8/4/2022 SCBA and CBRN SCBA

1

National Institute for Occupational Safety and Health (NIOSH)

National Personal Protective Technology Laboratory (NPPTL)

Conformity Verification and Standards Development Branch (CV&SDB)

The Standard Application Procedure

for the Approval of

Self-Contained Breathing Apparatus and

Chemical, Biological, Radiological, and Nuclear

Self-Contained Breathing Apparatus

Under 42 CFR Part 84

Revised: August 4, 2022

8/

4/2022 SCBA and CBRN SCBA

2

Table of Contents

Introduction .................................................................................................................................................................. 5

Section 1 General Information for Self-Contained Breathing Apparatus or CBRN SCBA ....................................... 6

1.1 Getting Started............................................................................................................................................. 6

1.1.1 Who May Apply ................................................................................................................................. 6

1.1.2 Approval ............................................................................................................................................. 6

1.1.3 Applicants Without a Three Character Manufacturer’s Code .......................................................... 6

1.1.4 Applicants Without a NIOSH Approval ............................................................................................. 6

1.1.5 Where to Find the Standard Application Form ................................................................................. 7

1.1.6 Submitting the Application ............................................................................................................... 7

1.1.7 Documents to Submit with the Application ..................................................................................... 7

1.1.8 Submitting the Application and Associated Documents ................................................................... 7

1.1.9 Submitting Test Samples (Hardware) ............................................................................................... 8

1.2 Types of Applications ................................................................................................................................... 8

1.2.1 New Approval Application ................................................................................................................. 8

1.2.2 Extensions of Approval Application .................................................................................................. 9

1.2.3 Quality Assurance Approval Application ........................................................................................ 13

1.2.4 Resubmission of Applications ......................................................................................................... 14

1.2.5 Amended Application ...................................................................................................................... 14

1.2.6 Correlation Testing Only Application .............................................................................................. 14

1.3 Approval Label Protections and Cautions and Limitations for SCBA and CBRN SCBA ............................. 15

Section 2 Specific Instructions for Preparing a SCBA or CBRN SCBA Application Package ................................... 16

Section 3 Supplemental Information for Preparing a SCBA or CBRN SCBA Application ..................................... ..26

3.1 Quality Assurance Documentation ........................................................................................................... 26

3.2 Quality Assurance Manual......................................................................................................................... 26

3.3 Product Quality Control Plan and Documentation ................................................................................... 27

3.4 Fees ............................................................................................................................................................ 28

3.5 Combination Supplied-Air Respirators and SCBA, SCBA, or CBRN SCBA Test Fees ................................. 29

3.6 Annual (Fixed) Certification (Approval) Fees ............................................................................................ 30

3.7 Pay.Gov Instructions .................................................................................................................................. 32

3.8 Drawings for a Self-Contained Breathing Apparatus or CBRN Self-Contained Breathing Apparatus .... 34

3.8.1 Exploded-View Drawing and Major Subassembly Drawing for a SCBA or a CBRN SCBA .............. 34

3.8.2 Example of an Exploded-View Drawing for an SCBA or a CBRN SCBA ........................................... 35

3.8.3 Major Subassembly Drawings for a SCBA or a CBRN SCBA ............................................................ 35

8/

4/2022 SCBA and CBRN SCBA

3

3.8.4 Material Specifications on Drawings for a SCBA or a CBRN SCBA.................................................. 36

3.9 Component Vendors .................................................................................................................................. 36

3.10 Assembly Matrix ...................................................................................................................................... 36

3.11 Approval Labels and Private Labels ......................................................................................................... 38

3.12 List of NIOSH Cautions and Limitations for SCBA or CBRN SCBA ........................................................... 38

3.13 Private Labeling Versus Private Packaging ............................................................................................. 39

3.14 User Instructions ...................................................................................................................................... 40

3.15 Packaging Art Work and Carton Design .................................................................................................. 41

3.16 Summary of Related Documents ............................................................................................................. 42

3.17 File Naming Conventions ......................................................................................................................... 43

Section 4 Approvals and Denials ............................................................................................................................ 45

4.1 Approval Documentation .......................................................................................................................... 45

4.2 Denial Documentation ............................................................................................................................... 45

4.3 Denial Prior to Assignment of a Task Number .......................................................................................... 45

4.4 Denial of a Project Undergoing NIOSH Evaluation ................................................................................... 46

4.5 Respirator Certification (Approval) Program Decision Review Process ................................................... 46

Section 5 Test Selection Guide for Self-Contained Breathing Apparatus and CBRN SCBA .................................. 47

Section 6 Checklists for Self-Contained Breathing Apparatus or CBRN SCBA ....................................................... 59

6.1 NIOSH Respirator Application Checklist .................................................................................................... 59

6.2 Exploded-View Drawing Checklist for a Self-Contained Breathing Apparatus or CBRN SCBA ................ 61

6.3 Major Subassemblies Checklist for a Self-Contained Breathing Apparatus or a CBRN SCBA .................. 62

6.4 Self-Contained Breathing Apparatus or CBRN Self-Contained Breathing Apparatus .............................. 63

6.5 Supplied-Air Respirator ............................................................................................................................. 65

6.6 Private Label Checklist for a Self-Contained Breathing Apparatus or a CBRN SCBA ............................... 66

6.7 Assembly Matrix Checklist for a Self-Contained Breathing Apparatus or a CBRN SCBA ........................ 67

Section 7 - Document Examples for a Self-Contained Breathing Apparatus or a CBRN SCBA ................................. 68

7.1 Example of a Product Quality Plan for a Self-Contained Breathing Apparatus or a CBRN SCBA ............ 68

7.2 Example of an Assembly Matrix for a Self-Contained Breathing Apparatus ........................................... 70

7.3 Example of an Assembly Matrix for a CBRN Self-Contained Breating Apparatus ................................... 71

7.4 Example of an Exploded-View Drawing for a SCBA or a CBRN SCBA ....................................................... 72

7.5 Example of an Approval Label for a Self-Contained Breathing Apparatus .............................................. 73

7.6 Example of an Approval Label for a CBRN Self-Contained Breathing Apparatus .................................... ....74

7.

7

Example of an Approval Label for a SCBA and Combination SCBA/SAR ................................................ ......76

7.8 Example of an Approval Label for a SCBA Harness ................................................................................. ......78

8/

4/2022 SCBA and CBRN SCBA

4

7.9 Example Approval Label for CBRN Self-Contained Breathing Apparatus Harness .................................. 79

S

ection 8 Label Format and Guidance .................................................................................................................... 80

Appendix ..................................................................................................................................................................... 81

Letter to All Respirator Manufacturers ...................................................................................................................... 81

Definitions ................................................................................................................................................................... 92

Acronyms ...................................................................................................................................................................100

8/

4/2022 SCBA and CBRN SCBA

5

Introduction

This document is a revision to the NIOSH Standard Application Procedure for the Approval of Respirators

dated August 2015. It is intended to add clarity to the approval process under Title 42, Code of Federal

Regulations (CFR) Part 84 (also known as 42 CFR Part 84). It is recommended that applicants review the

entire document before submitting a respirator for approval.

This Standard Application Procedure (SAP) correlates with version 8 of the Standard Application Form

(SAF).

NPPTL has developed individual instructions for each class of respirator. The information in this document

pertain to the approval of Self-Contained Breathing Apparatus (SCBA) and Chemical, Biological,

Radiological, and Nuclear Self-Contained Breathing Apparatus (CBRN SCBA). Please see the appropriate

application for the type of respirator being submitted.

This standard application procedure should be used for the following classes of respirators:

Schedule 13F

• Self-Contained Breathing Apparatus for Entry or Escape, Demand or Pressure-Demand, Open-

Circuit or Closed-Circuit;

• Self-Contained Self-Rescuers; Combination Escape Only Self-Contained Breathing

Apparatus/Supplied-Air Respirator; and

• Combination Self-Contained Breathing Apparatus and Supplied-Air Respirator.

Schedule 13F-CBRN

• Self-Contained Breathing Apparatus for Entry or Escape, Pressure-Demand, Open-Circuit with

Chemical, Biological, Radiological, and Nuclear Protection for Use in Firefighting and in

Conjunction with Safety Equipment Institute and the National Fire Protection Association.

Compliance with all instructions is essential for efficient processing of an application.

The information in Section 2 of this document provides specific step-by-step instructions to prepare an

application for a Self-Contained Breathing Apparatus or Chemical, Biological, Radiological, and Nuclear

Self-Contained Breathing Apparatus. The paragraphs are numbered to correspond with the sections of

version 8 of the standard application form (SAF).

Additional guidance and information related to SCBAs and CBRN SCBAs is included in the sections that

follow and should be used as reference.

8/

4/2022 SCBA and CBRN SCBA

6

Section 1 General Information for Self-Contained Breathing

Apparatus or CBRN Self-Contained Breathing

Apparatus

Instructions for Preparing an Application for a Self-Contained Breathing Apparatus

(SCBA) or a CBRN Self-Contained Breathing Apparatus (CBRN SCBA) (13F or 13F-CBRN

Approvals)

This guide applies strictly to SCBAs and CBRN SCBAs. Please see the appropriate

application and instructions for submitting an application for a different class of

respirators.

