To appear in Proc. IEEE Symposium on Security and Privacy, May 2009. For updates, visit http://citp.princeton.edu/paper/.

Fingerprinting Blank Paper Using Commodity Scanners

William Clarkson

∗

, Tim Weyrich

∗,†

, Adam Finkelstein

∗

, Nadia Heninger

∗

,

J. Alex Halderman

‡

and Edward W. Felten

∗

∗

Department of Computer Science

Princeton University

{wclarkso, af, nadiah, felten}

@cs.princeton.edu

†

Department of Computer Science

University College London

‡

Department of Electrical Engineering

and Computer Science

The University of Michigan

Abstract

This paper presents a novel technique for authenticating

physical documents based on random, naturally occurring

imperfections in paper texture. We introduce a new method

for measuring the three-dimensional surface of a page

using only a commodity scanner and without modifying

the document in any way. From this physical feature, we

generate a concise fingerprint that uniquely identifies the

document. Our technique is secure against counterfeiting

and robust to harsh handling; it can be used even before

any content is printed on a page. It has a wide range of

applications, including detecting forged currency and tickets,

authenticating passports, and halting counterfeit goods.

Document identification could also be applied maliciously to

de-anonymize printed surveys and to compromise the secrecy

of paper ballots.

1. Introduction and Roadmap

Viewed up close, the surface of a sheet of paper is not

perfectly flat but is a tangled mat of wood fibers with a

rich three-dimensional texture that is highly random and

difficult to reproduce. In this study, we introduce a new

method for identifying a physical document—and verifying

its authenticity—by measuring this unique natural structure.

We show that paper texture can be estimated using only

a flatbed scanner coupled with appropriate software, and

that this feature is robust against rough treatment—such as

printing or scribbling on the document or soaking it in water—

and adversarial counterfeiting. Under normal conditions, our

technique can identify documents with near-perfect accuracy

and a negligible false positive rate.

It has long been known how to authenticate the content

printed on a page by using cryptographic methods such as

digital signatures. We address a different problem: how to

authenticate the paper itself. For some kinds of documents,

such as currency and tickets, it matters not only that the

content is unaltered but also that the document is a genuine

original rather than a copy or forgery. Physical document

authentication has many applications, which we discuss

✹

paper

surface

light

sensor

normal

down

to glass

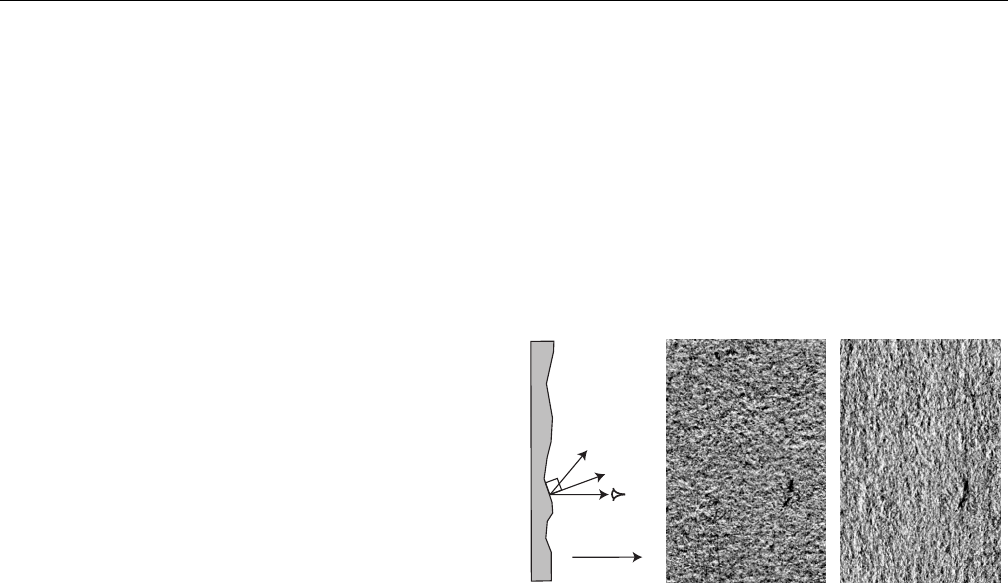

(a) (b) (c)

Figure 1. Since the surface of a sheet of paper is not

perfectly flat, a scanner will produce a different image

depending on the orientation of the page. The light

reaching the sensor depends on the relative angles of

the light source and surface normal, (a). A 10 mm tall

region of a document scanned from top to bottom, (b),

appears different from the same region scanned from left

to right, (c). By combining (b) and (c) we can estimate

the 3-D texture.

in Sections 7 and 8. Some of these applications may be

harmful; for example, our method allows re-identification of

supposedly anonymous surveys and paper ballots.

In contrast with previous efforts, our technique measures

paper’s 3-D texture, requires no exotic equipment, produces

a concise document fingerprint, does not require modifying

the document, and may be applied to blank paper before

content is printed. Previous systems lack one or more of these

properties. For example, Laser Surface Authentication [1]

requires a costly laser microscope to image paper texture,

while the technique proposed by Zhu et al. [2], which focuses

on ink splatter caused by randomness in the printing process,

requires the paper to be printed with known content prior to

fingerprinting. We discuss these and other related work in

Section 2.

The physical document authentication technique we pro-

pose is a three-stage process culminating in a robust and

secure fingerprint. In the first stage, we scan the original

document and estimate its surface texture. Scanners normally

measure only the color of a document, but by scanning the

paper several times at different orientations, we can estimate

the shape of the surface (see Figure 1). In the second stage,

we condense the surface texture into a concise feature vector,

which robustly identifies the page. The third and final stage

uses a secure sketch to generate a fingerprint that reveals little

information about the feature vector. The fingerprint can be

printed on the document (e.g., as a 2-D bar code) or stored

in a database. The verification procedure is similar to the

fingerprinting process, with a different final stage that verifies

that the generated feature vector is correct. We describe each

of these stages in detail in Section 3.

We designed our technique to satisfy several security and

usability goals:

• Uniqueness

Every document should be identifiable

and distinguishable from all others.

• Consistency

A fingerprint should be verifiable by

multiple parties over the lifetime of the document.

• Conciseness

Document fingerprints should be short

and easily computable.

• Robustness

It should be possible to verify a finger-

printed document even if it has been subjected to harsh

treatment.

• Resistance to Forgery

It should be very difficult or

costly for an adversary to forge a document by coercing

a second document to express the same fingerprint as

an original.

Sections 4–6 evaluate our system in terms of these goals.

The most recent version of this paper can be found on our

web site, http://citp.princeton.edu/paper/.

2. Related Work

The Fiberfingerprint system of Metois et al. first introduced

the notion of using surface texture to uniquely identify a

document [3]. Employing a custom device, Fiberfingerprint

measures “inhomogeneities in the substrate” of a document,

from which a unique identifier is derived. The system employs

alignment marks that are added to the document in order

to orient the verification system, and requires a specialized

hardware device rather than a commodity scanner.

Laser Surface Authentication is a technique that measures

the texture of a page using a high-powered laser micro-

scope [1]. Creating and verifying fingerprints in their system

requires access to this specialized device, which may be

prohibitively expensive for many users. Their system also

requires that the verifier be online, which may rule out

applications such as third-party ticket verification.

