P

ROVINCIAL RECONSTRUCTION,

REHABILITATION

& SETTLEMENT AUTHORITY

[Draft] Quality Assurance

& Quality Control Manual

PROVINCIAL DISASTER MANAGEMENT AUTHORITY, Government

of Khyber Pakhtunkhwa

November 2021

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

1 | Page

Abbreviations & Acronym

ACI

American Concrete Institute

ASCE

American Society of Civil Engineer

ASTM American Society for Testing and Materials

BOQ

Bill of Quantities

C&W

Communication & Works

CBR California Bearing Ratio

IBC

International Building Code

KPRP

Khyber Pakhtunkhwa Reconstruction Program

NFPA

National Fire Protection Association Code

PHED

Public Health Engineering Department

PM

Project Manager

QA

Quality Assurance

QC Quality Control

QCM

Quality Control Management

QS

Quality System

SOW Scope of work

TS

Technical Specifications

UFAS

Uniform Federal Accessibility Standards

USAID

United States Agency for International Development

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

2 | Page

Contents

Introduction .................................................................................................................. 4

Section 1: Definitions ................................................................................................... 6

Section 2: Introduction of QA/QC Manual .................................................................. 7

Section 3: Objectives of QA/QC Manual ..................................................................... 8

Section 4: Communication Plan for Construction Site ................................................ 9

Section 5: Duties, Responsibilities, and Authority of QC Personnel ........................ 10

5.1 KPRP/Client’s Engineer ............................................................................... 10

5.2 Consultant Engineer .................................................................................... 10

5.3 Contractor’s Project Manager ..................................................................... 10

5.4 Contractor’s Engineer(s) ............................................................................. 11

Section 6: Design Stage of Infrastructure Project ...................................................... 12

6.1 Background .................................................................................................. 12

6.2 Purposes of Design Quality Control Plan ................................................... 12

6.3 Conditions of Design Quality Control ........................................................ 12

6.4 Components of Design Quality ................................................................... 12

6.4.1 Proper Team ............................................................................................... 12

6.5 Key Steps in Achieving Desired Quality ...................................................... 13

6.5.1 Client Needs Assessment ........................................................................... 13

6.6 Design Quality Control Methodology ......................................................... 13

Section 7: Construction of Infrastructure Work ....................................................... 15

7.1 Contractor’s Submittals Procedures ........................................................... 15

7.2 Changes in Approved Submittals ................................................................. 16

7.2.1 Supplemental Submittals........................................................................... 16

7.2.2 Engineering Review .................................................................................. 16

Section 8: Laboratory Testing for Construction Materials ........................................ 12

8.1 Testing Plan and Logs .................................................................................. 12

8.2 List of Construction Materials for Testing .................................................. 12

8.3 Construction Materials Method of Testing and Frequency ......................... 13

Section 9: Complete Rework Items Procedures ....................................................... 17

9.1 Responsibility ............................................................................................... 17

9.2 Item List for Rework ................................................................................... 17

9.3 Rework Procedure for Construction Work ............................................... 17

Section 10: Reporting for Construction Works ........................................................ 19

10.1 Daily Inspection Report ............................................................................... 19

10.2 Monthly Progress Report ............................................................................ 19

10.3 Materials Testing Record............................................................................. 19

10.4 Site Document Control............................................................................... 19

10.5 Quality Records .......................................................................................... 19

10.6 Documentation Storage .............................................................................. 20

Section 11: Annexes ................................................................................................... 21

Annex 1: Daily Progress Report ........................................................................... 22

Annex 2: Weekly Progress Report ...................................................................... 24

Annex 3: Request for Testing (RFT) .................................................................... 27

Annex 4: Request for Survey (RFS) ...................................................................... 30

Annex 5: Request for Inspection (RFIP) ............................................................... 33

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

3 | Page

Annex 6: Non‐conformance Report .................................................................... 33

Annex 7: Request for Audit Testing ..................................................................... 36

Annex 8: Request for Audit Survey (RFS) ............................................................ 39

Annex 9: Request for Information ...................................................................... 41

Annex 10: Design Checklist ............................................................................... 43

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

4 | Page

Introduction

a) Khyber Pakhtunkhwa Reconstruction Program (KPRP)

The USAID funded Khyber Pakhtunkhwa (KP) Reconstruction Program supports the KP

Government's efforts to rebuild public infrastructure destroyed during the 2009 military

operations and the 2010 flooding. The Program rebuilds education, health, water, sanitation,

and irrigation facilities. It is also working closely with the KP Government to improve its

capacity to deliver essential services.

Objectives

The Program's objectives are to rebuild conflict-affected public schools, health and water

infrastructure; improve the learning environment in public schools by providing essential

furniture and laboratory equipment; and to rehabilitate essential irrigation and communication

infrastructure damaged by the 2010 flash floods.

Main Activities

• Reconstruct and rehabilitate militancy affected public schools

• Rehabilitate and improve outdated water systems

• Rehabilitate and restore flood-damaged infrastructure

• Provide essential equipment to damaged health facilities, and furniture and lab