1.1 Getting Started

1.1.1 Who May Apply

An individual, partnership, company, corporation, association, or other organization that designs,

manufactures, assembles, or controls the assembly of a respirator may apply to NIOSH to become an

approval holder (42 CFR Section 84.2). An organization may appoint an authorized representative to

complete and submit the Standard Application Form (SAF) to NIOSH.

1.

1.2 Approval

Approval is issued once NIOSH determines the product conforms to the requirements of 42 CFR Part 84.

1.1.3 Applicants Without a Three Character Manufacturer’s Code

A prospective approval holder that has not applied for a NIOSH-Assigned three character manufacturer’s

code will need to complete the Prospective Approval Holder Form and return it to the NIOSH NPPTL

Records Room. To obtain the form, contact the NIOSH NPPTL Records Room at recordsroom@cdc.gov

or (412) 386-4000.

1.1.4 Applicants Without a NIOSH Approval

Prospective approval holders, without a NIOSH-Approved respirator, who have received a three

character manufacturer’s code, may submit an initial application for a single new respirator along with a

signed and approved company Quality Assurance (QA) Manual.

For prospective approval holders, once the application is accepted, reviewed, the respirator is tested,

and a final review is successfully performed, a site qualification visit will be scheduled and conducted

prior to the issuance of any approval. Please see the fee schedules for the cost of the site qualification.

Other applications may be submitted with the initial application. However, subsequent applications will

not be reviewed until the site qualification is completed and the initial application is approved.

8/

4/2022 SCBA and CBRN SCBA

7

The site qualification visit is only performed for new applicants (those without a NIOSH approval).

Approval holders with joint NIOSH and Mine Safety and Health Administration (MSHA) approval have

routine site audits conducted annually. NIOSH performs routine site audits for all approval holders

every two years.

1.

1.5 Where to Find the Standard Application Form

The standard application form, version 7 can be downloaded from the NIOSH NPPTL website. SAF

versions 8 and 9 may be requested from the NPPTL Records Room once the manufacturer’s code is

issued.

1.1.6 Submitting the Application

Applications should be submitted on CD-R or DVD-R electronic media. Neither rewritable CDs nor thumb

drives will be accepted. Due to computer security policies, NIOSH cannot accept thumb drives.

Only one application per CD-R or DVD-R will be accepted. CD-Rs and DVD-Rs will be destroyed once the

project is closed, unless a prepaid shipping label is sent with the media.

Compressed or “zip” files are recommended for applications submitted via email. Applicants that

choose to email the attachments to NIOSH at recordsroom@cdc.gov risk having the information

stripped by mail routers.

Note: For part 84 SCBA applications, please use a standard Applicant-Assigned Reference Number

(AAR#). For the CBRN SCBA application, use the same AAR# but add the CBRN on the end. Example:

Part 84 application AAR#: LWN001 CBRN SCBA Application AAR#: LWN001CBRN

1.1.7 Documents to Submit with the Application

Checklists specific to the type of application being completed are included in Section 6. Fee schedules

are included in Section 3. Tests required for the specific respirator type are included in Section 5.

Documents must be named in accordance with the prescribed naming convention, using an acceptable

software package.

1.1.8 Submitting the Application and Associated Documents

The CD-R or DVD-R with the completed application form and associated documents, including the

application fee check or pay.gov receipt, must be sent to:

NIOSH NPPTL

CV&SDB, Records Room

626 Cochrans Mill Road

Pittsburgh, PA 15236

8/

4/2022 SCBA and CBRN SCBA

8

1.1.9 Submitting Test Samples (Hardware)

NIOSH NPPTL

CV&SDB, Evaluation and Testing

626 Cochrans Mill Road

Pittsburgh, PA 15236

All boxes containing test samples (hardware) must be marked with the AAR# and include a packing

slip.

Test samples (hardware) submitted for a series of applications must be identified for each project which

it is to be used. For example, a Self-Contained Breathing Apparatus (SCBA) that is to be used on three

projects, because the respirator has three different pressure reducers, must have all three Applicant-

Assigned Reference Numbers (AAR#s) on the packaging. If there are multiple containers, each container

must be labeled with all the appropriate information.

All sample components must be identified and labeled with their corresponding part numbers as listed

on the assembly matrix.

If test samples (hardware) is being sent to NIOSH for the testing of multiple projects, please include this

information in the first application where testing will be performed and label the test samples

(hardware) package with each AAR#.

1.2 Types of Applications

The types of applications include: New Approval Application, Extension of Approval Application, Quality

Assurance Approval Application, Amended Application, Correlation Testing Only Application,

Resubmission of New Approval Application, and Resubmission of Extension of Approval Application.

If there is any doubt about the appropriate type of application to submit, call the NIOSH NPPTL

Conformity Verification and Standards Development Branch (CV&SDB) at (412) 386-4000.

Several screens in the Standard Application Form for New Approval Applications and Extension of

Approval Applications identify the data fields that will be entered directly into the NIOSH Certified

Equipment List (CEL). The product description should be short and succinct for an accurate reporting of

the respirator in the CEL.

New Approval Applications and Extension of Approval Applications must contain or reference the

following items as described in detail in Section 2 and 3 of this SAP.

1.

2.1 New Approval Application

• Used for new design, substantially different design, or when a different type or level of

protection requested for an existing NIOSH-Approved respirator.

8/

4/2022 SCBA and CBRN SCBA

9

• NIOSH assigns a new testing and certification (TC) number for each new respirator system design

that is approved.

• An application may be submitted for only one basic new respirator design per application.

• Applications containing more than one design will be denied.

o For example, if an applicant submits a new respirator with and without an air-line

connection that uses the same regulator assembly, NIOSH requires two separate

applications resulting in two new approvals because each arrangement represents a

separate design and limitations for different uses.

• New Approval Applications must contain or reference the following items as described in detail

in Sections 2 and 3 of this SAP.

• NIOSH Standard Application Form.

• Pretest Data.

• Simplified Drawings.

• Assembly Matrix.

• Draft Approval Label(s).

• Quality Assurance Manual (Manual to be submitted separately as QA application after first

approval).

• Product Quality Control Plan.

o Classification of Defects Document.

o Sampling Plan.

• Application Fee, $200.

• User Instructions.

• Test Samples (Hardware).

1.

2.2 Extensions of Approval Application

Submitted when:

• A critical or major characteristic affecting performance is altered on a previously approved

respirator.

• A critical or major characteristic affecting design (including Quality Assurance provisions) is

altered on a previously approved respirator.

• A new accessory is added to a previously approved respirator.

• A change is made to an approval label, assembly matrix, User Instructions, or drawings.

• A product is made obsolete.

• The approval holder wants to add multiple components to one previously approved SCBA.

• All the TC numbers on a given assembly matrix apply to the extension. The assembly matrix may

be referenced in lieu of listing the individual TC numbers.

• All TC numbers affected must be listed in the “Reason for Application.”