A recent patent application by Cowburn and Buchanan de-

scribes using a commodity scanner to identify documents [4].

This method does not measure the normal vector field of a

document, but rather uses scans from multiple orientations

in order to extract other additional information. The feature

vector used by Cowburn and Buchanan is not concise, and

their fingerprint is not secure. An adversary with access to

the fingerprint is able to easily discover the surface texture

of the document, possibly making forgery less difficult.

Zhu et al. focus on identifying “non-repeatable randomness

existing in the printing process” [2]. They generate a

fingerprint from the random ink splatter that occurs around

the edges of any features printed on a page. Unlike our

scheme, their method can only be applied after a document

has been printed. Furthermore, their implementation requires

modifying the original document by printing a known target

pattern.

Our method is an improvement over previous work because

we measure the surface texture of a document without the

requirement of expensive equipment. We utilize the unique

fiber structure as identified and relied upon by Metois et al.,

Cowburn and Buchanan, and Zhu et al. but do so without

modifying the document in any way. Our method allows

documents to be fingerprinted before or after content is

printed. In fact, fingerprinting and tracking using our system

can begin during the paper manufacturing process. We have

also developed methods for hiding the target feature vector

through the use of a secure sketch. This means a potential

counterfeiter cannot learn what features he needs to reproduce

from the fingerprint alone but would need access to the

original document to even attempt a forgery.

3. Fingerprinting Process

Our fingerprinting process allows for registration and

validation of a sheet of paper without the participation of a

central registration authority. Depending on the application, a

document’s fingerprint can be stored in a database for future

verification, or it can be printed on the document along with

a digital signature, creating a self-verifying original. The

fingerprint can be used to ascertain whether two documents

share the same feature vector without revealing the registered

feature vector itself.

The registration and validation processes are quite similar,

as shown in Figure 2. In the registration process, we scan a

document, estimate its three-dimensional surface texture, and

generate a feature vector

V

that represents the document’s

unique texture. We consider two documents to be the same

if they have similar feature vectors. To protect the feature

vector and inhibit forgeries that might seek to reproduce

an exact feature vector, the fingerprint contains only a one-

way hash

H(V)

of the extracted feature vector. To achieve

robustness against measurement errors in the feature vector,

the registration process derives error-correction information

from

V

and stores it in the fingerprint in the form of a

secure sketch. The fingerprint also contains a random seed

to initialize the pseudorandom number generator used to

compute the feature vector, as described in Section 3.2.

2

Random Seed

Fingerprint

Registration

Validation

Scan Document

Estimate

Surface Texture

Determine

Feature Vector

Compute Error

Correction Bits

Apply Hash

Function

Scan Document

Estimate

Surface Texture

Determine

Feature Vector

Apply Error

Correction

Apply Hash

Function

Error Correction Bits Hash Value

?

=

Figure 2. Registration and validation pipelines. Registration: Our method creates a fingerprint that consists of a hash

value, error correction information, and a random seed. Validation: A document is authenticated if a newly computed

hash value is identical to the one stored in the fingerprint. The stored error correction information is used to correct

potentially faulty bits in the feature vector.

The validation process has no access to the original

feature vector. Validating a document requires determining

a document’s feature vector anew, using the seed stored in

the fingerprint. Validation assumes a potentially flawed raw

feature vector

e

V

0

and uses the secure sketch to obtain an

error corrected

e

V

, as described in Section 3.3. The candidate

document is considered valid if this feature vector maps to

the same hash value stored in the fingerprint—that is, if

H(

e

V) = H(V)

. The remainder of this section discusses the

registration and validation pipeline in detail.

3.1. Estimating document surface texture

To capture the surface texture of a document, we scan it

at four orientations: 0

◦

, 90

◦

, 180

◦

, and 270

◦

. This allows

recovery of the surface orientation for every sampled surface

point. Our procedure assumes that paper is perfectly diffuse,

which is an assumption that largely holds for near-orthogonal

observation. Diffuse materials reflect a portion of the incident

light that is proportional to the cosine of the angle between

the direction of incidence and the surface normal—that is,

proportional to the dot product of these normalized directions.

This property is commonly exploited in photometric stereo

to reconstruct surface normals from multiple images under

varying illumination by a point light source [5]. Similarly,

we apply photometric stereo to the four captured scans.

Flatbed scanners, however, contain a linear light source,

rather than a point source, which disallows the application

of traditional photometric stereo. Brown et al. recently

demonstrated how normals can be derived from flatbed scans

under multiple orientations [6]. Their method, however, relies

on an extensive calibration procedure, which would make

it impractical for authentication purposes. Instead, we will

Figure 3. Difference image between two 1200 DPI scans

showing the surface texture measured by the scanner in

the y direction. Actual size: “sum”.

derive a novel photometric stereo solution for flatbed scanners,

which provides us with information on surface orientation

without the need for dedicated calibration.

Let us define a coordinate system for the paper and the

scanner so that the paper lies in the

xy

-plane, the

z

-axis points

away from the flatbed of the scanner, and the scanner’s linear

light source is parallel to the

x

-axis. We approximate this light

source by a line segment extending from

x

1

to

x

2

. We further

assume that the light source is offset with respect to the line

on the paper imaged by the CCD sensor (see Figure 1(a))

by o

y

in the y-direction and by o

z

in the z-direction.

Each point on the paper has a normal

n

and a diffuse color,

or albedo,

ρ

. Without loss of generality, we concentrate on

a surface point at the origin of our coordinate system. The

observed intensity of such a surface point is then:

I = ρ

Z

x

2

x

1

D

n,

(x,o

y

,o

z

)

>

k(x,o

y

,o

z

)

>

k

3

E

dx , (1)

which is the integral over all light diffusely reflected off that

surface point and originating from points

(x,o

y

,o

z

)

>

along

3

the linear light source. As every flatbed scanner is designed

for even illumination, any limiting effects near ends of the

light source are negligible and we shall ignore the integral

limits in the remainder of this discussion.

Scanning the same surface point a second time with the

paper rotated by

180

◦

displaces the light source from

o

y

to

−o

y

. Subtracting the resulting two scans

I

0

◦

and

I

180

◦

from

each other leads to:

d

y

= I

0

◦

− I

180

◦

= ρ

Z

D

n,

(x,o

y

,o

z

)

>

k(x,o

y

,o

z

)

>

k

3

−

(x,−o

y

,o

z

)

>

k(x,−o

y

,o

z

)

>

k

3

E

dx

= ρ

Z

D

n,

(0,2o

y

,0)

>

k(x,o

y

,o

z

)

>

k

3

E

dx

= n

y

ρ

Z

2o

y

k(x,o

y

,o

z

)

>

k

3

dx

= n

y

ρs . (2)

That is, the difference

d

y

directly yields the

y

component

n

y

of the surface normal

n

, multiplied by the albedo

ρ

and a

fixed constant

s

that is dependent on the scanner geometry

only. Analogously,

d

x

= I

270

◦

− I

90

◦

= n

x

ρs

. With four scans

we can determine each surface normal’s projection into to

xy

-plane,

n

2

= (n

x

,n

y

)

, up to a scale. The factor

s

is assumed

to be fairly constant across the page, and the remaining scale

is given by the local surface reflectance

ρ

of the paper at

any given location.