equipment to schools

• Provide consultative services to improve the capacity of the KP government to

manage reconstruction programs

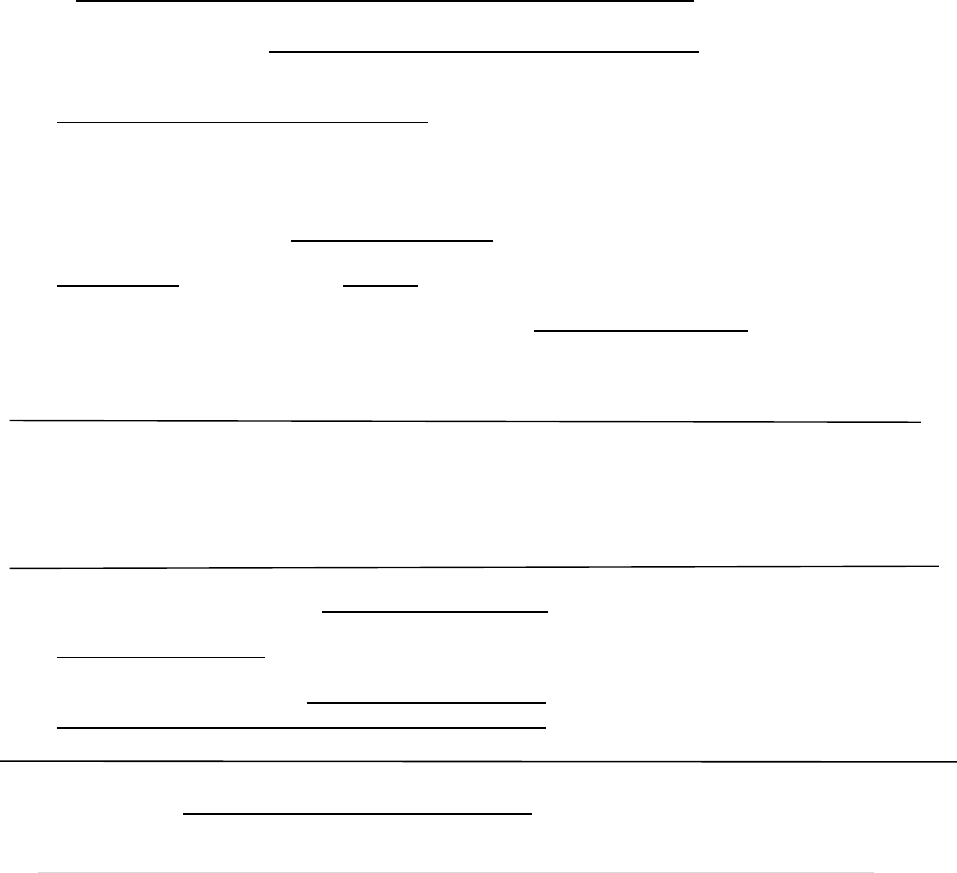

b) Quality Assurance and Quality Control function in KPRP/PaRRSA

The quality assurance (QA)/ quality control (QC) function in KPRP is a robust mechanism

encompassing different layers of site monitoring to ensure that quality of construction is in

accordance with the specifications and other contractual quality parameters. QC mechanism

comprises of site engineers of contractor and consultant companies, respectively. While the

QA mechanism comprises of designated engineers of Executing Agencies (i.e., C&W, PHED

etc.) and KPRP/PaRRSA. Please refer to the following graphic for the details of QA and QC

mechanism of KPRP/PaRRSA for construction related activities:

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

5 | Page

Organogram of QA/QC functions

KPRP/ PaRRSA

(Client)

Deputy Director

(Engineering)

Consultant

company

Site Engineer

Contractor

Project Manager

Site Engineers

Executing Agency

(Line departments

e.g., C&W, PHED)

Engineer

Engineers

Quality Assurance (QA)

Quality Control (QC)

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

6 | Page

Section 1: Definitions

Quality is a desirable characteristic (based on the expectations set by all stakeholders) in

construction. At its core, quality in construction means that a construction project is

completed within the defined guidelines set out in the Scope of Work (SOW). SOW serves

as a set of rules for the project based on the client’s expectations, and sheds light on how

to execute the project in a way that meets these standards.

Quality Assurance (QA): is a set of planned and systematic actions which are laid out

before and after a construction project starts. This is an additional layer of quality review

(in addition to the QC cycle) to provide adequate confidence that the construction work

satisfies quality requirements.

Quality Control (QC): The operational techniques and activities (such as reviewing,

checking, inspecting, testing, etc.) that are used to fulfill requirements for quality in

construction works. In simple words QC is the process of inspecting the construction site

to identify and correct defects.

Quality System (QS): A set of documented processes that seeks to provide confidence

that the project outputs will fulfill the functional requirements. The Quality System should

enclose the organization, responsibilities, human resources, materials, equipment,

processes, inspections, testing, and other parameters of subproject. A key element of QS is

the QA / QC Manual.

Deficiency: This shall be any deviation from the plan or specification that results in lower

quality of work, reduces useful life circle of work and impairs functionality of work and

unsafe condition, or materials change in the appearance than is deemed by the Site Engineer

to be unsatisfactory and to require fulfillment according to the contract, technical

specifications and Bill of Quantities (BOQ).

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

7 | Page

Section 2: Introduction of QA/QC Manual

Successful execution of construction projects is dependent on quality control, which

is essential to the

construction of infrastructure projects. Deficiencies in constructed

facilities can result in huge cost

overruns and lead to delays of the construction

schedule. Even with minor deficiencies, re‐construction

may be required, which causes

delays. In the worst case, failures may cause

personal injuries or fatalities. Sound

project management supported by a thorough

quality control system (QCS) ensures

that the construction work is executed professionally with value engineering.

For

efficiency of the quality control mechanism, it is mandatory to have a fair and

transparent mechanism with clear communication and instructions on construction site.

The quality system described in this manual shall form the basic activities and

processes to be utilized to monitor and control throughout the success of any

construction project.

The quality control plan requires the engineer to:

•

Maintain sufficient inspection system and perform inspections that will

ensure

compliance with agreed specifications.

•

Maintain inspection records and make them available to KPRP.

•

Allow KPRP to conduct its own tests and inspections.

•

Make follow ups on tests and inspections for its benefit to the project

deliverables. The

quality control obligations in the testing and inspection remain

independent and unchanged.

•

Assist KPRP in ensuring completion of the project within the approved

timeline,

budget, and quality.

•

Provide quality design management and construction management services that

consistently meet KPRP statutory and regulatory requirements.

•

Be responsive in executing good engineering practices to eliminate potential

quality

defects.

•

Continuously improve all functions within the project team in collaboration with

the client through innovation and creativity.

•

Ensure to rectify deficiencies and to prevent future defects.

•

Define and share the acceptance criteria for any construction project.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

8 | Page

Section 3: Objectives of QA/QC Manual

The main objective of quality control is to ensure that the under-construction facility is

achieving the approved standards and agreed specifications. With a clear and brief

quality system each member of the construction supervision team can ensure that it

has played its part in the success and value of the construction project. Procedures that

have been strictly followed will make sure that KPRP is receiving a cost-effective quality

construction in a timely manner.

It is essential that the quality system is evaluated regularly in order to revise

procedures as and when required. Suggestions for improvements in procedure

changes and revisions from all parties

involved in the program are necessary.

This quality control plan does not endeavor to repeat or summarize

agreement/contract requirements. It

describes the process and procedures that the

consultants’ engineers will use to ensure compliance with those requirements. The

agreement/contract is the foundation for the outcomes expected from the quality

control plan.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

9 | Page

Section 4: Communication Plan for Construction Site

A formal communication chain is the foundation of a successful construction project.

All team members should have a point of contact.

In order to have clear communication between KPRP, line department, consultant and

contractor

,

engineers of the parties involve shall have the following responsibilities:

•

All construction documents like approved drawings, BOQ’s, specifications,

submittals, test reports,

inspection reports, daily/ weekly /monthly reports, safety

reports shall be available, maintained and stored in Site Engineer office for review.

•

Engineers shall be available on construction site and perform inspections during

construction on daily basis.

•

Consultant’s engineer shall continuously coordinate/liaise with the client and

contractor during pre‐

construction (site preparations), construction, and post

construction project cycle.

•

Consultant’s engineer shall carry out routine joint inspections with client, site

engineer to document the actual status of the project to

ensure that work activities

at site have been done in accordance with the signed contract. Agreement on

observations shall be noted and entered in separate daily inspection reports.

•

Client engineer shall ensure that the quality control is applied in accordance

with quality control

procedures.

•

Client engineer shall conduct inspection independently with contractor’s

representative and write

notification in daily inspection report.

•

Client and site engineer shall reach consensus on methods of inspection and testing

according to the

specifications in accordance with QA/QC Manual.

