Refer to the service manual in the GSPN(see the rear cover) for the more information.

AIR CONDITIONER CONTENTS

SYSTEM AIR CONDITIONER

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

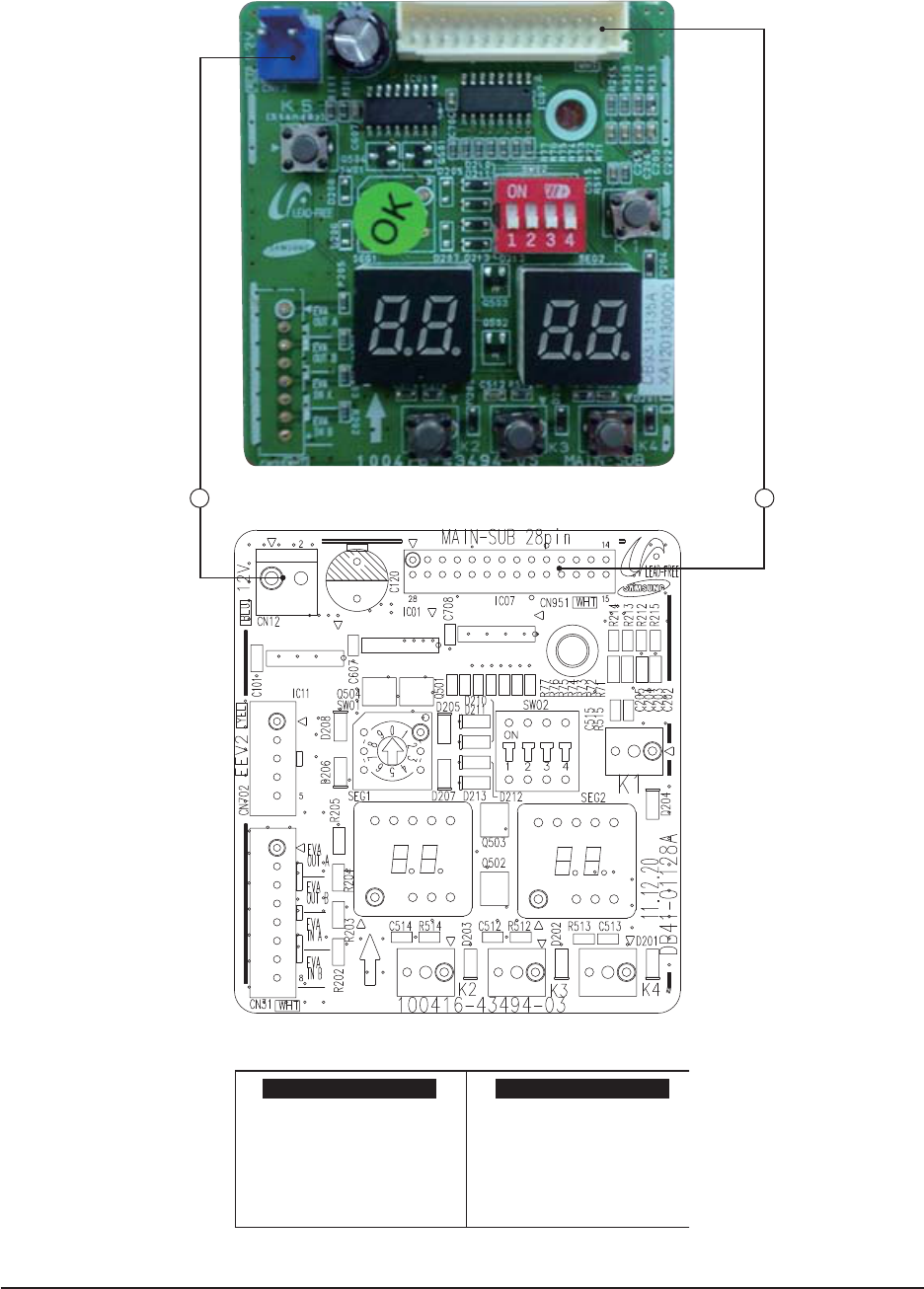

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

AC012/018/024MNADCH

INDOOR UNIT OUTDOOR UNIT

Model :

AC012MNADCH/AA

AC018MNADCH/AA

AC024MNADCH/AA

AC030MNTDCH/AA

AC036MNTDCH/AA

AC012KXADCH/AA

AC018JXADCH/AA

AC024JXADCH/AA

AC030JXADCH/AA

AC036JXADCH/AA

AC012KXADCH

AC024JXADCH

AC030JXADCH

AC018JXADCH

AC036JXADCH

AC030/036MNTDCH

2 Samsung Electronics

Contents

11. Precautions

........................................................................................................................................

1-1

1-1 Precautions for the Service

..............................................................................................................

1-1

1-2 Precautions related to static electricity and PL

............................................................................

1-1

1-3 Precautions related to product safety

...........................................................................................

1-2

1-4 Other precautions

..............................................................................................................................

1-2

12. Product Specifications

...............................................................................................................

2-1

2-1 The Feature of Product

.....................................................................................................................

2-1

2-2 Product Specifications

......................................................................................................................

2-2

2-3 Accessories

..........................................................................................................................................

2-5

13. Disassembly and Reassembly

...............................................................................................

3-1

3-1 Indoor Unit

.........................................................................................................................................

3-2

3-2 Outdoor Unit

.....................................................................................................................................

3-18

14. Troubleshooting

............................................................................................................................

4-1

4-1 Troubleshooting for indoor unit

..................................................................................................

4-1

4-2 Troubleshooting for outdoor unit

.................................................................................................

4-11

4-3 Troubleshooting by symptoms

.....................................................................................................

4-13

4-3-1 Indoor temperature sensor (open/short)

..........................................................................

4-13

4-3-2 Indoor heat exchanger temperature sensor (open/short)

.............................................

4-14

4-3-3 Indoor FAN error

.....................................................................................................................

4-15

4-3-4 Communication error after finishing Tracking

.................................................................

4-16

4-3-5 Indoor unit float sensor error

...............................................................................................

4-17

4-3-6 EEPROM circuit failure

...........................................................................................................

4-18

4-3-7 Outdoor unit is not powered on

.........................................................................................

4-19

4-4 Troubleshooting by symptoms

................................................................................................................... 4-21

4-4-1 Communication error

..........................................................................................................

4-21

4-4-2 Outdoor temperature sensor error

....................................................................................

4-22

4-4-3 Outdoor Coil temperature sensor error

............................................................................

4-24

4-4-4 Outdoor Discharge temperature sensor error

.................................................................

4-26

4-4-5 Outdoor Discharge over temperature error

.....................................................................

4-28

4-4-6 Outdoor Fan motor error

.................................................................................................................... 4-29

4-4-7 Compressor starting error .................................................................................................................. 4-30

4-4-8 Compressor wire missing error/rotation error .......................................................................... 4-31

4-4-9 O.C(Over Current) error ....................................................................................................................... 4-32

4-4-10 DC_link voltage sensor error .......................................................................................................... 4-33

4-4-11 DC_link voltage under/over error, Over voltage protection error/PFC over load ..... 4-34

Samsung Electronics 3

4-4-12 DC_link voltage sensor error ........................................................................................................... 4-35

4-4-13 Current sensor error/Input current sensor error .................................................................... 4-36

4-4-14 Heatsink sensor error/Heatsink over heat ................................................................................. 4-37

4-4-15 Comp Vlimit error/Comp current limit error ............................................................................ 4-38

4-4-16 EEPROM error/OTP error .................................................................................................................. 4-39

4-4-17 AC zero cross signal error ................................................................................................................. 4-40

4-4-18 Operation condition secession error............................................................................................ 4-41

4-4-19 Capacity miss match error ............................................................................................................... 4-42

4-4-20 Gas leak error ........................................................................................................................................ 4-43

15. PCB Diagram

.....................................................................................................................................

5-1

5-1 Indoor Unit

.........................................................................................................................................

5-1

5-2 Outdoor Unit

.....................................................................................................................................

5-4

16. Wiring Diagram

..............................................................................................................................

6-1

6-1 Indoor Unit

........................................................................................................................................

6-1

6-2 Outdoor Unit

....................................................................................................................................

6-2

7. Reference Sheet

.............................................................................................................................

7-1

7-1 Index for Model Name

......................................................................................................................

7-1

7-2 Refrigerating Cycle Diagram

............................................................................................................

7-2

Samsung Electronics 1-1

1. Precautions

1-1 Precautions for the Service

XUse the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

XWhen repairing the equipment, connection of the harness parts must be firm and solid.

– A loose connection may cause noise or other malfunction.

XWhen assembling and disassembling the equipment while it is laid down, lay it on soft cloth.

– Otherwise it may scratch the back of the exterior of the product.

XRemove dust or dirt completely from the housing block, wiring block and service parts during repair.

– This helps prevent the danger of fire caused by tracking or short circuit.

XFasten the valve caps of service valves and charging valves of outdoor unit as much as possible using adjustable wrenches.

XCheck the status of the components’ assembly after repair service.

– The status must be the same as before the repair service.

1-2 Precautions related to static electricity and PL

X The PCB power supply block is susceptible to static electricity. Therefore, care must be taken during repair or measuring

while the power is on.

– Wear insulation gloves for PCB repair or measuring.

X Check whether the installation location is at least two meters away from other electronic products such as TV, video, or

audio.

– Otherwise, the video quality might be degraded or noise might be generated.

X Do not let end users repair the products themselves.

– Unauthorized disassembly might cause electric shock or fire.

1-2 Samsung Electronics

1-3 Precautions related to product safety

X Do not pull the power cord and do not touch the power plug or aux power switch with wet hands.

– It might cause electric shock or fire.

X A damaged power line or power plug must be replaced to prevent danger.

X Do not bend the power cable with excessive force, and do not place a heavy weight on the case as it might damage the

cable.

– It might cause electric shock or fire.

X Do not use multiple electric outlets.

– This might cause electric shock or fire.

X Connect the ground terminal when necessary.

– You must connect the ground terminal if you determine that there is a danger of electric leakage due to moisture or water.

X Unplug the power cable or turn off the auxiliary power switch for electric part replacement and repair service.

– Otherwise it might cause electric shock.

X Instruct end users to separate the batteries from the remote controllers and store them separately when the product is not

used for long time.

– Otherwise leakage from the dry cell may cause problems with the remote controller.

1-4 Other precautions

X The pipes should have no leaks during installation, and the compressor must be stopped before removing connecting

pipes for pump down work. Operating the compressor while the service valve is open and coolant pipe is not properly

connected may cause explosion or injury due to abnormal high pressure created inside the coolant cycle as the air can be

absorbed through the pipe.

X Pump Down work procedure (When uninstalling the product)

– Turn on the air conditioner, select cooling operation, and run the compressor for more than three minutes.

– Release the high pressure and low pressure valve caps.

– Close the high pressure valve completely using an L-wrench

– After about two minutes, close the low pressure valve completely.

– Stop running the air conditioner.

– Separate the connecting pipe.

Samsung Electronics 2-1

X Built-in Cassette Type

After installed, the air conditioner can be harmonized with a room interior.

X High Performance & Energy Saving

With the advanced BLDC inverter technology, it makes a room cool with highly energy saving and arises the efficiency of air conditioner.

XLong Ambient Operation(In Low Temperature)

It can arise the reliability and the capacity of the air conditioner, especially operated in low temperature.

