to be correctly concentric to the

axle.

5. Install the 12 x 7/16-inch diameter drill bit into the drill.

Figure 2.29.

Figure 2.29

6. Thread the guide rails onto the axle spindle. Use a bar to

tighten the rails. Figure 2.30.

Figure 2.27

OUTER

SPINDLE

NUT

TWO

THREADS

4000435a

Figure 2.28

4000436a

Cover both

ends of the

axle with a

clean towel.

Figure 2.29

GUIDE

RAILS

DRILL

BIT

SPINDLE

INSTALLATION

NUT

FEED

GUIDE

DRILL MOTOR

ASSEMBLY

GUIDE RAIL

BUSHINGS

ADVANCING

HANDLE

ADVANCING

SCREW

DRILL BIT

GUIDE

4000434a

DRILL JIG — SOLID SPINDLE

14

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.30

7. Slide the drill motor assembly onto the guide rails. Ensure that

the drill bit is inserted into the drill bit guide. Figure 2.31 and

Figure 2.32.

Figure 2.31

Figure 2.32

8. Tighten the feed guide onto the guide rails. Figure 2.33.

Figure 2.33

9. Turn the advancing handle CLOCKWISE until the drill bit

bottoms out on the spindle. Then, back off the handle one full

turn. Figure 2.34.

Figure 2.34

10. Turn the motor ON and drill into the spindle by slowly turning

the advancing handle CLOCKWISE with a smooth, steady feed.

Remove the drill bit guide periodically to remove metal

shavings. No lubrication is needed during the drilling operation.

Check that the guide rails are clean to ensure that the drill will

advance smoothly. Figure 2.34 and Figure 2.35.

앫 If the drill stalls or lags: Back off the advancing handle

COUNTERCLOCKWISE a few turns while the drill is on, then

resume drilling. Figure 2.36.

Figure 2.30

Figure 2.31

Figure 2.32

BAR

GUIDE

RAILS

4000437a

DRILL

MOTOR

ASSEMBLY

GUIDE

RAILS

4000438a

DRILL BIT

GUIDE

DRILL BIT

4000439a

Figure 2.33

Figure 2.34

FEED

GUIDE

GUIDE

RAILS

4000440a

ADVANCING

HANDLE

4000441a

15

Meritor Maintenance Manual MM-14P (Revised 10-19)

앫 When the drill bottoms out or breaks through the solid

spindle: Turn the advancing handle COUNTERCLOCKWISE

a few turns while the drill is on. Release the feed guide and

pull the drill out of the hole.

앫 If the 12-inch drill bit does not break through: Install the

18 x 7/16-inch drill bit. Use the same procedure to

continue to drill until you break through the solid spindle.

Figure 2.35

Figure 2.36

11. Remove all drill jig components from the spindle. Clean the

axle end. Use shop air to clean the drilled hole. Figure 2.37.

Figure 2.37

CAUTION

Always use a tap guide to tap the hole in the axle spindle. This

will help to ensure that the threads are square to the spindle

end and help prevent damage to components.

12. Install the tap guide onto the axle spindle. Tap the axle spindle

with a 1/4-inch NPT tap. A 1/2-inch, 12-point socket and

3/8-inch drive ratchet can be used to drive the tap. Use

tapping lubricant. Figure 2.38. Refer to Section 7 for the solid

spindle tap guide part number.

Figure 2.38

13. Remove the tap guide. Clean the axle end. Use shop air to

clean the tapped hole. Figure 2.37.

Figure 2.35

Figure 2.36

METAL SHAVINGS

4000442a

DRILL JIG

INSTALLED

4000443a

Figure 2.37

Figure 2.38

SHOP

AIR

TOWEL

4000444a

TAP

GUIDE

TOWEL

4000445a

16

Meritor Maintenance Manual MM-14P (Revised 10-19)

앫 If the outer spindle nut was removed to install the drill

jig: Reinstall the spindle nut using the axle manufacturer’s

instructions. Verify that the wheel end play is correct. For

Meritor axles, refer to Maintenance Manual 14, Trailer

Axles. To obtain this publication, refer to the Service Notes

page on the front inside cover of this manual.

Stator

It is not necessary to apply a sealer when the stator is first installed

if current production stators have sealant pre-applied to the threads.

However, if the stator is removed, apply a thread sealant prior to

reinstalling. Figure 2.39.

Figure 2.39

1. Hand-tighten the stator into the spindle hole. Figure 2.40.

Figure 2.40

2. Use a 5/8-inch socket to tighten the stator approximately 2-1/2

additional turns, or 23-28 lb-ft (31.18-37.96 N폷m), to obtain

an airtight seal. Figure 2.41.

@

Figure 2.41

Wheel-End Components

Hubcaps are available in bolt-on or screw-on models, and models

for grease or oil-lubricated wheel ends. All tire inflation system

hubcaps include six vent holes designed to prevent pressure buildup

in the wheel end.

Oil hubcaps typically feature a side-mounted oil fill plug and vent

hole extensions located in the hubcap interior to keep oil from

leaking from the hubcap vent holes. Figure 2.42 and Figure 2.43.

Grease hubcaps also have six vent holes with vent extensions,

however, they typically don’t have a side-mounted fill plug.

Figure 2.43.

Figure 2.42

Figure 2.39

Figure 2.40

SEALANT

TAPE

NEW STATOR

PRE-APPLIED

SEALANT

REINSTALLING STATOR

4000446a

STATOR

TOWEL

4000447a

Figure 2.41

Figure 2.42

4005325b

TOWEL

OIL FILL PLUG

VENT

HOLES

4000451c

17

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.43

The thru-tee assembly consists of the tube, tee relief valve, deflector

shield and tee. Figure 2.44.

Figure 2.44

WARNING

Verify that the vent tube holes in a greased wheel end are not

blocked with grease. Blocked vent tube holes will prevent

system air from venting from the wheel end. Serious personal

injury and damage to components can result.

1. Follow the manufacturer’s instructions to install the hubcap.

For oil-lubricated wheel ends, locate the oil fill plug on the top.

Verify that the vent holes in a greased wheel end are not

blocked with grease. Blocked vent tube holes will prevent

system air from venting from the wheel end. Figure 2.42.