8/

4/2022 SCBA and CBRN SCBA

10

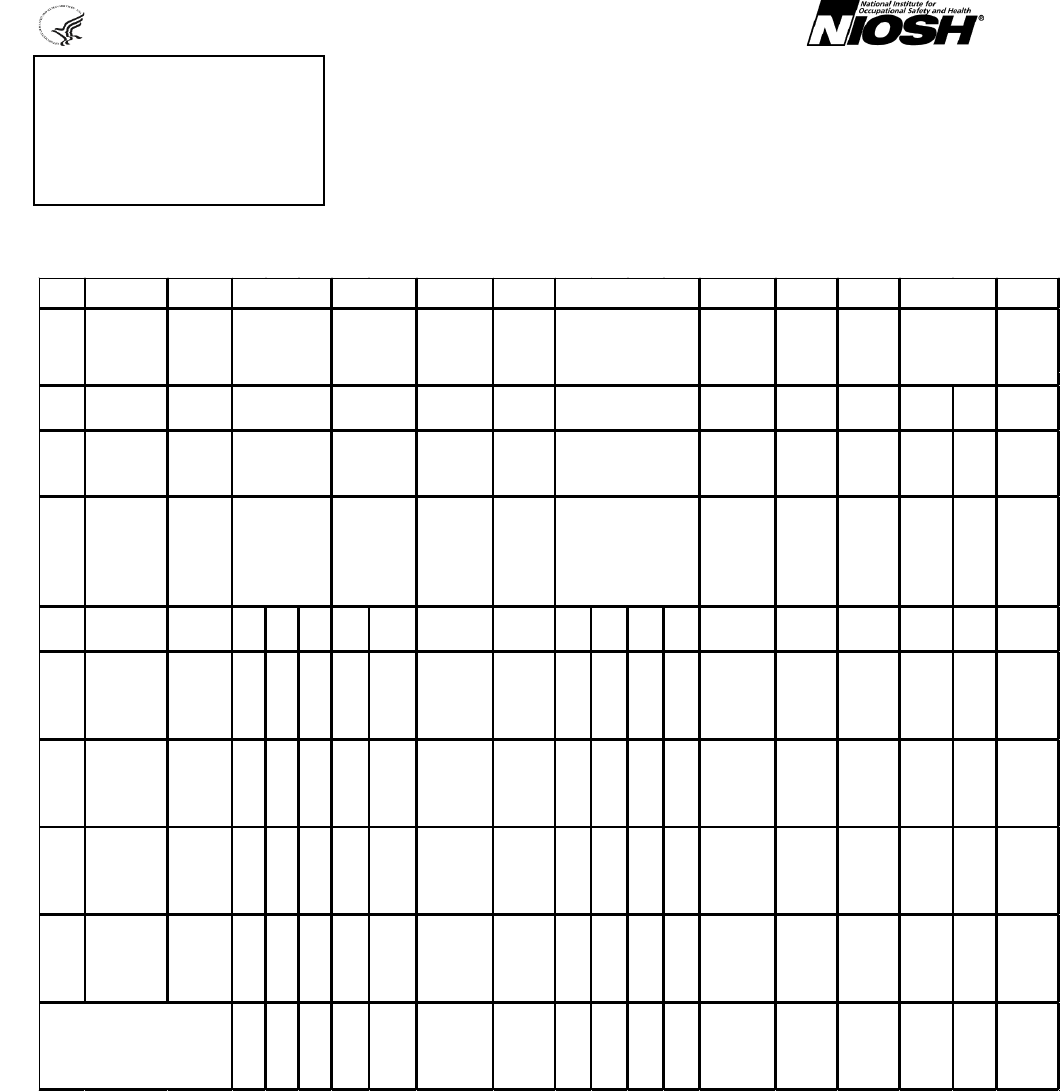

Additional Components Previously Approved SCBA

• An approval holder wants to add a component multiple previously approved respirators.

Component Previously Approved SCBAs

The approval holder,

company ABC, requests a

single accessory be added

to multiple previously

approved SCBAs.

TC-13F-1234

TC-13F-2345

TC-13F-1357

The approval holder,

company ABC, requests the

addition of multiple

accessories to a previously

approved SCBA described in

TC-13F-xxxx

Radio Interface

Regulator Docking Bracket

Spectacle Kit

8/

4/2022 SCBA and CBRN SCBA

11

Changes to minor characteristics not affecting performance or design which are not documented in the

NIOSH approval records do not have to be submitted to NIOSH. A minor characteristic is an attribute,

such as the size of the belt loops on the harness. Approval holders are responsible for keeping all

changes to minor characteristics on file and available for review at the request of NIOSH.

This includes any minor changes to any document that is part of the approval record. These changes

should be submitted for an extension of approval at your earliest convenience. Note, documents not up-

to-date in the NIOSH record could be identified during a site audit and resulting in a non-conformance.

If the type or level of protection changes, a New Approval Application must be submitted. For example,

an SCBA with a 4500 pressure cylinder and 30 minute service time may be submitted and approved. The

subsequent submission of the same SCBA with the same pressure cylinder but with a 45 minute service

time would be considered to be a new ‘Type,’ requiring a New Approval Application and a different TC

number being issued.

In addition, a New Approval Application is required and a different TC number will be issued for

additions of a new respirator arrangement to a respirator family, model, or series such as a new

facepiece on an existing SCBA model.

Extension of Approval Applications must contain the following items or reference as described in detail

in Sections 2 and 3 of this SAP.

• NIOSH Standard Application Form.

• Pretest Data.

• Simplified Drawings.

• Assembly Matrix.

• Draft Approval Label(s).

• Product Quality Control Plan.

o Classification of Defects Document.

o Sampling Plan.

• Application Fee, $200.

• User Instructions.

• Test Samples (Hardware).

In the “Reason for Application”: Describe exactly and completely the change(s) or addition(s) to the

approved respirator(s) and how the change(s) will affect the previously approved respirator(s). Provide

a succinct description on the previously approved respirator(s). For example, "An Extension of Approval

to allow our ‘xyz’ alternate second stage regulator to our SCBA models 123, 456, and 789. No other

respirators are affected. This request is for use of an alternate second stage regulator only." The

Extension of Approval Application request must clearly indicate:

8/

4/2022 SCBA and CBRN SCBA

12

1. The affected respirator(s) by name, TC number, and part number. If multiple approvals are

affected, the assembly matrix or matrices that contain these approvals may be listed in lieu of

the TC numbers.

2. Complete details of the change(s) or addition(s).

3. Related documentation that has changed since the last approval (assembly matrix, inspection

procedures, simplified drawings, draft approval label, product quality control plan, User

Instruction).

Example of a Well-Written Reason for Extension of Approval Application:

Provides the model number, TC number, type of respirator, and what is being requested in a

very descriptive manner. In this example, the request is to allow four new air-line/manifold

pneumatic components, a new supplement to the User Instructions, and to add additional

hose/handwheel assemblies. The details are provided.

This Extension of Approval Application is for a modification of approvals TC-13F-123, TC-13F-456,

TC-13F-789, and TC-13F-234 issued for the Eagle Open-Circuit, Pressure-Demand, Entry and

Escape, Self-Contained Breathing Apparatus or Combination, Open-Circuit, Pressure-Demand,

Entry and Escape, Self-Contained Breathing Apparatus and Type C, Supplied-Air Respirator to

make the following changes as indicated on assembly matrix Eagle_AM26.XLS:

• To add four new airline/manifold pneumatic components, part numbers 1000001,

1000002, 1000003, and 1000004.

• To add a new supplement to the User Instructions part number A000009 for the air-line

attachments.

• To add hose/handwheel assemblies 1005 and 1006 to backframes 1007 and 1008 and

remove hose/handwheel assemblies 1000 and 1001.

Specifies the change(s)

This request is for the use of an alternate pneumatic accessory, change a handwheel assembly,

and update the User Instructions. No other components or processes are affected. All the

changes pass the testing required to meet the criteria for an SCBA and a Supplied-Air Respirator.

States how the change(s) affect(s) the product

The current designs do not allow the user the option of using different manifolds, and the

current handwheel is somewhat difficult to manipulate when wearing gloves. The new

arrangements allow the user to pick a manifold that suits their needs and the new handwheel is

easier to manipulate when wearing gloves.

Any time the approval holder makes a change to a critical or major characteristic, as defined in 42 CFR

Part 84, affecting performance and/or design (including Quality Assurance provisions), the change must

be submitted to NIOSH for approval. NIOSH will not assign new approval (TC) numbers for Extension of

Approval Applications. New approvals can only be granted under a New Approval Application.

8/

4/2022 SCBA and CBRN SCBA

13

NIOSH will not assign new approval (TC) numbers for Extensions of Approval Applications. New

approvals can only be granted under a New Approval Application.

For SCBAs only, an Extension of Approval Application is acceptable for multiple changes affecting a single

SCBA even if it affects several major subassemblies.

For SCBAs with both Part 84 and CBRN approval, a Part 84 Extension of Approval Application cannot

contain changes to the CBRN approval. The only documents that may be submitted with this type of

application are those that are applicable to the Part 84 extension. When adding an accessory to an

already approved assembly, the applicant must include the accessory in the exploded-view drawing, the

assembly matrix, and the major subassembly drawings. If accessories are listed on the approval labels,

the labels must be updated.

Extensions of Approval Applications to add alternate components to respirators previously approved by

NIOSH apply to respirators that will be shipped from the manufacturer’s plant in the various

configurations. These Extensions of Approval Applications are not meant to apply to configuration

changes that will be done in the field either by the end user or by manufacturer representatives. If the

alternate components are to be field-replaceable, the approval holder must submit an Extension of

Approval Application for an upgrade (or retrofit) kit. The applicant must submit one application for each

upgrade (retrofit) kit that is being issued. The upgrade (retrofit) kit can be in the form of a parts list or a

drawing, and it must be listed on the assembly matrix with its own controlled document number and

revision level. If the upgrade (retrofit) kit is submitted as a picture drawing, the drawing must contain a

parts list. The manufacturer’s User Instructions to the field personnel or technician conducting the

upgrade (retrofit) must also be submitted as a controlled document and listed on the matrix. The first

time these items are listed on the matrix they will have a matrix code of “N.” Subsequent submittals will

be designated with a “R.”

When changes are made that affect the User Instructions, highlight or clearly note the changes in the

document.

1.2.3 Quality Assurance Approval Application

• Used for new or updated Quality Assurance (QA) Manuals only. This is for current NIOSH

approval holders only.

• No other actions will be accepted under this type of application.

• QA Manual changes must include a revision history sheet showing the revision date and reason

for revision.

Note: NIOSH will only accept QA Applications that request updates to the QA Manual. No other

requested actions will be accepted under a QA Application. QA Applications will not be accepted until

the requestor has at least one NIOSH-Approved product.