X Eco-friendly Product(Lead-Free, ROHS, WEEE)

X Easy installation of ultra-lightweight indoor unit

2. Product Specifications

2-1 The Feature of Product

2-2 Samsung Electronics

ITEM

AC012MNADCH

AC012KXADCH

AC018MNADCH

AC018JXADCH

IMAGE

Indoor Unit

Outdoor Unit

Remote Controller

Power Product 1Φ, 220~240V, 50Hz 1Φ, 220~240V, 50Hz

Indoor L x H x D mm 750*246*249

896*261*261

Outdoor L x H x D mm 790*285*548 880*310*638

Indoor Product kg(Net) 7.6 10.6

Outdoor Product kg(Net) 36.2 45.0

Capacity

Cooling(STD) Btu/h 12 000

18 000

Heating(STD) Btu/h

14 000 20 000

Power

Consumption

Cooling(STD) W

1220 2160

Heating(STD) W

1680 1960

Operation

current

Cooling(STD) A

5.7 9.4

Heating(STD) A

7.4 8 .5

Noise

(Cooling/

Heating)

Indoor unit

In case of strongest air

blow

dBA

43/43 48/48

Outdoor unit

In case of strongest air

blow

dBA

54/54 58/58

Refrigerant (R410A) g 1050 1300

Connecting Pipe

Liquid mm 6.35

6.35

Gas mm

9.52 12.70

Additional Refrigerant (R410A) g/m

10 10

Standard m

7. 5 7. 5

Extension length(Total) m 20

30

Extension length(Elevation) m

15 15

Option Code

Product

Option

0100FC-19548C-272328-371708

0100FC-19548E-27343E-3C170D

Installation

Option

020000-100000-200000-300000

020000-100000-200000-300000

2-2 Product Specifications

Samsung Electronics 2-3

ITEM

AC024MNADCH

AC024JXADCH

AC030MNTDCH

AC030JXADCH

IMAGE

Indoor Unit

Outdoor Unit

Remote Controller

Power Product 1Φ, 220~240V, 50Hz 1Φ, 220~240V, 50Hz

Indoor L x H x D mm

1065*294*301 1280*345*253

Outdoor L x H x D mm 940*330*998 940*330*998

Indoor Product kg(Net) 14.5 18.5

Outdoor Product kg(Net) 64.5 70.0

Capacity

Cooling(STD) Btu/h 24 000

30 000

Heating(STD) Btu/h

27 000 32 000

Power

Consumption

Cooling(STD) W

2350 3150

Heating(STD) W

2560 3360

Operation

current

Cooling(STD) A

10.4 13.7

Heating(STD) A

11. 4 14 .7

Noise

(Cooling/

Heating)

Indoor unit

In case of strongest air

blow

dBA

51/51 55/55

Outdoor unit

In case of strongest air

blow

dBA

60/60 60/60

Refrigerant (R410A) g 2100 2600

Connecting Pipe

Liquid mm 6.35

9.52

Gas mm

15.88 15.88

Additional Refrigerant (R410A) g/m

10 22

Standard m

7. 5 7. 5

Extension length(Total) m 50

50

Extension length(Elevation) m

30 30

Option Code

Product

Option

0100FC-19547F-274750-37170D

0110FC-193573-275A64-37770D

Installation

Option

020000-100000-200000-300000

020000-100000-200100-300000

2-4 Samsung Electronics

ITEM

AC036MNTDCH

AC036JXADCH

IMAGE

Indoor Unit

Outdoor Unit

Remote Controller

Power Product 1Φ, 220~240V, 50Hz

Indoor L x H x D mm

1280*345*253

Outdoor L x H x D mm 940*330*1210

Indoor Product kg(Net) 18.5

Outdoor Product kg(Net) 88.0

Capacity

Cooling(STD) Btu/h

36 000

Heating(STD) Btu/h

40 000

Power

Consumption

Cooling(STD) W

3870

Heating(STD) W

4120

Operation

current

Cooling(STD) A

16.5

Heating(STD) A

17.8

Noise

(Cooling/

Heating)

Indoor unit

In case of strongest air

blow

dBA

55/55

Outdoor unit

In case of strongest air

blow

dBA

60/60

Refrigerant (R410A) g 2800

Connecting Pipe

Liquid mm

9.52

Gas mm

15.88

Additional Refrigerant (R410A) g/m

33

Standard m

7. 5

Extension length(Total) m

75

Extension length(Elevation) m

30

Option Code

Product

Option

0110FC-194594-276470-39670D

Installation

Option

020000-100000-200100-300000

Samsung Electronics 2-5

Item Description Code No. Q’ty Remark

Remote Control

DB93-15882S

1

Essential Offer

(Indoor Unit)

Batteries for Remote Control

4301-000121

2

USER &

INSTALLATION

MANUAL DB68-07119A

1

Remote Control Holder

DB61-06087A

1

M4 x 16 Tapped Screws

6002-000234

2

Cap Screws

DB67-01404B

(AC012/018/024MNADCH)

3

CARD WARRNATY DB68-02596B

1

Drain Plug

DB67-20011A

1

Essential Offer

(Outdoor Unit)

Rubber Leg DB67-01533A 4

INSTALLATION MANUAL DB68-06488A 1

2-3 Accessories

Samsung Electronics 3-1

Item Remarks

+SCREW DRIVER

Adjustable Wrench

(8mm, 10mm, 13mm)

M6, M8 Hex Wrench

XNecessary Tools

3. Disassembly and Reassembly

3-2 Samsung Electronics

3-1 Indoor unit

XAC012MNADCH / AC018MNADCH / AC024MNADCH

No Parts

Procedure Remark

1 PANEL-FRONT 1) Stop the driving of air conditioner and shut off

main power supply.

2) Detach FILTER PRE from the PANEL FRONT.

3) Cover Panel is assembled on bottom of indoor

unit as shown in the figure.

Remove the Cap Screw as shown on the right

side and then remove the screw and separate

the Cover Panel.

Samsung Electronics 3-3

No Parts

Procedure Remark

4) Cover Panel is fixed to body by Hook in center area and

side area.

5) Separate the hook after pushing both end of Cover

Panel as shown in the figure.

(Watch out for the damage of the hook)

6) Raise front part upward obliquely as shown in the

figure and then remove the hooks.

Center area

Side area

Side area

HOOK

026/035

052/071

3-4 Samsung Electronics

No Parts

Procedure Remark

Caution:

Assembly of Cover Panel after service end.

-

Reassembly is in the reverse order of the

removal.

- Piping and drain hose must be careful not to

damage and Progress must be done with both

hands.

Hook (Side)

Hook (Center)

Screw

Cap Screw

Samsung Electronics 3-5

No Parts

Procedure Remark

7) To detach the PANEL-FRONT from the main

frame, unfasten 2 screws at the bottom.

(use + Screw Driver)

8) To detach the COVER-PANEL from the main

frame, loosen 4 HOOK Structures.

When separate the hook :

Use the (-) screw Driver.

(-)Screw Driver Insert the hook and then pull the

hook as shown on the right side.

(Watch out for the damage of the hook)

3-6 Samsung Electronics

No Parts

Procedure Remark

9) Remove the Panel Frame from the Main

Frame as shown on the right side.

Samsung Electronics 3-7

No Parts

Procedure Remark

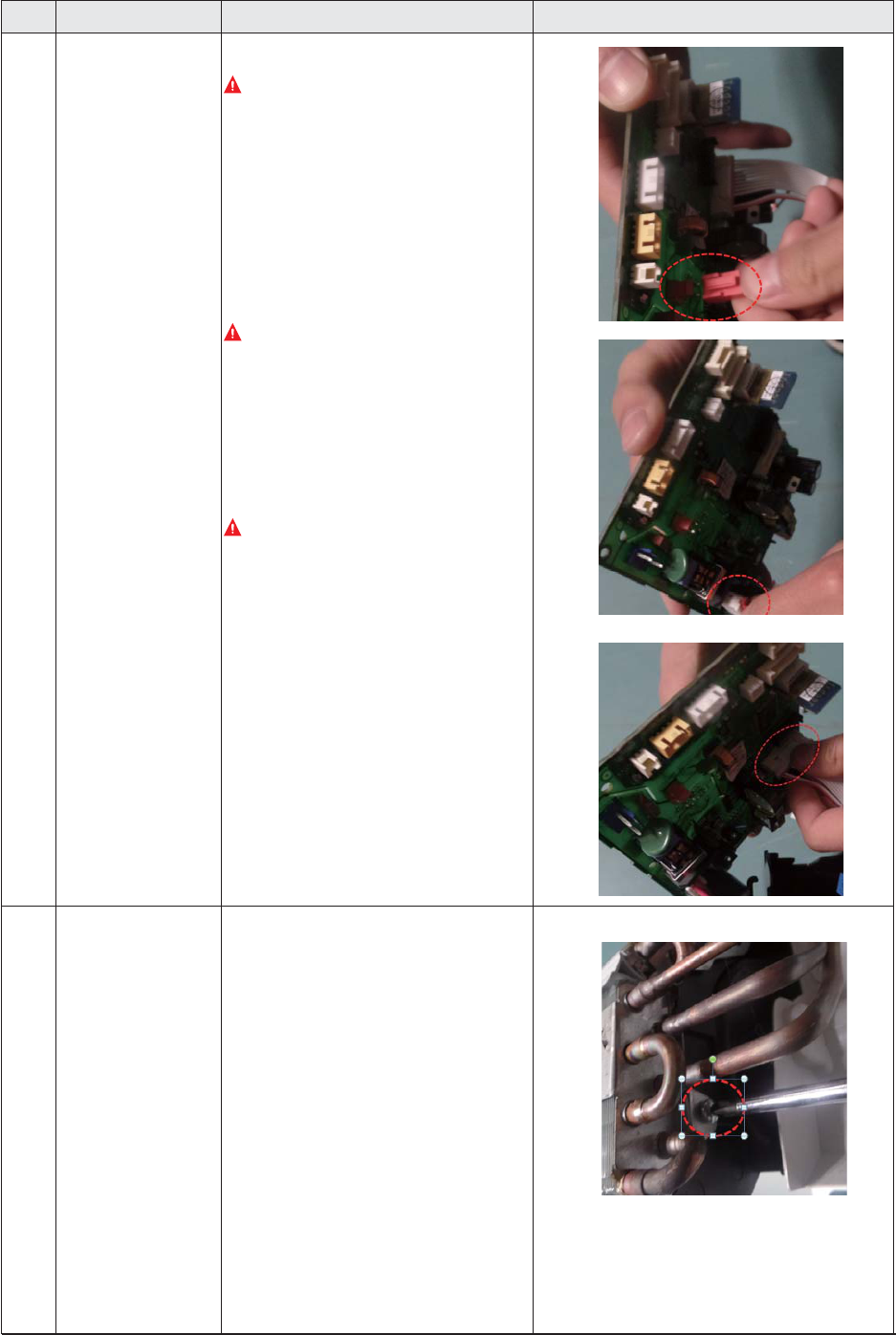

2

CONTORL IN

1) Lossen Sub PBA Wire.

Caution:

When you separate the connector,

pull pressing the locking button.

2) Lossen Stepping Motor, EEV, Display,

Sensor, SPI, Fuse Wire.

Caution:

When you separate the connector,

pull pressing the locking button.

3) Lossen Motor, Terminal Wire.

Caution:

When you separate the connector,

pull pressing the locking button.

4) Loosen Earth Wire.

3-8 Samsung Electronics

No Parts

Procedure Remark

5 EVAPORATOR 9) Take off the CASE-CONTROL from

the main frame after loosen the remaining

connector.

Caution:

When you separate the connector,

pull pressing the locking button.

3 TRAY DRAIN 1) To detach TRAY-DRAIN from the main frame,

pull the bottom of the TRAY-DRAIN towards

you.

Samsung Electronics 3-9

No Parts

Procedure Remark

4 Evaporator 1) Detach the HOLDER PIPE.

2) Unfasten the screw at the left side.

(use + Screw Driver)

3) Unfasten the screw at the right side.

(use + Screw Driver)

4) To detach Evaporator from the main frame,

pull the bottom of the Evaporator towards

you.

3-10 Samsung Electronics

No Parts

Procedure Remark

5 FAN MOTOR

&

CROSS FAN

1) Unfasten the screw. (use + Screw Driver)

2) Detach the FAN Motor case.