Application of equation

(2)

requires precise alignment of

each surface point across all scans. To reduce the effect

of alignment imprecision and to isolate frequencies of the

document that are stable across scans and different scanners,

we apply a low-pass filter to the document and down-sample

it. In our experiments we scanned each document at 1200

SPI (samples per inch) and down-sampled it by a factor of

eight, resulting in an effective resolution of 150 SPI.

After processing the four scans of a document, we recover

the surface texture as a two-dimensional vector field with

d =

(d

x

,d

y

)

>

= ρsn

2

defined at each location of the document.

3.2. Computing the feature vector

From this vector field

d

we determine the feature vector

of the document. A good feature vector captures unique

characteristics of a document, while at the same time being

concise. We model the feature vector

V

as an

N

-bit vector

of independent bits

f

i

whose values are derived from the

surface normals of the document.

In contrast to previous approaches, we do not extract a

feature vector from a single region of the document, but we

compute the feature vector from a collection of representative

subsections, patches, of the document. For documents down-

sampled to 150 SPI, we choose square patches of

8×8

samples, centered at a series of random locations

p

i

. For even

spacing we draw these locations from a Voronoi distribution

[7]: we use the random seed stored in the fingerprint to

initialize

P

pseudorandom start locations on the page and

use Lloyd’s Voronoi relaxation to obtain a set of locations

distributed evenly across the document, as shown in Figure 4.

In principle one could now directly compare the patches

of a document

A

to corresponding patches in a document

B

in order to verify two documents as being the same. The

disadvantages are that this requires access to the patches of

B

when verifying

A

, which would require an amount of storage

prohibitive for offline applications, and, more importantly,

that it would reveal the original document’s structure to a

forger. Hence, we derive a compressed feature vector and

store its hash along with a secure sketch to hide the feature

vector from an adversary.

Each patch contains 64 2-D samples

d

i

,

i = 1, . . . ,64

,

which we stack to create a patch vector

p ∈ IR

128

. Each

patch contributes

T

bits to the feature vector. We compute

these feature bits

f

i

,

i = 1, . ..,T

, by subsequently comparing

the patch vector to

T

template vectors

t

i

. The template

vectors are a set of pseudorandomly chosen orthonormal

vectors in

IR

128

generated using the same seed that is used

to determine patch locations: the

t

i

are initialized with vector

components drawn from a N(0, 1) distribution, followed by

Gram-Schmidt orthonormalization. Each template vector can

be interpreted as a template patch of

8×8

2-vectors denoting

surface orientation.

The comparison is performed by correlating the patch

vector

p

and each template vector

t

i

; i.e., by computing

the dot product

hp,t

i

i

. Positive correlation means that

surface orientations in the patch and the template patch

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

100 Locations Drawn from Voronoi Distribution

X-Axis of Unit Square

Y-Axis of Unit Square

Figure 4. Sample Voronoi distribution of 100 points in the

unit square. Voronoi distributions give relatively uniform

coverage of a region, while simultaneously ensuring no

overlap of patches.

4

agree; negative correlation denotes mostly opposing surface

orientations. The respective feature bit is determined by the

sign of the correlation:

f

i

=

1 + sign(

h

p,t

i

i

)

2

. (3)

See Algorithm 1 for further illustration.

V = bool[PT ]

Retrieve surface orientation vectors of document

Extract P patches based on Voronoi distribution

for p = 1 to P do

template = generate new set of T pseudo-

random orthonormal template vectors

for i = 1 to T do

c = h patch[p], template[i] i

f

(p−1)P+i

= TRUE if c > 0

end for

end for

Algorithm 1: Feature vector generation.

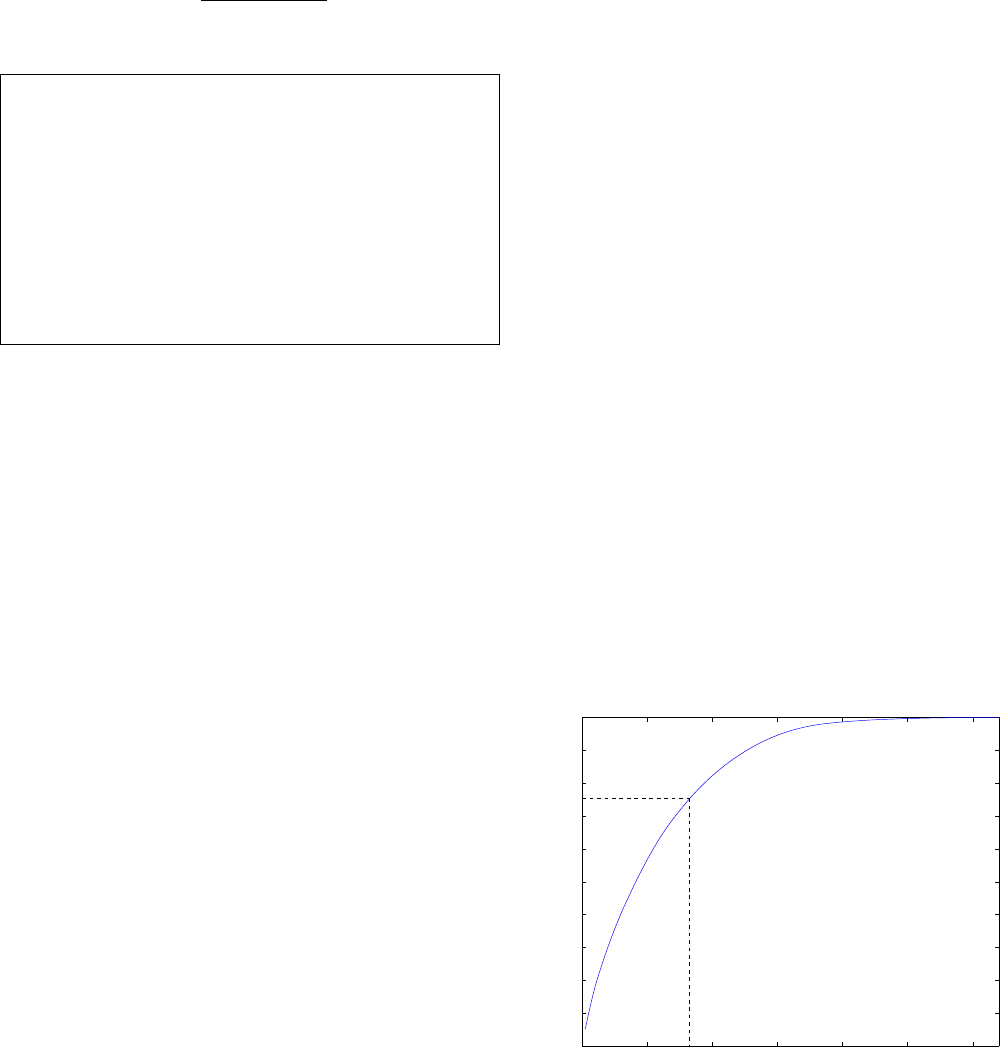

The number of independent bits that can be extracted

from a patch in this way is limited and depends on the

amount of information contained in a patch. A standard

tool to characterize this amount of information is principal

component analysis (PCA) [8]. We performed PCA on a large

set of randomly chosen patches from different documents.