8/

4/2022 SCBA and CBRN SCBA

14

In the “Reason for Application” state the details of the changes to the QA Manual. Also, indicate the

respirator(s) and manufacturing facility(ies) affected.

QA Approval Application submissions must not affect the performance or design of the respirator(s) and

must not result in a different type or level of protection. If the changes impact any of these aspects of

the covered respirator(s), then applicants must submit an Extension of Approval Application to address

these changes.

1.2.4 Resubmission of Applications

• Resubmissions are only accepted when allowed by NIOSH.

• Used for hardware or documentation previously denied by NIOSH.

If an application is for hardware or documentation that has been previously submitted to NIOSH and

denied, select request type ‘Resubmittal of New Application’ or ‘Resubmittal of Extension Application’ as

appropriate. The “Reason for Application” must include the changes made to address the respirator or

documentation deficiencies, an explanation of how the respirator or documentation now meets NIOSH

requirements, and the task number (TN) of the previously denied application. Failure to provide this

information will result in the application being denied again.

1.2.5 Amended Application

• Amended Applications are only accepted when requested by NIOSH.

• Used for open applications with an identified inaccuracy.

• Only the portion requested by NIOSH should be submitted.

• The AAR# and TN will remain the same.

1.2.6 Correlation Testing Only Application

Choose this type of application if the respirator is being submitted to be correlated with NIOSH Standard

Testing Procedures (STPs). NIOSH will only perform correlation testing using one of the NIOSH Standard

Test Procedures. The results of this testing cannot be used as pre-submission test data when submitting

the respirator for NIOSH approval. No approval will be issued with a Correlation Testing Only

Application.

Independent or internal testing is still required prior to submittal of the application. Explain what

testing is required, by STP number. NIOSH will only test the number of samples specified in the STP or

42 CFR Part 84. Specify the number of trials in the “Reason for Application” section.

8/

4/2022 SCBA and CBRN SCBA

15

1.3 Approval Label Protections and Cautions and Limitations for

Self-Contained Breathing Apparatus and CBRN Self-Contained

Breathing Apparatus

PROTECTIONS

CBRN - Chemical, Biological, Radiological, and Nuclear

CF - Continuous Flow DE - Demand ESC - Escape

PD - Pressure-Demand SA - Supplied-Air SB - Supplied-Air Abrasive Blast

SC - Self-Contained

EOSTI-25 - End-of-Service-Time Indicator 25%

EOSTI-33 - End-of-Service-Time Indicator 33%

CAUTIONS and LIMITATIONS

I Contains electrical parts that may cause an ignition in flammable or explosive atmospheres.

J Failure to properly use and maintain this product could result in injury or death.

M All approved respirators shall be selected, fitted, used, and maintained in accordance with MSHA,

OSHA, and other applicable regulations.

N Never substitute, modify, add, or omit parts. Use only exact replacement parts in the

configuration as specified by the manufacturer.

O Refer to User Instructions, and/or maintenance manuals for information on use and maintenance

of these respirators.

S Special or critical User Instructions and/or specific use limitations apply. Refer to User

Instructions before donning.

AA This respirator is to be used for escape only and will protect against the inhalation of certain

respiratory hazards.

CBRN-SPECIFIC CAUTIONS and LIMITATIONS

Q Use in conjunction with personal protective ensembles that provide appropriate levels of

protection against dermal hazard.

R Some CBRN agents may not present immediate effects from exposure, but can result in delayed

impairment, illness, or death.

T Direct contact with CBRN agents requires proper handling of the respirator after each use and

between multiple entries during the same use. Decontamination and disposal procedures must

be followed. If contaminated with liquid chemical warfare agents, dispose of the respirator after

decontamination.

U The respirator should not be used beyond 6 hours after initial exposure to chemical warfare

agents to avoid possibility of agent permeation.

8/

4/2022 SCBA and CBRN SCBA

16

Section 2 Specific Instructions for Preparing a Self-Contained

Breathing Apparatus or CBRN Self-Contained Breathing

Apparatus Application Package

The paragraphs in this section are numbered to correspond to the different sections on

version 8 of the Standard Application Form (SAF).

1 Project Reference Numbers (Section C.1)

Enter the three character NIOSH-Assigned manufacturer’s code.

Check box if the applicant currently has a NIOSH-Approved product.

Assign a unique reference number to this application.

This reference number must start with the three character NIOSH-Assigned manufacturer’s code.

There is no character limit on this reference number.

This number must appear on each hardware sample package and the payment.

Never reuse the Applicant-Assigned Reference Number (AAR#) except on Amended Applications

requested by NIOSH.

NIOSH assigns a unique Task Number (TN) to each project.

This number is emailed to the applicant once the application is received along with accompanying

documents, check or payment confirmation, and test samples (hardware).

All inquiries must refer to either the NIOSH-Assigned TN or the AAR#.

2 Type of Application (Section C.2)

Select from: New Approval Application, Resubmission of New Approval Application, Extension of

Approval Application, Resubmission of Extension of Approval Application, Quality Assurance Application,

Correlation Testing Only Application, or Amended Application.

New Approval Application

• Used for new design, substantially modified design, or different type or level of

protection requested for an existing NIOSH-Approved respirator.

Resubmission of New Approval Application

• Resubmission will only be accepted when allowed by NIOSH.

• Used for previously denied applications.

Extension of Approval Application

• A change is made to any document that was evaluated by NIOSH as part of an approval.

• A critical or major characteristic affecting performance or design (including Quality

Assurance provisions) is altered on a previously approved respirator.

8/

4/2022 SCBA and CBRN SCBA

17

• One new accessory is added to a previously approved respirator.

• A change is made to an approval label, assembly matrix, User Instructions, or drawings.

• A private label request is made.

• A product is made obsolete

Resubmission of Extension of Approval Application

• Resubmission applications are only accepted when allowed by NIOSH.

• Used for previously denied applications.

Quality Assurance Approval Application

• Choose this application for a new or updated QA Manual only.

• No other actions will be accepted under this type of application.

Correlation Testing Only Application

• Choose this type of application if the respirator is being submitted to be correlated with

NIOSH STPs.

• The results of this testing cannot be used as pre-submission test data when submitting

the respirator for NIOSH approval.

• Independent or internal testing is still required prior to submission of the application.

• Explain what testing is required and how many trials in the “Reason for Application.”

• No approval will be issued with a Correlation Testing Only Application.

Amended Application

• Amended submissions are only accepted when requested by NIOSH.

• Used for open applications with an inaccuracy in the application.

• Only the portion requested by NIOSH should be submitted.

• The AAR# and TN will remain the same.

3 and 5 Prospective Approval Holder (Section C.3 and Section C.5)

Enter the name of the prospective approval holder.

Status of Facility Manufacturer/Approval Holder Name (if different than above).

Check if the organization has submitted a request for approval for any respirator produced at this

manufacturing plant in the last three years.

Applicant – A person identified by the approval holder as completing and submitting the application.

Primary Contact – Person who will receive the approval or denial letter and all correspondence

concerning the application.

8/

4/2022 SCBA and CBRN SCBA

18

Only those persons identified to NIOSH by the manufacturer/approval holder as official company

contacts should be listed on the application. Multiple contacts can be identified as required by the

manufacturer/approval holder.

Enter Official Title.

Enter the first and last name, middle initial, and suffix for the applicant.

Enter the name of the prospective approval holder, if different from above.

Enter the manufacturing plant address.

Enter the manufacturing plant phone number.

Click “add contact” to add information for another person who can answer questions related to this

application.

6 Date of Application (Section C.6)

Choose the date from the drop down calendar. The NIOSH date of application is when the application is

assigned a TN by NIOSH.

7 Type of Product (Section C.7)

Select Air-Supplying since this application applies only to Self-Contained Breathing Apparatus

Respirators.

8 Specific Questions Pertaining to Submission (Section C.8)

Is this a resubmittal of a previous application?

If Yes, enter the previous TN.

Is this an amended application?

Yes or No.

Is this submission application a result of field problem or site audit?

If Yes, enter the relevant TN(s).

Is the respirator intended for use in mines?

Yes or No.

This is for Part 84 applications only.

Is this application dependent upon the approval of an application in process?

If Yes, specify the applicable AAR# or TN.

8/

4/2022 SCBA and CBRN SCBA

19

If the same respirator is being added as a private label, the second application cannot be approved until

the first application is approved.

If there are two or more applications that use the same assembly matrix, check the “yes” box and identify

all subsequent applications in the Approval History. The second and subsequent applications using the

same assembly matrix cannot be processed until the first application is approved. Additionally if a drawing

is currently under review at NIOSH and a separate matrix is submitted, the current application should indicate that

the project is dependent on the prior project and applicants should list the applicable TN.

9 Reason for Application (Section C.9)

Provide a complete, concise, descriptive reason for the application. Do not provide information relating

to respirator use or future respirator development. This is the information that will appear in the CEL.

The following must be addressed in the “Reason for Application”:

• If making respirators obsolete, include the TC numbers and model numbers.