3) Unfasten the screw a little.

(use + Screw Driver)

4) Pull the CROSS-FAN to the left side.

Samsung Electronics 3-11

XAC030MNTDCH / AC036MNTDCH

No Parts

Procedure Remark

1 PANEL-FRONT 1) Stop the driving of air conditioner and shut off

main power supply.

2) Open the FRONT-GRILLE and pull out from the

PANEL-FRONT.

3) Detach COVER-TERMINAL from the PANEL

FRONT. (use + Screw Driver)

4) Loosen connector wire(white) and detach the

temperature sensor wire .

5) To detach the FRONT-PANELthe main frame,

unfasten 2 screw at the bottom.(use + Screw

Driver )

6) Take off the FRONT-PANEL,lifting up the bottom

3-12 Samsung Electronics

No Parts

Procedure Remark

2

TRAY DRAIN

1) Loosen stepping motor wire and detach the

hook of main frame.

2) To detach TRAY-DRAIN from the main frame, pull

the bottom of the TRAY-DRAIN towards you.

3) To detach TRAY-DRAIN from the main frame ,

pull the bottom of the TRAY-DRAIN towards you.

3

CONTROL IN

1) Unfasten the earth screw.(use + ScrewDriver)

2) Detach the temperature sensor and Humidity

sensor.

3) Detach the temperature sensor.

Samsung Electronics 3-13

No Parts

Procedure Remark

4) Loosen MOTOR wires(white).

5) Take off the CASE-CONTROL from the main

frame. (use + Screw Driver)

4 PBA 1) Loosen the STEP UP/DOWN connector(CN802).

Caution:

When you separate the connector,

pull pressing the locking button.

2) Loosen the FUSE CHK connector (CN140).

Caution:

When you separate the connector,

pull pressing the locking button.

3-14 Samsung Electronics

No Parts

Procedure Remark

3) Loosen the EVA IN/OUT connector. (CN403)

Caution:

When you separate the connector,

pull pressing the locking button.

4) Loosen the Humidity sensor connector(CN401).

->Option connector.

Caution:

The terminal is locking type.

So, when you separate terminals, pull pressing

the button.

5) Loosen the DISPLAY connector. (CN501).

Caution:

The terminal is locking type.

So, when you separate terminals, pull pressing

the button.

6) Loosen the POWER connector.

Caution:

When you separate the connector,

pull pressing the locking button.

Samsung Electronics 3-15

No Parts

Procedure Remark

7) Loosen the COMM wire connector(CN303).

Caution:

When you take off the PBA, don’t touch

the components.

Please hold the PBA both side.

8) Loosen the Motor connector(CN701).

Caution:

When you separate the connector,

pull pressing the locking button.

9) Take off the main PBA from the ASS’Y Control in.

Caution:

When you take off the PBA, don’t touch

the components.

Please hold the PBA both side.

5 EVAPORATOR 1) Unfasten the screw at the right side. (use +

ScrewDriver)

3-16 Samsung Electronics

No Parts

Procedure Remark

2) Unfasten the screw at the left side. (use +

ScrewDriver)

3) Detach the HOLDER PIPE. (use + Screw Driver)

4) Detach the BRACKET-EVAP. (use + Screw Driver)

5) Detach the HOLDER EVAP. (use + Screw Driver)

6) Loosen 1 fixing earth screw right side. (use +

Screw Driver)

Samsung Electronics 3-17

No Parts

Procedure Remark

6 FAN MOTOR

&

CROSS FAN

1) Loosen 6 fixing screws of HOLDER-MOTOR

2) unfasten the screw a little. (use + Screw Driver)

3) unfasten the screw a little and pull the MOTOR

FAN to the right side. (use + Screw Driver)

4) Loosen 1 fixing screws of HOLDER-FAN.(use +

Screw Driver)

5) unfasten the screw a little.(use + Screw Driver)

3-18 Samsung Electronics

■ AC012KXADCH

No Parts Procedure Remark

1 common work 1) loosen 1 pcs screw of cover control,and

detach it.

2) loosen 5 pcs screws on both right and

left cabniet side edges and to detach the

cover-top

3) Loosen 7 screwsfixed to disassemble

cabi-front , and detach it.

3-2 Outdoor Unit

Samsung Electronics 3-19

No Parts Procedure Remark

common work 4) loosen 7 screws to disassemble the cabi-

right ,and detach it.

5) loosen 2 screws to disassemble steel-bar.

6) loosen 3 screws to disassemble cabi-left.

3-20 Samsung Electronics

No Parts Procedure Remark

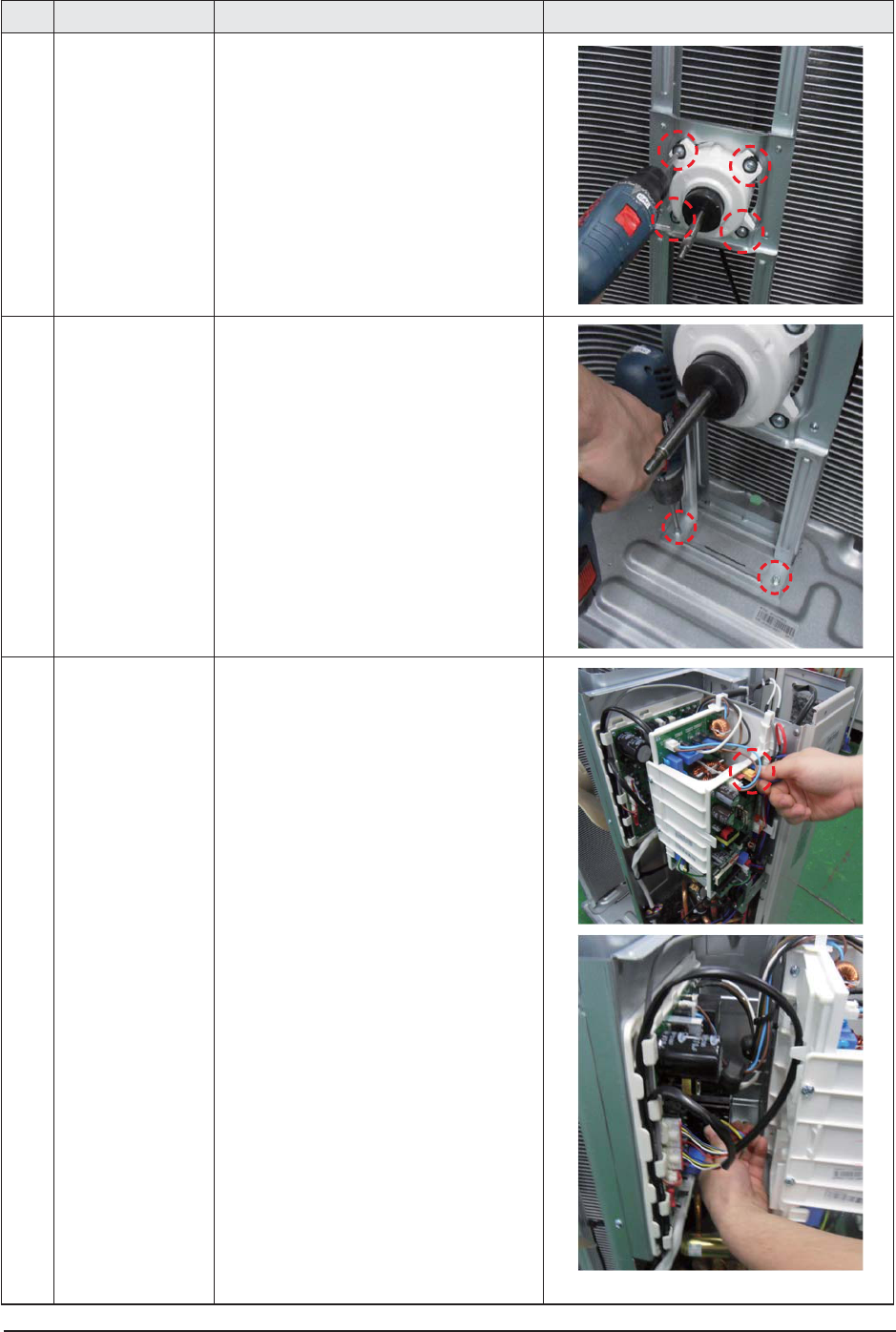

2 fan&motor 1) loosen 1 screw as indication and detached

the fan.

2) loosen 4 pcs motor screws and disconnect

the wire betwwen assy control out and motor.

3) loosen 2 pcs bracket-motor screw and

detach it.

Samsung Electronics 3-21

No Parts Procedure Remark

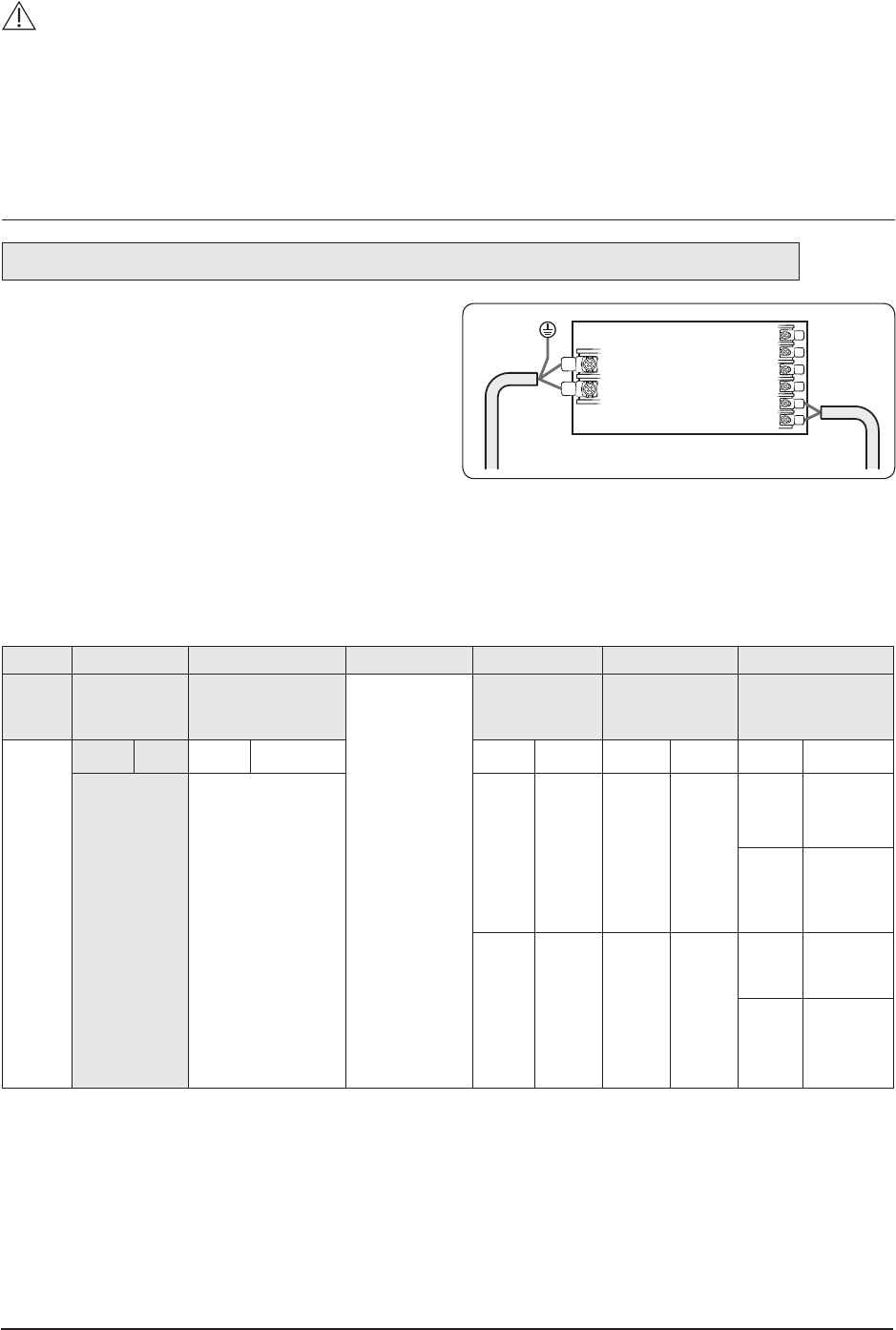

3 assy control out 1) lossen fixing 1 screw from cover -control

2) detach several connections from assy con-

trol out, take out assy control out.

