TECHNICAL MANUAL

TEH-908A

Hydronic System Design

with the Bell & Gossett

®

System Syzer

®

2

TABLE OF CONTENTS

Introduction ......................................................................................................................................................................................... 1

Determining required flow rate .....................................................................................................................................................1

System pressure drop ....................................................................................................................................................................2

Velocity and friction head loss limits ..............................................................................................................................................2

System piping arrangements ........................................................................................................................................................2

Design example: Series Loop System .................................................................................................................................................2

Design example: Two-Pipe System ......................................................................................................................................................3

Application of pump curve data ..........................................................................................................................................................4

Specific g ravity ...............................................................................................................................................................................4

Water ho rsepower .......................................................................................................................................................................... 4

Effect of volume flow changes .......................................................................................................................................................5

Calculating system pressure drop .......................................................................................................................................................5

Piping pressure drop .....................................................................................................................................................................5

Fitting and valve pressure drop .....................................................................................................................................................5

Pressure drop of other system components ..................................................................................................................................6

Control valve pressure drop: control valve types ...........................................................................................................................6

Procedures for calculating circuit pressure drop ............................................................................................................................8

The design process: Example: Two circuit series loop .........................................................................................................................8

Pump selection using the system curve ..............................................................................................................................................9

The Bell & Gossett System Syzer

®

.......................................................................................................................................................10

Scale 1: Load, flow and delta T relationship .................................................................................................................................10

Scale 2: Flow, head loss, and pipe size relationship....................................................................................................................11

Scale 3: Flow velocity ..................................................................................................................................................................12

Scale 4: Circuit pressure drop .....................................................................................................................................................12

Scale 5: Determining unknown pressure drops, system curves, and control valve Cv ................................................................13

Design example: Pumps in parallel using the System Syzer ............................................................................................................13

Design example: Three zone, two pipe system .................................................................................................................................14

Pump selection using Bell & Gossett ESP PLUS ...............................................................................................................................18

System design using ESP PLUS System Syzer ® ................................................................................................................................21

Advanced circuit analysis ...................................................................................................................................................................22

Circuit flow coefficient ..................................................................................................................................................................22

Equivalent Cv of components in series ........................................................................................................................................22

Control valve authority .................................................................................................................................................................22

Equivalent Cv of components in parallel .....................................................................................................................................23

Appendix ...........................................................................................................................................................................................25

NOTE:

Pump curves and other product data in this bulletin are for illustration only. See Bell & Gossett product literature for more

detailed, up to date information. Other training publications as well as the Bell & Gossett design tools described in this

booklet including the System Syzer, analog and digital versions, and ESP Plus are all available from your local Bell & Gossett

representative. Visit www.bellgossett.com for more information or contact your Bell & Gossett representative.

1

Introduction

Hydronic heating or cooling systems use water as the

means for carrying heat from one point to another. They are

becoming more complex as they grow in capacity, and as

control methods become more sophisticated. Small systems

may still use a single pump, but it now serves several different

temperature zones: low temperature radiant systems, higher

temperature supplemental heat or domestic water zones.

Large systems may use pumps in parallel, serving many

buildings. Flow may be controlled by automatic temperature

control valves and variable speed drives to reduce the amount

of energy used by the pump. As a result, pressures and flows

are constantly changing to meet the current need for heat

transfer.

All of these improvements and refinements depend upon

the design of the pumping and piping system. It is still vitally

important to design the piping system, size the piping, and

determine the actual system pressure drop in order to select a

pump for lowest overall life-cycle cost, and take full advantage

of modern energy saving techniques.

Determining the flow rate

Flow in a hydronic system is used to carry heat, so an accurate

heat load calculation is the foundation for any system design.

The following formula is often used to determine required

flow in hydronic systems:

GPM =

Heat Load

500 Δt

Where:

gpm is the volume flow rate, gallons/minute

Heat load is in BTU/Hr, or BTUH

Δt = Temperature difference between supply and return, ºF

500 is the constant for standard water properties at 60 ºF;

Density, 8.33 lbs. per gal.

Specific heat, 1 BTU/lb ºF

The complete calculation is then:

BTU

GPM =

hr

8.33

lb.

x 1

BTU

x 60

min

x ΔtºF

gal lbºf hr

Where 8.33 x 60 x 1 ≈ 500

Both the specific heat and density in the formula are

referenced to 60ºF water. Since 60°F water is too cool for

typical heating systems and too warm for typical cooling

systems, it may seem that flow should be calculated by taking

into account the following changes:

1. Specific heat and density changes caused by water

temperature changes.

2. Volume flow changes between supply and return

pipes due to temperature differences between

them.

Mr. Gil Carlson, the Director of Technical Services for Bell &

Gossett, discussed these issues in an article published in

HPAC Magazine in February, 1968 entitled “How to Save

Pumping Power in Hydronic System Design”. His basic

analysis was updated and extended for this book.

We can evaluate the effect of these changes in physical

properties on heat conveyance of water by determining the

net change in heat conveyance as system temperature rises.

The formula for determining system flow rate assumes a mass

flow rate of 500 lbs. per hour for each gpm which means

that at a 20º Δt, 1 gpm will convey 10,000 BTUH (500 x 20)

referenced to 60º water. Now determine what happens to

the heat conveyance of 1 gpm @ 20º Δt when the circulated

water has a system average temperature of 200º, (supply

temperature = 210 and return temperature = 190). Water at

200º has a density of 8.04 lb/gallon instead of 8.33 as at 60º,

however, the specific heat goes up to 1.003 from 1.0 as at

60º. The heat conveyance for 1 gpm at 20º Δt will then be:

8. 04 x 60 x 1.003 x 20 = 9,677 BTUH

The net effect is therefore not significant in itself, but there

is another factor to be considered for a complete evaluation.

As water temperature rises, it becomes less viscous, and

therefore its pressure drop is reduced. At 200º, water pressure

drop, or “head loss”, is about 81% of water at 60º for typical

small hydronic systems. Figure 1 gives a graphical analysis

of the effect on system flow. The “system curve” represents

the changes in system head loss as system flow changes for

any fixed piping system. It will be described more completely

later.

Flow increase resulting from operation at 200ºF rather than at 60ºF base

amounts to 10.5 percent.

Figure 1

Note that the flow increase amounts to 10.5% in this

case. Multiply the heat conveyance just calculated by the

percentage of flow increase:

1.105 X 9,677 = 10,693 BTUH

It is apparent that from the standpoint of heat conveyance, the

simple “round number” approach will result in design flows

very close to the “temperature corrected” flows, providing the

result from the “round number” approach is left uncorrected

from the original 60ºF. base for both heat conveyance and

piping pressure drop. The plus and minus factors very closely

100

0

90

80

70

60

50

40

30

20

10

10 20 30 40 50 60 70 80 90 100 110 120

PEERCENT OF HEAD

PERCENT OF FLOW

Actual system curve

Actual head, only 80%

of specified at specified

flow for 200ºF water

Actual Flow, 110.5%

of specified @ 100% head

Specified point:

100% head at 100% flow

2

offset one another. A similar analysis for chilled water systems

shows that increased viscosity at lower temperatures reduces

flow compared to 60ºF water, but the changes are small.

Sometimes other fluids are used to carry heat; for example,

water and glycol solutions. Their properties are likely to be

quite different from those of standard water, so the system

designer must account for them. The tools for doing that will

be described later.

System Pressure Drop

Water flowing through piping encounters resistance due to

friction at the confining walls of the piping. This resistance is

called the “pressure drop”, or “friction head loss” of the piping

system. Pumps are installed in a closed loop piping system in

order to apply work to the system fluid to overcome friction

head loss and maintain flow.

Pressure drop will, of course, vary with the condition of the

piping; the rougher or more corroded or scaled the piping,

the higher the pressure drop for a given pipe length and flow.

Pressure drop tables are available for new, clean pipe as well

as for piping which has aged and offers more resistance to

flow because of its relatively poor condition.

Piping in a closed system, with little or no make-up water, can

be considered to be clean pipe since it does not deteriorate or

scale with the passing years. Use of aged pipe pressure drops

will result in deceptively high calculated pressure drops which

in turn result in the selection of pumps which are oversized

for the system. The oversized pump will cause flows much

greater than design requirements resulting in high water

velocities which in many cases become audible and result in

unhappy building tenants. On the other hand, piping in open

systems like cooling towers can experience aging. Higher

design velocity in these piping systems may retard scale

deposits. Any noise is unlikely to cause objections, although

the resulting higher pressure drops will increase pumping

costs.