•

Client and consultants’ site engineers shall agree on the size of the construction task

and the required materials for the tasks require to be

tested in accordance with

the technical specifications and QA/QC. Follow up joint witness inspections

at the

test laboratory by client and site engineer is mandatory.

•

Client and Site Engineer shall reach consensus on defect rectification requirements

which shall be noted in separate defects log/reports.

•

Client and site engineer shall be bound to rectify all such defects and to notify the

contractor to take

immediate action in accordance with “Rework” section of this

Manual.

•

In case of any differences on defects between client and consultant site engineer,

the matter will be forwarded to the KPRP head office for further expertise.

•

Client and site engineer shall update their QC and QA reports on daily basis and

old issues shall not be

repeated after rectifications measures are taken and closed.

•

Client and site engineer shall conduct weekly QC meetings on site. Minutes of

the meetings have to be

prepared by site engineer.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

10 | Page

Section 5: Duties, Responsibilities, and Authority of

QC Personnel

5.1 KPRP/Client’s Engineer

The client's engineer role is very important to the overall success of construction project.

They play an active role in approving project plans, requesting changes, raising issues and

risks, approving milestones, releasing payments, and accepting (or declining) the final

deliverables of the project.

The client engineer is responsible and accountable for the execution of

all activities

from the start to the end of the project. The client shall facilitate the efforts of the

design and construction projects.

5.2 Consultant Engineer

The role of consultant engineer is supervision and monitoring of the site to assure the

construction quality control system.

Site engineer shall report directly on daily basis

regarding the progress of the construction works. Site

engineer’s quality control team

ensures that the program quality management and safety systems are

being implemented

according to the requirements of the client. The site engineer oversees all technical

aspects in the specified technical area of the work including but not limited to

assessment, design, Bill of

Quantities (BOQ) calculations, technical specification,

monitoring and other related tasks.

The site engineer's responsibilities include managing different parts of construction

projects, supervision of his team members, preparing estimates for time and material costs,

completing quality assurance, observing health and safety standards, and compiling reports

for different stakeholders.

The site engineer also supervises contractors’ site engineers including

contractors QC

engineers. He/she shall provide field project control support by identifying and monitoring

project

related issues. He/she shall directly communicate with contractors and client

when necessary and

directly report to the client for technical advice, support, and field

resolution when necessary. The site

engineer shall supervise all technical aspects of

infrastructure project implementation work in the specified

technical area of work

including but not limited to assessment, design, Bill of Quantities (BOQ),

calculation,

technical specification, and monitoring of work. The site engineer shall be responsible for

the

design integrity, professional design standards and all services required by the

agreement.

In addition to

implementation and management of the quality control

program, the site engineer is required to perform submittal review and approval, make

sure testing is performed and provide QC certification and documentation as required in

the agreement.

5.3 Contractor’s Project Manager

A Project Manager oversees the planning and delivery of construction projects to ensure

the work is completed as per agreed specifications, on time and within budget. With so

many facets to consider in both pre- and post-construction, the Project Manager works

closely with engineers, architects and more to drive the best outcome.

In the approved contract agreement, the contactor is bound to assign a Project Manager

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

11 | Page

with required qualifications and skills to ensure the completion of the infrastructure project

according to the approved construction schedule The Project Manager shall ensure that

Quality Control Management (QCM) standards are executed, and the QC certifications

and documentation are prepared as required under the agreement.

The Project Manager shall be on the construction site during any shifts when construction

work is in progress.

5.4 Contractor’s Engineer(s)

The role of contractor site engineers is to supervise all construction activities of site and

shall assist the Project Manager in processing and maintaining files for submittals, reports,

• To ensure the quality and quantity of the work based on the design and technical

specifications.

• Manage all processes on site and be responsible for the material planning and timely

provision, the planning of work force to ensure the project implementation in time.

The site engineer is empowered by the Project Manager to suspend construction activities

while defects are corrected after informing the client’s representative. There shall be at

least one site engineer present per site.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

12 | Page

Section 6: Design Stage of Infrastructure Project

6.1 Background

Considering the limited resources, and the social and economic conditions and

aiming to produce and achieve the highest yield, quality control and quality assurance

are gaining

considerably large importance.

6.2 Purposes of Design Quality Control Plan

The purpose of the design quality control plan is to:

• Align the project outputs as per Client’s needs

• Decrease the design and development cost in terms of time and money

• Maximize the use of local construction materials like sand, stone, bricks, etc.

• Maximize the use of local men‐power (skilled and un-skilled labor)

• Achieve the maximum possible yield from available resources

6.3 Conditions of Design Quality Control

The safety, durability, comfort, and aesthetical requirements of universally accepted

standards and codes such as ASCE, IBC or equivalent are fulfilled technology proposed

should be applied in the location technology proposed is tutorial and educative to local

people.

6.4 Components of Design Quality

6.4.1 Proper Team

The consultant responsible for design QC shall provide or recruit trained professionals

who have experience in developing designs. All matters concerning the

quality control of

the project shall be reported in writing to the client and site engineer.

6.4.2 Proper Utilities

The consultant shall provide proper equipment and dependable software for analysis,

design, and computer aided drawings.

6.4.3 Adequate Training

The consultant engineer who will have contributions to the designs shall be

trained about

internationally accepted codes designs techniques and construction systems.

6.4.4 Codes and Standards

Conformation of the designs to the following codes and standards will be achieved by:

• Training of team

• Spontaneous checks during all phases of design

• By preparation of code conformation reports at the milestones of the design schedule

6.4.5 Governing Codes of Quality Control

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

13 | Page

• IBC, International Building Code

• ACI, American Concrete Institute Code

• NFPA, National Fire Protection Association Code

• UFAS, Uniform Federal Accessibility Standards

• ADA, Standards of Accessibility Design, Department of Justice

• ASTM, ACI Construction Standard Index

6.5 Key Steps in Achieving Desired Quality

6.5.1 Client Needs Assessment

• Clear understanding of the requirements of the Client

• Developing and proposing a satisfactory architectural preliminary design that satisfies

the above-mentioned code requirements

• Documentation of geographic and climatic requirements

• Documentation of cost efficiency requirements

• Presentation of the above to the Client together with code analysis report.

• Obtaining approval of the Client

6.5.2 Design Criteria and Construction Materials

• Selection of design criteria for construction project, selection of materials of

construction, technologies.

• Reporting to the Client together with possible alternatives.

• Obtaining final approval of the Client for design and construction materials

• Finalizing architectural designs according to comments of the Client and

Consultant’s Site Engineer

• Obtaining approval of the client for architectural designs

6.5.3 Finalizing Drawings, BOQ and Technical Specifications

• Developing structural, mechanical, electrical designs considering the seismic,

dynamic, live load evaluations, permissible or ultimate stresses, alternate loadings

possible, heat and electric energy requirements, applicable codes and technologies.

• Presenting and reporting the designs and calculations to the Client, accompanied by

code analysis.