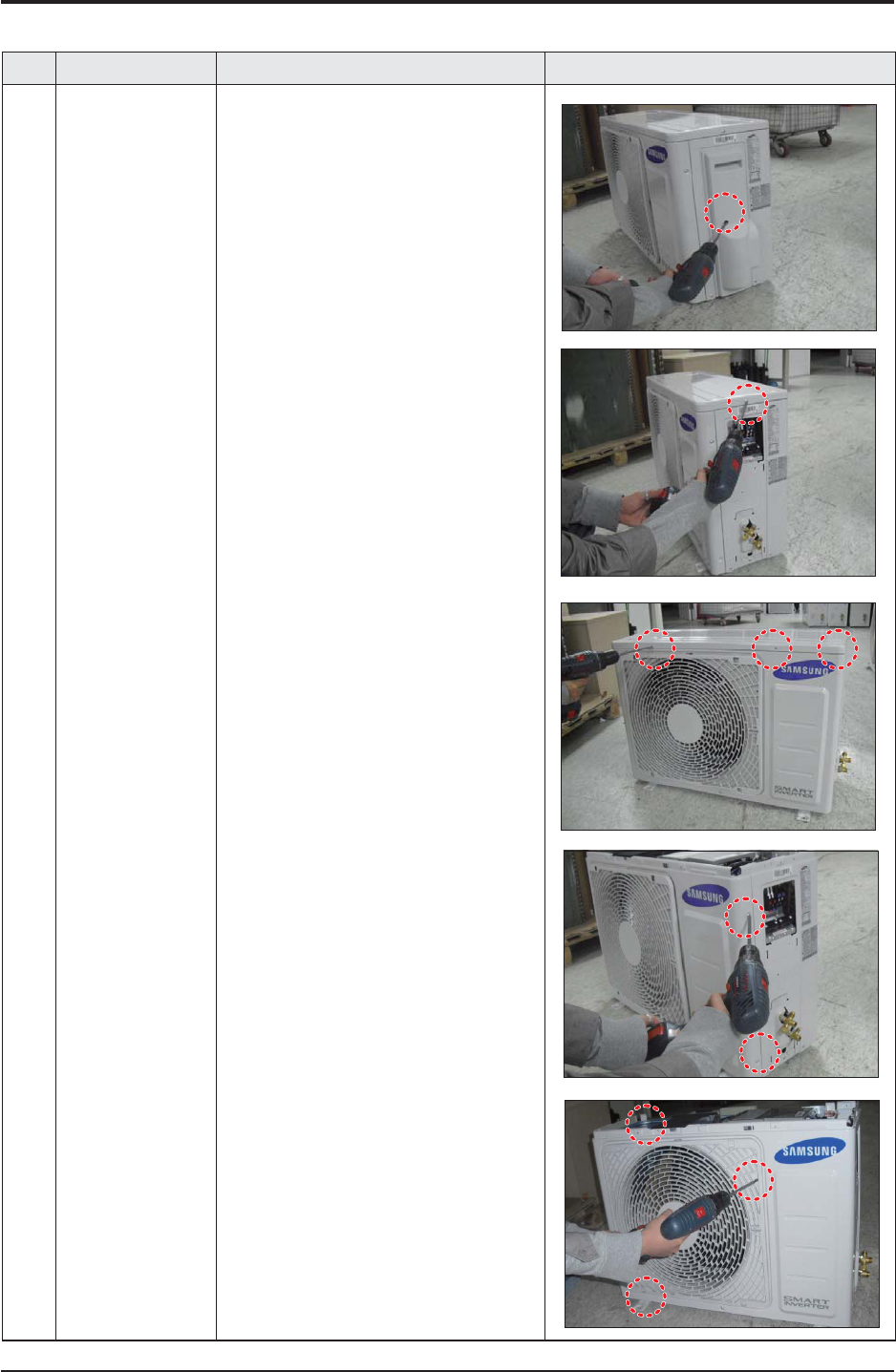

4 Heat exchanger 1) Release the refrigerant at first

2) Looosen fixing screw on both side.

3) Disaessembly the pipes in both inlet and

outlet with welding torch.

4) detach the heat exchanger.

3-22 Samsung Electronics

No Parts Procedure Remark

5 compressor 1) Disconnect the compressor lead wire .

2) Disassembly the felt comp sound.

loosen the 3 bolts at the bottom of

Samsung Electronics 3-23

No Parts Procedure Remark

1common work 1) loosen 1 pcs screw of cover control,and

detach it.

2) loosen 5 pcs screws on both right and

left cabniet side edges and to detach the

cover-top

3) Loosen 7 screwsfixed to disassemble

cabi-front , and detach it.

QAC018JXADCH

3-24 Samsung Electronics

No Parts Procedure Remark

common work 4) loosen 7 screws to disassemble the cabi-

right ,and detach it.

5) loosen 2 screws to disassemble steel-bar.

6) loosen 3 screws to disassemble cabi-left.

Samsung Electronics 3-25

No Parts Procedure Remark

2 fan&motor 1) loosen 1 screw as indication and detached

the fan.

2) loosen 4 pcs motor screws and disconnect

the wire betwwen assy control out and motor.

3) loosen 2 pcs bracket-motor screw and

detach it.

3-26 Samsung Electronics

No Parts Procedure Remark

3 assy control out 1) lossen fixing 1 screw from cover -control

2) detach several connections from assy con-

trol out, take out assy control out.

4 Heat exchanger 1) Release the refrigerant at first

2) Looosen fixing screw on both side.

3) disaessembly the pipes in both inlet and

outlet with welding torch.

4) detach the heat exchanger.

Samsung Electronics 3-27

No Parts Procedure Remark

5compressor 1) disconnect the compressor lead wire .

2)disassembly the felt comp sound.

loosen the 3 bolts at the bottom of

3-28 Samsung Electronics

No Parts Procedure Remark

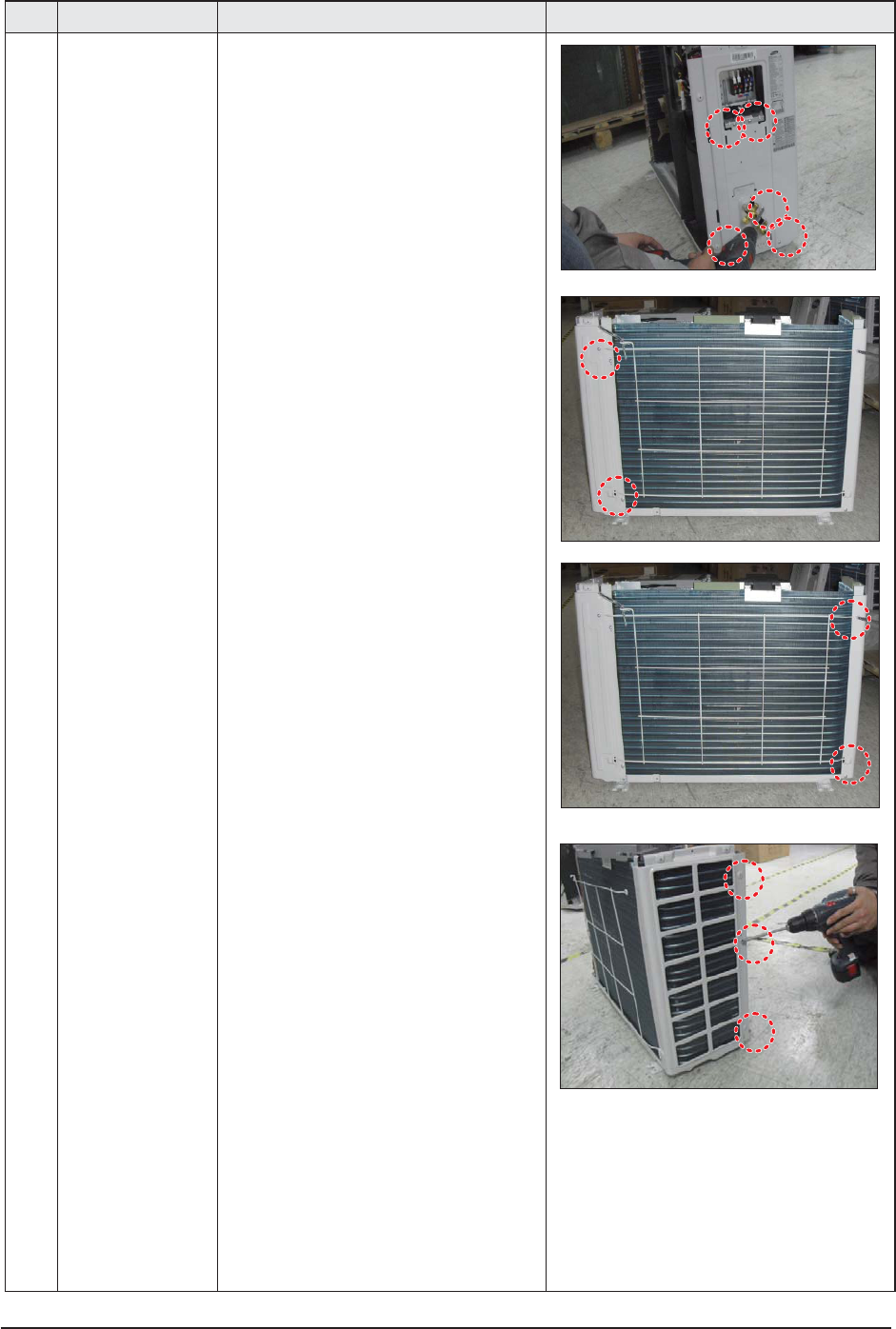

1 Cabi Front RH

You must turn off the Power before

disassembly.

1) Unscrew and remove two mounting screw

in the Cabinet Front RH. (Use +Screw Driver)

2 Cabi Top 1) Unscrew and remove 9 screws

on each side of the Cabinet-Top.

(Use +Screw Driver)

3 Cabi Install Front 1) Unscrew and remove 1 screw

in the Cabinet-Install Front.

(Use +Screw Driver)

QAC024JXADCH, AC030JXADCH

Samsung Electronics 3-29

No Parts Procedure Remark

4 Guard Cond 1) Pull the sensor from Guard Cond.

2) Unscrew and remove 4 screws

in the Guard Cond.

(Use +Screw Driver)

5 Cabi Back RH 1) Pull the sensor from Cabi Back RH.

2) Unscrew and remove 4 screws

on each side of the Cabinet Back RH.

(Use +Screw Driver)

3-30 Samsung Electronics

No Parts Procedure Remark

6 Cabi Install Back 1) Unscrew and remove 1 screw

in the Cabinet-Install Back.

(Use +Screw Driver)

7 Cabi Front LF 1) Unscrew and remove 10 screws

in the Cabinet-Front LF.

(Use +Screw Driver)

Samsung Electronics 3-31

No Parts Procedure Remark

8 Fan 1) Turn 2 mounting nuts as shown in the

picture and remove it. (Use Adjustable

Wrench)

3-32 Samsung Electronics

No Parts Procedure Remark

9 Motor 1) Separate the Fan Propeller.

2) Unscrew and remove the 8 Motor mounting

screws. (Use +Screw Driver)

3) Disconnect the Motor wire From

Ass'y Control Out.