Velocity and Friction Head Loss Limits

The selection of pipe sizes and pumping equipment also

involves economic factors. Pumps which are larger than

necessary result in higher initial costs and increased

operating costs, especially in larger horsepower ranges.

Pipe size is determined by the flow rate required in

that portion of the system. The designer must give due

consideration to the effect of the pipe size on water velocity

and pressure drop. The water velocity should, of course,

be evaluated on the basis of both the lowest and highest

velocities which can be tolerated. Velocities must be high

enough to entrain any air and carry it to the air separator but

low enough to avoid the generation of flow noise.

Tests have shown that minimum velocities of 1½ to 2 feet

per second must be maintained to entrain air bubbles;

particularly to drive them down vertical piping. Selecting a

pipe with a friction loss rate of 0.85 feet of head loss per 100

feet of length will insure adequate minimum velocity. The

maximum allowable velocity depends on pipe size. Small

diameter pipes up to 1½" can allow velocities up to 4 feet per

second. Higher velocities can be allowed in larger pipe sizes.

Where quiet operation is a design objective, sizing piping for

friction loss rate no greater than 4.5 feet of head loss per

100 feet of length will give good results.

Where noise is not an important consideration, higher

velocities may be used within the limits imposed by

economical pump selection. A prime consideration in any

case is entrained air, which can cause noise even at low

water velocities. System design for proper management of

entrained air can be accomplished as outlined in other Bell &

Gossett publications.

System Piping Arrangements

Prior to the determination of actual pipe size and pressure

drop determination, the designer must establish the piping

configuration of the proposed system to deliver water to

the heat transfer units. Single pipe and two-pipe systems of

various kinds are available. Each has characteristics which

may make it more or less appropriate for the system being

designed. The flow required to carry heat to or from each

terminal unit, and the pipe size to carry this flow can be

determined next. The pressure drop can then be calculated

for the various pipe sizes and lengths in the circuit using tools

provided for this purpose. In addition to the piping, the circuit

will contain fittings, heat transfer equipment, valves of various

types and the terminal units themselves; these will also offer

resistance to flow so their pressure drops must be calculated

or estimated and added to that of the piping.

Design Example:

Series Loop Piping System

The simplest distribution piping arrangement is the series

loop, used primarily for residential, small apartment systems

and retrofits. In this system, the radiation is connected in

series and therefore, becomes a part of the piping main.

The basic advantage is economy as substantial savings in

piping materials and the cost of installing these materials are

affected. Figure 2 illustrates a one-pipe series loop system.

Series Loop System

Figure 2

Water temperature entering each unit depends upon how

much heat was extracted or added upstream. This makes it

impractical to install too many units in series since the water

temperature could become too high or too low for effective

heat transfer. The flow through a single circuit system is

limited to the water carrying capacity of the tube size used in

the heating units. In residential systems, these units are often

¾" copper baseboard, but commercial systems may use 1"

or 1½" units. They may also use much higher pressure drop

units like convectors or unit heaters. Another limit to circuit

Pump

Heating units

Boiler

Compression

Tank

3

length is the combined pressure drop of all the components.

Too many components in series would require very high

pump head. Control of heat transfer by modifying the flow is

limited since a reduction at one device reduces flow through

all of the terminals in that circuit.

When the system flow requirements exceed the capacity

of a single circuit, two or more circuits may be taken off a

distribution or “trunk” main. A return trunk main is used to

pick up the various circuits and return them to the boiler.

Three Circuit Series Loop System

Figure 3

This is a three circuit series loop system. Assuming the use

of ¾" copper tube convector baseboard, each circuit must

be limited to the flow this size tube can handle within

practical limits of pressure drop and velocity; about 4 gpm.

The minimum flow rate and supply temperature leaving

the boiler must be great enough to supply all three zones

simultaneously. At a 20° Δt, that means:

• Circuit #1 is getting 40,000 BTUH

• Circuit #2 is getting 40,000 BTUH

• Circuit #3 is getting 30,000 BTUH

The supply trunk, A-B, must carry 11 gpm, section B-C must

carry 8 gpm, and so on.

The system pressure drop is determined by that of the highest

pressure drop circuit. Circuit #2 is the longest as measured

from the boiler supply, through the circuit and back to the

boiler return. A pump must be able to provide the sum of all

three circuit flow rates, 11 gpm at the head determined by the

longest, or highest pressure drop circuit.

Design Example:

Two-Pipe Systems

In a two-pipe system, the heat transfer terminals are in

parallel. The difference in pressure from the supply main at

the pump discharge to the return main at the pump suction

allows the use of higher pressure drop coils. All of the devices

see the same supply temperature, and “zoning”, is easy and

effective since the flow through one circuit can be changed

without a substantial effect on the other zones. A “zone” is a

room or a collection of rooms which are sufficiently similar

in terms of heat transfer requirements that they could be

controlled by a single control device, e.g., a thermostat. In

an apartment building, each apartment will probably be a

separate zone. Larger, multiple zone systems, will benefit in

piping cost savings from a careful analysis of pressure drop.

Figure 4 shows a two-pipe, direct return system on the left.

The first circuit to get water is the first to return it. Since the

farthest unit has the longest pipe run, it probably determines

the pump head required, assuming that all the terminals have

roughly equal pressure drop. A reverse return system, shown

on the right will equalize the piping length, so all terminals

see the same pressure difference from supply to return.

Direct Return and Reverse Return Two-Pipe

Pumping Systems

Figure 4

Figure 5 is a piping layout for a 12-apartment, zone controlled

heating system. The system layout is based on overhead

supply, with four supply risers dropping down from the

supply main. Each supply riser feeds three apartments, with

series loop connected baseboard controlled by a zone valve

in each apartment. Return risers drop down from each group

of three apartments and are picked up by the basement

return main. Both the mains and the risers are hooked up in

reverse return. Apartments are all the same size; the four top

apartments each have a heat loss of 40,000 BTUH while the

other apartments are 34,000 BTUH each.

Circuit #1

4 gpm

100 ft.

Circuit #2

4 gpm

120 ft.

C

B

A

Circuit #1

3 gpm

90 ft.

Boiler Boiler

4

Figure 5

Figure 6 shows only the top floor circuit which will be used to

determine the system pressure drop, and therefore, the pump

head requirement. The flow in each pipe section is shown and

the lengths are determined from the plan.

Figure 6

The trunk main, A to B, is sized to carry full system flow, but

flow in the supply main becomes smaller as each radiation

zone gets its share of the flow, while the flow in the return

main gets larger. An experienced designer would probably

select a 2½" or possibly a 2" pipe for section A-B. The smaller

pipe would have the greater friction loss rate over the length

of A to B. The product of length and friction rate yields the

total head loss in that pipe. Section B-C carries 22.4 gpm but

is very short. Section C-D carries only 11.2 gpm but is much

longer, and contains more fittings. Theoretically, each section

of pipe must be evaluated in terms of the flow it must carry, a

pipe size must be chosen, friction loss rate determined, then

multiplied by length to get the total head loss in that section.

After that, the sum of head loss in all sections has to be added

to the head loss of the boiler and the fittings before the pump

can be selected. In practice, the process can be simplified by

applying some judgment. For example, an average flow rate,

or most important flow rate could be applied to a long pipe

section to reduce the number of calculations, rules of thumb

might be applied to account for fittings, etc. Later in this book,

we’ll see that the Bell & Gossett System Syzer

®

is invaluable in

this process.

Application of Pump Curve Data

Centrifugal pump performance curves are developed by test

with 85ºF water and usually relate flow in gpm to foot head.

In terms of relating pumping capacity, the term “foot head”

indicates that the pump is applying one foot-pound of energy

to each pound of liquid being pumped. The curve can be used

for water at any temperature, since “foot pounds per pound”

is an energy statement based on a specific weight to energy

relationship that remains the same regardless of temperature

or fluid density.