List the TC numbers of all approvals affected by the application. If all of the TC numbers on the assembly

matrix apply to the extension, the assembly matrix may be referenced instead of the individual TC

numbers.

If an Extension of Approval Application is the result of a field problem, site audit, or product audit, state

that fact and list any associated task numbers (TN) here. Also, list the Corrective Action Request (CAR)

number associated with the application.

Please do not list “approval” as the “Reason for Application.”

Quality Assurance Approval Applications must state the details of the change(s) to the QA Manual and

the respirator(s) and manufacturing facility(ies) affected. QA Approval Applications must not affect

performance or design and must not result in a different type or level of protection.

Correlation Testing Only Applications must state which NIOSH Standard Testing Procedures is to be used

and indicate how many trials are requested. Special correlation tests that are not consistent with a

NIOSH Standard Testing Procedures will not be conducted unless previously agreed upon by NIOSH. An

approval will not be issued with a Correlation Testing Only Application.

Resubmittals must state the modification(s) that was (were) made to address the rejection/denial, and

demonstrate that the respirator or documentation now meets all requirements.

8/

4/2022 SCBA and CBRN SCBA

20

10 Approval History (Section C.10)

Provide additional information on Approval History and any other information pertaining to this

application. Do not list additional requests in the Approval History.

If the application is one of a series being submitted, clearly list the AAR#s of all applications in the series.

Include a suggested processing order. Include an explanation how the applications build upon each

other. When using a common assembly matrix for the entire series of applications, place the assembly

matrix in the last application of the series and reference the application in which it is located in all

applications in the series. Applications in a series will not be approved until the entire series is

complete.

List the application TN where the respirator was last tested by NIOSH.

Example of a Well-Written Approval History for a Self-Contained Breathing Apparatus:

The new mask material is documented on revised specification sheet ZM-FL-A02 Rev A.

The change is documented in the mask's bill of materials (Item 2) on page 3 of drawing 103-01

Revision M.

This modification does not affect the respirator performance, but may affect facepiece fit. Happy

Breathing Company has tested the facepiece covering this extension and finds that it still meets

the requirements of 42 CFR Part 84 for facepiece fit. Happy Breathing Company has not changed

any of the respirator components since the components were granted NIOSH approval under TN-

xxxxx. The Happy Breathing Company is relying on the facepiece fit data accompanying this

submission, AAR#ph24, to obtain this approval.

This change will be applicable to the XXX mask and III respirator and private labels YYY & ZZZ.

11 Description of Respirator (Section C.11)

Information for New Approval Applications and Extension of Approval Applications is entered in the SAF

by selecting options from dropdown options. The respirator description fields vary based on the type of

respirator selected. Both New Approval Applications and Extension of Approval Applications require a

detailed narrative description.

Is this a joint SEI (CBRN NFPA) submission?

Yes or No.

Is this an SEI retrofit respirator?

Yes or No.

Is this a CBRN application?

Yes or No.

8/

4/2022 SCBA and CBRN SCBA

21

Select type of CBRN, if applicable.

In this case, select SCBA if submitting for CBRN approval.

Is testing required?

Yes or No.

Return sample hardware?

Yes or No.

Note: If No, NIOSH will dispose of the equipment.

Source of submitted samples – Choose from dropdown options:

Prototype, Regular Production Unit, Correlation Test Sample.

If no testing is required, please provide the reason.

Facepiece type – Choose from the dropdown options:

Filtering Facepiece, Full Facepiece, Half-Mask, Quarter-Mask, Mouthpiece, Hood, Helmet, or

Tight-Fitting Full Facepiece with Neckdam Seal.

Fit – Choose from the dropdown options:

Tight-Fit, Loose-Fit, Both Tight- and Loose-Fit, or Mouthbit.

Is this respirator fit checkable?

Yes or No.

If the respirator contains electrical components, have the components been approved by MSHA for

intrinsic safety?

Yes, No, or Not Applicable.

Note: If the respirator is to be used in underground mines or for mine rescue and has electronics,

MSHA intrinsic safety approval must be received prior to submitting to NIOSH. However, if the

respirator is not intended for mine use or mine rescue, then the unit’s electrical components do not

require MSHA approval.

Does the respirator have an inhalation valve?

Yes or No.

Does the respirator have an exhalation valve?

Yes or No.

Move to Air-Supplied Respirator Questions

Type of Supplied-Air Respirator – Choose from dropdown options:

8/

4/2022 SCBA and CBRN SCBA

22

Self-Contained Breathing Apparatus (SCBA), Supplied-Air Respirator (SAR), or Combination

SCBA/SAR.

SCBA Type – Choose from dropdown options:

Open-Circuit, Closed-Circuit, or Other Technology.

SCBA Use – Choose from dropdown options:

Escape-only or Entry and Escape.

SAR Category – Choose from dropdown options:

A, AE, A and AE, B, BE, B and BE, C, CE, C and CE, or Other.

Selected the Rated Service Time (minutes):

3, 5, 10, 15, 30, 45, 60, 120, 180, or 240.

Airflow – Choose from dropdown options:

Demand, Pressure-Demand, Continuous Flow, or Negative Pressure.

Breathing Gas – Choose from dropdown options:

Compressed Air, Compressed Oxygen, Compressed and Rich Air, Chemical Oxygen, Liquid

Oxygen, or Other Technology.

Enter the Concentration of Oxygen in Breathing Gas (percentage).

Enter the Cylinder Rating (psi).

Regulator Mounting Location – Choose from dropdown options:

Belt, Chest, Facepiece, Back or Backpack, or Helmet.

Are the materials used in the construction which may be exposed to oxygen at pressures above

atmospheric pressures, safe and compatible for their intended use?

Yes or No.

If a hose set is needed, click on “Add Hose Set” and provide the model number, hose type, shortest

length, maximum length, other lengths, total sections, valve type, and pressure.

Also provide a description of the respirator(s).

12 Intended Protection and Safety Design (Section C.12)

Atmosphere-Supplying respirators only:

8/

4/2022 SCBA and CBRN SCBA

23

Confirm that any materials used in the construction of the respirator which may be exposed to oxygen

pressures above atmospheric pressure are safe and compatible for the intended use (e.g., exposure to

elevated concentrations of oxygen).

Identify CBRN when applicable.

The term “Intended for Mine Use” identifies respirators to be used for emergency use in mines. NIOSH

requires this information to determine if the application must be evaluated and approved by both

NIOSH and the Mine Safety and Health Administration (MSHA). Respirators to be used for mine rescue

and other emergency use in mines must be approved by MSHA under 30 CFR Part 75.1714. In addition,

if the respirator has electrical components, MSHA intrinsic safety approval must be received prior to

submitting to NIOSH. Any questions regarding the need for joint approval, please call NIOSH at 412-386-

4000.

13 Pre-Submission Performance Test Data and Statements (Section C.13)

Respirator pre-submission performance test data must accompany each application and must:

• Specify components used for test configuration by part number.

• Show units of measure for all test data (units of measure must match 42 CFR Part 84 Subparts

H through J criteria).

Submit copies of actual test data with all results and conclusions.

To verify which tests need to be performed as part of the pre-submission testing, please refer to the

Respirator Test Selection Guide. NIOSH expects that applicants will have performed each NIOSH test

and any additional tests the applicants deem appropriate during the process of validating that the device

meets NIOSH approval requirements.

Any respirators that have an EOSTI should list caution “S” on the approval label. Also, the User

Instructions must contain a special section that is labeled “S-Special or Critical User Instructions” where

the EOSTI information is contained. See Approval Labels in Section 7 for an example.

14 Model Numbers and Product Trade Names (Section C.14)

The information provided in this field is how the product will appear in the Certified Equipment List.

A product trade name that uniquely identifies the respirator or family is required. This name will be

listed in the Certified Equipment List for public reference. In version 8 of the electronic standard

application form for a New Approval Application, the model number field can be blank, but the product

trade name field must be completed before proceeding to the next data screen. A product trade name

may indicate a protection, but it may not imply use. Model numbers previously used for particulate

filtering devices approved under 30 CFR 11 standards may not be reused or carried over to devices or

configurations to be approved under 42 CFR Part 84 standards.

8/

4/2022 SCBA and CBRN SCBA

24

15 Test Samples (Hardware) (Section C.15)

Regular production units submitted for approval must be the result of actual manufacturing processes

(42 CFR Section 84.11(e)).

Applications will be denied if the test samples (hardware) provided for testing did not go through the

manufacturer’s normal assembly, inspection, and test processes.

Applications may be denied even if the component that failed is not related to the “Reason for

Application.”

Use the Respirator Test Selection Guide to determine the minimum number of hardware samples

required for testing. Submit a sufficient number of hardware samples for testing at the time of

application. The hardware samples to be used for testing must be sent under a separate cover from the

application. In the application and on the packing slip with the hardware samples, list the item by part

number and description, and indicate the quantity submitted for testing. Include a copy of the User

Instructions in the box or shipping container with the hardware samples to be used for testing.