2. Ensure the correct length tube is assembled to the thru-tee.

Refer to Table A for the correct length. Figure 2.45.

Figure 2.45

Table A: Thru-Tee Tube Length

3. Use your fingers to check that there is no debris on the tube.

Figure 2.46.

Figure 2.46

Figure 2.43

Figure 2.44

4010950a

OIL AND GREASE

HUBCAP INTERIOR

VENT TUBES

DEFLECTOR

SHIELD

RELIEF

VALVE

TEE

THRU-TEE

ASSEMBLY

TUBE

4000452a

Figure 2.45

Axle/

Spindle

Type Hub Type

“A” Thru-Tee Tube

Length

TN/TQ, HN Ductile Iron 3.5 (88.9 mm)

TN/TQ, HN Aluminum 4 (101.6 mm)

TP, WP, HP

(2.75

[69.85 mm]

Bore)

Ductile Iron 4 (101.6 mm)

TP, WP, HP

(2.75

[69.85 mm]

Bore)

Aluminum 5 (127 mm)

TN/TQ or TP PreSet or PreSet

Plus

5 (127 mm)

Figure 2.46

4010951a

“A”

TUBE

TUBE

4000697a

THRU-TEE

ASSEMBLY

18

Meritor Maintenance Manual MM-14P (Revised 10-19)

4. Carefully install the thru-tee assembly STRAIGHT into the

hubcap to insert the tube into the stator. When you insert the

tube into the stator, it’s normal to feel some resistance when

the tube contacts the stator seal. Figure 2.47.

Figure 2.47

CAUTION

Do not overtighten the thru-tee assembly during installation.

Damage to the component threads can result.

5. Hand-tighten the thru-tee assembly. Tighten the tee with a

torque wrench set at 45 lb-in (5 N폷m). Check alignment of the

tee air fittings to the tire valve stems. If aligned, go to Step 6. If

not aligned, retighten the tee with a torque wrench set to

55 lb-in (6 N폷m) and tighten until aligned. Do not exceed

55 lb-in (6 N폷m). If still not aligned, repeat Step 5.

Figure 2.48.

@

Figure 2.48

6. The air fittings must point TOWARD the tire valve stems. Check

that the tire valve stems are 180 degrees opposite each other.

The valve stems must be in this position to install the tire

inflation system. Figure 2.49. If necessary, bolt-on hubcaps or

wheels may be “clocked” to align the thru-tee with the tire

valve stems. Screw-on hubcaps may be rotated for this

alignment, as long as the hubcap tightening specification is

within the hubcap manufacturer’s recommended guidelines.

Figure 2.49

CAUTION

During installation, hand-tighten the tire inflation system

hoses to the tire valve stems, then use a wrench to tighten the

hoses to the correct specification. Do not overtighten the

connection, this may damage the hose seal and cause a tire to

deflate when the trailer is parked. Damage to components can

result.

7. Hand-tighten the tire inflation system hoses to the tire valve

stems. Then use a 7/16-inch wrench to tighten the

connections an additional half-turn. Figure 2.50.

Figure 2.50

Figure 2.47

Figure 2.48

THRU-TEE

TUBE

4000488a

THRU-TEE

ASSEMBLY

THRU-TEE

ASSEMBLY

4000698c

Figure 2.49

Figure 2.50

TIRE

VALVE

STEMS

THRU-TEE

ASSEMBLY

4000454a

TIRE

VALVE

STEM

TIRE

INFLATION

SYSTEM

HOSE

TIRE

VALVE

STEM

TIRE

INFLATION

SYSTEM

HOSE

4000700c

19

Meritor Maintenance Manual MM-14P (Revised 10-19)

Air Components

Control Box

WARNING

A standard MTIS can have a control box with either a black

flow sensing switch or a grey flow sensing switch. Both

control boxes mount to the trailer in the same way. However,

MTIS equipped with a ThermALERT system must have a

control box with a grey flow sensing switch, which is more

sensitive to air flow than the black switch.

If a ThermALERT system has a control box with a black flow

sensing switch, replace it with a control box that has a grey

switch. Otherwise, the warning light may not come ON if a

wheel end overheats. Serious personal injury and damage to

components can result.

It is important to note that there are two different control boxes. One

is for the standard MTIS, and the other is for the MTIS with the

ThermALERT system.

The control box for the standard MTIS can include a flow sensing

switch that is either black or grey. The control box for the MTIS with

the ThermALERT system must include a grey flow sensing switch.

Both control boxes mount to the trailer in the same way.

The preferable location to install the tire inflation system control box

is the ROADSIDE REAR of the subframe facing the REAR of the

trailer. Mount the control box in a location that’s accessible, free of

hazards and positioned so the control box door can be opened.

Use the following procedure to mount the control box either to the

supplied mounting bracket or directly to the trailer subframe. Check

to ensure that the control box, electrical lines or air lines do not

interfere with any suspension components in the system.

Mounting Bracket Installation

WARNING

Axle weld locations and welding procedures must adhere to

Meritor standards. Welding at locations other than those

authorized by Meritor will void the warranty and can reduce

component fatigue life. Serious personal injury and damage to

components can result.

Wear safe clothing and eye protection when you use welding

equipment. Welding equipment can burn you and cause

serious personal injury. Follow the operating instructions and

safety procedures recommended by the welding equipment

manufacturers.

You can either weld or bolt the supplied mounting bracket to the

trailer subframe.

1. Wear safe eye protection.

2. Park the vehicle on a level surface. Block the wheels to prevent

the vehicle from moving.

3. Install the mounting bracket to position the control box as

described in this section. Use one of the following installation

procedures.

앫 Weld the bracket to the subframe.

앫 Use the supplied mounting bracket as a template and drill

two 5/16-inch (0.80 cm) holes into the trailer subframe.

Use the supplied fasteners, washers and locknuts to secure

the bracket to the subframe. Figure 2.51 and Figure 2.52.