Specific Gravity

Standard water, with a specific gravity of 1.0 supports a water

column of 2.3 ft. for each PSI, or 0.43 psi per foot of water

column. The fluid column required for any other specific

gravity is derived by the formula:

Fluid column in feet = 2.3

SG

For a fluid of lower density, specific gravity of 0.6:

Fluid column in feet = 2.3/0.6

= 3.85 feet

Water Horsepower

Bell & Gossett Series 1531 Pump Curve

Figure 7

A pump curve indicates the pump will deliver 400 gpm at

30 ft. head. This means the pump will add 30 ft-lbs energy

to every pound of liquid when 400 gpm are circulating. If

the liquid is water at 8.3 lbs/gal, the weight of the circulated

water would be 3,320 lb /min. At 30 ft-lb per lb this would be

30 x 3,320 or 99,600 ft-lb/min energy input to the pumped

water. Dividing by 33,000 ft-lb/min per HP indicates the

pump is applying about three water horsepower, “WHP”.

44.8 GPM

44.8

GPM

A

N

B

C

D

22.4 GPM

22.4 GPM

11.2 GPM

11.2

GPM

E

22.4 GPM

22.4 GPM

11.2 GPM

11.2 GPM

11.2 GPM

M

L

K

J

H

4.0 GPM

4.0 GPM

7.6 GPM

COPPER TUBE

D

E

F

C

B

G

A

N

M

K

L

J

H

5

Head,

ft-lb x

Flow,

gal

x Specific gravity

WHP =

lb min

33,000 ft-lb x 1 gal

min 8.34 lb

hp

WHP =

Head (ft) x Flow (gpm) x SG

3960

WHP =

30 x 400 x 1

3960

WHP = 3.03 hp

The WHP used by a pump is very important because it relates

the system head and flow to the pump’s power requirement.

WHP represents the “transport energy” required to move

water against the system’s resistance. No practical machine

can be 100% efficient, so the actual horsepower input to the

pump will always be greater then the WHP. The efficiency of

the pump and the WHP combine to determine the actual

amount of power required by the pump in the given system.

This factor is called brake horsepower, or “BHP”. If the pump is

80% efficient at 400 gpm and 30 feet of head, it would use a

little less than 4 hp.

BHP =

BHP

Pump efficiency

BHP = 30 x 400 x 1

3960 x .08

BHP = 3.79 HP

Since 4 HP motors are not standard, this power would

probably be provided by a motor rated to provide 5 HP, but

actually delivering only 3.79 HP to the pump. These values

are displayed in Figure 7, which is a screen taken from Bell &

Gossett’s ESP Plus. This useful computer application will be

described in more detail later. The electrical energy used by

the pump, and therefore the building owner’s cost to operate

that pump, make BHP a very important factor in selecting and

evaluating pump performance.

Assuming that gauges were placed on the suction and

discharge openings of the pump and that these gauges were

calibrated in PSI, what would the differential readings be?

Since we have added 30 ft-lbs of energy per pound, each

pound is equivalent to 30 feet of the pumped liquid. In this

case, water is being pumped with a weight of 0.43 PSI per ft.,

so the gauges would read a differential of 30 ft. x 0.43 PSI or

12.9 PSI differential.

The specific gravity of the pumped fluid affects the required

water horsepower to raise the energy level of the pumped

fluid. Suppose the fluid being pumped had a specific gravity

of 0.6, or 0.6 times the density of standard water. This fluid

would have a weight of 0.26 psi per ft. The gauge differential

would be 30 ft. x .26 or 7.8 PSI.

Thus, the gauge differential, regardless of specific gravity,

will always read the energy level in terms of feet of the fluid

being pumped. In the case of the gauge differential with

water, the head can be determined by using the differential

of 12.9 PSI and multiplying this by 2.31 feet per PSI, which

gives 30 feet of head. Reference to the pump curve would

indicate a flow of 400 gpm.

The fluid with a specific gravity of 0.6 would require a column

3.85 ft. high to exert a pressure of 1 PSI. The gauge reading

differential for this fluid was 7.8 PSI; multiplying by 3.85 ft.

per PSI gives 30 ft. as the pump head.

Therefore the pump curve can be applied to liquids of any

specific gravity without correction. The changes in specific

gravity of water due to temperature have no affect on the

pump curve. Even though these curves are established

by test with 85º water, they may be used for water of any

temperature.

Effect of Volume Flow Changes

Water expands when it’s heated, contracts when it cools, so

volume flow, in ft

3

/min changes a little bit due to temperature

differences. Warmer water in the supply will flow a little

bit faster than the return water. These differences are small

enough to ignore without introducing any appreciable error.

But the mass flow rate, lb/min remains a constant because

water is essentially incompressible. At steady state conditions,

that is, the average water temperature in the system is not

changing; the mass flow rate must be the same in the supply

and return mains regardless of the difference in temperature

between them. In other words, the heat input at one point in

the system must be equal to the heat rejected at some

other point.

Calculating system pressure drop

Piping Pressure Drop

Pressure drop in straight runs of piping could be calculated by

reference to charts which state these losses in terms of feet of

60 °F water head per hundred feet of piping. An example is

included in the appendix.

The Darcy-Weisbach relationship is the basis for

determining friction head loss in pipes:

Friction head loss = f

L V

2

D 2g

Where:

Friction head loss is in units of feet of head, or foot-pounds of

work lost to friction/pound of fluid

f is the friction factor, which relates variables such as

Reynolds number, relative roughness of the pipe, and

flow regime, e.g. laminar, transition, or turbulent flow.

L is the pipe length in feet

D is the pipe diameter in feet

V is the average flow velocity in the pipe in feet per

second

g is the gravitational constant, 32.2 feet per second

2

The rate of friction head loss used to be stated in terms of

“milinches” per foot of pipe. A milinch is 1/1000 of an inch;

therefore, one foot of head is equivalent to 12,000 milinches.

This term was used because it was convenient to work with

when dealing with small increments of head loss. Most

designers today use units of feet of head loss per 100 feet of

system length. Design flow rate, pipe size, and pipe type will

determine the friction loss rate.

()

(

)

6

Fitting and Valve Pressure Drop

Pressure drop for various fittings and standard valves is

sometimes stated as some multiple of the velocity head:

Fitting head loss = k x

V

2

2g

Where

k is the head loss coefficient for the type of fitting

V is the average velocity of flow through the fitting

g is the gravitational constant

It is possible to save time-consuming calculations for

determining fitting pressure drops by establishing a table

which reads directly in equivalent feet of piping for all fittings.

The variation in equivalent length due to velocity differences

is not of great magnitude in the flow ranges encountered in

hydronic design work. A table of fitting equivalent length

is included in the appendix. In determining the length of

pipe and the pipe size attributable to a given fitting, the

downstream pipe size is used and the fitting pressure drop is

established as the number of feet of that pipe size multiplied

by the friction loss rate. Figure 8 illustrates how the pipe size

is determined. For example, if the flow pattern is from C to B,

the pipe size of F would be used in assigning pressure drop

for the branch flow of the tee.

Where flow enters a tee at C and splits to both A and B, the

pressure drop of the circuit flowing from C to B would involve

the tee branch loss based on pipe size F. The circuit flowing

from C to A would include the tee branch loss based on pipe

size J.

Flow Path Pipe Size Applying to Equivalent Length

A to B F

A to C H

C to B F

D to E G

Figure 8

Pressure Drop of Other System Components

A piping circuit has, in addition to the pipe and fittings,

components such as heat exchangers, boilers, or other units

which have a substantial pressure drop. The pressure drop

of these components is usually stated by the component

manufacturer in either tabular form at various flow conditions

or as pressure drop curves on a chart. Figure 10 is such a chart

showing the pressure drop characteristics for Bell & Gossett

Circuit Setter Balancing Valves. Circuit Setters are used to

prevent unwanted excess flow in the branch of the system

where it’s installed. The round dial sets, and indicates the

valve opening.

Bell & Gossett Circuit Setter

Figure 9

As an example of the use of this chart, assume that a circuit

branch has a Circuit Setter Valve in it set at “0”. The valve

presents little resistance to flow, so a given pressure difference

on the vertical axis results in a large flow rate represented

on the horizontal axis by gpm 1. As the valve is set more

nearly closed, the flow rate at the given differential pressure

would be reduced shown as gpm 2 and then gpm 3. All

components in the system: pipes, elbows, heat exchangers,

demonstrate a similar relationship between flow rate and

head loss or pressure drop. The Circuit Setter is unlike those

other components in that it can change the relationship as it

is manually set from wide open to dead shut.