• Preparing quantitative calculations for tendering (BOQ)

• Preparing Technical Specifications (TS) to achieve desired quality and to enable the

bidders to submit the correct cost estimation to avoid future disputes

• obtaining approval of the client

6.6 Design Quality Control Methodology

The following steps shall be followed while designing any construction activity:

•

A network that is accessible to all designers shall be established and all daily works

shall be stored to a

common area in this network at the end of each working day.

•

Architects and Engineers shall proceed according to the items listed in the

checklists as presented on

Annexes-10 and at the start of each activity shall

prepare a list of particulars of the requirement (e.g.

main requirement of client or

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

14 | Page

task, codes to be followed, minimum or maximum size requirements etc.).

•

The Engineer of Record shall examine the report, shall invite the other engineers

or architects for their

comments if the task requires additional information from

different disciplines etc. and shall approve the report together with his/her additional

comments.

•

After achieving the mentioned approval, the designer shall proceed. The designer

shall provide a code

confirmation list as soon as he completes the design.

•

The design team shall have one quality control meeting every week to discuss the

parts of the

designs that were produced in the preceding week. All comments shall

be recorded, and minutes be provided to the Client and site Engineer.

•

After completion of a specific design the design team will make a final review of

the work and check whether it fulfills all the requirements of the Client, checklists

of this QC plan, and the codes.

•

A spreadsheet highlighting the changes shall be

made accordingly.

•

Any field design changes will be brought to the knowledge of the Client and Site

Engineer so that the reasons of the request are clearly understood and

negotiated. If required, the client shall be informed about the design changes

accompanying a report explaining the

reasons, effects on the project and financial

requirements.

•

After approval of the request by the Client, the designs shall be revised and

submitted to the client for the

final approval.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

15 | Page

Section 7: Construction of Infrastructure Work

7.1 Contractor’s Submittals Procedures

In construction, submittals are a contractor’s proof of complying with construction

documents or a permitted plan set. These include shop drawings, specifications, technical

data, and samples for items such as steel, bricks, sanatory fitting etc.

Consultant’s Site Engineer shall manage and control the processing of contractors’

submittals. After being reviewed

for completeness, submittal documents shall be passed

on to the relevant staff in consultant design team for review and verification for

compliance with the requirements of contract. Submittal documents need to be

approved

finally by the Client.

The detailed progress schedule shall be submitted within 14 days after the award of the

contract

and may be updated as required or as per request by the contractor. If

any changes apply, the

contractor shall get it approved by the Client.

Site Engineer shall maintain a completed submittal schedule and a list of products for

all items requiring

Client’s review and approval, as follows:

• Submittals, including description of the item and the name of the manufacturer,

trade name, and model number

• Specification and BOQ reference

• Intended submission/resubmission date(s)

• Lead time to delivery/anticipated delivery date(s)

• Highlight any items that require expedited review to meet the project schedule

• Identify which submittals require Client’s and/or Site Engineer’s approval

These schedules shall be presented in the prescribed form in both electronic and hard

copy versions and

shall be updated and sent to the Client and/or Site Engineer on a

monthly basis.

7.1.1 Review Period

Contractor shall ensure that submittals are prepared in advance to enable the Client

(in coordination with site engineer) to conduct a review and accord approval before

commencement of

the

related work. The contractor is responsible for the preparation

of submittals according to the time

schedule to avoid delays. If any delays occur due

to contractor’s default, penalties shall be applied according to the

terms of

contract.

7.1.2 Submittal Reviewers

• The Contractor shall submit all the required submittal forms in paper as well as

in electronic form to the Site Engineer.

• Site Engineer shall review the submittal documents and assess whether the

package is complete. If submittal is incomplete the submittal shall be returned to

the contractor.

• The complete submittal documents (along with all the attachments) shall be

stored in client engineers’ database and shall be forwarded to the relevant

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

16 | Page

reviewer of the consultant’s design department.

• The consultant design team shall review the submittal documents and ensure

that the submittal is in compliance with the contract specifications and will

accord its approval if the submittal documents were in agreement the

specifications. However, in the consultant will require explanations then the

consultant will return to the Site Engineer with comments.

• Site Engineer, in consultation with the client, shall re-submit the submittal to the

contractor with his/her determination.

• The contractor’s Project Manager and/or site engineers and design engineers

shall be authorized to review and certify submittals prior to its submission to the

consultant Site Engineer. The Client shall accord the final approval after the

submittal is approved by the Consultant.

7.2 Changes in Approved Submittals

Changes in approved submittals shall not be allowed unless these approved submittals

with changes have

been resubmitted and approved as prescribed in section 7.1.

7.2.1 Supplemental Submittals

Supplemental submittals initiated by the contractors for consideration of corrective

procedures shall

contain sufficient data for review. Supplemental submittals shall be

made in the same manner as initial submittals.

7.2.2 Engineering Review

•

Submittals shall be reviewed for conformance with the TS, BOQ and the contract

agreement.

•

Review actions shall have the following meanings:

• Approved: is an acceptance

• Submittal appears to conform to the respective requirements of the

specifications and

agreement

• Disapproved: is a non‐acceptance

• Means that the submittal is deficient to the degree that the reviewer cannot

make a thorough

review of the submittal

• The submittal needs revision and is to be corrected and resubmitted.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

12 | Page

Section 8: Laboratory Testing for Construction

Materials

Construction materials testing involves the essential examination of all structural

materials used in the construction of a project. Materials testing helps us to quantify

and understand whether a material or product is suitable to a certain

application. Materials testing points us to limits of a material to handle a load or an

operating condition. Materials that have not been tested and directly used in a product

can be extremely dangerous. The data collected during testing and the final test results

can be very useful to engineers and designers.

If required, the Client and Site Engineer reserves the right to require the

contractor to conduct materials

testing through approved laboratories for onsite

and off-site testing. The selected laboratory for

each location needs to be approved by

the Client and Site Engineer.

8.1 Testing Plan and Logs

A testing plan is a detailed document that describes the testing strategy, objectives,

schedule, estimation, deliverables, and resources required to perform testing of a

construction work. Testing Plan helps to determine the efforts needed to validate the

When the tests are performed, the Contractor’s Project Manager or site engineer shall

record on the “Testing Plan and Log”

the date the test was performed and the date the

test results were sent to the Site Engineer. The

site engineer shall submit all test results

to the Client.

If necessary, materials qualification testing shall be done before commencement of

construction activity to verify that the materials

comply with the requirements of the

contract, the technical specifications and BOQ. The

contractor shall obtain

representative samples of the materials designated as the proposed source of the

materials. Test samples shall be sent by the contractor to the approved testing

laboratories. The testing

laboratory shall report all test results for determination of

materials quality.

The Client shall periodically inspect the material being used. If determined that the

characteristics of the

material being used differ from the material initially tested or

designed, the contractor shall repeat the

qualification testing. If the new material

qualification test results meet the criteria of the technical

specification as determined,

the materials may be used for the work, otherwise, previously approved

materials

shall be used or other acceptable materials shall be sampled and tested as noted above.