10 Bracket Motor 1) Unscrew and remove 2 mounting screws

in Bracket Motor. (Use +Screw Driver)

Samsung Electronics 3-33

No Parts Procedure Remark

11 Control Out 1) Disconnect 4 Connecters From

Ass'y Control Out.

2) Unscrew and remove 1 mounting screw

in Control Out. (Use +Screw Driver)

3) Separate Ass'y Control Out.

3-34 Samsung Electronics

No Parts Procedure Remark

12 Ass'y 4way Valve 1) Purge the Coolant first.

2) Unscrew and remove 2mounting screws

in muffler.

3) Unscrew and remove 2 mounting screws

in Service Valve. (Use +Screw Driver)

4) Separate the pipe from the Entrance/Exit

using a welder.

When removing the compressor,

Heat Exchanger, and Pipe, purge the

Coolant inside the Compressor

completely and remove the pipe

with a welding flame.

Samsung Electronics 3-35

No Parts Procedure Remark

13 Ass;y EEV Valve 1) Unscrew and remove 2 mounting screws

in Service Valve. (Use +Screw Driver)

2) Separate the pipe from the Entrance/Exit

using a welder.

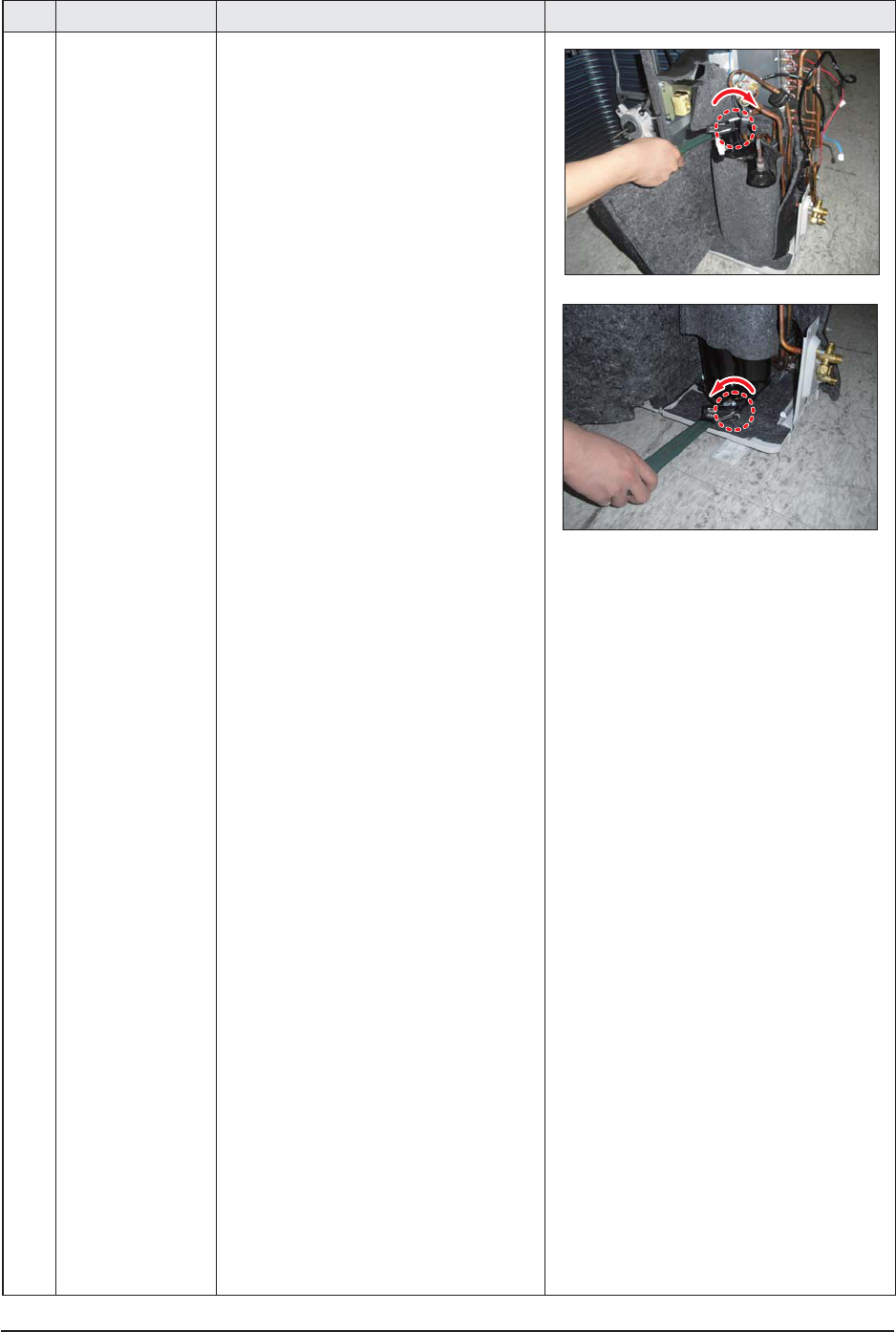

14 Compressor 1) Unscrew and remove 1 mounting nut

in Cover Terminal. (Use Adjustable Wrench)

2) Separate the Compressor Felt Sound.

3-36 Samsung Electronics

No Parts Procedure Remark

3) As shown in the picture, unscrew and

remove 3 mounting screws from the

bottom. (Use Adjustable Wrench)

15 Cond Out 1) Unscrew and remove 3 screws

on each side of the Assy Cond Out.

(Use +Screw Driver)

2) Separate the Compressor Felt Sound.

Samsung Electronics 3-37

No Parts Procedure Remark

1 Cabi Front RH

You must turn off the Power before

disassembly.

1) Unscrew and remove two mounting

screw in the Cabinet Front RH.

(Use +Screw Driver)

2 Cabi Top

1) Unscrew and remove 9 screws

on each side of the Cabinet-Top.

(Use +Screw Driver)

3 Cabi Install Front

1) Unscrew and remove 1 screw

in the Cabinet-Install Front.

(Use +Screw Driver)

4 Guard Cond

1) Pull the sensor from Guard Cond.

2) Unscrew and remove 4 screws

in the Guard Cond.

(Use +Screw Driver)

QAC036JXADCH

3-38 Samsung Electronics

No Parts Procedure Remark

5 Cabi Back RH

1) Pull the sensor from Cabi Back RH.

2) Unscrew and remove 4 screws

on each side of the Cabinet Back RH.

(Use +Screw Driver)

6 Cabi Install Back

1) Unscrew and remove 1 screw

in the Cabinet-Install Back.

(Use +Screw Driver)

7 Cabi Front LF

1) Unscrew and remove 10 screws

in the Cabinet-Front LF.

(Use +Screw Driver)

8 Fan

1) Turn 2 mounting nuts as shown in

the picture and remove it.

(Use Adjustable Wrench)

Samsung Electronics 3-39

No Parts Procedure Remark

9 Motor

1) Separate the Fan Propeller.

2) Unscrew and remove the 8 Motor

mounting

screws. (Use +Screw Driver)

3) Disconnect the Motor wire From

Ass'y Control Out.

10 Bracket Motor

1) Unscrew and remove 2 mounting

screws in Bracket Motor.

(Use +Screw Driver)

11 Control Out

1) Disconnect 4 Connecters From

Ass'y Control Out.

2) Unscrew and remove 1 mounting

screw in Control Out.

(Use +Screw Driver)

3) Separate Ass'y Control Out.

3-40 Samsung Electronics

No Parts Procedure Remark

12 Assy 4way Valve

1) Purge the Coolant first.

2) Unscrew and remove 2 mounting

screws in Service Valve. (Use +Screw

Driver)

3) Separate the pipe from the

Entrance/Exit using a welder.

When removing the compres-

sor, Heat Exchanger, and Pipe,

purge the Coolant inside the

Compressor completely and

remove the pipe with a welding

flame.

13 Assy EEV Valve

1) Unscrew and remove 2 mounting

screws in Service Valve.

(Use +Screw Driver)

2) Separate the pipe from the Entrance/

Exit using a welder.

Samsung Electronics 4-1

4. Troubleshooting

You cannot set both of the indoor unit addresses and

the installation options in a batch: set both of them

respectively.

4-1-1 Common steps for setting the

addresses and options

MR-EC00 and MR-EH00 remote controls

Low Temp button

High Temp button

Mode button

Low Fan button

High Fan button

Setting the

option values

for setting the

options

NOTE

t The remote control display and buttons may vary

depending on the model.

1 Enter the mode for setting the options:

a Remove the batteries from the remote control, and

then insert them again.

b While holding down the

(High Temp) and

(Low Temp) buttons simultaneously, insert the

batteries into the remote control.

c Make sure that you are entered to the mode for

setting the options:

2 Set the option values.

CAUTION

t The total number of available options are 24: SEG1 to

SEG24.

t Because SEG1, SEG7, SEG13, and SEG19 are the page

options used by the previous remote control models,

the modes to set values for these options are skipped

automatically.

t Set a 2-digit value for each option pair in the following

order: SEG2 and SEG3 ¤ SEG4 and SEG5 ¤ SEG6 and

SEG8 ¤ SEG9 and SEG10 ¤ SEG11 and SEG12 ¤ SEG14

and SEG15 ¤SEG16 and SEG17 ¤ SEG18 and SEG20 ¤

SEG21 and SEG22 ¤ SEG23 and SEG24

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

0XXXXX

SEG7 SEG8 SEG9 SEG10 SEG11 SEG12

1XXXXX

SEG13 SEG14 SEG15 SEG16 SEG17 SEG18

2XXXXX

SEG19 SEG20 SEG21 SEG22 SEG23 SEG24

3XXXXX

On (SEG1 to SEG12) Off (SEG13 to SEG24)

4-2 Samsung Electronics

Take the steps presented in the following table:

Steps Remote control display

1 Set the SEG2 and SEG3 values:

a Set the SEG2 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG2

b Set the SEG3 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG3

2 Press the (Mode) button. Cool and On appear on the remote control display.

3 Set the SEG4 and SEG5 values:

a Set the SEG4 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG4

b Set the SEG5 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG5

4 Press the (Mode) button. Dry and On appear on the remote control display.

5 Set the SEG6 and SEG8 values:

a Set the SEG6 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG6

b Set the SEG8 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG8

Samsung Electronics 4-3

Steps Remote control display

6 Press the

(Mode) button. Fan and On appear on the remote control display.

7 Set the SEG9 and SEG10 values:

a Set the SEG9 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG9

b Set the SEG10 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG10

8 Press the (Mode) button. Heat and On appear on the remote control display.

9 Set the SEG11 and SEG12 values:

a Set the SEG11 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG11

b Set the SEG12 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG12

10 Press the (Mode) button. Auto and Off appear on the remote control display.

11 Set the SEG14 and SEG15 values:

a Set the SEG14 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG14

4-4 Samsung Electronics

Steps Remote control display

b Set the SEG15 value by pressing the

(High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG15

1 Press the (Mode) button. Cool and Off appear on the remote control display.

2 Set the SEG16 and SEG17 values:

a Set the SEG16 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG16

b Set the SEG17 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG17

3 Press the (Mode) button. Dry and Off appear on the remote control display.

4 Set the SEG18 and SEG20 values:

a Set the SEG18 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG18

b Set the SEG20 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG20

5 Press the (Mode) button. Fan and Off appear on the remote control display.

Samsung Electronics 4-5

Steps Remote control display

6 Set the SEG21 and SEG22 values:

a Set the SEG21 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG21

b Set the SEG22 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG22

7 Press the (Mode) button. Heat and Off appear on the remote control display.

8 Set the SEG23 and SEG24 values:

a Set the SEG23 value by pressing the

(Low Fan) button repeatedly until the

value you want to set appears on the remote control display.

SEG23

b Set the SEG24 value by pressing the (High Fan) button repeatedly until the

value you want to set appears on the remote control display.