Figure 2.51

Figure 2.51

MOUNTING

BRACKET

MOUNTING

FLANGE

4000457a

20

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.52

4. Install the control box to the mounting bracket opposite side of

the mounting flange using the supplied 1/4-inch (6.36 mm)

fasteners, washers and locknuts. Figure 2.52, Figure 2.53 and

Figure 2.54.

NOTE: The bracket mounting flange must make complete

contact with the surface area it is mounted on.

Figure 2.53

Figure 2.54

Trailer Subframe Installation

1. Locate the control box as described in this section. Use the

supplied mounting bracket as a template and drill three

1/4-inch (6.36 mm) holes into an appropriate mounting

surface to position the control box as described in this section.

Figure 2.55.

Figure 2.55

2. Discard the supplied mounting bracket. Use the supplied

1/4-inch (6.36 mm) fasteners, washers and locknuts to install

the control box directly to the subframe. Figure 2.56,

Figure 2.57 and Figure 2.58.

Figure 2.56

Figure 2.52

Figure 2.53

Figure 2.54

WASHER

FASTENER

WASHER

MOUNTING

FLANGE

SUBFRAME

MEMBER

LOCKNUT

MOUNTING

BRACKET

MOUNT

CONTROL

BOX ON

THIS SIDE

TYPICAL TWO

LOCATIONS

4000702a

4000458c

Inflation System Control Box

Meritor Tire Inflation System

BRACKET MOUNT

CONTROL BOX

CONTROL BOX (ORIGINAL DESIGN)

4016803a

BRACKET MOUNT

CONTROL BOX

CONTROL BOX (MANIFOLD DESIGN)

Inflation System Control Box

Meritor Tire Inflation System

Figure 2.55

Figure 2.56

MOUNTING

BRACKET

4000459a

LOCKNUT

FASTENER

TRAILER

SUBFRAME

CONTROL

BOX

WASHER

TYPICAL THREE

LOCATIONS

4010952a

21

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.57

Figure 2.58

Pressure Protection Valve (PPV)

CAUTION

Check the wheel ends to ensure the tire inflation system valve

stems and hoses do not contact the wheels or brake drums.

Damage to components can result.

It is not necessary to apply a sealer when the PPV and installation

nipple are first installed if the current production components have

sealant pre-applied to the threads. However, if the PPV is removed,

apply thread sealant prior to reinstalling. Figure 2.59.

Figure 2.59

1. Drain the air from the trailer air system service tank.

2. Hand-tighten the installation nipple into a spare port in the air

tank, preferably in the top half of the air tank. Then use an

11/16-inch wrench to tighten the nipple approximately two

additional turns to obtain an airtight seal.

3. Hand-tighten the PPV into the installation nipple. Use a wrench

to tighten the PPV approximately two additional turns to obtain

an airtight seal. When correctly installed, the slotted screw in

the PPV should face DOWN. Figure 2.60.

Figure 2.60

Air Lines

When you route the tire inflation system air lines, use grommets to

protect them from contacting sharp edges at hole locations. Use tie

wraps to secure them to the existing trailer brake air lines.

Figure 2.57

Figure 2.58

SUBFRAME

MOUNT

CONTROL

BOX

4000460b

CONTROL BOX (ORIGINAL DESIGN)

SUBFRAME

MOUNT

CONTROL

BOX

4016804a

CONTROL BOX (MANIFOLD DESIGN)

Inflation System Control Box

Meritor Tire Inflation System

Figure 2.59

Figure 2.60

4005327b

PRESSURE

PROTECTION

VALVE

PRESSURE

PROTECTION

VALVE

PRE-APPLIED

SEALANT

NEW PPV REINSTALLING PPV

SEALANT

TAPE

PRESSURE

PROTECTION

VALVE

SLOTTED

SCREW

4000462b

22

Meritor Maintenance Manual MM-14P (Revised 10-19)

1. Route an air line from the PPV to the control box inlet port.

Figure 2.61, Figure 2.62 and Figure 2.63. Hand-tighten the air

line fittings, then use a 9/16-inch wrench to tighten them

approximately one additional turn to obtain an airtight seal.

Figure 2.61

Figure 2.62

Figure 2.63

2. Route an air line from the control box outlet port to the air line

tee. Suspend the tee AWAY from the trailer brake lines to

protect these lines from damage. Figure 2.64. Hand-tighten

the air line fittings, then use a 9/16-inch wrench to tighten

them approximately one additional turn to obtain an airtight

seal.

Figure 2.64

3. Route the air lines from the tee to the axle air fittings. Provide

sufficient slack in the lines to allow for suspension movement.

Use the slack in the existing trailer brake lines as a guide.

Figure 2.65. Hand-tighten the air line fittings, then use a

9/16-inch wrench to tighten them approximately one additional

turn to obtain an airtight seal.

Figure 2.65

Figure 2.61

Figure 2.62

Figure 2.63

PRESSURE

PROTECTION

VALVE

4000462a

AIR LINE TO

CONTROL BOX

INLET PORT

OUTLET

PORT

INLET

PORT

GROMMET

CONTROL BOX

4000463b

CONTROL BOX (ORIGINAL DESIGN)

OUTLET

PORT

INLET

PORT

GROMMET

CONTROL BOX

4016805a

CONTROL BOX (MANIFOLD DESIGN)

HOLD HERE

Figure 2.64

Figure 2.65

4006234b

TRAILER

BRAKE

LINES

FROM

CONTROL BOX

OUTLET PORT

INFLATION

SYSTEM

AIR LINE

AIR LINE

TEE

HOSE

CLIPS

AXLE

AIR FITTING

TRAILER

BRAKE

LINES

INFLATION

SYSTEM

AIR LINE

4000465a

23

Meritor Maintenance Manual MM-14P (Revised 10-19)

Electrical Components

WARNING

When working on an electrical system, the possibility of

electrical shock exists, and sparks can ignite flammable

substances. Always disconnect the battery ground cable

before working on an electrical system to prevent serious

personal injury and damage to components.

Standard Connection of Seven-Way Box

1. Disconnect the trailer’s electric system from the tractor prior to

working on the trailer’s electrical system.

2. Connect the warning light to the wiring harness. The standard

wire harness is shipped as a single assembly consisting of a

black and white wire with spade terminals on one end that

connect to the control box, and bullet terminals that connect to

the warning light. Figure 2.66.