8.2 List of Construction Materials for Testing

Following is the list of materials which are essential to be tested before and during

construction of project. The client and site engineer reserve the right to require testing of

materials in addition to the materials as stated below:

• Cement

• Sand

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

13 | Page

• Crush

• Bricks

• Asphalt

• Mortar

• Aggregates

• Concrete

• Reinforcement steel

• Wires

• Plaster

• Electrical Material

• Plumbing Material

• Sanitary Material

• Guard Rails

• Signs

• PPE

• Wood

• Shuttering Material

• Other as necessary (refer to technical specification, BOQ, and technical drawings

recommendations)

8.3 Construction Materials Method of Testing and Frequency

All quality assurance testing shall be conducted in line with project specifications,

the contract, technical specifications, BOQ and individual project construction

plan.

The Site Engineer shall observe all relevant testing methods, as previously identified.

The

documentation and reporting of test results shall be included with the daily

construction quality control report and

entered QC system.

All test results shall be updated, filed separately and be presented to the Client. All

tests shall be carried out in accordance with international codes and/or

specifications.

The table below shall be adjusted according to the project specifications and

required standards

in the design:

Required Test Test Method Test Frequency Acceptance Criteria (Verified

by consultant

Engineer )

Grading & leveling

As per IBC 1803 Land surveying Prior to start excavation To establish finish floor

elevation

as per

specifications and

drawings

Compaction

CBR Test

Modified

Proctor

compaction test

ASTM D 1883 &

ASTM D1557

One sample of material

delivered 5

samples of

compacted material for each

400m2

Ensure compact fill to

95% or higher grade of

maximum density and

layers of 20cm.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

14 | Page

Required Test Test Method Test Frequency Acceptance Criteria

Verified by Consultant

Engineer)

Concrete

Compressive Strength ASTM C39 Preliminary testing of mix

design (Test at first 7 day and

28 days). Samples of strength

test will be

taken not less

than once (Five samples) for

every 100 m3, or less than

once for each 465 m2, nor

less than once a day. 3

cylinders @ 7days, 3

cylinders @ 28days and 2

cylinders reserve

Minimum strength

based on

technical

requirements and

structural design

Water/Cement Ratio

Preliminary testing of mix

Di

Limit .45 by weight

Slump Test ASTM C143 1 per batch prior to pouring

concrete

Reinforced concrete

100mm Non reinforced

concrete, side

Reinforcement Steel

Minimum Yield Strength ACI 318 Section

3.5

On delivery on site samples

will be

taken from every type

of rebar prior to installation

and suppliers’ certificate

Must meet specifications

requirement of grade 60,

> / 420

MPa yield strength

Water

Clearness & Cleanness ACI 318 Sec.3.4 Prior to concrete mix Insure free of oil, acids,

salts,

organic and other

substances

Aggregate Concrete

Gradation, salt, harmful

materials

As per 318 Sec. 3.3

ASTM C33 &

C330

One sample at source prior to

commencement of work

Insure physical

requirement of coarse &

fine aggregate. Absence of

harmful substances

Grout

Minimum Compressive

Strength

ASTM C1019 Preliminary testing of mix

design. Test once on a daily

basis during grouting

operations.

(i) Compressive strength

for MTC project remain at

least 13.8

MPa) @ 28 days

Compressive strength

at least 3000 psi (21

MPa) @ 28 days

Cement Mortar

Type M and / or S

Cement

ASTM C 270

‐

08a

Building Code

Requirements for

Masonry

Structures

Table

2.2.3.2, Table

3.1.8.2, Table

5.4.2

Masonry cement mortar

(pre

‐

packaged).

Mix Ratio:

‐

Correct proportion of sand &

water

to meet ACI 530.08 min.

required strength.

Ref. Mix Ratio for Type M & S

(refer:

QC/SITE/7)

Type M: Compressive Strength

(

17.2 MPa) 2500 PSI @ 28

days.

(ii) Type S: Compressive

Strength 1800 psi (12.4

MPa) @ 28 days

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

15 | Page

Required Test Test Method Test Frequency Acceptance Criteria

Verified by Consultant

Engineer)

Masonry Block

Compressive

strength &

dimensions

Sampled and

tested in

accordance with

ASTM C 140

Preliminary test of 3 samples

of concrete blocks delivered on

site

Unit conforms to ASTM

C90. ASTM do not require

design

standard. Only help

assure compliance with the

design.

Compressive strength and

not

less than of 1500 psi

Ceramic Tiles

Inspect Appearance

and dimensions of

tiles

As per

manufacturer’s

approved

specifications

Samples to be submitted for

approval

Conform to the

requirement of ANSI

A137.1.& Specifications

Carpet

Adhesive as per

ASTM D 6004

As per

manufacturer’s

approved

specifications

Samples to be submitted for

approval

Ensure compliance with

approved sample and

adhesive

Linoleum Flooring & Vinyl Flooring

Thickness,

resistance

chemicals, heat

light,

flexibility,

static load

ASTM F2034 Provide sample of Linoleum

and adhesive for approval

Ensure approved materials,

self-leveling cement used as

per specs.

Insulation

Thickness, thermal

conductivity,

compressive

strength,

water

absorption

ASTM C1153‐97

ASTM D3564

Sample upon delivery Insure 5cm thick, thermal

conductivity .032, strength

120

pa as per specs.

Bituminous Roofing Membrane & Roof Insulation

Tensile strength,

rapture strength

Roof Insulation

system / product

ASTM C 578‐01

(Extruded,

expanded rigi

d

thermal

properties

Prior to application

Ensure tensile strength

600N/5cm, rapture

strength130N/5cm, as per

specifications

Structural Steel Roof

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

16 | Page

Required Test Test Method Test Frequency Acceptance Criteria

Verified by Consultant

Engineer)

Welding

Reqr: welding

rod ,

Heater’s inspection

materials, Dye

Penetrant,

magnetic

flux

Inspection

according to

AWS D1.1 and

IBC 1704

AWS D 1.1 & 1.8

Inspection continuous onsite

and shop

Ensure welding is in

compliance with AWS

D1.1, workmanship,

technique, qualification of

welders

Electrical wires & Cables

Manufacturer’s

certificate

Inspection

Electrical QC/

Design

Engineers

and

NEC standards

Samples to submitted prior to

installation

To be approved by QC

electrical

Engineer

Plumbing Pipes

Manufacturer’s

certificate

Field Pressure

test and IPC

standards

After installation of plumbing

pipes

According to the

mechanical

specifications

Water Well

Physical,

Chemical &

Bacteriological

Test according

to

WHO

requirements

Well water will be tested after

drilling well

Tested by approved

water testing lab.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

17 | Page

Section 9: Complete Rework Items Procedures

Any sign of system deficiencies whether discovered by the Client, Site Engineer and/or

the Contractor/Designer, shall result in modifications to the system to correct these

defects.