When you press the

(Low Fan) or (High Fan) button, values appear in the

following order:

SEG24

3 Check whether the option values that you have set are correct by pressing the (Mode) button repeatedly

[

SEG21

,

SEG22

]

[

SEG23

,

SEG24

]

44

[

SEG2

,

SEG3

]

[

SEG4

,

SEG5

]

[

SEG6

,

SEG8

]

[

SEG9

,

SEG10

]

0

0

[

SEG11

,

SEG12

]

[

SEG14

,

SEG15

]

[

SEG16

,

SEG17

]

77

[

SEG18

,

SEG20

]

00

4 Save the option values into the indoor unit:

Point the remote control to the remote control sensor on the indoor unit and then press the

(Power) button on the

remote control twice. Make sure that this command is received by the indoor unit. When it is successfully received, you

can hear a short sound from the indoor unit. If the command is not received, press the

(Power) button again.

4-6 Samsung Electronics

1 Check whether the air conditioner operates in accordance with the option values you have set:

a Reset the indoor or outdoor unit.

t Indoor unit : Press the

(Set) and (Low Fan) buttons on the remote control simultaneously for 4 seconds.

t Outdoor unit : Press the K3 button.

b Remove the batteries from the remote control, insert them again, and then press the

(Power) button on the

remote control.

4-1-2 Setting the indoor unit addresses

Option No. for an indoor unit address: 0AXXXX-1XXXXX-2XXXXX-3XXXXX

Before installing an indoor unit, be sure to set an address for the indoor unit by taking the following steps:

1 Make sure that the power is supplied to the indoor

unit. If the indoor unit is not plugged in, it must

include a power supply.

F1

1(L)

2(M)

F2

V1

V2

F3

F4

Indoor Unit

2 Set an address for each indoor unit using the remote control, according to your air conditioning system plan, by

referring to the following table and by following the steps in Common steps for setting the addresses and options on

page <?>.

t The indoor unit addresses (main and RMC addresses) are set to 0A0000-100000-200000-300000 by default.

t If indoor units and outdoor units match 1:1, you don’t need to set the main address because it is automatically set

by the outdoor unit.

t If you are using on or off controller, set RMC address.

Option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

Function Page Mode Setting main address

Reserved Reserved

Indoor unit

number

Indication

and details

Indication Details Indication Details Indication Details Indication Details

0A

0

No main

address

0 to 9

Units

digit

1

Main address

setting mode

Option SEG7 SEG8 SEG9 SEG10 SEG11 SEG12

Function Page

Reserved

Setting RMC address

Reserved

Group channel

(x16)

Group address

Indication

and details

Indication Details Indication Details Indication Details Indication Details

1

0

No RMC

address

RMC1 0 to 2 RMC2 0 to F

1

RMC address

setting mode

Samsung Electronics 4-7

CAUTION

t The main address must be set to a value in the range 0 to 14. If you set other values, communication error will occur.

t If any of SEG5 and SEG6 is set to a value in the range A to F, the main address of the indoor unit does not change.

t If SEG3 is set to 0, the indoor unit maintains the existing main address even if SEG6 is set to a new value.

t If SEG9 is set 0, the indoor unit maintains the existing RMC address even if SEG11 and SET12 are set to new values.

4-1-3 Setting the installation options in a batch

Option No. for an indoor unit address: 02XXXX-1XXXXX-2XXXXX-3XXXXX

1 Make sure that the power is supplied to the

indoor unit. If the indoor unit is not plugged in, it

must include a power supply.

F1

1(L)

2(M)

F2

V1

V2

F3

F4

Indoor Unit

2 Set the installation options of indoor units, by referring to the following table and by following the steps in Common

steps for setting the addresses and options on page <?>.

t The installation options of indoor units are set to 020000-100000-200000-300000 by default.

t The SEG20 option, Individual control with remote control, allows you to control multiple indoor units individually

by using the remote control.

Option

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

Function

Page Mode

Reserved

Use of external

temperature

sensor

Use of central

control

Compensation of the

fan RPM

Indication

and details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

02

0 Disuse 0 Disuse

0

Disuse

(recessed

installation)

1

High-ceiling

mode

(recessed

installation)

1Use1Use

4

Disuse

(exposed

installation)

5

High-ceiling

mode

(exposed

installation)

4-8 Samsung Electronics

Option

SEG7 SEG8 SEG9 SEG10 SEG11 SEG12

Function

Page Use of drain pump

Reserved Reserved Reserved Reserved

Indication

and details

Indication

Details

Indication

Details

1

0

Disuse

1

Use

2

Use with 3

minute delay

Option

SEG13 SEG14 SEG15 SEG16 SEG17 SEG18

Function

Page Use of external control

Setting the

output of

external control

S-Plasma ion Buzzer control

Maximum filter

usage time

Indication

and details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

2

0

Disuse

Slave

(disable

Level

control*)

0

Thermo

on

0

Disuse

0

Use of

buzzer

2

1000

hours

1

On/Off

control

2

Off

control

3

Window

on/off

control

4

Disuse

Master

(enable

Level

control*)

1

Operation

on

1

Use

1

Disuse

of

buzzer

6

2000

hours

5

On/Off

control

6

Off

control

7

Window

on/off

control

Option

SEG19 SEG20 SEG21 SEG22 SEG23 SEG24

Function

Page

Individual control with

remote control

Heating setting

compensation

Reserved Reserved

Cycle time of

Swing

Indication

and details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

3

0 or 1

Indoor 1

0

Default

0

34

seconds

(default)

2

Indoor 2

1 2°C 1

30

seconds

3

Indoor 3

2 5°C 2

38

seconds

4

Indoor 4

Samsung Electronics 4-9

t Even if you set the Use of drain pump (SEG8) option to 0, it is automatically set to 2 (the drain pump is used with 3 minute delay).

t If you set the Maximum filter usage time (SEG18) option to a value other than 2 and 6, it is automatically set to 2 (1000 hours).

t If you set the Individual control with remote control (SEG20) option to a value other than 0 to 4, it is automatically set to 0

(Indoor 1).

t Default value of Heating setting compensation (SEG21) is 5°C for 360 cassette model.

* Level control: The centralized controller can limit the functions and inputs of connected products with this function

enabled. (Example: Operation mode limit (Cooling only/Heating only/No limitation), Heating

temperature upper limit, Cooling temperature lower limit)

To enable 'Level control' when applying the DPM with the centralized controller, appoint the master (Set

'Use of external control [SEG14] option to 4 or higher).

Example: When installing DPM (1 Outdoor unit with 4 indoor units)

Condition SEG14 Setting

Result

External control Level control Indoor 1 Indoor 2 Indoor 3 Indoor 4

Default Not set (0) Slave (All)

Disuse Use 4 Not set (0) Not set (0) Not set (0)

Master (Indoor 1), Slave

(Indoor 2,3,4)

Use (Indoor 3) Disuse Not set (0) Not set (0) 1~3 Not set (0) Slave (All)

Use (Indoor 4) Use Not set (0) Not set (0) Not set (0) 5~7

Master (Indoor 4), Slave

(Indoor 1,2,3)

4-1-4 Changing the addresses and options individually

When you want to change the value of a specific option, refer to the following table and follow the steps in Common

steps for setting the addresses and options on page <?>.

Option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

Function Page Mode

Option mode to

change

Tens position

of the option

number

Units position

of the option

number

New value

Indication

and details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

Indication

Details

0D

Option

type

0 to F

Tens

position

value

0 to 9

Units

position

value

0 to 9

New

value

0 to F

Example: Changing the Buzzer control (SEG17) option of the installation options to 1 disuse.

Option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

Function Page Mode

Option mode to

change

Tens position

of the option

number

Units position

of the option

number

New value

Indication 0 D 2 1 7 1

4-10 Samsung Electronics

Abnormal condition Error code

LED Display

Error on indoor temperature sensor (Short or Open)

E121

1. Error on Eva-in sensor (Short or Open)

2. Error on Eva-out sensor (Short or Open)

3. Discharge sensor error (Short or Open)

E122

E123

E126

Indoor fan error

E154

1. Error on outdoor temperature sensor (Short or Open)

2. Error on cond sensor

3. Error on discharge sensor

Other outdoor unit sensor error that is not on the above list

E221

E237

E251

1. When there is no communication between the indoor∙outdoor units for

2 minutes

2. Communication error received from the outdoor unit

3. 3 miniute tracking error on outdoor unit

4. Communication error after tracking due to unmatching number of

installed units

5. Error due to repeated communication address

6. Communication address not confirmed

Other outdoor unit communication error that is not on the above list

E101

E102

E202

E201

E108

E109

Self diagnosis error display

1. Error due to opened EEV (2nd detection)

2. Error due to closed EEV (2nd detection)

3. Eva in sensor is detached

4. Eva out sensor is detached

5. Thermal fuse error (Open)

E151

E152

E128

E129

E198

O

1. COND mid sensor is detached

2. Refrigerant leakage (2nd detection)

3. Abnomally high temperature on Cond (2nd detection)

4. Low pressure s/w (2nd detection)

5. Abnomally high temperature on discharged air on outdoor unit

(2nd detection)

6.

Indoor operation stop due to unconfirmed error on outdoor unit

7. Error due to reverse phase detection

8. Comp stop due to freeze detection (6th detection)

9. High pressure sensor is detached

10. Low pressure sensor is detached

11. Outdoor unit copression ration error

12. Outdoor sump down_1 prevetion control

13. Compressor down due to low pressure sensor prevention control_1

14. Simultaneous opening of cooling/heating MCU SOL valve

(1st detection)

15. Simultaneous opening of cooling/heating MCU SOL valve

(2nd detection)

Other outdoor unit self-diagnosis error that is not on the above list

E241

E554

E450

E451

E416

E559

E425

E403

E301

E306

E428

E413

E410

E180

E181

O

EEPROM error

E162

EEPROM option error

E163

OOn Flickering

X

O

X

If an error occurs during the operation, an LED flickers and the operation is stopped except the LED.

X

If you re-operate the air conditioner, it operates normally at first, then detect an error again.

X

If you turn off the air conditioner when the LED is flickering, the LED is also turned off.

X

If you re-operate the air conditioner, it operates normally at first, then detect an error again.

X

When E108 error occurs, change the address and reset the system.Ex.) When address of the indoor unit #1 and #2

are set as 5, address of the indoor unit #1 will become 5 and indoor unit #2 will display E108, A002.

Detection of errors

Samsung Electronics 4-11

4-2 Troubleshooting for outdoor unit

The table below list the self-diagnostic routines. For some of error codes, you must contact an authorized service centre.

If an error occurs during the operation, it is displayed on the outdoor unit PCB LED, both MAIN PCB and INVERTER PCB.

No.

Error Code Meaning

Remarks

1 E108 Error due to duplicated communication address Check on repeated indoor unit main address

2 E121

Error on room temperature sensor of indoor unit (Short or

Open)

Indoor unit Room Thermistor Open/Short

3 E122 Error on EVA IN sensor of indoor unit (Short or Open) Indoor unit EVA_IN Thermistor Open/Short

4 E123 Error on EVA OUT sensor of indoor unit (Short or Open) Indoor unit EVA_OUT Thermistor Open/Short

5 E153 Error on float switch (2nd detection)

Indoor unit Float Switch Open/Short Drain

Pump operation Check

6 E154 Indoor fan error Check on indoor unit indoor Fan operation

7 E198 Error on thermal fuse of indoor unit (Open)

Thermal Fuse Open Check of indoor unit

Terminal Block

8 E201

Communication error between the indoor unit and outdoor

unit (Pre-tracking failure or when the actual number of indoor

units are different from the indoor unit quantity setting on the

outdoor unit)

Error due to communication tracking failure after initial power

is supplied (The error occurs regardless of the number of

units.)

Check indoor quantity setting in outdoor

9 E202

Communication error between indoor unit and outdoor unit

(When there is no response from indoor units after tracking is

completed)

Check electrical connection and setting

between indoor unit and outdoor unit

10 E203

Communication error between the outdoor unit and main

micom (For PF #4 to #6 controllers, error will be determined

from the time when the compressor is turned on.)