Figure 2.66

3. Mount the warning light vertically onto the roadside front of the

trailer, approximately 30-inches (76 cm) from the bottom of the

coupler and as close as possible to the outside of the trailer.

The driver should be able to see the warning light from the

roadside rear view mirror. Figure 2.67.

Figure 2.67

4. Route the wiring harness from the warning light to the trailer

seven-way box. Secure the harness to the front of the trailer

using the supplied P-clamps. Cut the harness ensuring there is

sufficient length to make the connections in the seven-way

box. Route the harness into the seven-way box. Figure 2.68.

Figure 2.68

5. Route the remaining wire harness through the liquid tight seal

on the control box and connect the harness to the electrical

contacts of the flow sensing switch. The black or white wire

can be connected to either terminal on the flow switch and are

interchangeable. Figure 2.69 and Figure 2.70.

Figure 2.66

WARNING

LIGHT

ELECTRICAL

CABLE

CONNECTORS

4000704a

Figure 2.67

Figure 2.68

4000466b

ThermALERT™

DECAL

WARNING

LIGHT

ELECTRICAL

CABLE

P-CLAMPS

4000705a

24

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.69

Figure 2.70

6. Route the wiring harness from the control box to the seven-way

box. When you route the harness, use grommets to protect it

from contacting sharp edges and use tie wraps to secure the

harness.

앫 If the trailer is equipped with a sliding subframe:

Provide sufficient slack in the harness to allow for

suspension movement. Use the slack in the existing trailer

brake lines and electrical lines as a guide.

7. Route the harness into the seven-way box and remove any

excess cable.

8. In the trailer seven-way box, connect the supplied eye

connectors to the white wires, one coming from the warning

light and one coming from the control box. Figure 2.71 and

Figure 2.72.

Figure 2.71

Figure 2.72

9. In the trailer seven-way box, connect the white wire eye

connector from the control box to a pin that will supply

constant power. Connect the white wire from the light to the

ground. Figure 2.73.

Figure 2.69

Figure 2.70

4000467b

FLOW SENSING

SWITCH

ELECTRICAL

CABLE

CONTROL BOX

ELECTRICAL

CONTACTS

CONTROL BOX (ORIGINAL DESIGN)

4016806a

FLOW SENSING

SWITCH

CONTROL BOX

ELECTRICAL

CONTACTS

CONTROL BOX (MANIFOLD DESIGN)

ELECTRICAL

CABLE

Figure 2.71

Figure 2.72

4010953b

FLOW

SENSING

SWITCH

BUTT SPLICE

CONNECTION

(MAKE INSIDE

ENCLOSURE)

WHITE

WIRE

BLACK

WIRE

WHITE

WIRE

STANDARD CONNECTION WIRING DIAGRAM

GROUND

PIN

AUXILARY

POWER PIN

TRAILER

SEVEN-

WAY BOX

BULLET

CONNECTION

WARNING

LIGHT

CONTROL BOX (ORIGINAL DESIGN)

WARNING

LIGHT

WARNING

LIGHT

4010953b

FLOW SENSING SWITCH

BUTT SPLICE

CONNECTION

(MAKE INSIDE

ENCLOSURE)

WHITE

WIRE

BLACK

WIRE

WHITE

WIRE

STANDARD CONNECTION WIRING DIAGRAM

GROUND

PIN

AUXILARY

POWER PIN

TRAILER

SEVEN-

WAY BOX

BULLET

CONNECTION

CONTROL BOX (MANIFOLD DESIGN)

25

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.73

10. In the trailer seven-way box, use the supplied butt connector to

connect the black wire from the warning light to the black wire

from the control box.

11. If necessary, reconnect the trailer to the tractor’s electrical

system.

Optional Installation 1 — ABS Connection Inside Box

1. Mount the warning light.

2. Route the electrical cable from the warning light to the control

box.

3. Route the ABS connector electrical cable to the control box.

4. Connect the blue wire from the ABS connector to the flow

sensing switch. Connect the black wire from the warning light

to the flow sensing switch. Connect the white wire from the

warning light to the white wire from the ABS connector.

Figure 2.74 and Figure 2.75.

Figure 2.74

Figure 2.75

Optional Installation 2 — ABS Connection Outside

Box

1. Mount the warning light.

2. Route a length of electrical cable from the warning light to the

ABS connector.

3. Route the electrical cable from the control box to the ABS

connector. Connect the electrical cable to the electrical

contacts of the flow sensing switch.

4. At the ABS connector, connect the white wire from the control

box to the blue wire from the ABS connector. Connect the black

wire from the control box to the black wire from the warning

light. Connect the white wire from the warning light to the

white wire from the ABS connector. Use a liquid tight connector

at all connections. Figure 2.76 and Figure 2.77.

Figure 2.73

Figure 2.74

OPTIONAL INSTALLATION 1

BUTT

CONNECTOR

EYE

CONNECTOR

4000706a

4010954b

WARNING

LIGHT

FLOW

SENSING SWITCH

ABS

CONNECTOR

BUTT

CONNECTOR

BULLET

CONNECTOR

BLUE

WHITE

BLACK

CONTROL BOX (ORIGINAL DESIGN)

Figure 2.75

OPTIONAL INSTALLATION 1

4016808a

FLOW

SENSING SWITCH

ABS

CONNECTOR

BUTT

CONNECTOR

BULLET

CONNECTOR

BLUE

WHITE

BLACK

CONTROL BOX (MANIFOLD DESIGN)

26

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.76

Figure 2.77

Wheel-End Oil

Refer to the trailer axle manufacturer literature for service

instructions. For Meritor trailer axles, refer to Maintenance Manual

14, Trailer Axles. To obtain this publication, refer to the Service

Notes page on the front inside cover of this manual.

If the wheel end is oil-lubricated, add oil through the hubcap fill plug

to the manufacturer’s recommended level. The oil level must be

below the level of the six hubcap wheel-end vents. Figure 2.78 and

Figure 2.79.

CAUTION

Do not overfill the wheel end with oil or damage to

components may result.