The results show that for

8×8

-patches 75% of the information

can be expressed with only 32 principal components; that

is, within a 32-dimensional subspace. We hence decided to

restrict ourselves to

T = 32

of 128 possible orthonormal

template vectors, as additional template vectors are likely

to produce increasingly correlated feature bits. We further

choose 100 patches,

P = 100

, leading to a feature vector of

3,200 bits for each document.

3.3. Creating the document fingerprint

From the feature vector we can create a document

fingerprint that can be used to authenticate the document

without revealing information about the document. The

fingerprinting method should be both concise and robust to

errors. This situation is similar to that of biometrics, where a

user provides a value

e

V

which is close to, but not identical

to the registered value

V

(e.g., the Hamming distance is

relatively small). Additionally, providing an adversary with

the full feature vector may not be desirable, as it provides a

blueprint for potential forgery.

A document fingerprint consists of a hash of the feature

vector

H(V)

, where

H

is a collision-resistant cryptographic

hash function, along with a secure sketch

ss(V)

following

the ideas of Dodis et al. [9] and Juels and Wattenberg [10].

The secure sketch allows the system to correct any errors that

may occur in the candidate

e

V, assuming

e

V is close enough

to

V

, without revealing

V

to an adversary who does not have

any information about V.

Suppose the registered value for a document is an

N

-bit

value

V

, and we wish to accept any

e

V

within Hamming

distance

δ N

of

V

. The secure sketch proposed by Juels and

Wattenberg chooses a random codeword

x

from an error-

correcting code of length

N

that can correct

δ N

errors, and

stores

ss(V) = V ⊕ x

. To recover

V

from a candidate

e

V

, the

system calculates

ˆx = ss(V) ⊕

e

V

, corrects

ˆx

to the nearest

codeword, and verifies that

H(V) = H(x ⊕ ss(V))

. If

V

and

e

V

have Hamming distance less than

δ N

, the system correctly

outputs V.

Dodis et al. [9] show that the number of bits of information

about the fingerprint revealed by the secure sketch is

N − k

,

where

k = log K

is the dimension of the error-correcting code

used in the secure sketch when it has

K

codewords. Thus, in

order to maximize the security of the system for a fixed

N

,

the error-correcting code should have as high a dimension

k

as possible.

Low-Density Parity Check (LDPC) codes, along with turbo

codes, are among the strongest error-correcting codes in use,

thanks to efficient decoding algorithms developed in the last

two decades. In our implementation, we used the LDPC

library written by Neal [11]. LDPC codes are well-suited

to this application because they work well on large block

sizes and in practice can often correctly decode beyond

the minimum distance of the code [12]. In addition, the

LDPC decoding algorithm can take into account a confidence

level specified for each individual bit to further improve the

performance of the code. In our case, this confidence level

can be calculated from the magnitude of the dot product of

0 20 40 60 80 100 120

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

Cumulative Energy of Eigenvalues of Template Basis Functions

Number of Templete Vectors

% Information Accounted For

Figure 5. Principal component analysis of a large num-

ber of 8

×

8-patches shows that 75% of the information

has been extracted after 32 components.

5

10 15 20 25 30 35

0

10

20

30

40

50

60

70

80

90

100

% Error in Fingerprint

% Successful Decoding of Fingerprint

% Error in Fingerprint vs. % Successful Decoding

1000

800

500

400

300

200

Figure 6. Fraction of fingerprints successfully decoded

for varying fingerprint error rates using LDPC codes of

different dimensions k.

the template vector with the patch vector. The correspondence

between the two is graphed in Figure 7.

The length of our feature vector is

N = 3200

bits. We

experimented with codes of suitable dimension to correct bit

error rates between

δ = 10%

, allowing correct identification

of all types of paper we experimented with under ideal

conditions (see Figure 8), and

δ = 30%

, suitable to identify

documents under less-ideal conditions such as soaking and

scribbling (see Figure 9). For the case of decoding under

ideal conditions, a code of dimension

k = 1000

and

N = 3200

is sufficient to correctly verify all test documents, with no

false positives. For the case of decoding under less ideal

conditions, a code of dimension

k = 300

and

N = 3200

sufficed to correctly verify 95% of all test documents, with

no false positives. See Figure 6 for a summary of these

results.

The feature vector length can be adjusted to suit the needs

of the application (and the expected document treatment

conditions) by increasing or reducing the number of patches.

Longer feature vectors provide a higher level of accuracy

when distinguishing two documents, especially under harsh

treatment, but require increased storage. We chose

N = 3200

bits as our feature vector length to ensure that it would fit

in a 2-D barcode.

4. Robustness

Section 3 describes a process for registration and validation

of a document fingerprint. In this section we evaluate docu-

ment fingerprints across different types of paper, including

normal copy paper (Boise Aspen 50), university letterhead

with a visible watermark, and index cards. We also evaluate

Figure 7. Correspondence between dot product magni-

tude and error probability during validation. (Fit to normal

distribution with µ=0 and σ =0.1314.)

the fragility of a document fingerprint under various treatment

conditions. Our goal is to test whether our technique typically

validates different observations of the same document (true

positives) and rejects pairs of observations of different

documents (true negatives), while rarely validating pairs

of observations of different documents (false positives) or

rejecting different observations of the same document (false

negatives).

Our experiments show that a fingerprint can be found for

a variety of different types of paper. Unless otherwise noted,

each experiment began with a document scanned at 1200

DPI on an Epson Perfection v700 scanner. Each test focused

on a 3×3 inch square in the center of the page.

1

For each test, we captured five observations of a set of five

documents, for a total of 25 observations. Each observation

consisted of four scans taken at

0

◦

,

90

◦

,

180

◦

, and

270

◦

that we used to estimate surface normals. We expect no two

scans of the same document to be exactly alike due to slight

variations in placement on the scanner, random noise, and

other uncontrollable variables in the process.

The amount of error tolerated in a matching fingerprint can

be adjusted by choosing an appropriate error-correcting code

during the fingerprinting process described in Section 3. The

number of bits that can be corrected by the code should be

determined by the needs of the application, as it establishes

1.

In our robustness experiments, we used a printed box on the test pages

to identify the region to be fingerprinted and to align the different scans.

However, alignment could be accomplished by other means, such as by

relying on the boundaries of the page or other printed material, or by simply

recording a few patches at high resolution [13]. Different sets of patches

should be used for alignment and verification, because using the same

patches could increase the false positive rate.

6

a tradeoff between the security of the system and the relative

likelihood (or harm) of a false positive or false negative.

4.1. Ideal handling conditions

As a baseline test, we measured the frequency of correct

and incorrect validation and rejection under ideal handling

conditions, when we expect no document degradation.

We began with 25 observations (5 from each of 5 docu-

ments). We chose 40 random seeds and sampled a fingerprint

from each observation for each seed, following the process

described in Section 3. We made

25

2

= 300

comparisons

for each seed, yielding a total of 12, 000 comparisons.

For each comparison, we computed the Hamming distance

between the two fingerprints. These distances are summarized

for the 12,000 comparisons by the histogram shown in the

top graph in Figure 8. Under non-adversarial conditions,

document fingerprints of normal copy paper differ, on average,

in only 99 (3.1%) of the 3200 bits. In contrast, as one would

expect, the average Hamming distance for fingerprints made

from observations of different documents is 50% of the

bits. These distributions are well-separated; the maximum

Hamming distance between feature vectors from the same

document is 177, while the minimum distance between

feature vectors of different documents is 1490. An error

tolerance anywhere in this range should give no false positives

and no false negatives for these tests. We found similar results

for index cards and university letterhead; see Figure 8.