Control Valve Pressure Drop

Pressure drop data for control valves is often given in terms

of a “Cv” rating for the valve. The Cv for any given valve is the

flow in gallons per minute that would cause a 1 psi pressure

drop to appear across the valve. For example, a valve with a

Cv rating of 10 would have 1 psi pressure drop when 10 gpm

flow occurred through the valve.

Flow Rate vs Pressure Drop

Figure 10

In the Circuit Setter, each manual dial setting establishes a

unique Cv. If the horizontal dashed line represents 1 psi or

2.31 feet of head loss for standard water, then gpm1 is the

Cv for the fully open Circuit Setter, gpm2 and gpm3 are the

lower Cv’s as the valve is closed. If the valve is shut dead tight,

the Cv is 0.

System control valves react in exactly this way, but they

operate automatically in response to a thermostat and

temperature control system.

Headloss Feet

or

Pressure Drop

PSID

Flow Rate

GPM

gpm 1gpm 2gpm 3

Valve Set

Fully Open

Valve Set

Midway Open

Valve Set

Almost

Closed

HG

DBA

FJ

C

E

7

The pressure drop of the valve will vary as the square of the

flow difference. Since the valve pressure drop is 1 PSI at its

Cv flow rating, the formula is:

C

V

=

GPM

Δp

The flow and pressure drop relationship can be

established for any condition using the Cv.

To illustrate, assume a valve with a Cv of 10 will be used to

control a flow of 30 gpm, what will the pressure drop through

the valve be at this flow?

Valve pressure drop (psi) =

GPM

2

C

V

Valve pressure drop (psi) = (30/10)

2

= 9 psi

To determine the pressure drop in terms of feet of water head,

multiply by 2.3 assuming standard water.

9 x 2.3 = 20.7 Ft.

Control Valve Types

Control valves are used to modulate the system water

temperature or to control the quantity of water flowing

through the system heat exchangers. The valves are furnished

in two general types, two-way or three-way, depending on the

number of ports in the valve.

Two-way valves are often used as two-position valves, either

open or closed. A commonly used illustration is the zone

valve, operated by a thermostat, which opens the valve on a

call for heat and closes it when the heat demand is satisfied.

Double and Single Seated Control Valves

Figure 11

The double-seated valve has no hydraulic forces acting on

the valve stem, as water flowing through the ports tends

to open one disc and close the other. The single-seated

valve must operate against the hydraulic force of the water

entering the port as the valve moves toward the closed

position. The double-seated valve is not used for tight shut-off

requirements as the common shaft connecting the two discs

expands and contracts with temperature changes, making it

difficult to close both ports simultaneously. Therefore, either

valve may be used for modulating type operation but for two-

position, (on-off) the single-seated valve is used.

For two-position operation, the valves are usually line-sized

and are selected for low pressure drop. Modulating valves,

on the other hand, should be selected for high initial (wide

open) pressure drops as this enhances control operation by

keeping the pressure drop increase ratio at a minimum as the

valve modulates to close-off. The topic of “valve authority” is

discussed later in this book. Other Bell & Gossett publications

explain valve selection in detail.

Three-way valves are furnished in two basic types. The mixing

type has two inlet ports and the third, or common port is the

outlet. The diverting type makes the common port the inlet

and the other two ports are outlets as shown in Figure 12.

Three-Way Mixing and Diverting Valves

Figure 12

Severe valve chatter may result if the common port of a

mixing valve is used as an inlet with the other two ports as

outlets as in a diverting valve. As the valve disc approaches

either seat, the velocity pressure will tend to over-ride the

operator and slam the valve shut. The velocity pressure is now

gone and the valve motor will then open the valve again. This

occurs rapidly, with severe chattering as a result.

The same thing happens with a diverting valve if an attempt

is made to use it as a mixing valve. This would require the A

and the B ports to be inlets, with the AB port as the outlet. The

velocity pressure would act to over-ride the operator as either

disc approached its port, resulting in valve slam or chatter.

The application and sizing of three-way valves is covered in

other Bell & Gossett publications. A general statement on

valve selection can be made without going into the actual

procedures. Three-way valves applied in the equipment room

for temperature modulation or system change from heating

to cooling should be selected for low pressure drops, if

possible under ten feet, in order to minimize required

pump head.

It is important from the standpoint of flow stability in a system

using three-way valves to control coil flow, to select the valves

for a substantial portion of the available pump head. As in

two-way valves used for this purpose, the pressure drop across

the valve increases as the valve closes down. This causes an

increase in flow through the valve, making it necessary to

close off still further to compensate for the increase in flow. If

the valve is selected for a low pressure drop, the pressure drop

ratio necessary to throttle to a given flow will be very large

and the valve will have to “ride” its seat to achieve control.

Therefore, it is good practice to select the valve for high initial

pressure drops, on the order of three times the coil pressure

drop at design flow, if possible. Due to the fall off of coil

pressure drop with reduced flow, coils used with three-way

valve control should be selected for low design pressure

drop. This decreases the effect on circuit pressure drop as the

control valve goes to bypass. Typical three-way valve and coil

installations are shown in Figure 13. The bypass pipe around

the coil must have a Circuit Setter in order to equalize the

√

[

]

8

resistance of the paths through the coil and bypass. Without

the Circuit Setter, the pump flow would increase whenever

flow shifted to the bypass.

Circuit Setters in Diverting and Mixing Valve Applications

Figure 13

Procedures for Calculating Circuit Pressure Drop

Total Equivalent Length Method for Fitting Pressure Drop.

Calculating the actual pressure drop for each fitting can be a

time-consuming and therefore, expensive procedure. In an

effort to reduce design time, an alternate method was devised

in which it is assumed that the fittings and other system

components are equal to 50% of the circuit length. This 50%

is added to the circuit length and the total is considered to

be the Total Equivalent Length, TEL, of the circuit. Practical

experience has shown that this method leads to sufficiently

accurate results for systems up to about 400,000 BTUH. Larger

systems would warrant a more detailed analysis since savings

in pipe size or pumps may result. Short circuits with more

than the average member of fittings should also be carefully

evaluated, since the 50% allowance may not be sufficient to

cover the actual fitting losses. Simple logic and experience

will indicate when a pipe sizing check using actual pressure

drop data for each fitting is required.

Keep in mind that the “50% method” is for fittings and

conventional baseboard radiation only. In the event that

there are high pressure drop devices such as fan coil units

in the circuit, the pressure drop of these devices should be

considered separately.

When the system consists of a single circuit, the pump must

provide the needed flow and overcome the piping pressure

drop at this flow. Larger systems require more circuits to keep

the pressure drop and pipe size down. The pump on multi-

circuit systems must be capable of meeting the pressure

drop of the highest pressure drop circuit, which is usually the

longest circuit. The pump also must furnish the flow required

by all circuits.

The circuits with lower pressure drops will tend to short circuit

the high pressure drop circuit and must be brought up to the

pressure drop level of this circuit by the use of balance valves

or by reduction of pipe size to achieve the desired pressure

drop.

Flow in a pumped system will apportion itself among the

various circuits so that the pressure drops between the pump

and the individual circuits are just equal. The designer should

therefore endeavor, by judicious pipe sizing to keep circuit

pressure drops as close as possible, even though design flows

may vary considerably. This will make the eventual balancing

requirements simpler.

The Design Process

It’s important to follow a coherent process of making

calculations, then making choices based on those calculations

in an orderly manner. Though this is not the only way to

do it, the Bell & Gossett design process makes sure all

the important details are covered. The most economical

combination of pump size and piping size within good

design parameters should be selected.

1. Calculate heat loss and select terminal units

2. Make piping layout to scale

3. Calculate required water flow to carry the load

4. Size the piping

5. Select the pump

6. Select the boiler and other accessories

This method permits very quick pump selection and pipe

sizing for smaller systems. Larger systems should be

evaluated using more sophisticated procedures.

DESIGN EXAMPLE NO. 1

A two-circuit series loop system utilizing ¾" copper convector

baseboard is shown in Figure 14. The Six Step Method will be

used for designing the system at a 20º Δt.