Figure 2.78

Figure 2.79

NOTE: ThermALERT became a standard feature in all MTIS kits

starting October 1, 2017.

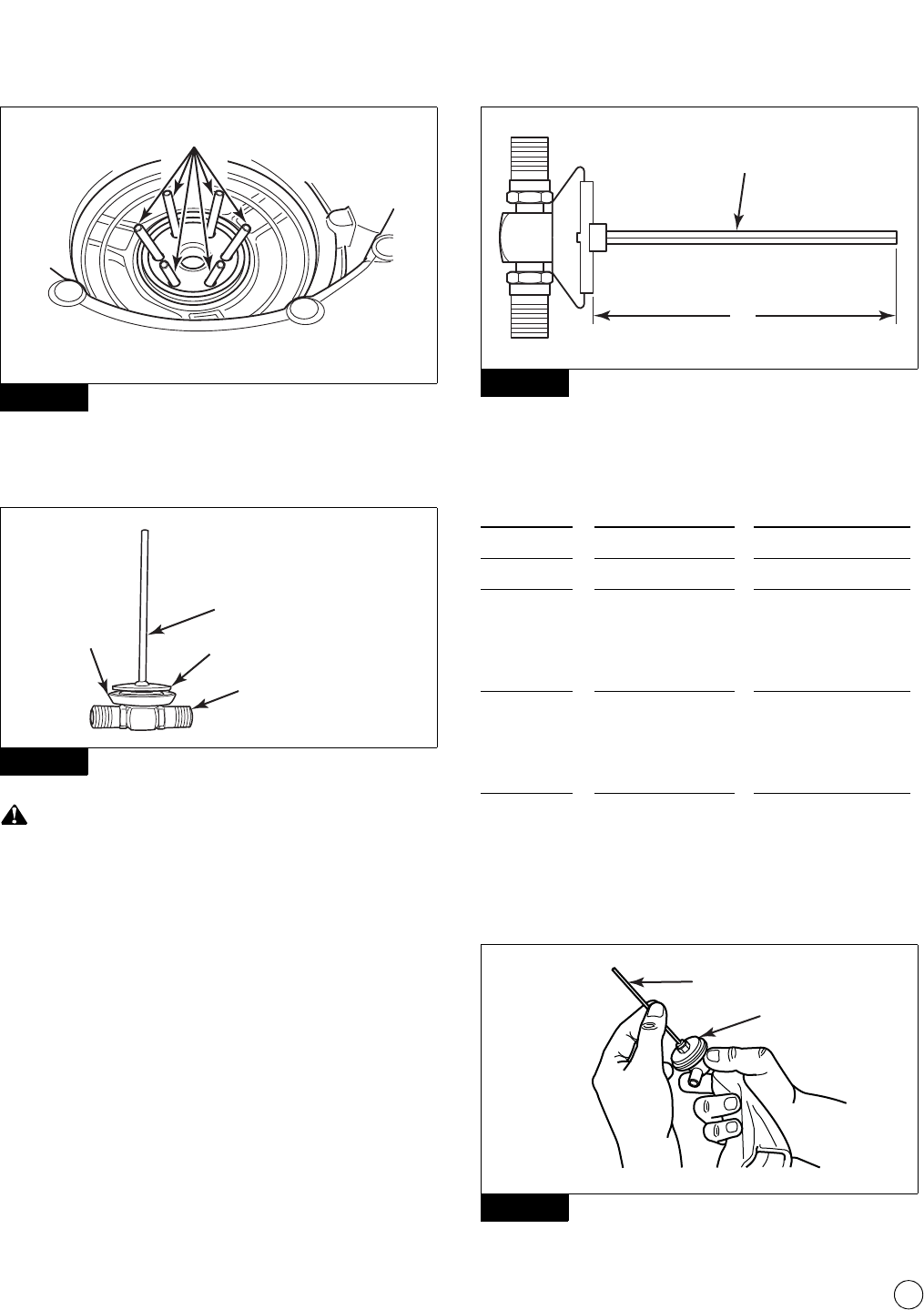

Standard MTIS and ThermALERT System

Decals

Identification and information decals are used with the tire inflation

system.

1. Install an identification and hose installation decal on each side

of the trailer above the suspension. Figure 2.80.

Figure 2.76

OPTIONAL INSTALLATION 2

Figure 2.77

OPTIONAL INSTALLATION 2

4010955b

WARNING

LIGHT

FLOW

SENSING SWITCH

ABS

CONNECTOR

LIQUID TIGHT

BUTT CONNECTOR

(3 PLCS.)

BLUE

WHITE

BLACK

WHITE

CONTROL BOX (ORIGINAL DESIGN)

WARNING

LIGHT

4016809a

FLOW

SENSING SWITCH

ABS

CONNECTOR

LIQUID TIGHT

BUTT CONNECTOR

(3 PLCS.)

BLUE

WHITE

BLACK

WHITE

CONTROL BOX (MANIFOLD DESIGN)

Figure 2.78

Figure 2.79

OIL LEVEL

BELOW THE

HUBCAP

WHEEL-END

VENTS

4000469a

4011849a

OIL FILL

PLUG

SIX HUBCAP

WHEEL-END

VENTS

HUBCAP

FULL LINE

27

Meritor Maintenance Manual MM-14P (Revised 10-19)