The distributions for the “same” fingerprint comparison

tests and “different” fingerprint comparison tests seem to be

reasonably approximated by a normal distribution. Fitting

Gaussian curves to this data, we can find a summary statistic,

Egan’s sensitivity index for Gaussian distributions of signal

and noise with unequal variances, given by:

d

s

= 2(µ

2

− µ

1

)/(σ

1

+ σ

2

) (4)

where

µ

1

,

µ

2

,

σ

1

and

σ

2

are the means and standard

deviations of the distributions [14]. For this experiment,

d

s

= 52.0

. To give some intuition about the significance

of this statistic, the two Gaussians intersect at a Hamming

distance of

731

bits; the heights of the curves are such that

the chance of a single comparison resulting in either a false

positive or false negative is 1 in

10

148

. If we reduce the

feature vector length from

N = 3200

bits to

1600

,

800

, or

400

bits, the probability of such errors is 1 in

10

96

, 1 in

10

57

,

or 1 in 10

35

, respectively.

We repeated these experiments on different scanner models

and found similar results. When comparing a document

fingerprinted on one model and verified on another, results

are slightly worse.

2

2.

We chose several of the parameters of our algorithm (e.g., the

downsample factor and size of the patches) based on preliminary experiments

using the Epson v700 scanner. The optimal settings for verification of

documents using other scanner models may vary.

4.2. Non-ideal handling conditions

The previous experiments were performed under ideal han-

dling conditions. We performed additional tests to ascertain

the robustness of fingerprints when the document is subjected

to less-than-ideal conditions. These tests included scribbling

on the paper, printing on it with ink, and soaking the page

in water.

Scribbling.

We first scanned a set of five blank documents,

then scanned them again after scribbling over them with a

pen. In each document the scribble was unique, covering an

average of 8% of the test region. In this test, 25 pre-scribble

observations were compared against their 25 post-scribble

counterparts, for a total of 625 pairs. We used 40 different

fingerprint samples per document to yield a total of 25,000

comparisons. The Hamming distances resulting from these

comparisons are plotted in the top graph in Figure 9. The

sensitivity index in this case is lower (

d

s

= 28.8

), although the

curves remain quite well-separated. With a decision threshold

of 1130 bit errors in the fingerprint, the chance of a false

positive or false negative is 1 in 10

47

.

Printing.

In this experiment we printed single-spaced text

in 12 pt. Times New Roman lettering over the test region,

covering approximately 13% of the area with ink. The

distributions shown in the middle graph of Figure 9 were

obtained as in the scribble test. Even in this experiment, in

which most patches used for the fingerprint were partially

covered by ink, the sensitivity index is 26.1 and the chance

of a false positive or false negative at the crossover is 1 in

10

38

.

Wetting and drying.

The bottom graph in Figure 9 shows

the resiliency of document fingerprints after the document

was submerged in water for five minutes. We dried each test

document and ironed it until it was as flat as possible. Using

the same evaluation protocol as for the scribble and printing

tests, we found that documents could still be validated with

100% reliability, even with this fairly extreme mistreatment

of the page (d

s

= 33.3).

These experiments demonstrate that our fingerprinting

method is robust when a document is handled under certain

rough conditions. The ability to identify a document before

and after it is printed on, scribbled on, or soaked in water

has many potential applications.

5. Security

The security of our method relies on the inability of an

attacker to reproduce the document’s surface, either because

he does not know what features to produce or because he

cannot recreate the normal vectors at the required scale. The

threat model of each application is determined by several

7

0 10 20 30 40 50 60 70 80 90 100

0

0.005

0.01

0.015

Histogram of Distances Beteween Fingerprints of Copy Paper

% Hamming distance between document fingerprints (length 3200 bits)

Probability of Hamming Distance

Mean: 99

Std: 24.29

Mean: 1600

Std: 33.42

0 10 20 30 40 50 60 70 80 90 100

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

0.018

Histogram of Distances Between Fingerprints of Index Cards

% Hamming distance between document fingerprints (length 3200 bits)

Probability of Hamming Distance

Mean: 98

Std: 35.45

Mean: 1597

Std: 28.16

0 10 20 30 40 50 60 70 80 90 100

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

Histogram of Distances Between Fingerprints of Letterhead

% Hamming distance between document fingerprints (length 3200 bits)

Probability of Hamming Distance

Mean: 98

Std: 31.93

Mean: 1596

Std: 29.86

Figure 8. Distributions of Hamming distances between

fingerprints for three paper types: copy paper (top), index

cards (middle), and letterhead (bottom). In all graphs,

the curve on the left depicts the distribution for scans of

the same document, while the curve on the right gives

the distribution for different documents.

0 10 20 30 40 50 60 70 80 90 100

0

0.005

0.01

0.015

Histogram of Distances Between Fingerprints: After Scribbling

% Hamming distance between document fingerprints (length 3200 bits)

Probability of Hamming Distance

Mean: 286

Std: 58.75

Mean: 1599

Std: 32.56

0 10 20 30 40 50 60 70 80 90 100

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

Histogram of Distances Between Fingerprints: After Printing

% Hamming distance between document fingerprints (length 3200 bits)

Probability of Hamming Distance

Mean: 562

Std: 49.77

Mean: 1600

Std: 29.84

0 10 20 30 40 50 60 70 80 90 100

0

0.005

0.01

0.015

Probability of Hamming Distance

% Hamming distance between document fingerprints (length 3200 bits)

Mean: 570

Std: 31.36

Mean: 1604

Std: 32.64

Histogram of Distances Between Fingerprints: After Soaking

Figure 9. Distributions of Hamming distances after

subjecting documents to non-ideal treatments: scribbling

(top), printing (middle), and soaking in water (bottom).

The curves remain well separated even under these

adverse conditions.

8

factors: the availability of an original to the attacker, whether

verification is performed online or offline, and whether the

verification device is trusted. Under the most common threat

models, our method should prevent an attacker from forging

a copy of an original.

Performing verification online or offline results in different

considerations. Here “online” means that the verification

device can communicate with a remote trusted server which

can store data and perform computations; “offline” means

that the verification device cannot communicate, although it

can be preprogrammed with a limited amount of information

such as a constant number of cryptographic keys. Online

verification of a document has a straightforward solution,

while offline verification requires security tradeoffs.

5.1. Online verification

Online verification need not reveal in advance the patch

locations that will be analyzed. This forces an attacker to

reproduce the entire surface of a document before presenting

it for verification. In one approach, the verification server

requests complete raw scans of the document at each of four

orientations, which the server uses to perform the verification

algorithm. Under this construction, the verification server

does not reveal the chosen patches.

In an alternative approach, the verification server provides

a fresh pseudorandom challenge to the client, and the client

uses the challenge to seed a pseudorandom generator which is

used to pick the patches and templates used in the verification

algorithm. The client then computes the feature vector and

sends it to the server. The server, having computed the same

feature vector on its stored scans of the original document,

verifies that the two feature vectors are similar enough.