The outside of each box or shipping container and packing slip(s) should clearly indicate "Test

Samples/Hardware" along with the name of the applicant, AAR#(s), part number(s), and quantity(ies).

The hardware samples to be used for testing and any additional hardware samples requested by NIOSH

must clearly show the part number on each item, as it is listed on the assembly matrix, regardless of

how it is packaged. If additional hardware samples to be used for testing are requested by NIOSH, mark

the shipment to the attention of the NIOSH employee requesting the samples. Include the AAR#, TN,

and state “Additional Test Samples” on the outside of the box or shipping container. Cross-referenced

lists will not be accepted.

The applicant must submit prepaid return shipping labels or provide other return means with the

hardware samples for any materials to be returned upon completion of testing. “Please Return Samples”

should be indicated on the packing slip. If NIOSH denies an application based upon documentation

issues, the application, and in most cases, all hardware samples will be returned.

NIOSH does not retain hardware samples for any completed projects, approved or denied. The

hardware samples will be promptly destroyed unless the applicant indicates the samples should be

returned and prepaid return shipping instructions are provided. NIOSH is not responsible for customs

charges. The applicant is responsible for all shipping costs and making all arrangements to clear the

hardware samples through customs when shipping hardware samples to be used for testing to or from

NIOSH.

The test sample hardware submitted with the application will be tested. No substitutions, additions, or

deletions are permitted by the applicant once NIOSH receives the application.

If NIOSH evaluators determine a need for additional testing, additional test samples (hardware) may be

requested.

8/

4/2022 SCBA and CBRN SCBA

25

Saving the Application

Once the application form has been completed, save the data file by selecting FILE, then SAVE AS, from

the menu bar on the main menu screen.

8/

4/2022 SCBA and CBRN SCBA

26

Section 3 Supplemental Information for Preparing a Self-

Contained Breathing Apparatus or CBRN

Self-Contained Breathing Apparatus Application

3.

1 Quality Assurance Documentation

Understanding the requirements of 42 CFR Part 84 Subpart E and specific quality system characteristics

as noted below are necessary to adequately develop and maintain Quality Assurance and quality control

programs acceptable to NIOSH. Prior to obtaining any approvals under 42 CFR Part 84, all approval

holders are required to have an approved Quality Assurance Manual on file at NIOSH.

If an organization has an approved QA Manual and there is no change, complete the applicable blocks

on the SAF. If a previously approved QA Manual is being revised, it is not necessary to submit the entire

manual. In a separate QA application, submit only the sections that have been revised and an updated

revision history sheet.

3.2 Quality Assurance Manual

Submit a Quality Assurance Manual that documents the following elements at a minimum:

A. Statement of Quality Assurance.

- Upper management approval of the manual (usually a signature).

- A revision history sheet showing date and reason for revision.

- A Table of Contents.

- Management assurance that the QA system meets NIOSH requirements in 42 CFR Part

84 Subpart E.

B. Description of Management Responsibilities as they relate to:

- The company quality policy.

- Personnel/organization structure necessary to carry out these provisions.

- Verification of quality (internal auditing).

- Quality system review.

- International Standards Organization (ISO) certification (if applicable).

C. Structure of Quality System.

- Identify how quality procedures and instructions are prepared and implemented.

D. Contract Review Activities (as applicable).

E. Design Control for aspects of safety, performance, and dependability of the product reliability

programs.

F. Control of All Documents and Data (control of engineering drawings, documentations, and

changes).

G. Quality in Purchasing.

H. Control of Customer-Supplied Product (control of purchased material to include incoming

inspection).

I. Product Identification and Traceability.

8/

4/2022 SCBA and CBRN SCBA

27

J. Control of Production Processes (lot identification, control of processes, manufacturing,

fabrication, and assembly work conducted in the plant).

K. All Areas of Inspection and Testing: Receiving, In Process, and Final Inspection.

L. Control of Inspection, Measuring, and Test Equipment.

M. Inspection and Test Status.

N. Control of Nonconforming Product.

O. Corrective and Preventive Actions (as applicable).

P. Inventory and Handling Controls.

Q. Control of Quality Records.

R. Internal Quality Audits (audit of final inspection of the completed product).

S. Training.

T. Servicing (as applicable).

Note: If the manual does not incorporate the specific elements within the document, then the manual

must link or list the Standard Operating Procedures (SOPs) for the various elements.

3.3 Product Quality Control Plan and Documentation

Product Quality Control Plan (PQP) documentation is required to be submitted as part of an application

to demonstrate to NIOSH the applicant’s process characteristics involved in controlling and monitoring

the quality of the respirator being manufactured.

Items that must be submitted are the:

A. PQP flowcharts showing all inspection and test operations. Identify each procedure by AAR#.

Inspection or test procedures clearly identified on the flow chart.

B. Sampling plan and classification of defects document as described in 42 CFR Section 84.41 (c),

(d), (e), (f), (g), and (h).

C. In process inspection and test procedures for items listed on the assembly matrix.

D. Final inspection and test procedures for the complete respirator and items listed on the assembly

matrix.

E. Simplified Self-Contained Breathing Apparatus respirator drawing.

F. Assembly matrix.

8/

4/2022 SCBA and CBRN SCBA

28

3.4 Fees

An application fee of $200 is required at the time of submission for all approval requests. Checks are to

be made payable to NIOSH, dated less than 30 days prior to the submission date, and contain the AAR#.

The specific AAR# for the application must be written on the check. Checks older than 30 days may be

returned. Separate checks are required for each application submitted. Do not issue multiple

application fees on one check. Otherwise, checks will be returned and application processing delayed.

NIOSH will not begin processing the request until all items (application, check, and test samples

(hardware)) are received. If a domestic applicant utilizes Pay.Gov, send a copy of the Pay.Gov receipt to

the NIOSH NPPTL Records Room to facilitate linking the payment to the approval request.

As part of the Initial Review Process, an estimate of the costs anticipated to be incurred during the

evaluation will be provided. An email from the initial reviewer will be sent to the applicant towards the

end of the Initial Review Phase.

This estimate is prepared based on the “Reason for the Application,” the number of approvals affected,

and the assigned tests. In the event other testing or other additional cost items are identified after the

acceptance of the original estimate, the company will be contacted and an addendum to the estimate

will be forwarded for acceptance.

Once the applicant has provided authorization to the initial reviewer via email, the evaluation can begin.

During the Final Review Phase, an invoice for all fees, including testing of equipment, incurred in the

processing of an application will be generated. Invoices will contain specific payment instructions and

identify authorized methods of payment, and will be provided to the approval holder for payment.