Figure 2.80

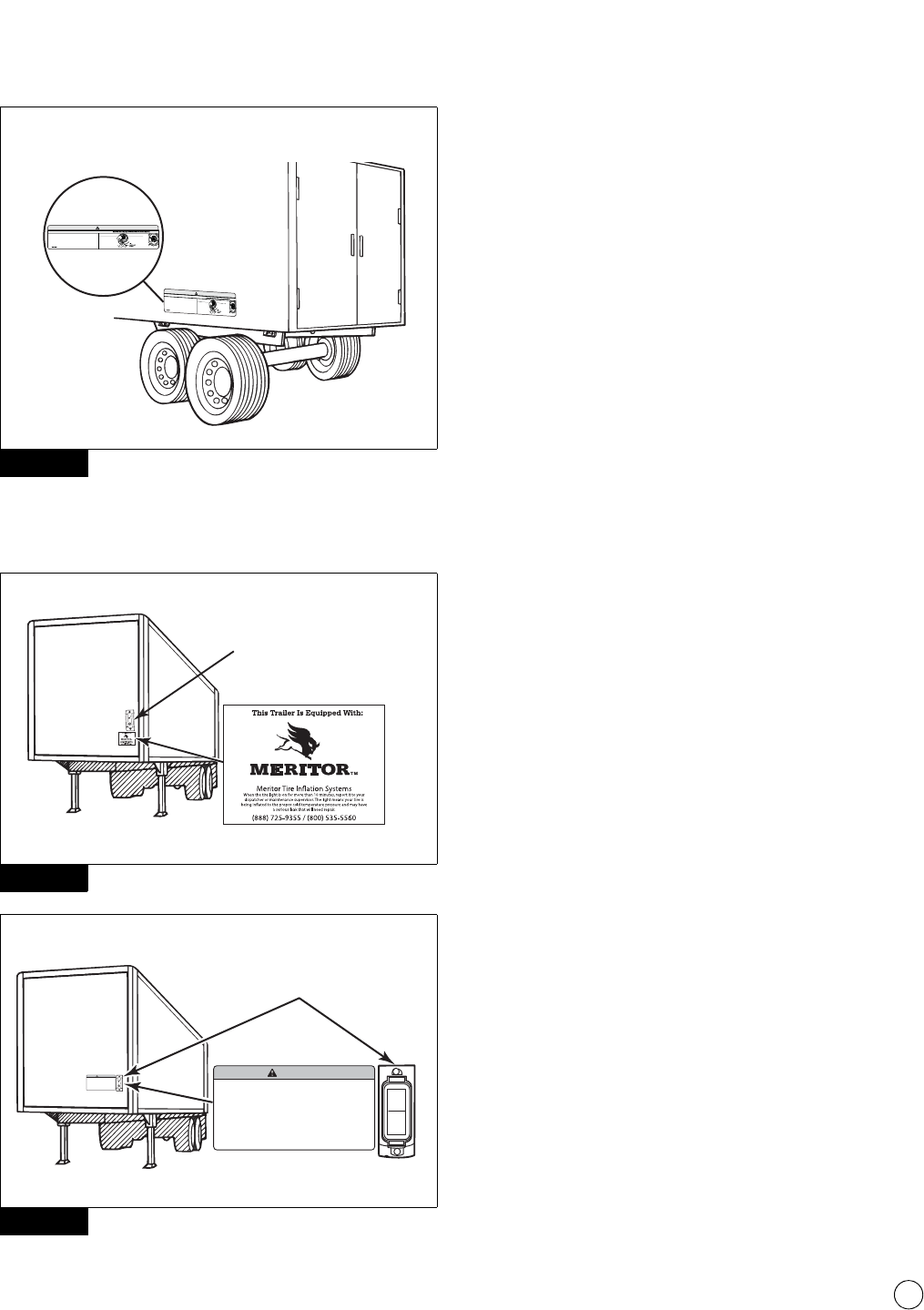

2. Install the warning light decal near the light. Figure 2.81 or

Figure 2.82.

Figure 2.81

Figure 2.82

Figure 2.80

Figure 2.81

Figure 2.82

4000471c

3

7

9

9

H

MTIS with ThermALERT

TM

Standard Hose

1. Disconnect tire hose at hub

cap end.

2. Measure tire pressure using

conventional air pressure gauge.

3. Re-attach hose at hub cap end

and HAND-TIGHTEN knurled nut.

TO MANUALLY CHECK TIRE PRESSURE:

1.Measure tire pressure

using conventional

gauge as shown.

Check Port Hose

Follow the instructions below when installing PSI Tire Inflation System hoses. Note that improperly

tightened hoses can leak and may cause the trailer tires to deflate when the trailer is parked.

1.

HAND-TIGHTEN the hose to the tire valve stem.

2.

Use a 7/16 inch wrench to tighten the hose an additional HALF TURN.

3.

4.

5.

6.

If the connection continues to leak, replace the hose.

HAND-TIGHTEN the hose fitting at the hub cap tee (DO NOT USE PLIERS)

Apply soapy water at the connections to test for leaks.

If a leak is found, disconnect the hose and reinstall per the instructions above and retest.

For additional information see PSI Tire Inflation System Maintenance Manual at www.psitireinflation.com.

Or call

1-210-222-1926

MADE IN THE USA

TO PREVENT SERIOUS EYE INJURY, ALWAYS WEAR SAFE EYE PROTECTION

PN: 31284-00-US REV. C

is covered by one or more of the following U.S. Patents: see www.psitireinflation.com/IP.

WARNING

S

t

a

n

d

a

r

d

H

o

s

e

1

.

D

i

s

con

n

e

ct

t

i

r

e

h

o

s

e

at

h

u

b

c

a

p

e

n

d

.

2.

M

e

as

ur

e

t

i

r

e

p

r

e

s

s

u

r

e

u

s

i

n

g

co

n

v

e

n

t

i

o

n

a

l

a

i

r

p

r

e

ssu

r

e

g

a

u

g

e

.

3

.

Re

-

a

t

t

a

c

h

h

o

s

e

a

t

h

u

b

c

a

p

e

n

d

a

n

d

H

A

N

D

-

T

IG

H

T

E

N

k

n

u

r

l

e

d

n

u

t.

T

O

M

A

N

U

A

L

L

Y

C

H

E

C

K

T

I

R

E

P

R

E

S

S

U

R

E

:

1

.

M

e

a

s

u

r

e

t

i

r

e

p

r

e

s

s

u

r

e

u

s

i

n

g

c

o

n

v

e

n

t

i

o

n

a

l

g

a

u

g

e

a

s

s

h

o

wn

.

C

he

c

k

P

o

r

t

H

os

e

F

o

l

l

o

w

t

h

e

i

n

s

t

r

u

c

t

i

o

n

s

b

e

l

o

w

w

h

e

n

i

n

s

t

a

l

l

i

n

g

P

S

I

T

i

r

e

I

n

f

l

a

t

i

o

n

S

y

s

t

e

m

h

o

s

e

s

.