In this threat model an attacker does not know a priori

which patch locations on a document will be sampled. This

forces an attacker to reproduce the surface texture of the

document at each sample point in order to pass a counterfeit

as an original.

5.2. Offline verification

The security of offline verification depends on whether

the verification client is trusted and on the availability of

an original to the attacker. In the offline case, we assume

that the fingerprint of the legitimate original document is

either pre-stored on the client or is printed onto the document

(perhaps as a 2-D barcode) along with the authority’s digital

signature of the fingerprint. In either case, the client device

checks the document against a known fingerprint.

5.2.1. Offline: trusted device.

Currency and ticket coun-

terfeit detection at banks and concerts are two important

examples of offline verification with a trusted device. By

“trusted” we mean that the device outputs a Boolean match/no-

match result but does not leak any other information.

The secret information stored in the device could be the

public key of the registration entity. The seed stored in the

document fingerprint could be encrypted under the secret

key of the registration entity. Therefore, knowledge of the

fingerprint for a document does not reveal the patch locations.

The hash of the feature vector could also be signed by the

registration entity, preferably using a separate key. This allows

only trusted devices to determine patch locations and verify

the authenticity of a document. No access to the registration

entity is required, provided that the device has knowledge of

the decryption and verification keys of the registration entity.

In this threat model the adversary does not know which

patches will be analyzed. This forces the attacker to recreate

the surface normals across the entire document to ensure

verification of the document.

5.2.2. Offline: untrusted device, no access to original.

In

the next case, the verification device is offline and untrusted

(i.e., it might leak everything it knows to the attacker) and

the attacker has not seen the original document that he is

trying to forge. In this case, the attacker cannot forge the

document because he does not know anything useful about

the normal field that he must create. At most, he knows the

fingerprint (if it is stored in the device) but this does not

help him because the fingerprint is a secure sketch.

5.2.3. Offline: untrusted device, access to original.

The

final case is the most challenging one, where the verification

device is offline and untrusted, and the attacker has access to

an original document that he wants to copy. Because there are

no secrets from the attacker—he sees the original document

including anything printed on it, and he knows the full state

of the device—the attacker knows exactly which patches will

be used for verification and how the feature vector will be

computed from those patches. The attacker’s only task is to

make a document that will generate a feature vector close

enough to the original. Whether the attacker can do this is

the subject of the next section.

6. Forging a Document

Suppose an attacker has seen an original document and

wants to create a second document that will pass verification

as the original. The attacker will start with an arbitrary piece

of paper which, by assumption, will have a very different

feature vector from the original. He will then try to modify

the target paper so that its feature vector is close to that

of the original document. To do this, the attacker needs to

make fine-grained modifications to the document’s surface

normals. This might be done via lithography or photographic

techniques, but these will be expensive and will probably

require special equipment. The most effective, economical

9

way to control the surface, we believe, is to print on the

document.

Equation

(2)

shows that the fingerprinted vector (

d

x

,d

y

)

contains additional factors

s

and

ρ

. The scanner-dependent

factor

s

can be assumed to be fairly constant across the page

and hence has no influence on the sign of the correlation

results in the feature vector generation. The remaining scale

is given by the local surface reflectance

ρ

of the paper at a

given location, which should be stable across multiple scans.

On empty paper it is nearly constant; in the presence of

print,

ρ

is greatly attenuated, which lessens the influence of

the printed portion onto the correlation result. The adversary

can try to control bits of the feature vector by printing dark

ink at selected points in order to reduce their influence in

the correlation calculations. Besides reducing ρ, printing at

a point tends to flatten the document surface, as shown in

Figure 3.

An adversary who aims at forging a document might

try to leverage these effects by printing a set of carefully

placed dots, either to cause the surface texture of a candidate

document to express the same fingerprint as an original,

or to down-weight unfavorable contributions to the patch

correlation. To do this the forger must overcome two hurdles:

printing dots on the page at desirable locations and/or printing

dots with favorable surface normal vectors. Dark ink on a

document would directly affect reflectivity, while light ink

might solely change the normal vectors at a specific location.

We assume that the adversary uses commercially available

equipment and is able to print dots in any color from black

to white. He has less control over the exact shape of the

dots, which varies by printing technology and type of paper.

We conducted experiments to characterize the ability of a

forger to precisely control the effect of a printed pattern. We

measured the effective resolution—the number of distinct

printable dots—for a high-end office printer, a Xerox Phaser

8550, with a nominal resolution of 2400x2400 DPI. The

effective resolution is limited by dot gain, which causes

printed dots to become larger than intended (see Figure

10) due to factors such as the viscosity of the ink and the

absorbency of the paper. The smallest dots that the test printer

could produce on a normal piece of copy paper are

1/240

inch, or 20x20 samples when scanned at 4800 SPI. This

limits the effective resolution to 240 DPI. On the other hand,

the positional accuracy of the printer seems closer to the rated

2400 DPI. We conclude that a forger could use commodity

printers to print dots with positional accuracy similar to what

commodity scanners can measure but size much greater than

the scanner’s pixels.

Because printed dots typically span more than one sample

in a patch, printing a dot at a specific location affects the

neighboring surface normal vectors in unpredictable and

uncontrollable ways. Due to paper variations as well as

limited precision in the placement and viscosity of ink, the

forger does not have precise control over the normal vectors

Figure 10. The smallest dots that can be produced by

our test printer are 1/240 inch—20 samples wide in this

4800 SPI scan—despite the printer’s nominal 2400 DPI

positional accuracy.

caused by a dot. We performed an experiment where we

printed a series of black dots in a region of the document.

We identified the black dots and measured the normal vectors

in the surrounding region. For each printed dot, the desired

normal vector of a location occurred on only one point of

the surface.

The bottom-line question is how many degrees of freedom

the adversary has in controllably modifying the normal vector

field in a patch. Given the linear transformation used to

determine each feature vector bit, the adversary will likely

be able to achieve a desired set of feature vector values if

he has enough degrees of freedom.

If there are

N

feature vector bits, and each bit is computed

as the sign of the correlation of the normal field with a

random vector field, then a truly random normal field value

would match all N feature vector bits with probability 2

−N

.

However, it is likely that the feature vector bits are not fully

independent. Although we have some evidence about the

degree of independence (see, e.g., Figure 5), we do not have

a precise estimate of how much entropy is encoded in the

feature vector.

We are thus left with an open question: does the amount

of information in a patch, as encoded in a feature vector,

exceed the adversary’s ability to inject information into the

patch? If we knew the answer to this question, we could

state with some confidence whether an adversary could forge

a document in the most favorable case (for the adversary),

where the adversary sees the original document and the

verification device is offline and untrusted. Unfortunately, we

have to leave this question for future work.

10

7. Applications

There are a large number of applications that could

benefit from the ability to uniquely identify a document.

Many situations where physical possession of an item must

be verified or authentication of an item is required could

fruitfully employ our technique. Currency, ticket, and art

counterfeit detection, as well as verification of product

packaging are some of the applications where physical

document authentication is desirable.

Counterfeit currency detection is one obvious application.

The financial impact of counterfeit currency is large. Esti-

mates of annual global revenue loss range from $250- to

$500 billion [15], [16]. The ability to authenticate bills could

change the way currency is produced and fraud is detected.