Two Circuit Series Loop System

Figure 14

STEP 1 RADIATION REQUIRED

Calculate the heat loss in terms of BTUH for each room. Find

the output per lineal foot of baseboard at the desired mean

water temperature from the manufacturer’s catalog then

divide room heat loss by this figure to determine the lineal

feet of radiation required in each room

STEP 2 LAYOUT THE PIPING

Make a scale drawing of the piping system. Because the

radiation is in series, the flow in each circuit should not

exceed the carrying capacity imposed by the pipe size of the

radiation. See Step 3 for flow rate calculation.

Nomogram A (in the Appendix) indicates that a 1" pipe could

carry the flow if a single circuit were used, but the proposed

baseboard units are constructed with ¾" copper which is

limited to about 4 gpm, so the system must be split into

two circuits of about 40,000 BTUH each which allows ¾"

baseboard to be used.

STEP 3 CALCULATE REQUIRED WATER FLOW

The total load is 76,000 BTUH. Required flow is therefore:

Flow =

Heat Load

500 Δt

Flow =

76,000

= 7.6 gpm

500 x 20

Circuit 1 will need about 3.6 gpm, circuit 2 about 4.0 gpm

Circuit #1

35,500 BTUH

111 Ft.

Circuit #2

40,500 BTUH

134 Ft.

Mixing Valve

Diverting Valve

Circuit

Setters

Boiler

Circulator

Air Vent

9

STEP 4 SIZE PIPING

The trunk main must be 1”, each circuit will be ¾".

STEP 5 SELECT PUMP

A “Booster” pump is a small in-line circulator often used

for systems like this. It’s a simple pump whose selection

requires little more than knowing the system head and flow.

System flow is 7.6 gpm. System head loss could be estimated

by assuming that the friction head loss everywhere in the

system is near the upper limit of head loss, say 4.0 feet of

head loss per 100 feet of length. The measured length of the

longer circuit is 134 feet, a 50% allowance for fittings would

add 67 more feet for a Total Equivalent Length (TEL) of about

200 feet. Pump head would then be estimated as:

Pump head =

4.0 feet of head loss

x

200 feet of TEL

100 feet of length

= 8 feet of head

If the head loss of other components like the boiler is low,

it may be assumed that this estimate of pump head will be

adequate. If higher pressure drop components are included

in the system, then the published data for their head loss at

the design flow must also be included.

Plot the system head and flow, the “design point”, on a chart

showing the performance of all sizes of booster pumps to

select the specific pump required. A more detailed discussion

follows.

STEP 6 SELECT THE BOILER

Select a boiler with a net rating equal to or slightly greater

than the 76,000 BTUH total heat loss. A discussion of required

air management and other equipment can be found in other

Bell & Gossett publications.

Pump Selection: the System Curve

In many cases, available pumps do not exactly fit the system

requirements. In most cases, designers choose the next

larger size pump. While such a selection may cause no actual

problems, using the next smaller pump can save money, if an

analysis of the problem indicates that this can be done.

The analysis consists of plotting a “system curve”, which shows

system flow versus system pressure drop, on the proposed

pump curves. This analysis will determine how any given

pump will perform in the system because a given pump in

a system must operate at the flow rate determined by the

intersection of the two curves. This is a consequence of the

principle of conservation of energy. The system curve shows

the relationship between flow and pressure drop in a given

piping system. The pressure drop varies in a direct ratio with

the square of the flow change ratio. As an example, if the flow

in a piping system should double, the pressure drop would

increase by a factor of four.

This simple relationship allows us to construct a curve which

can be superimposed on a pump performance curve. The

intersection of the two curves defines the flow, or the point

of operation for the pump in the system. To illustrate this

method we will assume a pump is needed for a system

requiring a flow of 30 gpm at a pressure drop of 20 ft.

The pump curves in Figure 15 show that this design point

falls between a PL-36 and a PL-55 pump. There is no point of

intersection at exactly 30 gpm. Which pump should be used?

Using the design condition as a starting point, we can

construct a system curve which will indicate the flows which

either pump would produce.

Figure 15 shows the design point – 30 gpm @ 20 ft. We will

determine several points, beginning with 50% flow, or 15

gpm. The system pressure drop at 15 gpm will then be the

square of the flow ratio; that is the square of 0.50 which is

0.25 of the design pressure drop. 25% of 20 = 5 ft. Several

other points could be determined in similar fashion.

Assumed Ratio to Ratio to Design Head at

Flow Design Design Head New

gpm Flow Head Feet Flow

0 0 0 20 0

15 0.50 0.25 20 5.0

20 0.66 0.43 20 8.6

25 0.83 0.69 20 13.8

30 Design 1.00 1.00 20 Design 20

35 1.17 1.37 20 27.4

Plot these points on the curve as in Figure 15 and connect

them with a smooth line. This is the system curve. The line

intersects the PL-55 curve at 33 gpm and the PL-36 at 27 gpm.

We can now calculate the effect of either pump on system

operation.

10

System Curve Method for Pump Selection

Figure 15

If the system uses a 20º temperature drop, the lower flow

of 27 gpm will increase the design temperature drop. The

relationship between flow and temperature drop is an inverse

one; if we double the flow we halve the temperature drop and

vice-versa. We can therefore, set up a proportion to calculate

the effect of reducing flow:

30 gpm

=

x

Δ

t

= 22º

27 gpm 20 Δt

From this, we can determine that the system will operate at

a 22º design temperature drop instead of 20º, if we use the

smaller pump. This is negligible since heat output in units

like baseboards or convectors is not greatly affected by small

changes in flow. Output is strongly affected by changes in

average water temperature so the lower flow rate could

be easily compensated for by slightly raising the system

operating temperature if necessary.

The effect of using the PL-55 pump at 33 gpm can be

calculated in the same way. The larger pump provides 33

gpm, so the temperature change at the boiler would be about

18ºF.

It is probable that the smaller pump is the better selection

since it probably has a lower initial cost. It also has a smaller

motor, thus reducing operating costs at least a little bit.

The Bell & Gossett System Syzer

®

Determining the required operating head and flow for small

hydronic systems is relatively simple. However, an engineer

must consult several different design tables, charts, and

formulae to establish flow requirements, pipe size, pipe

pressure drops, water velocities, pumping heads, system

curves, control valve Cv ratings, etc. The B&G System Syzer

®

Calculator consolidates all necessary design information in a

simple, easy to use circular slide rule.

The System Syzer

®

Calculator is useful both in final design

work and in preliminary system planning. Proposed pump

and pipe sizes can be quickly roughed out for estimating

purposes.