N

o

t

e

t

h

a

t

i

m

p

r

o

p

e

r

l

y

t

i

g

h

t

e

n

e

d

h

o

se

s

ca

n

l

e

a

k

a

n

d

m

a

y

c

a

u

s

e

t

h

e

t

r

a

i

l

e

r

t

i

r

e

s

t

o

d

e

f

l

a

t

e

w

h

e

n

t

h

e

t

r

a

i

l

e

r

i

s

p

a

r

k

e

d

.

1

.

H

AN

D

-

T

I

G

H

T

E

N

t

h

e

h

o

s

e

t

o

t

h

e

t

i

r

e

v

a

lv

e

s

t

e

m

.

2

.

U

s

e

a

7

/

16

i

n

c

h

w

r

e

nc

h

t

o

t

i

ght

e

n

t

he

h

o

s

e

an

ad

di

t

i

o

n

a

l

H

A

LF

TU

R

N

.

3

.

4

.

5

.

6

.

.

e

s

o

h

e

h

t

e

c

a

l

p

e

r

,

k

a

e

l

o

t

s

e

u

n

i

t

n

o

c

n

o

i

tc

e

n

n

o

c

e

h

t

f

I

H

A

N

D

-

T

I

GH

T

E

N

t

h

e

h

o

s

e

f

i

t

t

ing

a

t

t

h

e

h

u

b

c

a

p

t

e

e

(

D

O

N

O

T

U

S

E

P

L

I

E

R

S)

A

p

p

l

y

s

o

a

p

y

w

a

t

e

r

a

t

t

h

e

c

o

n

n

e

c

t

i

o

n

s

t

o

t

e

s

t

f

o

r

l

e

a

k

s

.

I

f

a

l

e

a

k

i

s

f

o

u

n

d

,

d

i

s

c

o

n

n

e

c

t

t

h

e

h

o

s

e

a

n

d

r

e

i

n

s

t

a

l

l

p

e

r

t

h

e

i

n

s

t

r

u

c

t

i

o

n

s

a

b

o

ve

a

n

d

r

e

t

e

s

t

.

F

o

r

a

d

d

i

t

i

o

n

a

l

i

n

f

o

r

m

a

t

i

o

n

s

e

e

P

S

I

T

i

r

e

I

n

f

l

a

t

i

o

n

S

y

s

t

e

m

M

a

i

n

t

e

n

a

n

c

e

M

a

n

u

a

l

a

t

w

w

w

.

p

s

i

t

i

r

e

i

n

f

l

a

t

i

o

n

.

c

o

m

.

O

r

c

a

l

l

1

-

2

1

0

-

2

2

2

-

1

9

2

6

M

A

D

E

I

N

T

H

E

US

A

T

O

PR

E

VE

N

T

SER

I

O

U

S

EY

E

I

N

J

U

R

Y

,

A

L

W

AY

S

W

EA

R

SAF

E

EYE

PR

O

T

EC

T

I

O

N

P

N

:

3

1

2

8

4

-

0

0

-

U

S

R

E

V

.

C

i

s

c

o

ve

r

e

d

b

y

o

n

e

o

r

m

o

r

e

o

f

t

h

e

f

o

l

l

o

w

i

n

g

U

.

S

.

P

a

t

e

n

t

s

:

s

e

e

w

w

w

.

p

si

t

i

r

e

i

n

f

l

a

t

i

o

n

.

c

o

m

/

I

P

.

WARNING

WARNING

LIGHT

4000472c

MTIS without ThermALERT

WARNING

This trailer is equipped wi th the Meritor Tire Inflation System (MTIS™) and the ThermALERT™ system.

When you start a vehicle, the MTIS indicator light initially may come ON while the air system is charging.

However, if the indicator light stays ON for more than 10 minutes, a tire may be damaged and losing air pressure.

Inspect the tires for damage and air leaks. Repair damaged or leaking tires before returning the vehicle to

service.

If the MTIS detects excessive air flow through the system during vehicle operation, the indicator light comes ON

to alert you that either a tire is losing air pressure, or the ThermALERT™ system has detected air discharging

through the hubcap tee vent, which occurs when a wheel end is operating at an abnormally high temperature. If

a wheel end overheats during operation, it can separate from the vehicle. Serious personal injury and damage

to components can result. Follow these instructions if the MTIS indicator light comes ON during operation.

1. Immediately find a safe place to bring the tractor and trailer to a complete stop.

2. Inspect the trailer hubs and tires for air leaks.

3. Listen for the ThermALERT™ system sound at the wheel end. If you hear the sound, the wheel end is

overheated. Do not operate the trailer until the components are repaired.

4. If you do not hear the ThermALERT™ system sound at the wheel end, inspect the tires for damage. Repair

damaged or leaking tires before returning the vehicle to service.

5. Refer to Meritor’s Maintenance Manual 14P for service instructions. Notify your dispatcher or service

department, or contact ArvinMeritor’s Customer Service Center at 800-535-5560 for assistance.

WARNING

LIGHT

4010956a

MTIS with ThermALERT

ThermALERT DECAL

WARNING

This trailer is equipped with the Meritor Tire Inflation System (MTIS) and the ThermALERT™ system.

When you start a vehicle, the MTIS indicator light initially may come ON while the air system is charging.

However, if the indicator light stays ON for more than 10 minutes, a tire may be damaged and losing air pressure.

Inspect the tires for damage and air leaks. Repair damaged or leaking tires before returning the vehicle to

service.

If the MTIS detects excessive air flow through the system during vehicle operation, the indicator light comes ON

to alert you that either a tire is losing air pressure, or the ThermALERT™ system has detected air discharging

through the hubcap tee vent, which occurs when a wheel end is operating at an abnormally high temperature. If

a wheel end overheats during operation, it can separate from the vehicle. Serious personal injury and damage

to components can result. Follow these instructions if the MTIS indicator light comes ON during operation.

1. Immediately find a safe place to bring the tractor and trailer to a complete stop.

2. Inspect the trailer hubs and tires for air leaks.

3. Listen for the ThermALERT™ system sound at the wheel end. If you hear the sound, the wheel end is

overheated. Do not operate the trailer until the components are repaired.