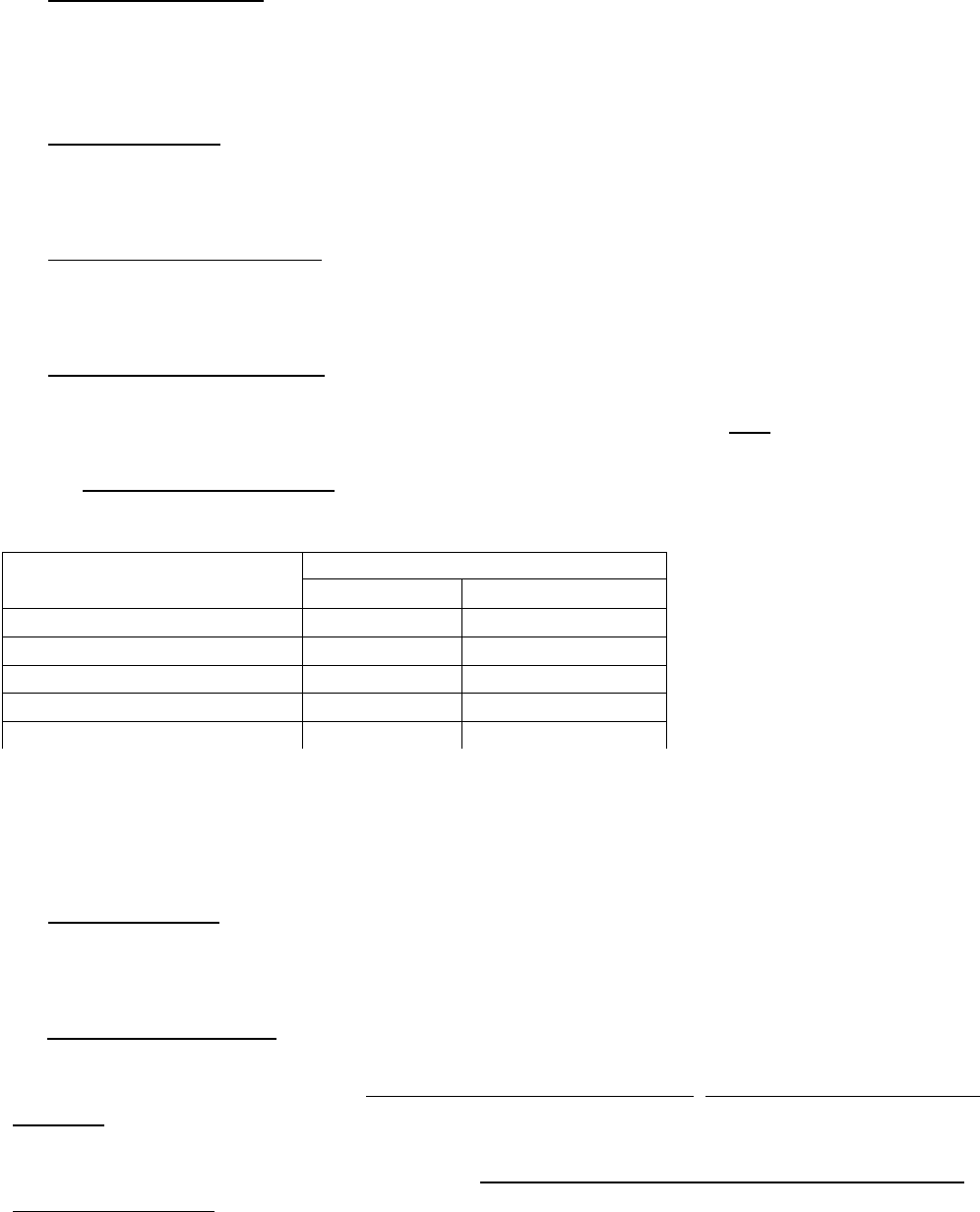

Respirator Approval Application-Based fees are as follows:

Administrative Fees:

Fee Type

Legal Citation

Amount

Due Date

Application

42 CFR

§84.20(b)(1)

$200 per application submitted.

Upon receipt of any application

request. To be submitted with

application.

Approval

42 CFR

§84.20(b)(1)

$100 per each certificate of approval

issued.

Upon receipt of the invoice.

Approval

Modification

42 CFR

§84.20(b)(1)

$50 per each certificate of approval

modified.

Upon receipt of the invoice.

Site

Qualification

42 CFR

§84.20(b)(3)

• Existing approval holder, paper review:

$400 per each request to inspect new

p

roduction facility.

• Prospective approval holders:

▫ O

ne day domestic site visit - $2,500.

▫ One day international site visit - $7,500.

Upon agreement on the date of

the site qualification.

8/

4/2022 SCBA and CBRN SCBA

29

Note: For any modification to an existing approval, such as changes to User Instructions or PQP, the

approval modification fee will be charged for all the approvals affected by this change. For example, if

the User Instructions are revised due to a change in a specific respirator, but the same User Instructions

are used on a family of respirators (example: family consists of 20 approvals), the approval modification

fee of $50 will be charged for all the approvals under that family of respirators (20 X $50 = $1,000).

Testing fees will be charged in accordance with the following fee tables and will be due upon receipt of

the invoice. The final letter (approval or denial) will be issued to the primary contact once all reviews

are complete. The invoice is to be paid within 30 days after receipt.

3.5 Combination Supplied-Air Respirators and Self-Contained Breathing

Apparatus, Self-Contained Breathing Apparatus, or CBRN Self-

Contained Breathing Apparatus Test Fees

All of these tests may not apply to the specific type of respirator being submitted.

These apply only to Supplied-Air and Self-Contained Breathing Apparatus Respirators.

Supplied-Air Testing Fees:

0100 Strength of Hose and Coupling, C and CE SAR

$150.00

0101 Tightness of Hose and Couplings, C and CE, SAR

$150.00

0102 Nonkinkability of Hose, C and CE, SAR $150.00

0103 Gasoline Permeability of Hose/Couplings, C and CE

$450.00

0104 Regulator 100,000 Cycle Test, Demand/PD, C/CE

$3,000.00

0105 Airflow Determination, CF, C and CE SAR

$300.00

0105A Airflow Determination, Demand/PD, C and CE SAR $300.00

0106 Inhalation Airflow Resistance, PD, C and CE SAR

$150.00

0107 Exhalation Airflow Resistance, PD, C and CE SAR

$150.00

0108 Inhalation Airflow Resistance, Demand, C/CE SAR

$150.00

0109 Exhalation Airflow Resistance, Demand, C/CE SAR $150.00

0110 Gas Tightness Test, IAA, C and CE SAR

$450.00

0111 Sound Level in Hood or Helmet, C and CE SAR

$450.00

0112 Protection Level, Abrasive Blast, CE, NaCl or Corn Oil

$450.00

0113 Airflow Resistance, CF, C and CE SAR $150.00

0118 Low Temperature Operation SCBA

$1,200.00

0119 Low Temp Operation, Combo SCBA and C/CE SAR

$1,200.00

0120 Positive Pressure, SCBA

$75.00

0121 Rated Service Time, SCBA, Demand and PD

$75.00

0121A Rated Service Time, CCSCBA, Demand and PD

$75.00

0122 Exhalation Resistance, SCBA, Demand and PD

$150.00

0123 Gas Flow Measurement, SCBA, Demand and PD

$150.00

8/

4/2022 SCBA and CBRN SCBA

30

0124 Remaining Service Life Indicator, SCBA, Demand/PD

$150.00

0124A Alarm Pressure, CCSCBA, Demand and PD

$150.00

0125 Gas Tightness, IAA, SCBA, Facepiece and Mouthpiece $750.00

0125A Gas Tightness, IAA, SCBA, Hoods or Helmets

$750.00

0126 Bypass Valve Flow, SCBA, Demand and PD

$150.00

0128 Accuracy of Gauge, SCBA

$150.00

0133 Exhalation Breathing Resistance, PD SCBA $150.00

0139 CO

2

Facepiece Level Determination, SCBA

$450.00

0140 Man Tests, SCBA

$3,000.00

0145 Sound Level End of Service Life Indicator, SCBA

$750.00

0147 Mode Transfer Test, SCBA/SAR $150.00

0148 Remote Gauge Leak Flow, SCBA, Demand and PD

$150.00

New Site Qualification Fee, Existing Manufacturer

$400.00

Self-Contained Breathing Apparatus and Retrofit, CBRN:

0200 GB LAT

1

$9,142.00

0201 HD LAT

1

$9,142.00

0202 LRPL

$20,000.00

0202 Partial LRPL $16,000.00

0200/0201 Aerosol Process TDA-99M (SMARTMAN) Only

$600.00

Note:

1

Testing Performed at RDECOM.

Test Fees to be Charged for New and Unspecified Tests:

Emergency Breathing Safety System (EBSS)

testing for SCBA

$500/day for test, plus actual costs for test subjects

and required medical coverage.

$100/day per human test subject.

$1,300/day for medical staff.

A single payment (check or pay.gov) for multiple invoices is allowed. Include the AAR#s for each

associated application on the check or the pay.gov receipt so they will be properly credited. Separate

payments (check or pay.gov) will also be allowed for each application invoice. For application fee

invoices, included the TN number(s) associated with the payment. To indicate a final payment for a

specific application(s), add an -F after the TN number(s) (TN-nnnn-F).

3.6 Annual (Fixed) Certification (Approval) Fees

Annual (fixed) certification (approval) fees will be invoiced to approval holders who hold active or

obsolete certificates of approval. Invoices will be sent in September with payment due by October 30 of

the applicable year. Invoices will itemize the number of manufacturing sites and approvals and apply

the fees per the following table:

8/

4/2022 SCBA and CBRN SCBA

31

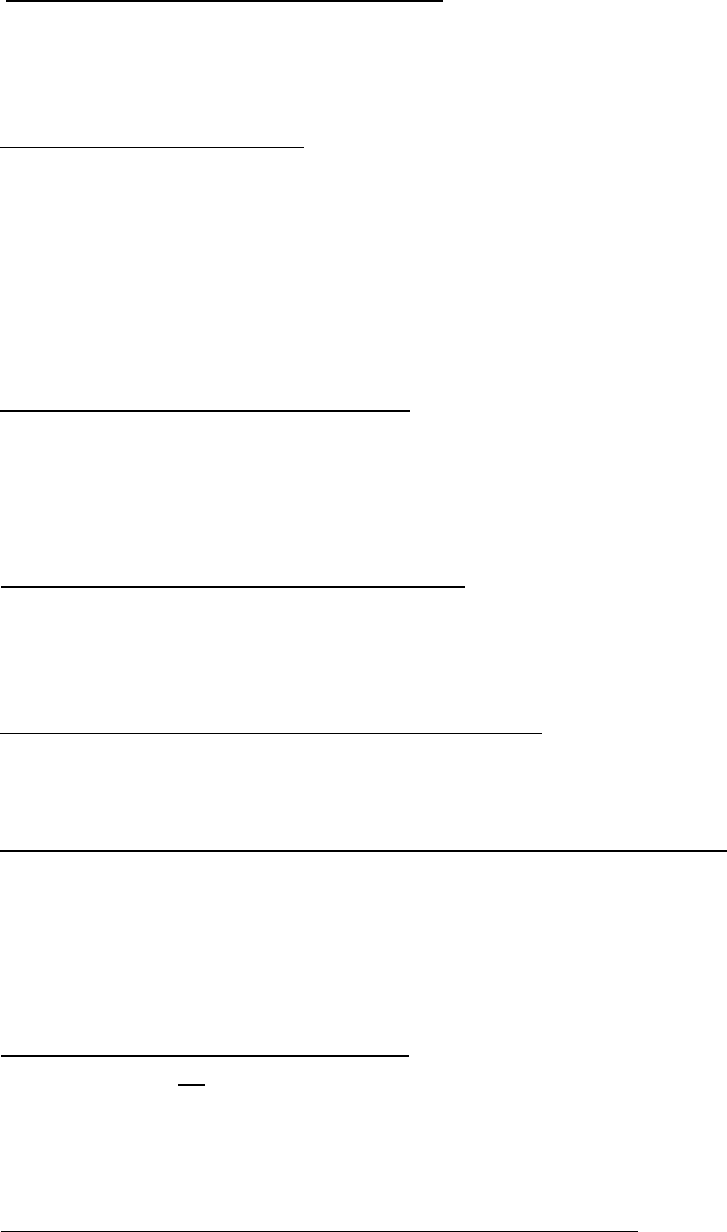

Respirator Certification (Approval) Fee Schedule A—Annual (Fixed) Fees

Fee Type Legal Citation Amount Due Date

Maintenance of

Product

Performance

(Product Audit)

42 CFR

§84.20(b)(5)

• Annual fee: $761 per each approval holder.

• Variable fee: as billed by NIOSH based on the

respirators chosen to be tested each

year.

October 30 of applicable year.

Records

Maintenance

42 CFR

§84.20(b)(1)

$50 per every listed

1

approval on file with

NIOSH on July 1

st

of each year.

October 30 of applicable year.

Quality Assurance

Maintenance

(Site Audit)

42 CFR

§84.20(b)(4

)

• Annual fee: $3,000 per every manufacturing

site registered with NIOSH.

• Variable fee:

2

▫ 1

day domestic audit - $2,500 per site.

▫

2

day domestic audit - $5,000 per site.

▫ 1 day international audit - $7,500 per site.

▫ 2 day international audit - $10,000 per

site.

October 30 of applicable year.

Maintenance of

Testing and

Approval Facilities

42 CFR

§84.20(b)(2)

$34 per every listed

1

approval on file with

NIOSH on July 1

st

of each applicable year.

October 30 of applicable year.

Maintenance of

Test Equipment

42 CFR

§84.20(b)(2)

$36 per every active

3

approval on file with

NIOSH on July 1

st

of each applicable year.

October 30 of applicable year.

1. “Listed” approvals include all active and obsolete approvals. The Certified Equipment List (CEL) reflects the current listed

approvals maintained by NIOSH.

2.

Applies to design as well as manufacturing sites.

3. Does not include obsolete approvals.

Checks are to be made payable to NIOSH, must be dated less than 30 days prior to the submittal date,

and must reference the AAR# or TN or NIOSH invoice number.

8/

4/2022 SCBA and CBRN SCBA

32

3.7 Pay.Gov Instructions

Domestic applicants may use the electronic fees transfer program known as Pay.Gov.

Note: Prior to making any payment of respirator approval fees, applicants must establish an account

with Pay.Gov.

A. Follow the web link provided below:

a. PAY.GOV homepage: https://pay.gov/paygov/homepage.

B. On the center of the web page click on the link “Click here to register” to start the process or

go to the web page address provided below:

a. Registration: Pay.gov - Register for a Pay.gov Account.

b. Read the User Responsibility Statement, fill in the box, and select accept.

c. Select the “Continue with Self Enrollment” tab.

d. Complete the required fields in the Online Self Enrollment form and then select

“submit.”

e. Use Pay.Gov username and password to log into the Pay.Gov system from the

homepage.

f. Access the forms necessary to submit payments online using this process.

C. Fee Payment User Instructions.

a. Open the Pay.Gov homepage.

b. Locate the “User Fee Form.”

i. Go to the Find Public Forms section below the login.

ii. Search for forms by three options:

1. Form Name.

2. Agency Name.

3. Search Public Forms.

iii. Use one of three links listed on the six forms in the system for the Centers for

Disease Control and Prevention (CDC).

1. Form Name: CDC Royalty BMLA and User fee Form.

a. Select CDC User Fee Form.

2. Agency Name: CDC Royalty BMLA and User Fee Form.

a. Select CDC User Fee Form.

3. Search Forms: CDC Royalty BMLA and User Fee Form.

a. Select CDC User Fee Form.

4. Click on the form name to open the online fillable form.

iv. Complete the Online CDC User Fee Form.

1. Complete all mandatory blocks marked with asterisks.

2. Under CDC Invoice Number, enter the three digit Applicant-Assigned

Reference Number (AAR#).

a. If payment is for an existing Task Number (TN), enter the

associated TN.

8/

4/2022 SCBA and CBRN SCBA

33

3. For “Payment Options,” select the “NIOSH User Fee” from the three

choices.

4. Enter a short description in the comments block regarding the

payment. Add any specific identifying information regarding the

submission that may help in processing the payment.

c. When submitting the form, users will be prompted to enter their Automated Clearing

House (ACH) debit information.

D. Currently Pay.Gov accepts payment directly by the Automated Clearing House (ACH) feature

or through credit or debit cards as follows:

a. Credit Cards: Visa, MasterCard, American Express, and Discover.

b. Debit Cards: Visa and MasterCard processed only.

Note: More in-depth instructions and information can be found at Pay.Gov homepage.

8/

4/2022 SCBA and CBRN SCBA

34

3.8 Drawings for Self-Contained Breathing Apparatus or CBRN Self-

Contained Breathing Apparatus

All drawings must be in English. Drawings are accepted in Adobe PDF, ProEngineer, Autodesk, Smart

Draw, and Corel Draw. Drawings should be named using a unique identifier of the organization’s choice,

R for drawing, the revision level (e.g., a, b, c, etc.), and the file extension representing the software

program (e.g., nnnnRa.dwg). All engineering and CAD drawings must be saved and submitted in full

view mode. All engineering and CAD drawings must be submitted in black and white. The signature

blocks on each submitted drawing must contain the initials or signature of the preparer and approver

along with the approval date for the drawing revision.

3.

8.1 Exploded-View Drawing and Major Subassembly Drawing for a SCBA or

a CBRN SCBA

For Self-Contained Breathing Apparatus, the exploded-view drawing is the major subassembly drawing

and must include the complete respirator with critical or major dimensions, materials, and

characteristics as listed on the Self-Contained Breathing Apparatus drawing checklist. User Instructions

do not need to be illustrated on the exploded-view drawing. Do not include future submittals or

unapproved assemblies on the exploded-view drawing.

Use an identifying numbering system of the major subassemblies on the exploded-view drawing to

reference major subassemblies from the assembly matrix to the exploded-view drawing. The identifying

numbering system on the major subassemblies must match exactly with the assembly matrix.

If a facepiece is shown as item 1 on the assembly matrix, it must also be item 1 on the exploded-view

drawing. The applicant may use dotted lines around subassemblies on an exploded-view drawing to

group the smaller parts together into one major subassembly. If the profile of a component changes,

i.e., from a facepiece to a facepiece with a side window, the components must be shown separately as

1a, 1b, 1c, etc.

8/

4/2022 SCBA and CBRN SCBA

35

3.8.2 Example of an Exploded-View Drawing for a SCBA or a CBRN SCBA

3.8.3 Major Subassembly Drawing for a SCBA or a CBRN SCBA

Applicants must submit major subassembly drawings for each major subassembly shown on the

exploded-view drawing. If a major subassembly is unchanged from a previous submittal and the

drawing is already on file at NIOSH, the drawing does not have to be resubmitted. The major

subassembly drawings may not contain future submissions or show unapproved assemblies.

All major subassembly drawings must meet the requirements defined in the “Major Subassembly

Drawing Checklists” found in Section 6. All drawings must be under the approval holder’s control and in

compliance with the document control system. Major subassembly drawing numbers and revision levels

must match exactly with those found on the assembly matrix.

DWM

8/

4/2022 SCBA and CBRN SCBA

36

Major subassemblies must have permanent identifying part numbers marked on them. This part

number must appear in the part number row of the assembly matrix. The part number location must be

clearly shown on the major subassembly drawings.

3.8.4 Material Specifications on Drawings for a SCBA or a CBRN SCBA

For material specifications, use the criteria affecting performance or design.

For example, if an accessory would not affect the performance or design, materials could be identified

as plastic, metal, rubber, etc. However, if the items do affect performance or design, they would be

identified as aluminum, butyl rubber, etc. The phrase “or equivalent” should not be used.

3.9 Component Vendors

If the applicant controls all specifications for the component, the component vendors do not need to be

specified. If the applicant does not control all specifications of the component, then the applicant must

provide the name of the vendor. In accordance with 42 CFR Sections 84.42 (c) and 84.43 (c) the