System Syzer

®

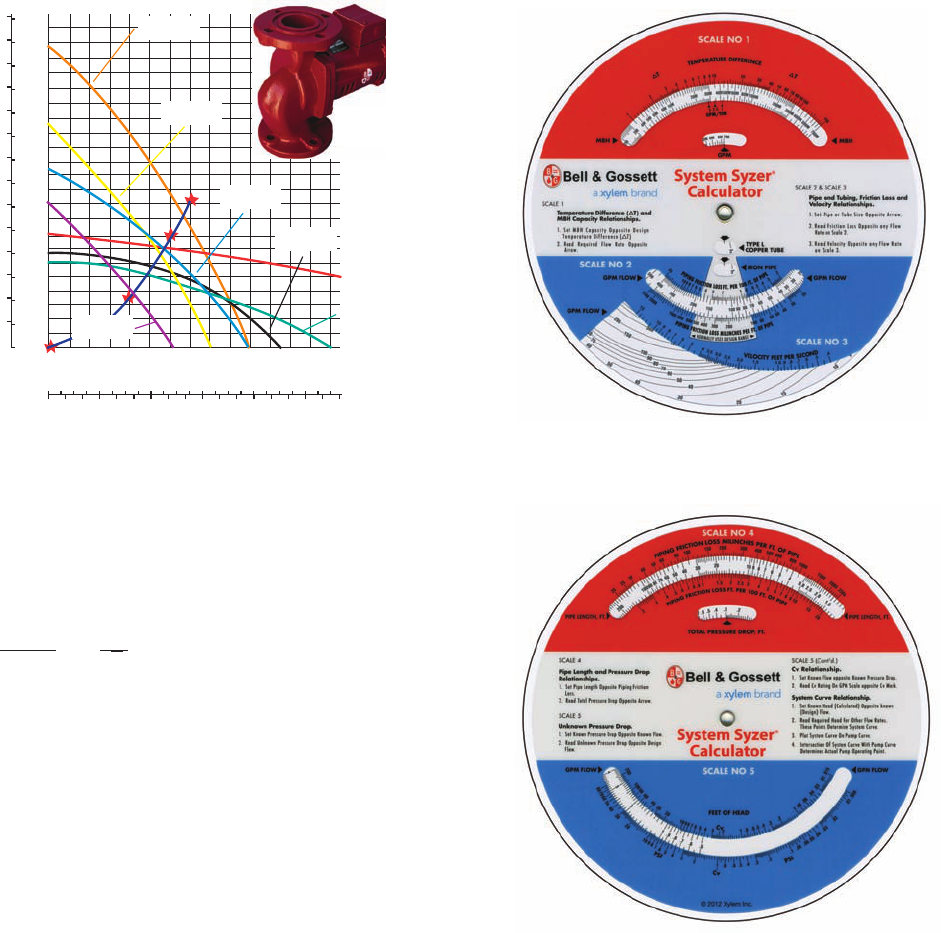

Scales 1-3

Figure 16

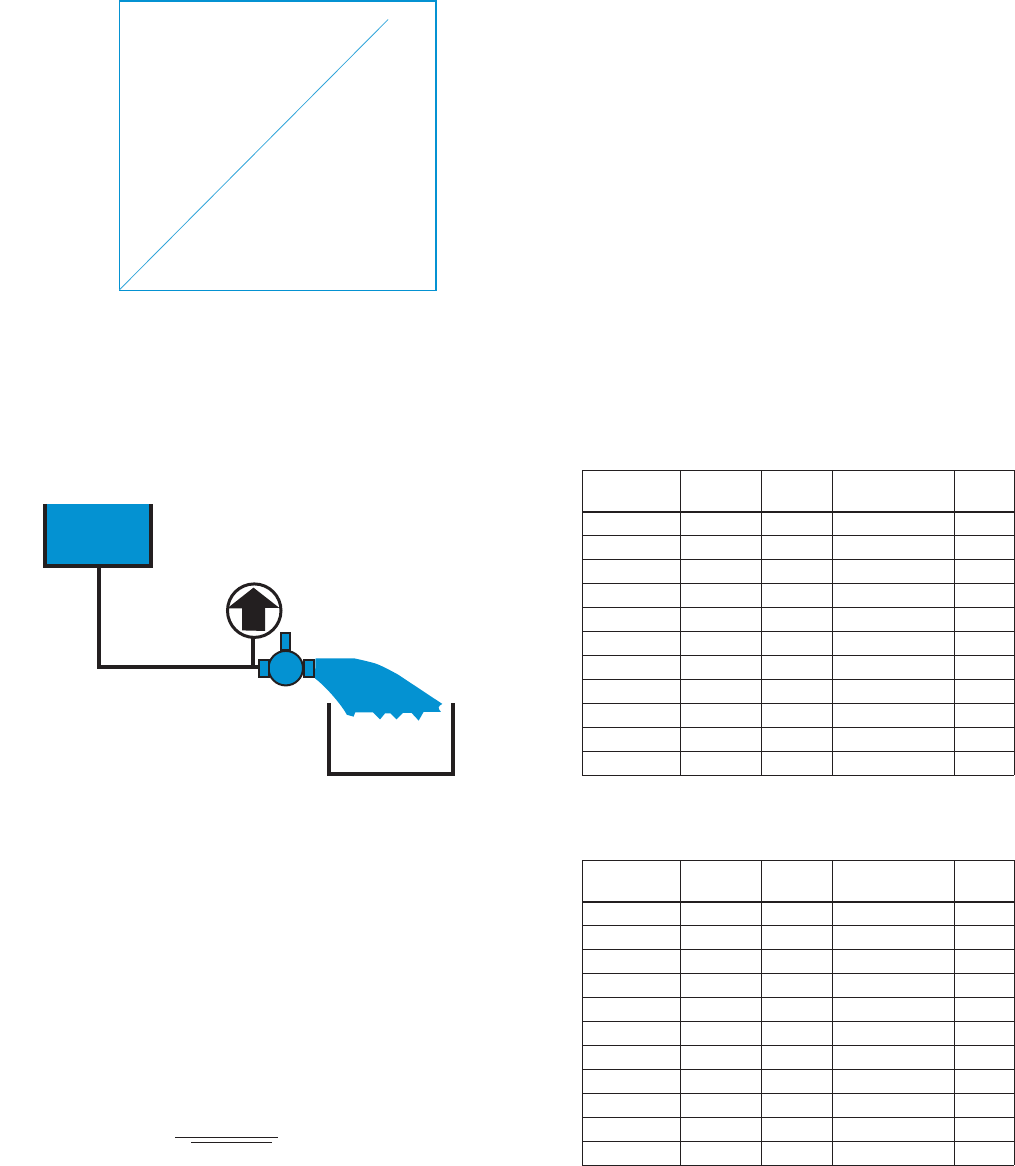

System Syzer

®

Scales 4-5

Figure 17

The System Syzer

®

Calculator has five scales sequenced

in the same way in which they would typically be used in

designing a hydronic system. The following discussion gives

the reference base of the various scales and illustrates their

uses with design examples. It’s best to obtain a System Syzer

®

calculator from your Bell & Gossett representative and use it to

work through these examples.

Scale #1 – Load-Flow Relationships

Scale #1 is stated in terms of temperature difference, MBH

and gpm. These terms are defined as follows:

A. Temperature difference is the temperature drop (heating)

or temperature rise (cooling) taken by the water as it

transports heat through the system.

PL-55

PL-36

PL-45

PL-50

PL-30

55

50

45

40

35

30

25

20

15

10

5

10 20 30 40 50 60 700

140

130

120

110

100

90

80

70

60

50

40

30

20

10

00

1

2

3

4

5

6

7

8

9

10

11

12

13

14

01234

0246810 12 14 16

Bell & Gossett

Series PL Circulator

11

B. MBH is the heating or cooling load in Btu per hour where

1 MBH = 1000 Btu per hour; 10 MBH= 10,000 Btu per

hour; 1000 MBH = 1,000,000 Btu per hour or 1M.

C. gpm is the circulation rate in gallons per minute required

to convey the design heat load at design temperature

difference.

Flow rate in gpm, temperature difference in degrees F and

MBH load are related by the following formula:

Flow =

Heat Load

500 Δt

Scale #1 uses a specic heat equal to one and

water density at 8

1

⁄

3

lbs. per gallon (60ºF conditions). Changes

in these properties and their effect on heat transfer have

already been discussed.

Example #1: Determine required ow rate for a load of

150,000 Btu per hour at a temperature drop of 30º.

Set the 150 MBH capacity in the large window under the 30º

design Δt. Read gpm flow rate in the small window opposite

the arrow: 10 gpm.

Example #2: Determine required ow rate for a cooling load

of 20 tons at a 10º temperature rise. At 12,000 Btuh per ton,

a 20 ton load is equivalent to 240,000 Btu per hour or

240 MBH.

Set 240 MBH opposite 10º temperature difference and read

48 gpm on the gpm scale.

Design Temperature Difference: For many years hot water

systems have been designed for a 20º temperature drop. This

has been done because at a 20º temperature drop, each gpm

circulated conveys about 10,000 Btu/hr. This allows simple

determination of flow rates by use of the following formula:

GPM =

Heat Load

10,000

A 20º temperature drop in typical terminal units also provides

a great deal of “forgiveness”; 100% of design flow is not

necessarily required to get a very high percentage of design

heat transfer. While the 20º design temperature drop is still

useful for small hydronic system, it is not necessarily best for

a larger engineered system. Higher temperature drops permit

lower flow rates, smaller pipe and pump sizes and in general

return economic benefits.

Scale #1 of the System Syzer

®

Calculator will assist the

hydronic designer in establishing minimum flow – maximum

temperature difference system design through the various

design approaches now available. These include primary-

secondary pumping, coil re-circuiting, terminal unit flow

evaluation, etc. Because of the simplicity of determining flow

rates for various temperature differences, the System Syzer

®

Calculator will aid greatly in the design of higher temperature

difference systems.