The contractor shall be informed by the Site Engineer in writing when a defect is

identified and shall

immediately stop work or use of the defective materials. The

contractor shall repair /replace or correct deficiency

before work commences.

If the contractor believes a suitable repair is possible, executed at their expenses, the

Contractor has to

prepare a plan to affect repair or correction and submit to the Client

and Site Engineer for approval.

9.1 Responsibility

It is the responsibility of the Site Engineer to ensure that identified construction

defects are corrected in a

timely manner. Defects identified by the client shall also be

noted and rectified in a timely

manner.

9.2 Item List for Rework

The Site Engineer shall maintain a list of works that do not comply with the

construction plans, technical specifications, contract and BOQ. The list shall have the

following details:

•

Identification, what items need to be reworked

•

The date the defect was originally discovered

•

The date the item was corrected

An item that is corrected on the same day it is discovered shall not be reported in this

log, but in the daily

quality control report.

9.3 Rework Procedure for Construction Work

When non‐compliances with technical

specifications or drawings are observed in the

executed construction works, materials and installations, the contractors’ project

manager and Site Engineer shall make sure that non‐conforming materials, works, or

installations are identified and separately stored to prevent unintended use.

The Site Engineer shall immediately inform the contractor of any non-compliances. After

receipt of such notice, the

contractor shall take corrective actions immediately.

Variations from the contract requirements and/or quality shall be

documented for

corrective actions by the contractor. A non‐conformance report shall be issued

to the

contractor for corrective actions to be taken within 3 working days.

If the contractor fails to correct a minor defect after 5 days of the notice, it shall

result in a non‐conformance which shall be formally documented.

If the contractor fails to take corrective actions regarding the identified non‐

conformances within the specified period of

time, a Stop Work Order shall be issued to

the contractor.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

18 | Page

Related or continuing activities of construction shall be stopped forthwith until the

rectification of deficiencies

that are critical to the integrity of the structure or the facility

and/ or safety of public.

After issuing the Stop Work Order, the site engineer shall inform the client to

help

resolve the issues with contractors’ management.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

19 | Page

Section 10: Reporting for Construction Works

10.1 Daily Inspection Report

Daily inspection reports shall be prepared by consultant’s site engineer to document

complete details of the day-to-day progress on site.

The Site Engineer shall inspect contractor’s daily construction work, efficiency of

deployed manpower, tools,

and equipment, start and stop times, and QC inspections of

work activities.

The Site Engineer shall review, comment, and approve the daily reports presented by the

contractor. Reports shall include pertinent information including problems encountered

during construction, work progress, safety hazards encountered, instructions given, and

corrective actions taken, delays encounters, a record of visitors to the work site, quality

control problem areas, weather conditions, photographs, deviations from the QC plan,

construction deficiencies encountered, and record of meetings held.

10.2 Monthly Progress Report

The monthly progress reports shall contain overall progress of project activities

reported for the

current month including financial progress, milestones, key dates,

accomplishments, bottlenecks, materials’

certification, tests performed, and QC

deficiencies corrected.

10.3 Materials Testing Record

Results of materials testing are also important record to be maintained at construction

site as a proof of construction quality. Test results of all the construction materials are

recorded in the record book maintained on the construction site to improve the quality

of work.

All testing activities shall be recorded on the relevant construction QC Report,

indicating the name and

number of tests performed, specification paragraph reference,

and location performed. It shall be

entered into computerized QC tracking system.

10.4 Site Document Control

Document controllers shall maintain project documents. These documents ensure that

accurate information is distributed throughout the organization, on time, to the people

who need it.

The Document Controller (Administration support staff) shall implement the project

quality system to

control the identification, numbering, modification, approval,

distribution and filing of all documents,

data and drawings.

The checking, approval, identification and distribution of the document and drawings are

as indicated in

the Project Quality System Procedure (PQSP). Each document shall be

assigned a unique number in

accordance with standard numbering procedures.

10.5 Quality Records

The quality records to be maintained and kept for the program are as follows:

• Inspection Records

• Method Statements

• Non-conformances and corrective reports

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

20 | Page

• QC plan and audit reports

• Test records, certificates, warranties, and guarantee

• Client, contractor, and consultant progress reports

• Contractor and consultant monthly payment reports

• Incoming and outgoing correspondence

• Technical drawings, shop drawing and as-build drawings

• Document register log

• Design documents

• Tender documents

• Construction records

• Other related records

10.6 Documentation Storage

QC team shall maintain all construction related documents and submittals in a

combination

of a secure e‐document filing and storage system. The computerized

document control tracking system

shall be archived in consultant’s network server.

Internal project QC audit shall be conducted at a random interval on

the document

controls system when necessary.

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

21 | Page

Section 11: Annexes

Annex 1: Daily Progress Report

Annex 2: Weekly Progress Report

Annex 3: Request for Testing (RFT)

Annex 4: Request for Survey (RFS)

Annex 5: Request for Inspection (RFIP)

Annex 6: Non‐conformance Report

Annex 7: Request for Audit Testing

Annex 8: Request for Audit Survey (RFS)