4. If you do not hear the ThermALERT™ system sound at the wheel end, inspect the tires for damage. Repair

damaged or leaking tires before returning the vehicle to service.

5. Refer to Meritor’s Maintenance Manual 14P for service instructions. Notify your dispatcher or service

department, or contact ArvinMeritor’s Customer Service Center at 800-535-5560 for assistance.

3 Check System Operation

28

Meritor Maintenance Manual MM-14P (Revised 10-19)

3 Check System Operation

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

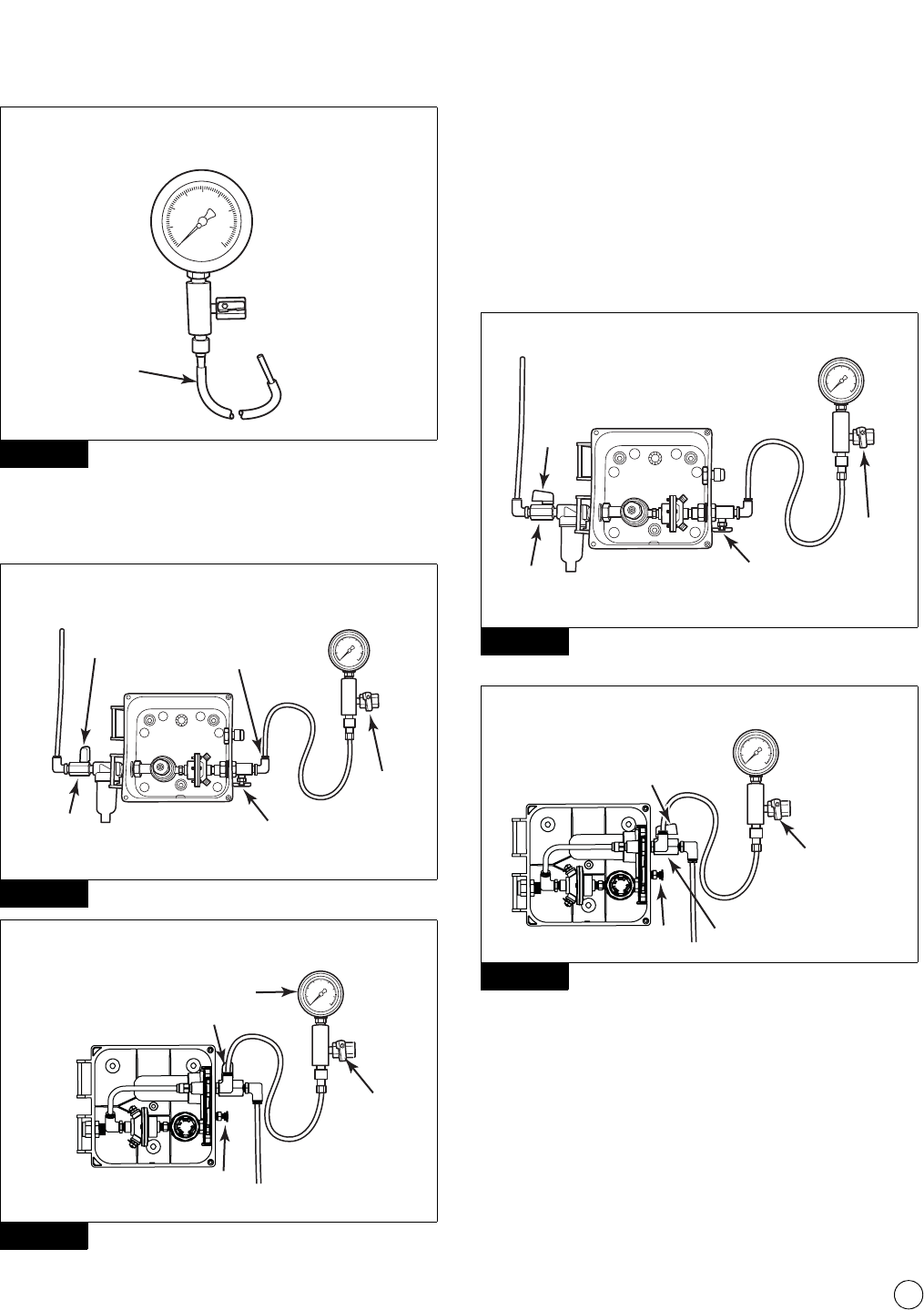

Check System Operation

Use the following procedure to check the tire inflation system for

correct operation. This inspection ensures that the system is

activated, the warning light works, the hoses are installed correctly

and that the system delivers the correct pressure to the tires.

1. Wear safe eye protection.

2. Check that the system ball valve is open. When the valve is

open, the knob aligns with the valve body. Also, check that the

drain petcock is closed. Figure 3.1 and Figure 3.2.

Figure 3.1

Figure 3.2

3. The tire inflation system must be fully pressurized before

proceeding. This may take up to 10 minutes, since the axles,

tires and possibly the brake system will have to be pressurized.

A shop air source will charge the system more quickly than a

tractor compressor.

Fully pressurize the tire inflation system by connecting the

trailer to a pressure source that can deliver 20 psi (137.9 kPa)

above the control box setting, typically 120-130 psi (827-896

kPa) to the trailer gladhands. Allow the air pressure source

sufficient time to pressurize the system, which may take up to

10 minutes.

Check all fittings, hose connections and thru-tee relief valves

for air leaks using non-corrosive leak detecting solution.

4. Connect a 12-volt power source to the trailer seven-way box.

Figure 3.3.

Figure 3.3

Figure 3.1

DRAIN

PETCOCK

SYSTEM

SUPPLY LINE

BALL VALVE

CONTROL BOX

KNOB

4000473b

CONTROL BOX (ORIGINAL DESIGN)

Figure 3.2

Figure 3.3

4016810a

MAINTENANCE

DRAIN VALVE

(CLOSED)

SYSTEM

ON/OFF

VALVE

KNOB OPEN (ON)

CONTROL BOX (MANIFOLD DESIGN)

CONTROL BOX

4005336a

3 Check System Operation