Example #3: Determine primary to secondary ow rate for

a secondary zone using a heat injection pump as illustrated

in Figure 18. Negligible pressure drop in a pipe which is

common to two pumping circuits makes the two pumps

operate independently of one another. Details of primary-

secondary pumping are available in other Bell & Gossett

publications.

Figure 18

The radiant panel in the secondary zone requires 10 gpm

of 110º water at a 10º Δt to provide the zone requirements

of 50,000 Btu/Hr. Water at 200F is available at the primary

supply pipe. At design load conditions, the required quantity

of 200º water must flow from point A to point B. An equal

quantity of 100º water must flow from point C to point D. The

temperature difference between point A and point D of 100º

(200º-100º) and the 50,000 Btuh required for the secondary

zone determine the flow required from the primary to the

secondary circuit.

On scale # 1 of the System Syzer Calculator, set the 100º

temperature difference opposite 50 MBH. Read the required

primary to secondary flow rate: 1.0 gpm. The heat injection

pump should be sized to deliver 1.0 gpm against a head

determined by circuit A-B-C-D.

Example #4: There are many ways to use primary-secondary

pumping principles. In the next example, a one-pipe primary

loop supplies hot water to an independent secondary zone

through a small control valve. Determine the temperature

drop in the primary main of a one-pipe primary system with

a circulation rate of 50 gpm, after supplying 50,000 Btuh to a

secondary zone as illustrated in Figure 19.

Figure 19

As in the preceding example, the flow from A to B is 1.0 gpm.

Since the total primary flow is 50 gpm, a flow of 50 minus 1.0

or 49 gpm of 200º water will flow from point A to D. At point

D, 1.0 gpm of 100º water will blend with the 49 gpm of 200º

Radiant Panel

50,000 Btu/Hr

110F 100F

Primary Supply

200F

Primary Return

?F

BC

AD

BC and AD are the low pressure drop

“common” pipes that allow

the pumps to operate independently

Circuit Setter

Secondary Panel

50,000 Btu/Hr

110F 100F

Primary Supply 50 gpm 200F

?F

BC

AD

Circuit Setter

Control Valve

12

water to give 50 gpm, but at a reduced temperature. What is

the temperature downstream of point D?

Set 50 gpm in the small window of scale #1. Directly opposite

50 MBH read the temperature difference: 2º. Therefore, the

temperature beyond point D is 200º minus 2º = 198º.

Scale #2 – Flow-Pressure Drop Relationships and

Pipe Sizing

Scale #2 relates gpm ow rate to friction loss rate for both type

“L” copper tubing and for Schedule 40 steel pipe. Friction loss

is stated in terms of milinches per foot and in feet per 100

feet of pipe. Either milinches per foot or feet per 100 feet are

valid expressions of pipe friction loss. Defining these terms:

A. Milinch means 1/1000 of an inch or 1/12,000 of a foot of

pressure energy head.

B. Feet per 100 feet expresses the rate of pipe friction loss as

foot head of energy loss per I 00 feet of pipe.

The pipe friction loss data used as a basis for construction

of scale #2 are The Hydraulic Institute Values, The ASHRAE-

Giesecke Chart Values and The ASHRAE Unified Pressure

Drop Chart data. Both the Hydraulic Institute values and

The ASHRAE Unified Pipe Pressure Drop data are based on

Moody’s pipe pressure drop correlation. Though established

by an entirely different experimental approach, the Giesecke

Chart values closely approximate Moody’s correlation-

generally accepted as most valid. Friction loss indicated for

type “L” copper tubing has been derived from the ASHRAE

Handbook.

Scale #2 is based on a water temperature of 60º. When used

for hot water design with temperatures in the area of 200º

piping pressure drop is over-stated on the order of 10% since

pressure drop decreases slightly as water temperature is

increased. However, the difference is not sufficient to warrant

correction.

The normally used range of pipe friction loss rates is indicated

by a white wedge shape band on scale #2. Experience

indicates that the optimum friction loss range is from 100 to

500 milinches per foot or from approximately 0.85 foot to 4

.5 feet per 100 feet of piping.

Example #1: Determine pipe size for 70 gpm ow rate. Set

the rule so that 70 gpm appears in the “white” or optimum

design range on the rule. It is apparent that either 2½" or 3”

pipe can be used. Setting the arrow to 2½" pipe size in the

iron pipe window, a pipe friction loss rate of 3.6' per 100'

appears opposite 70 gpm. A simultaneous reading on scale

#3 establishes that at 70 gpm a water velocity will be 4.5' per

second.

Setting the rule to 3" pipe illustrates that at 70 gpm flow

rate a pipe friction loss rate of 1.2' per 100' will occur. A

simultaneous reading on scale #3 indicates a water velocity of

3.0' per second.

Setting the rule to any pipe size then provides a complete

flow-pressure drop-velocity relationship for that particular

pipe size. In the example, either 2½" or 3" piping, could be

used for the flow rate of 70 gpm, depending on circuit needs,

available pumping head, etc. In many cases, the hydronic

system designer may also wish to evaluate water velocity as

this affects pipe sizing.

Scale #3 – Water Velocity

Scale #3 establishes water velocity in feet per second for

any given flow rate through the particular pipe size. Water

velocity in the hydronic system should be high enough to

carry entrained air in the water stream-yet not high enough to

cause noise. Water velocity should be above 1½ to 2 feet per

second in order to carry entrained air along with the flowing

water to the point of air separation (Rolairtrol, EAS, etc.) where

the air can then be separated from the water and directed to

the compression tank or vented from the system. See other

Bell & Gossett publications for details about air management

in hydronic systems.

Piping noise considerations establish the upper velocity

limitations. For piping 2" and under a maximum velocity of

4 feet per second is recommended. Note that in smaller pipe

sizes, this velocity limitation permits the use of friction loss

rates higher than 4 feet per hundred foot.

Velocities in excess of 4 feet per second are often used on

piping larger than 2 inch. It seems apparent that water

velocity noise is caused by entrained system air, sharp

pressure drops, turbulence, or a combination of these which

in turn cause flow separation, cavitation and consequent

noise in the piping system.

It is generally accepted that if proper air management is

provided to eliminate air and reduce turbulence in the

system, the maximum flow rate can be established by the

piping friction loss rate; at 4 feet per 100 foot. This permits

the use of velocities higher than 4 feet per second in pipe

sizes 2" and larger.

Example #1: A supply main in an apartment building has a

design flow rate of 1600 gpm. Select the proper pipe size.

Setting Scale #2 at 8" pipe shows that at 1600 gpm, the pipe

friction loss is 3.8 feet per hundred feet. Scale #3 shows that a

water velocity in excess of 10 feet per second will result.

Setting the rule at 10" pipe illustrates a pressure drop of

1.2 feet per 100 foot and a water velocity of 6.5 feet per

second, less likely to cause noise. Because the main must

run adjacent to living quarters, a critical location concerning

possible noise generation, the 10" pipe would be preferred.

Scale #4 – Circuit Piping Pressure Drop

Scale #4 provides a simple method of determining required

pump head from the equivalent circuit piping length and the

resistance per unit length. To use Scale #4, it is rst necessary

to establish the total equivalent length (TEL) of the piping

circuit. As all fittings have a greater resistance to flow than

a straight length of pipe, this must be taken into account.

TEL is a summation of the straight lengths of pipe plus the

equivalent length of valves fittings, etc.

In preliminary pipe and pump sizing, it is common practice

to consider the resistance of fittings in a circuit to be a

percentage of the straight length of pipe (usually 50%). In

making a more accurate pressure drop calculation, the actual

resistance of each fitting should be considered. The table on

the back of the System Syzer Calculator envelope indicates

the equivalent length of most commonly used fittings. Recent

research has shown that these equivalent lengths tend to

13

overstate the fitting head loss by some amount depending on

type of fitting and fitting size. Therefore, use of these values

builds in a small safety factor.

Example #1: A circuit owing 200 gpm is sized at 4" providing

a friction loss of 2.3 feet per l00 feet. The circuit has a TEL of

130 feet. What is the total circuit pressure drop?