Annex 9: Request for Information

Annex 10: Design Checklist

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

22 | Page

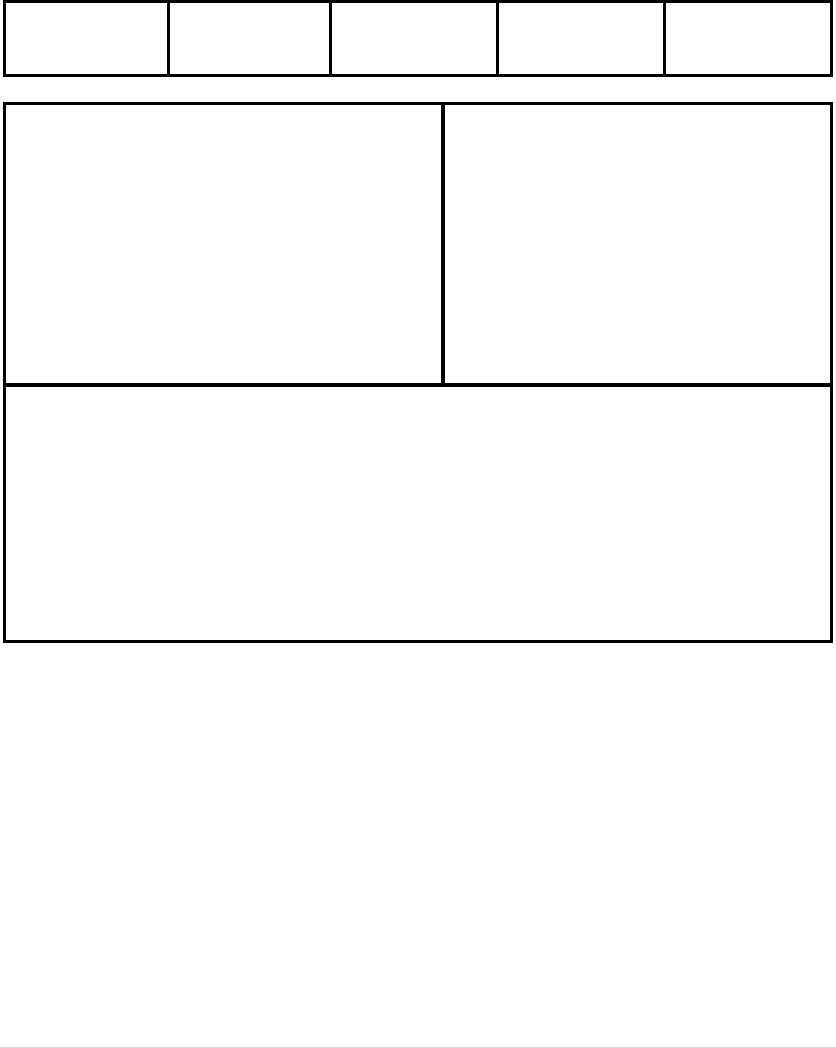

Annex 1: Daily Progress Report

DPR Date

Site No.

Project Title

Location

Province

Coordinates

Contractor

Date of Contract Signature

Date of Construction Start

Date of Completion (Contract)

New Completion Date

(Time

Amendment)

Percentage of Project Complete

Is project on schedule Y/N

Weather/

precipitation

Temp.

day

(°C)

Temp.

night

(°C)

Work on Stop

If “YES”, short explanation

Reported by

1.

Personnel on Site:

Contractor

Super

visor

Enginee

r

Fore

man

Skilled

Labor

Unskille

d

Labor

Operators

Others

2.

Major equipment/machinery on site:

Type:

Number

Acceptable Quality: Y/N

Remarks

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

23 | Page

3.

Supplied Material:

Type

Quantity

Delivered

Acceptable

Quality Y/N

Total

Quan

tity

Acceptable

Approved

Y/N

Remarks

4.

Work Progress :

Building/

Structure

BoQ No

Work

Description

5.

Inspection & Testing:

Type

Y/N

Forms

Attache

d

Forms

Sent

Separatel

y

Remarks

Material

Test

Routine Inspection

Preparatory

Inspection

Initial Inspection

Follow up

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

22 | Page

6.

Issued documents (RFI, Non Conformity, Non

Compliance etc.) :

Date

No.

Issued

by

Issued to

Description

Date of

rectificat

ion

7.

Instructions to the Contractor:

Occasion

Instructions for rectifying

Date for rectification

8.

Design Issues:

Date

No.

Issued

by

Issued to

Description

Date of

rectificatio

n

9.

QA Report : ( Deficiency Ongoing / completed )

Deficiency

Status

Remarks

10.

Safety Issues:

Attended by

Safety issues discussed

Date for

rectificatio

n

11.

Other Discussions/ Meetings:

With

Discussed

Comments

[Draft] QA/QC Manual Khyber Pakhtunkhwa

Reconstruction Program

(KPRP)

23 | Page

12.

Visitors

Visitor

Reason for visit

Comments

13.

Pictures:

Please insert pictures documenting activities and defects and describe when

necessary, the

number of photos is not limited

Description/ location

Description/ location

P

H

O

T

O

P

H

O

T

O

Description/ location

Description/ location

P

H

O

T

O

P

H

O

T

O

24 | Page

Annex 2: Weekly Progress Report

WPR Date

2014-MM-DD

Report

Period

DD

th

to DD

th

of MM.

YY

Site No.

Project Title

Location

Province

Contractor

Date of Contract Signature

Date of Construction Start

Date of Completion (Contract)

New Completion Date

(Time

Amendment)

Percentage of Project Complete

Is project on schedule?

Weather conditions

(brief description)

Average

Temperature

in

rep.

+5° C/

-4° C

Work on Stop(Y/N) /

Day

If “Y” brief explanation

Reported by

1.

Labor on site:

Day

2.

Equipment on site:

Day

3.

Issued documents (RFI, Non-Conformity, Non

Compliance etc.) :

Date

No.

Issued

by

Issued

to

Description

Date of

rectification

25 | Page

4.

Instructions:

Occasion

Instructions to contractor/ subcontractor/

supplier

Date of

rectification

5.

Design Issues:

Date

No.

Issued

by

Issued

to

Description

Date of

rectification

6.

Safety and Security Issues:

Attended by

Day

Safety Issues discussed

Date for

rectification

7.

Other Discussions:

With

Day

Discussed

Comments

8.

Visitors:

Visitors

Day

Reason for visit

Comments

26 | Page

9.

Pictures:

Please insert pictures documenting activities and defects and describe when

necessary

(photos have to be compressed) 10-20 photos

Description/ location

Description/ location

P

H

O

T

O

P

H

O

T

O

Description/ location

Description/ location

P

H

O

T

O

P

H

O

T

O

27 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 3: Request for Testing (RFT)

DOCUMENT NO: Rev No:

Request for Testing of the following works:

□

Embankment (Layer…)

□

Embankment Top (Layer…) □ Stone Masonry Work

□

Base Course (Layer…) □ Culvert

□

Structural Concrete □ Material Source

□ Others…………………………

Type of Test:

Location: Km

to Km

Test Frequency: Volume/Area/Weight Tested:

No.

tests:

This will be ready for test on: Date: Time:

Contractor’s comment/Description:

Requested by (Contractor):

(day/month/year)

Received by (Contractor):

(day/month/year)

Date:

Date:

28 | Page

Test Result:

Lab No.:

Site Engineer’s Comments:

29 | Page

Material Engineer’s Comments

□

Approved by: □ Not

Approved, Re-

submit

Checked By:

(day/month/year)

Approved By:

(day/month/year)

Date:

Date:

30 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 4: Request for Survey (RFS)

DOCUMENT NO: Rev No:

Request for Survey of the following works:

□

O.G.L □

Drainage Structure

□

Embankment □ Culvert

Structure

□

Embankment Top □ Base

Course

□

Others……………

Type of Survey Check:

□

Dimensional Tolerance

□Benchm

ark & stations

□

Alignment □

Topographic pick-up

□

□

Volume/Area/Length to be checked:

No. Points:

Location: Km

to Km

Chainage/Station Offset (m)

This will be ready for survey on: Date: Time:

Contractor’s comment/Description:

31 | Page

Requested by (Contractor):

(day/month/year)

Received by (Contractor):

(day/month/year)

Date:

Date:

32 | Page

Survey Engineer’s Comments/Recommendations:

Construction Engineer’s Comments:

□

Approved by: □ Not

Approved, Re-

submit

Checked By:

Date:

(day/month/year)

Approved By:

Date:

(day/month/year)

33 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 5: Request for Inspection (RFIP)

DOCUMENT NO: Rev No:

Request for Inspection of the following works:

□

Embankment (Layer…) □ Stone Masonry

Work

□

Embankment Top (Layer…) □ Culvert

□

Base Course (Layer…) □ Material Source

□

Structural Concrete □ Others

Type of Inspection:

Location: Km

to Km

Inspection Frequency: Volume/Area/Weight inspected:

No. Inspection:

This will be ready for inspection on: Date: Time:

Contractor’s comment/Description:

Requested by (Contractor): Date:

(day/month/year)

Received by (Contractor): Date:

(day/month/year)

Test Result: Lab No.:

32 | Page

Site Engineer’s Comments:

Materials Engineer’s Comments:

□

Approved by: □ Not

Approved, Re-

submit

Checked By: Date:

(day/month/year)

Approved By:

Date:

(day/month/year)

33 | Page

Project

No.:

Project

Name:

Contrac

tor:

Annex 6: Non‐conformance Report

DOCUMENT NO: Rev No:

NCR No.:

Rev No:

Date Issued

Issued By:

Page:

1

of

2

Description of Non-Conformance:

(List Specification/Drawings,

Other

attachment)

Effect on Construction Schedule:

34 | Page

Proposed

Disposition/Action to

Resolve:

Accept as is:

□

Remove and replace:

□

Repair:

□

Other (Explain):

□

Comment

Pre

par

Na

m

Dat

e:

35 | Page

Acknowledgement of receipt by Contractor:

Name: Signature:

Date:

Contractor Proposed Action/Remedial Measure:

Remedial Work will be carried out by the Date:

Contractor’s QC Manager/Representative

Name: Signature:

Date:

Contractor’s Project Manager

Name: Signature:

Date:

PO Approval to Proposed

Action/Remedial Measure:

Approve □

Not

Approve □

Comment:

PO

Representati

ve:

Name:

Signature: Date:

Confirmation/Inspection of

Action/Remedial Measure:

Approve □

Not

Approve □

Comment:

PO

Representati

ve:

Name:

Signature: Date:

Non-Conformance

Close-Out:

Re-

issued □

Close-Out □

PO

Representative:

Name:

PO Representative: Verification Non-Conformance Close-Out:

Name: Signature:

Date:

36 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 7: Request for Audit Testing

DOCUMENT NO: Rev No:

Request for Audit Test of the following works:

□

Embankment (Layer…)

□

Embankment Top (Layer…) □ Stone Masonry

Work

□

Base Course (Layer…) □ Culvert

□

Structural Concrete □ Material Source

□

Others

Type of Test:

Location: Km

to Km

Test Frequency: Volume/Area/Weight Tested: No.

tests:

Chainage/Station

Off

set (m)

Requested by: Date:

(

day/month/year)

Received by:

Date:

(day/month/year)

Test Result: Lab No.:

37 | Page

(Lab) Comments/Recommendations:

38 | Page

Engineer’s Comments:

□

Approved by: □ Not

Approved, Re-

submit

Checked By:

Date: (day/month/year)

Approved By:

Date: (day/month/year)

39 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 8: Request for Audit Survey (RFS)

DOCUMENT NO: Rev No:

Request for Survey of the following works:

□

O.G.L □ Base Course

□

Embankment □ Drainage Structure

□

Embankment Top □ Bridge Structure

□

Others……………

Type of Survey Check:

□

Dimensional Tolerance

□

Benchmark & Stations

□

Alignment

□

Topographic pick-up

Volume/Area/Length to be checked: No. Points:

Location: Km to Km

Chainage

Offset (m)

Requested by: Date:

(day/month/year)

Received by:

Date:

(day/month/year)

Survey Engineer’s Comments/Recommendations:

40 | Page

Engineer’s Comments:

□

Approved by: □ Not

Approved, Re-submit

Checked By: Date:

(day/month/year)

Approved By: Date:

(day/month/year)

41 | Page

Project

No.:

Project

Name:

Contrac

tor:

Annex 9: Request for Information

Project Code / Location:

RFI No.:

Project Manager:

Report Date:

Site QC Engineer:

Response

Status: / /

Date By:

Documents Ref:

Division:

Area of Concern:

Subject Matter:

(i) Issues:

(ii) Impact:

(iii) Recommendations by

Proposed Solution / follow up Action:

Submitted By: Signature : Date:

Issue closed/open

By:

Date:

Changes :

1.Design

2.Construction

3.Cost Impact

4.Extension of

Yes

No

Signed by:

Site Engineer: Date:

(day/month/year)

Client representative: Date:

42 | Page

Attachments: - (Photos, sketches etc.)

43 | Page

Project

No.:

Project

Name:

Contract

or:

Annex 10: Design Checklist

44 | Page

Date

Project Title

Province

Specific Location

Client

ARCHITECTURAL REVIEW

Yes No Remarks

Have all previous design comments been answered?

Do the drawings comply with the BoQ?

Do the drawings comply with the technical specifications?

Have the designs been coordinated with Structural

Ei ?

Have the designs been coordinated with Electrical

Ei ?

Have the designs been coordinated with Mechanical

Ei ?

Are title blocks labeled correctly?

Are relevant calculations submitted?

Are the drawings updated on the drawing register?

PO PM Signature Date

STRUCTURAL REVIEW

Yes No Remarks

Have all previous design comments been answered?

Do the drawings comply with the BOQ?

Do the drawings comply with the technical specifications?

Have the designs been coordinated with Architects?

Have the designs been coordinated with Electrical

Ei ?

Have the designs been coordinated with Mechanical

Ei ?

Are title blocks labeled correctly?

Are relevant calculations submitted?

Are the drawings updated on the drawing register?

PO

PM

Signature Date

MECHANICAL REVIEW

Yes No Remarks

Have all previous design comments been answered?

Do the drawings comply with the BOQ?

Do the drawings comply with the technical specifications?

Have the designs been coordinated with Architects?

45 | Page

Have the designs been coordinated with Structural

Ei ?

Have the designs been coordinated with Electrical

Ei ?

Are title blocks labeled correctly?

Are relevant calculations submitted?

Are the drawings updated on the drawing register?

P

O

P

M

Signatur

e

Date

ELECTRICAL REVIEW

Yes

No

Remark

Have all previous design comments been answered?

Do the drawings comply with the BOQ?

Do the drawings comply with the technical specifications?

Have the designs been coordinated with Architects?

Have the designs been coordinated with Structural

Ei ?

Have the designs been coordinated with Mechanical

Ei ?

Are title blocks labeled correctly?

Are relevant calculations submitted?

Are the drawings updated on the drawing register?

P

O

P

M

Signature Date

BILL OF QUANTITY REVIEW

Yes No

Remark

Have all previous review comments been answered?

Does the BOQ comply with the drawings?

Does the BOQ comply with the technical specifications?

Has a spell check been carried out?

Are the titles of the BOQ correct?

Are the drawings updated on the drawing register?

P

O

P

M

Signature Date

PO COMMENTS ATTACHED Signature Date

YES

NO

Submitted by

Signature

Date

46 | Page

Reviewed by

Approved by