Such a system would begin during currency production. The

government would generate a fingerprint for each bill. This

fingerprint could be stored in a database, along with the bill’s

serial number, or the government could digitally sign the

fingerprint and print the fingerprint and signature on the bill.

Any party wishing to verify a particular bill would scan the

bill and verify that the fingerprint matched the one signed

by the government. The authentication of a bill could be

performed offline or online. Businesses and banks accepting

large cash deposits could verify the currency was legitimate

before completing the transaction. Offline authentication

could be performed provided that the verification device

had the public key of the currency issuer.

Ticket forgery at major concerts and sporting events is

another large black-market business. Counterfeit event passes

were widespread at the 2008 Beijing Olympics [17], and

a British website recently sold more than $2.5 million in

fake tickets [18]. The ability for purchasers to verify the

authenticity of tickets prior to purchase could greatly reduce

the prevalence of online ticket fraud. Trust in ticket purchases

on websites such as Stub Hub and eBay could be dramatically

increased if the seller had to prove access to the item being

auctioned or sold. Ticket clearing houses such as Ticketmaster

could maintain an online database of fingerprints for all

purchased tickets. Any party selling a ticket could scan and

upload the ticket to Ticketmaster and receive verification of

authenticity.

Forgery of artwork is a black-market business where the

application of our technique may not be initially obvious.

European police estimate that over half of the works in

international markets are forgeries [19]. One family of art

forgers was able to make $2 million before they were

caught. The ability of art forgers to reproduce the individual

brush strokes of a work makes authenticating paintings

increasingly difficult. In the best forgeries, art verifiers must

sometimes rely on the chain of custody of the work in order

to authenticate it [20]. However, we believe that it would

be difficult to duplicate features of the canvas (down to the

detailed arrangement of the weave) upon which the work is

painted. Thus art authenticity or forgery might be detectable

by applying a technique like ours to the canvas, most probably

on the back side of the painting.

Lottery tickets are similar to currency except that players

need not be aware of a fingerprinting technique at all. In

order for a lottery winner to collect on their winnings, the

ticket must be verified by the lottery authority. The fingerprint

of a winning ticket need not be printed on the document at

all. Fingerprints of all possible winning lottery tickets can

be privately maintained, and any claimants can be required

to produce the actual winning ticket, with correctly verified

fingerprint, in order to collect their winnings.

The accurate identification of paper based product pack-

aging could benefit from this technique as well. When

inspecting cargo, customs officials often inspect the contents

of packages to weed out counterfeit goods. We can increase

confidence in package contents by authenticating a product’s

packaging. If the packaging of a product is legitimate, then

the contents of the package have a much higher likelihood

of being authentic.

8. Privacy Implications

The feasibility of paper-based authentication demonstrates

that some undesirable attacks are possible. Because our

results do not modify the paper in any way, there is no way to

detect, by inspecting a piece of paper, whether its fingerprint

might have been recorded in advance by an adversary. This

fact violates the traditional assumption that pieces of paper

cannot easily be traced without the addition of distinguishing

marks. Even unopened sheaves of blank printer paper might in

principle have been fingerprinted at the factory. Applications

such as paper-based voting, in which the secrecy of individual

ballots is important, are challenged by our results.

For example, consider an optical-scan voting system in

which voters fill out paper ballots. In such a system, the

secrecy of ballots relies on the assumption that individual

paper ballots are indistinguishable. Our work shows that this

assumption may not be valid.

A corrupt official could scan the blank ballots in advance

and record a unique fingerprint for each ballot in the stack.

If ballots are given out to voters in a predictable order (e.g.,

from the top of the stack down) and the order of voters is

recorded, as it is in many polling places, or observable by the

attacker, then ballots can be re-identified after the election.

Even worse, because pre-scanning leaves no evidence on

the ballots themselves, a mere rumor that someone might

have scanned the ballots in advance would be very difficult

to disprove, and such a rumor would make coercion and

vote-buying more credible.

More generally, the ability to re-identify ordinary sheets

of paper casts doubt on any purportedly private information

gathering process that relies on paper forms. “Anonymous”

surveys or reporting systems may not in fact be anonymous.

11

Though it has long been possible to track sheets of

paper using subtle chemical markers or “invisible ink,” these

methods require some level of special expertise, and the

presence of markers leaves evidence of the attack. Our

research shows that an attacker armed with only ordinary

equipment—a commodity scanner—is able to re-identify

paper reliably without leaving any telltale marks.

9. Conclusion and Future Work

Our work shows that ordinary pieces of paper can be

fingerprinted and later identified using commodity desktop

scanners. The technique we developed functions like a

“biometric” for paper and allows original documents to be

securely and reliably distinguished from copies or forgeries.

At least two questions remain to be answered in future

work. First, in the threat model where the adversary has

access to the original document and the fingerprint, we do

not know for certain that a clever adversary cannot forge

a copy of the document with a high-resolution printer. Our

initial work could not determine conclusively whether an

adversary who can use a good printer will have enough

degrees of freedom in modifying a document to make the

document match a known fingerprint. Second, while we

conjecture that our method can be applied to other materials

such as fabric, more testing is needed to verify this, and

special methods might be needed for some materials. We

leave both of these questions for future work.

Our results are a tribute to the resolution of today’s

scanners. Future scanners will capture ever more detailed

images of paper documents, eventually allowing individual

wood fibers to be imaged clearly. The security of our methods

against forgery, in cases where the adversary has full access

to information, will depend ultimately on a race between the

resolution of the printers that can create patterns on a page,

and the resolution of the scanners that can observe patterns.

10. Acknowledgments

We thank Andrew Appel, Victoria Hill, Andrew Moore, N.

J. A. Sloane, Joshua R. Smith, and the anonymous reviewers

for their invaluable suggestions and assistance.

References

[1]

J. D. R. Buchanan, R. P. Cowburn, A.-V. Jausovec, D. Petit,

P. Seem, G. Xiong, D. Atkinson, K. Fenton, D. A. Allwood,

and M. T. Bryan, “Forgery: ‘fingerprinting’ documents and

packaging,” Nature, vol. 436, p. 475, 2005.

[2]

B. Zhu, J. Wu, and M. S. Kankanhalli, “Print signatures for

document authentication,” in Proc. 10th ACM Conference on

Computer and Communications Security, 2003, pp. 145–154.

[3] E. Metois, P. Yarin, N. Salzman, and J. R. Smith, “FiberFin-

gerprint identification,” in Proc. 3rd Workshop on Automatic

Identification, 2002, pp. 147–154.

[4]

R. P. Cowburn and J. D. R. Buchanan, “Verification of

authenticity,” US patent application 2007/0028093, Jul. 2006.

[5]

R. Woodham, “Photometric stereo: A reflectance map tech-

nique for determining surface orientation from image intesity,”

in Proc. 22nd SPIE Annual Technical Symposium, vol. 155,

1978, pp. 136–143.

[6]

B. Brown, C. Toler-Franklin, D. Nehab, M. Burns, A. Vla-

chopoulos, C. Doumas, D. Dobkin, S. Rusinkiewicz, and

T. Weyrich, “A system for high-volume acquisition and

matching of fresco fragments: Reassembling Theran wall

paintings,” ACM Trans. Graphics (Proc. SIGGRAPH 2008),

p. 84 (9 pp.), Aug. 2008.