Set 130 foot pipe length opposite 2.3 feet per 100 feet and

read 3 feet as the total circuit pressure drop.

In some instances, the system designer may wish to make

a preliminary pump selection and proportion its available

head over the longest circuit in the system to determine the

average resistance rate on which the piping should be sized.

Example #2: A designer is evaluating a pump with an

available head of 50 feet at the design flow . The longest

circuit in the system has a TEL of 1500 feet. At what average

friction loss rate should the piping be sized?

Set 50 foot head opposite the arrow. At the TEL of 1500 feet,

a resistance of 3.3 feet per 100 feet is indicated.

Scale #5 – Determining Unknown Pressure Drops,

System Curves and Control Valve Cv ratings.

Scale #5 is based on the relationship which exists between

flow and system resistance where the head varies

approximately as the square of the ow. Scale #5 can be

used in several ways: to determine an unknown pressure

drop from a known pressure drop, to establish system curve

relationships , to select control valves to their Cv ratings, and

to convert between pressure gauge readings in psi and head

loss values in feet of head.

To determine unknown pressure drop from a known pressure

drop condition, set the known pressure drop opposite the

known flow and read the unknown pressure drop opposite

the design flow.

Example #1: From manufacturer’s data, a chiller has a

pressure drop of 12 feet at 100 gpm. Determine pressure

drop at a flow of 150 gpm.

Set 100 gpm in the window of scale #5 immediately below

12 feet of head. Read the unknown pressure drop at

150 gpm: 27 feet.

Scale #5 of the System Syzer

®

Calculator can also be used to

select control valves by their Cv rating .

Example #2: In the example of Figure 19, a control valve was

used to supply zero to 2.9 gpm from the primary circuit to

the secondary circuit in order to maintain circuit temperature.

Control valves must be selected for adequate pressure drop

in order to insure proper operation. They are usually selected

by their Cv rating. Control valve selection is discussed in detail

in other Bell & Gossett publications. In Figure 20, a control

valve for use with a secondary zone is to be selected for a 3 psi

differential at 2.9 gpm. Determine the required control valve

Cv rating.

Figure 20

On scale 5, set 2.9 gpm directly opposite 3 psi. Read the

required valve Cv rating at 1 psi: approximately 1.7. If a

control valve with a Cv of approximately 1.7 can be installed,

then with the control valve open and the secondary pump

on, the pressure drop across the Circuit Setter balance valve

should be adjusted to 3 psi. This will set the flow into the

secondary zone to the design point of 2.9 gpm.

To plot a system curve, set the known (calculated) head loss

opposite the known (design) flow. Read the required head

for several other flow rates. These points determine a system

curve. Plot the system curve on a pump curve. The intersection

of the system curve with the pump curve determines the

actual pump operating point (on open systems, adjust the

system curve in accordance with the total static head).

Example #3: Your analysis of a closed loop piping system

indicates that a 200 gpm flow rate results in 30 feet of head

loss. Calculate the resistance at several other flow rates plot

a system curve on the pump curves illustrated below and

determine their actual operating points.

Set 200 gpm in the window below 30 foot head. Read the

resultant head at 100, 150, 250 and 300 gpm. These points

establish the system curve for this “friction only” system.

Pressure gauges

Circuit Setter

Control

Valve

14

Figure 21

Operation of the pump in the piping circuit described by

the system curve must be at the intersection of the pump

curve and the system curve. This is because of the first law of

thermodynamics – energy in must equal energy out. Energy

put into the water by the pump must exactly match the

energy lost by the water as it flows through the piping system.

The point of intersection is the only point that can meet this

basic engineering law. The specific points of operation for the

two pumps illustrated are 180 and 225 gpm.

Pumps in parallel

The application of pumps in parallel always requires a system

curve – pump curve analysis. When two identical pumps

are placed in parallel, each pump operates at the same

differential head and each supplies ½ the total system flow.

Parallel Pumps

Figure 22

A parallel pump curve can be developed by doubling the

flows at any constant head for the single pump curve.

Parallel Pumps Curve

Figure 23

The system curve for any piping circuit must be plotted on

the developed parallel pump curve. With both the pumps

in operation, the system flow and head will be at point A.

However, each pump will operate at point B. This is because

each pump supplies half the total flow and consumes half the

power requirement.

System Curve Plotted on Parallel Pumps Curve

Figure 24

When only one pump is operating, the point of operation is at

C. The operating point shifts to the right on the pump curve,

which means that the single pump can provide more than

50% of design flow. This means that a single pump operating

alone will draw more power than when operating in parallel:

It is important that each pump be supplied with a motor large

enough to operate at point C.

Note that simply adding a second pump without changing

the existing system will increase the flow, but will not double

it because the system curve was unchanged.

Two - Pipe System Design Example

A three zone heating system using air handling coils will be

used to illustrate the procedure to be followed in sizing a

typical two-pipe system, calculating its pressure drop, and

selecting a pump. In order to clearly understand this process,

it’s best to obtain a System Syzer

®

from your local Bell &

Gossett representative while you work through this example.

The system is illustrated in Figure 25. The water is heated by

means of a heat exchanger. Heat exchangers are discussed in

more detail later. The system is equipped with a Rolairtrol air

separator and vent. The pump is base mounted, end suction,

equipped with a Triple Duty Valve at the discharge and a

Suction Diffuser at the suction. The system expansion tank is

located near the pump suction.

Two-Pipe Fan Coil System

Figure 25

The coil pressure drops at their design flow rates are shown

on the drawing. Each air handler coil was selected to provide

design heat transfer at design delta tee. For example, in a

typical heating system the flow rate for standard water at

20° Δt is easily found by dividing the heat load in BTUH

by 10,000.

Capacity in U.S. Gallons per Minute

50 100 150 200 250 300 350 400 450

0

10

20

30

40

50

60

Total Head in Feet

500 550 600

Single Pump Curve

Flow “A” Flow “A”

Note: Flow “A” is Doubled to

Obtain Parallel Pump Curve

Operational Curve

For Two Pumps

In Parallel

Capacity in U.S. Gallons per Minute

50 100 150 200 250 300 350 400 450

0

10

20

30

40

50

60

Total Head in Feet

500 550 600

Single Pump Curve

Point “A”

System Curve

Operational Curve

For Two Pumps

In Parallel

Point “B”

Point “C”

Capacity in U.S. Gallons per Minute

50 100 150 200 250 300 350 400 450

180

225

0

10

20

30

40

50

60

Total Head in Feet

15

Heating Load at

Zone 20° Δt Flow rate (gpm)

(BTUH)

1 800,000 80

2 1,100,000 110

3 900,000 90

280

But suppose it’s a typical chilled water system designed for a

12° Δt. The cooling loads would require greater flow.

Heating Load at

Zone 12° Δt Flow rate (gpm)

(BTUH)

1 800,000 130

2 1,100,000 180

3 900,000 150

460

Scale #1 of the System Syzer

®

can easily be used to calculate

the design flow rate for each zone. Line up the heat load in

MBH in the white scale with the 12° Δt in the red scale to get

the chilled water flow rates required.

Equipment Room Head Loss

The equipment room piping is common to all three zones.

The pressure drop between points A and B will be calculated

separately for each of the three zones in order to balance the

flow. The greatest head loss zone will determine the pump

head required.

The total flow rate of 280 gpm dictates the equipment room

pipe size and equipment selection since all of this equipment

must carry the total flow. The system will use steel piping.

Scale #2 of the System Syzer can determine the pipe size.

Adjust the total flow rate of 280 gpm within the white arc

in Scale #2 dened by the maximum and minimum friction

loss rates recommended for hydronic systems. Note that two

choices exist:

a. A 3" pipe would have a friction loss rate much greater than

the maximum allowable 4.5 feet head loss per 100 feet

of equivalent length. From Scale #3, the velocity would be

over 12 feet per second; much too high.

b. At 280 gpm, a 4" pipe would have a friction loss rate of

4.3 feet head loss per 100 feet of length, and a velocity of

about 7.0 f/s. This is within normal design limits.

c. A 5" pipe would have only 1.4 feet of head loss per 100

feet of length, so the total head loss in the equipment

room would be significantly less. Low head loss in the

equipment room results in systems that are easier to

balance and easier to control at part load. However, the cost