Check electrical connection and setting

between indoor unit MAIN PBA - INVERTER PBA

11 E221 Error on outdoor temperature sensor (Short or Open) Check Outdoor sensor Open / Short

12 E231 Error on outdoor COND OUT sensor (Short or Open) Check Cond-Out sensor Open / Short

13 E251

Error on discharge temperature sensor of compressor 1 (Short

or Open)

Check Discharge sensor Open / Short

14 E320 Error on OLP sensor (Short or Open) Check OLP sensor Open / Short

15 E403 Compressor down due to freeze protection control Check Outdoor Cond.

16 E404 System stop due to overload protection control Check Comp. when it starts

17 E416 System stop due to discharge temperature -

18

E422

Blockage detected on high pressure pipe

1. Check if the service valve is open

2. Check for refrigerant leakage (pipe

connections, heat exchanger) and charge

refrigerant if necessary

3. Check if there's any blockage on the

refrigerant cycle (indoor unit/outdoor unit)

4. Check if additional refrigerant has been

added after pipe extension

19

E425

Reverse phase or open phase Check whether 3 phase is reversed or opened.

20

E440

Heating operation restricted at outdoor temperature over

Theat_high value

HEATING

21

E441

Cooling operation restricted at outdoor temperature below

Tcool_low value

COOLING

22

E458

Fan speed error FAN1 ERROR

4-12 Samsung Electronics

No.

Error Code Meaning

Remarks

23

E461

Error due to operation failure of inverter compressor -

24

E462

System stop due to full current control -

25

E463

Over current trip / PFC over current error Check OLP sensor

26

E464

IPM Over Current(O.C) IPM

27

E465

Comp. Over load error -

28

E466

DC-Link voltage under/over error Check AC Power and DC Link Voltage

29

E467

Error due to abnormal rotation of the compressor or

unconnected wire of compressor

Check Comp wire

30

E468

Error on current sensor (Short or Open) Check Outdoor Inverter PBA.

31

E469

Error on DC-Link voltage sensor (Short or Open) -

32

E470

Outdoor unit EEPROM Read/Write error (Option) Check Outdoor EEPROM Data

33

E471

Outdoor unit EEPROM Read/Write error (H/W) Check Outdoor EEPROM PBA

34

E472

AC Line Zero Cross Signal out -

35

E473

Comp Lock error -

36

E474

Error on IPM Heat Sink sensor of inverter 1 (Short or Open) Check Outdoor Inverter PBA.

37

E475

Error on inverter fan 2 FAN2 ERROR

38

E484

PFC Overload (Over current) Error Check Outdoor Inverter PBA.

39

E485

Error on input current sensor of inverter 1 (Short or Open) Check Outdoor EEPROM PBA

40

E500

IPM over heat error on inverter 1 Check Outdoor Inverter PBA.

41 E508

Smart install is not installed -

42

E554

Gas leak detected Check the refrigerant

43

E556

Error due to mismatching capacity of indoor and outdoor unit

Check the indoor and outdoor unit capacity

45

E590

Inverter EEPROM Checksum error -

46

E660

Inverter Boot Code error -

Samsung Electronics 4-13

Indoor unit display

Symptom

In case of open or short circuit of indoor temperature sensor

Failure

Short or leakage of the corresponding sensor

Yes

No

No

In this case, is the resistance

value out of range in the temperature

table on the right?

Yes

Is indoor temperature

sensor disconnected from the

connector in PCB?

Restart the system after replacing the PCB

Restart the system after connecting

to the PCB connector

Indoor temperature sensor

failure (replace)

Remove the indoor temperature sensor

connector from the PCB and measure the

resistance between two terminals

4-3 Troubleshooting by symptoms

4-3-1 Indoor temperature sensor (open/short)

Current

temperature

(°C)

Resistance

(kΩ)

40 5.800

35 6.900

30 8.300

25 10.00

20 12.10

15 14.70

10 18.00

5 22.00

0 28.30

-5 33.90

-10 42.30

<Temperature sensor

resistance value>

4-14 Samsung Electronics

Yes

No

No

In this case, is the resistance

value out of range in the temperature table

on the right?

Yes

Is the indoor heat exchanger

temperature sensor connector disconnected

from the PCB?

Restart the system after replacing the PCB

Restart the system after

connecting the connector to PCB

Failure of the indoor heat

exchanger temperature sensor

(replace)

Remove the indoor heat exchanger

temperature sensor connector from

the PCB and measure the resistance

between two terminals

Indoor unit display

Symptom

Short or open circuit of indoor heat exchanger temperature sensor

Failure

Short or open circuit in the corresponding sensor

4-3-2 Indoor heat exchanger temperature sensor (open/short)

Current

temperature

(°C)

Resistance

(kΩ)

40 5.800

35 6.900

30 8.300

25 10.00

20 12.10

15 14.70

10 18.00

5 22.00

0 28.30

-5 33.90

-10 42.30

<Temperature sensor

resistance value>

Samsung Electronics 4-15

Indoor unit display

Symptom

Indoor unit fan does not run /Runs at excessive high speed and stops

Failure

Check if the motor connector is disconnected/ check the motor fan assembly status

4-3-3 Indoor FAN error

Yes

No

Yes

Is there foreign substance

stuck in the motor fan?

Yes

Is the motor connector

disconnected from the PCB?

Replace the PCB and restart the unit

Connect the connector to

PCB and restart the unit

Remove the foreign substance

and restart the unit

4-16 Samsung Electronics

Indoor unit display

Symptom

Communication error between the indoor and outdoor unit for two minutes

Failure

Communication error between the indoor unit and outdoor unit

4-3-4 Communication error after finishing Tracking

No

Yes

No

Yes

Is there a response from the indoor PCB?

(LED01 (RED) is not ON)

In this case, is the

voltage waveform between the lines square

wave with amplitude over ±0.7V as shown

in the following picture?

+0.7V

-0.7V

Good

Bad

Check the communication cable and

replace the indoor unit PCB

Remove the communication cable

connecting the outdoor unit to indoor unit,

and measure the signal on LINE 2 of the

outdoor unit with a scope

Reconnect the cable connecting

the outdoor unit to the indoor unit

and restart the unit.

If the communication still doesn’t work,

replace the indoor unit PCB.

Check the communication

cable in the outdoor unit PCB

and replace the PCB

LED01

Samsung Electronics 4-17

Indoor unit display

Symptom

The indoor unit floating sensor is open and that state is maintained for more than one minute

Failure

Increase in the drain pan water level due to failure of the indoor unit drain pump,

or float sensor failure

4-3-5 Indoor unit float sensor error

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Remove the floating sensor

connector connected to the indoor unit

PCB and the resistance measured between the

two terminals. Is the resistance ∞?

(open circuit)

Is the water level in the drain pan high?

Does drain pump operate

when compressor operates?

Same error occurs again

No

Drain pump PCB

Is the terminal voltage around

AC 220V?

Is the water level in

drain pan decreasing?

Reset the indoor unit power and

check the operation of the drain pump.

(it vibrates when operating)

Normal operation

Replace the indoor unit PCB

Reassemble the floating sensor

connector and reset the outdoor unit

power. (Indoor unit power reset is

required)

Normal operation

Replace the floating sensor

when it fails and reset the

indoor unit power

Replace the drain pump

Replace the drain pump Replace the indoor unit PCB

Error occurs

t 'MPBUTFOTPSFSSPSJTDMFBSFEPOMZ

when the indoor power is reset

4-18 Samsung Electronics

Restart the unit after replacing the PCB

Indoor unit display

Symptom

EEPROM circuit failure

Failure

EEPROM component failure, EEPROM circuit parts missing/damaged/soldering failure

4-3-6 EEPROM circuit failure

No

Yes

Are the EEPROM circuit

components in good conditions?

(missing components / damage /

soldering failure)

Replace the PCB if the restart fails

Samsung Electronics 4-194-19

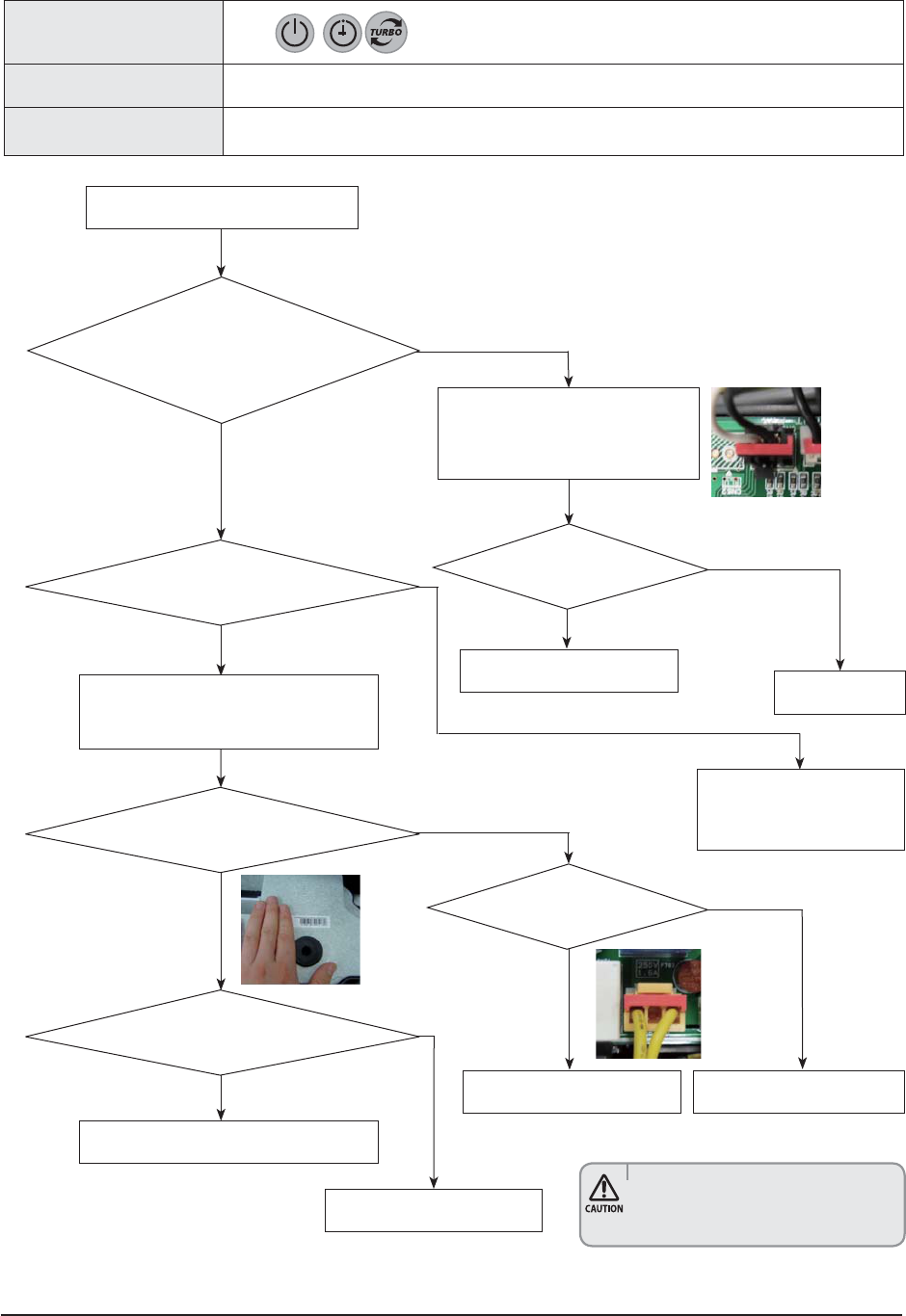

4-3-7 Outdoor unit is not powered on – Initial diagnosis

1. Check items

1) Is the power supply voltage 220V?

2) Is the AC power connected correctly?

3) Are the LEDs in the main PCB and inverter PCB of the outdoor unit ON?

4) Is the input power voltage of the indoor unit 220V?

5) Is the wired remote controller connected correctly?

2. Check procedure

Yes

Turn off the main power switch

(circuit break of power outlet) and turn on

again after 30 seconds.

Check the input power

No

Is the outdoor unit power

supply (L-N) 220V?

Yes

Check the connection of the terminal block

No

Is the outdoor unit power

voltage (L-N) 220V?

Yes

Replace the inverter PBA

No

Is the voltage between

the terminal 2 (~) and 4 (~) of the

bridge diode 220V?

Yes

Replace the fuse

No

Is the fuse connected?

Yes

Replace the inverter PBA

No

Is the resistance value of R001 200Ω?

Cont.

4-20 Samsung Electronics

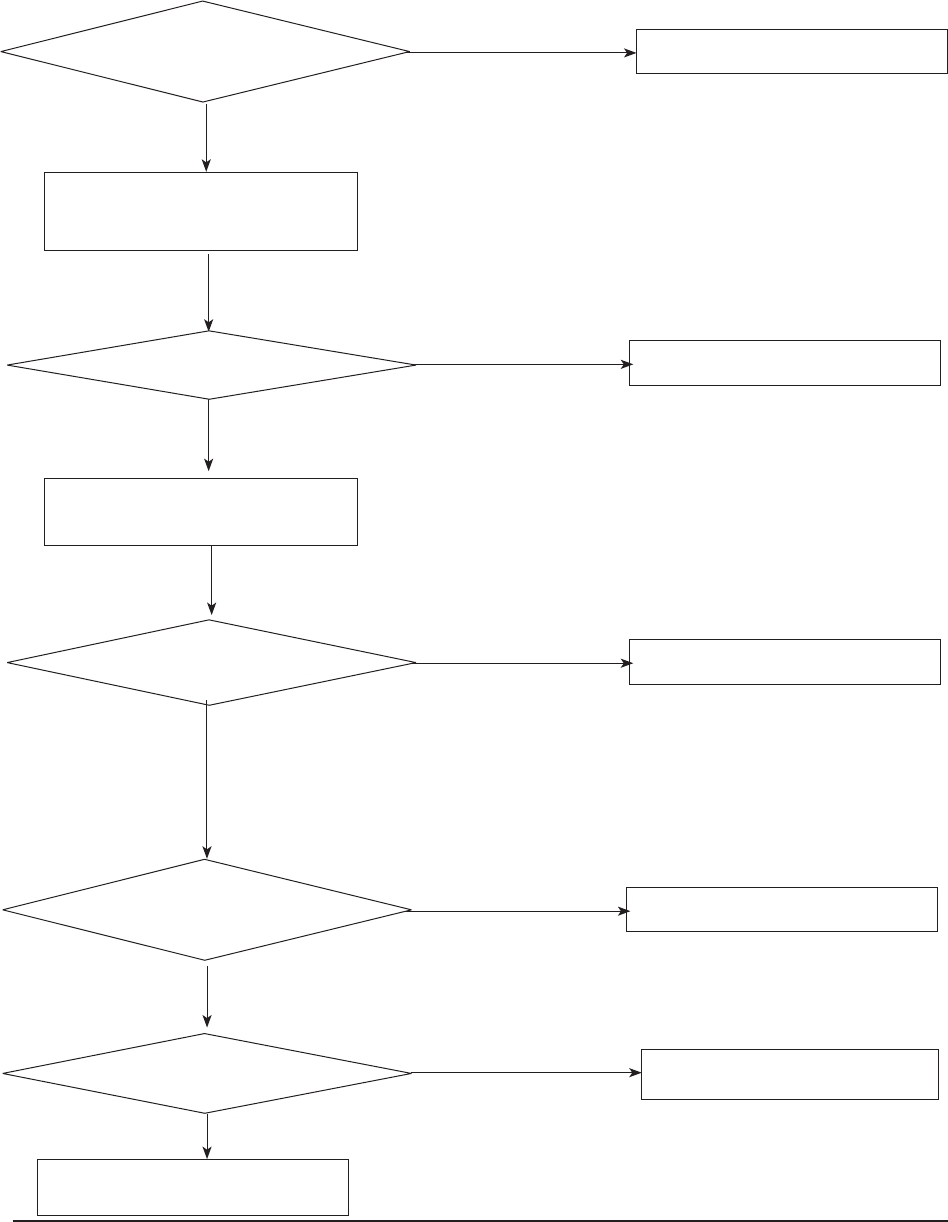

Yes

Outdoor unit is not powered on – Initial diagnosis (cont.)

Yes

Connect the reactor

No

Is the reactor connector

connected correctly?

Replace the PBA.

Cont.

Samsung Electronics 4-21

4-4-1 Communication error

1. 1.Checklist :

1) Is the cable between the indoor unit and outdoor unit connected correctly?

2) Isn't the power cable and communication cable cross?

2. Troubleshooting procedure

Yes

Restart after power off.

Terminate the service

Exchange the indoor unit PBA.

No

Is the communication error occurred again?

Yes

Correct the wrong cable

No

Is the connection of power cable and

communication cable normal?

Yes

Exchange the PBA of no power unit

No

Is the power is normal?

(check the LED Lamp

Yes

Yes

Terminate the service.

No

Is the communication error occurred again?

Exchange the outdoor unit PBA.

4-22 Samsung Electronics

4-4-2 Outdoor temperature sensor error

1. 1.Checklist :

1) Is the cable between the indoor unit and outdoor unit connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #1-#2

10kohm±3% at the room temperature

of 25°C

Is the sensor connector(CN251) connected

correctly in accordance with a color(BLU,6PIN)?

Sensor Replace

Sensor resistance value : 20°C - 12.09kohm

30°C - 8.31kohm

35°C - 6.94kohm

40°C - 5.83kohm

No

No

Exchange the PBA of no power unit

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector (6pin)

supply power and measure the voltage of

#1-#2 in the connector

Exchange the Outdoor PBA

Yes

4-4-2-1. Troubleshooting procedure (PF2)

Samsung Electronics 4-23

4-4-2-2. Troubleshooting procedure (PF3)

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #1-#2

10kohm±3% at the room temperature

of 25°C

Is the sensor connector(CN502) connected

correctly in accordance with a colorRED,4PIN)?

Sensor Replace

Sensor resistance value : 20°C - 12.09kohm

30°C - 8.31kohm

35°C - 6.94kohm

40°C - 5.83kohm

No

No

Exchange the PBA of no Ourdoor PBA

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector (4pin)

supply power and measure the voltage of

#1-#2 in the connector

Exchange the Outdoor PBA

Yes

4-24 Samsung Electronics

4-4-3 Outdoor Coil temperature sensor error

1.Checklist :

1) Is the sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

4-4-3-1. Troubleshooting procedure (PF2)

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #5-#6

10kohm±3% at the room temperature

of 25°C

Is the sensor connector(CN251) connected

correctly in accordance with a color(BLU,6PIN)?

Sensor Replace

Sensor resistance value : 20°C - 12.09kohm

30°C - 8.31kohm

35°C - 6.94kohm

40°C - 5.83kohm

No

No

Exchange the Outdoor PBA

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector (6pin)

supply power and measure the voltage of

#5-#6 in the connector

Exchange the Outdoor PBA

Yes

Samsung Electronics 4-25

4-4-3-2. Troubleshooting procedure (PF3)

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #3-#4

(CN501) 10kohm±3% at the room temperature

of 25 25°C

Is the sensor connector(CN501) connected

correctly in accordance with a colorRED,4PIN)?

Sensor Replace

Sensor resistance value : 20°C - 12.09kohm

30°C - 8.31kohm

35°C - 6.94kohm

40°C - 5.83kohm

No

No

Exchange the Outdoor PBA

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector(4pin)

supply power and measure the voltage of

#3-#4 in the connector

Exchange the Outdoor PBA

Yes

4-26 Samsung Electronics

4-4-4 Outdoor Discharge temperature sensor error

1.Checklist :

1) Is the sensor connected correctly?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull-up correct?

4-4-4-1. Troubleshooting procedure (PF2)

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #3-#4

10kohm±3% at the room temperature

of 25°C

Is the sensor connector(CN251) connected

correctly in accordance with a color(BLU,6PIN)?

Sensor Replace

Sensor resistance value : 20°C - 242kohm

30°C - 166ohm

35°C - 138ohm

40°C - 115kohm

No

No

Exchange the Outdoor PBA

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector (6pin)

supply power and measure the voltage of

#3-#4 in the connector

Exchange the Outdoor PBA

Yes

Samsung Electronics 4-27

Sensor Replace

Sensor resistance value : 20°C - 242kohm

30°C - 166ohm

35°C - 138ohm

40°C - 115kohm

4-4-4-2. Troubleshooting procedure (PF3)

Yes

Reconnect the sensor connector.

Micom error or connector check

No

Is the sensor resistance value #3-#4

(CN501) 10kohm±3% at the room temperature

of 25 25°C

Is the sensor connector(CN502) connected

correctly in accordance with a colorRED,4PIN)?

No

No

Exchange the Outdoor PBA

Yes

Below 0.5V or Over 4.5V?

Yes

Connect the sensor to PBA connector(4pin)

supply power and measure the voltage of

#3-#4 in the connector

Exchange the Outdoor PBA

Yes

4-28 Samsung Electronics

4-4-5 Outdoor Discharge over temperature error

1.Checklist :

1) Check the discharge temperature in the outdoor unit

2) Check the compressor locking or gas leak

3) 3) Download the EEPROM data

2. Troubleshooting procedure

Yes

Yes

Terminate the service

Exchange the Outdoor PBA

Download the EEPROM data

No

Is the discharge over temperature sensor error

appeared again?

Terminate the service

No

No

Terminate the service

Is the discharge over temperature sensor error

appeared again?

Is the discharge over temperature sensor error

appeared again?

The condition is too poor for air conditioner to

operate

Wait until discharge temperature is decreased

Exchanged the Compressor

Restart after power off.

Yes

after 30min ~ 1Hr

Samsung Electronics 4-29

4-4-6 Outdoor Fan motor error

1.Checklist :

1) Are the input power voltage and the power connection correct?

2) Is the motor wire connected to the outdoor PBA correctly?

3) Is there no assembly error or none-assembly in the terminal of motor wire connector?

4) Is there no obstacle at the surrounding of motor and propeller?

2. Troubleshooting procedure

Yes

Yes

Power off and Separate the Fan motor wire

from CN901 on Outdoor PBA

PBA problem or Motor problem

Change the PBA first and check the operation

No

Yes

Does the fan rotate?

Terminate the service

Exchange the Fan motor

No

No

No

Follow the check procedure of outdoor unit

power supply error check

Exchange the Outdoor PBA

Is the fan error appeared again?

Is there short among each pin #1~#6

Is the voltage of CN901 #3-#5 and #3-#6 with in

1Vdc~15Vdc during the operation?

Is the voltage of CN901 #1-#3 over 250Vdc

Reassemble the fan wire and input the power

again

Exchange the Fan motor

Restart after power off.

Yes

No

4-30 Samsung Electronics

4-4-7 Compressor starting error

1.Checklist :

1) Is the connection of cable for the compressor?

2) Is the compressor wire is connected clockwise? U(RED)-V(BLU)-W(YEL)

3) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Terminate the service

Download the EEPROM data

No

Is the restart error occurred again?

Is the connection of compressor wire is

normal?

Connect the comp wire normally

No

No

No

Yes

Terminate the service

Exchange the Outdoor PBA

Is the restart error occurred again?

Is the compressor body and interphase

resistance insulated?

Exchanged the Compressor

Restart after power off.

Yes

Yes

Yes

Samsung Electronics 4-31