[7]

A. Okabe, B. Boots, K. Sugihara, and S. N. Chiu, Spatial

Tesselations: Concepts and Applications of Voronoi Diagrams.

Wiley, 2000.

[8]

J. E. Jackson, A User’s Guide to Principal Component Analysis.

Wiley-Interscience, 2003.

[9]

Y. Dodis, R. Ostrovsky, L. Reyzin, and A. Smith, “Fuzzy

extractors: How to generate strong keys from biometrics and

other noisy data,” SIAM Journal on Computing, vol. 38, no. 1,

pp. 97–137, 2008.

[10]

A. Juels and M. Wattenberg, “A fuzzy commitment scheme,” in

Proc. 6th ACM Conference on Computer and Communications

Security, 1999, pp. 28–36.

[11]

R. M. Neal. (2006, Feb.) Software for low density parity

check codes. [Online]. Available: http://www.cs.utoronto.ca/

∼

radford/ldpc.software.html

[12]

D. MacKay and R. Neal, “Near shannon limit performance of

low density parity check codes,” Electronics Letters, vol. 33,

no. 6, pp. 457–458, Mar. 1997.

[13]

C. Sorzano, P. Thevenaz, and M. Unser, “Elastic registration

of biological images using vector-spline regularization,” IEEE

Trans. Biomedical Engineering, vol. 52, no. 4, pp. 652–663,

Apr. 2005.

[14]

D. McNicol, A Primer on Signal Detection Theory. Lawrence

Erlbaum Assoc., 2004.

[15]

L. S. Amine and P. Magnusson, “Cost-benefit models of stake-

holders in the global counterfeiting industry and marketing

response strategies,” Multinational Business Review, vol. 15,

no. 2, pp. 1–23, 2007.

[16]

U.S. Department of Commerce. Top 10 ways to protect

yourself from counterfeiting and piracy. [Online]. Available:

http://www.stopfakes.gov/pdf/Consumer Tips.pdf

[17]

C. Balmer and K. Wills, “Beijing games hit by internet ticket

scam,” Reuters, Aug. 4, 2008.

[18]

“Ticket site closed on fraud fears,” BBC News, Oct. 21, 2008.

12

[19]

J. L. Shreeve, “Art forgers: What lies beneath,” The Indepen-

dent, Sep. 3, 2008.

[20] R. D. Spencer, The Expert versus the Object: Judging Fakes

and False Attributions in the Visual Arts. Oxford University

Press, 2004.

[21]

F. A. P. Petitcolas, R. J. Anderson, and M. G. Kuhn,

“Information hiding—a survey,” Proc. IEEE, vol. 87, no. 7,

pp. 1062–1078, Jul. 1999.

Appendix

Section 3 introduces a process for fingerprinting and

verifying the fingerprint of a document. In this appendix

we briefly outline some alternative strategies that might be

desirable under different criteria for robustness or different

levels of concern about forgery.

Using albedo versus normals.

Because the high-resolution

paper scans shown in figures throughout this paper reveal

obvious color variation in addition to surface texture, perhaps

a more straightforward approach would be to use the albedo

(color) of the page as the basis for a fingerprint, rather than, or

in addition to, the shape. Indeed, our initial implementations

explored this approach, using a single scan (which combines

albedo and normal information) to construct the fingerprint

of a document. This approach is simpler and offers the

substantial benefit that the document can be fingerprinted or

verified more quickly, through a single scan.

The intensities of most of the pixels in a scanned page are

modeled well by a truncated normal distribution, centered

around the “white” color. To use this data as the basis

for a fingerprint, we simply construct the vector

p

as the

concatenation of these intensities from a given patch. For

example, an

8 × 8

patch would yield a vector

p ∈ IR

64

. The

fingerprint is then extracted from a collection of patches as

described in Algorithm 1.

We did not pursue this approach because we believe this

form of fingerprint may not resist forgers who use very

light ink to print a desired pattern on the page. Another

drawback is that any black ink on the page, which lies well

outside the roughly-normal distribution of intensities found in

blank paper, contributes to a very strong negative value in

p

,

introducing a bias in the dot products for the patch. Thus, any

value outside the range of the truncated normal distribution

must be zeroed out before constructing the fingerprint. This

provides another opportunity for a forger to deliberately zero

out regions of the patch with the goal of flipping bits towards

a desired fingerprint. These attacks might be difficult to carry

out in practice, since they require excellent registration in the

printing process. Therefore, albedo-based fingerprints may

be suitable for applications where some added risk of forgery

is an acceptable tradeoff for increased speed and simplicity.

Patch-pair comparisons.

Recall from Algorithm 1 that the

vector

p

contributes

K

bits to the overall fingerprint by taking

the signs of the dot product of

p

and a series of ortho-normal

template vectors. We have also considered (and implemented)

an alternate version of the algorithm where the bits of the

fingerprint are taken to be the signs of the dot products of

pairs of patches

p

and

q

. The na

¨

ıve version divides the pool

of patch positions into pairs and computes one bit of the

feature vector from each pair. Unfortunately that approach

allows an attacker to tweak each pair in turn independently.

A more robust version considers bits from all patch pairs

(p, q)

where

p 6= q

. For example, for 64 patches each patch

would participate in 63 bits, and this scheme could generate

64

2

= 2016 total bits.

In the case where a forger has a copy of an original

document and therefore knows the fingerprint he is trying to

reproduce (Section 5.2.3), this formulation has the advantage

that the bits of the fingerprint are more tightly bound than

those of the template vectors. Any attack on a single bit—for

example, printing on a patch—is likely to impinge on the

other (62) bits affected by that patch. Thus, a forger would

have to solve an optimization problem to figure out how best

to perform the attack.

However, the bits of the fingerprint generated from all patch

pairs seem to be less independent than the bits generated

by the template vectors. Preliminary experiments similar to

those described in Section 4 indicate that “all-pairs” bits are

mostly independent, but not as independent as the “template”

bits. Since the arguments in Section 5.2.2 for security against

“blind” attackers rely on bit independence, we generally prefer

the “template” scheme.

Short fingerprints with no error-correcting information.

Section 3.2 describes a process for generating fingerprints

composed of a hash of 3200 or more bits concatenated

with some error correction bits. For some applications

requiring less security, fewer feature vector bits may be used.

Suppose only 100 bits are used, and further suppose that the

application tends to produce fewer bit errors (say 15% or less).

In such scenarios an alternate approach would be to simply

record the secure hash of those bits. An attacker, without

the benefit of the original, is forced to guess among

2

100

bit

sequences, checking guesses against the hash. Unfortunately,

this leaves the na

¨

ıve authentication process with no way to

do error correction other than to guess among the roughly

10

17

strings within Hamming distance of 15 of the sequence

extracted from a page—easier, but also daunting.

Fortunately, there is a better approach for the authentication

process. Recall that the bits of the fingerprint are taken as

the signs of a series of dot products (patches and templates).

We have observed that these dot products are well-modeled

by samples from a truncated normal distribution. Moreover,

we have also observed that the flipped bits mostly come

from dot products near zero, and that the bit-flipping process

13

seems to be well-modeled by the addition of “noise” also

selected from a truncated normal distribution (with smaller

standard deviation than that of the “signal”). With this model

in hand, the verification process can search for bit strings

similar to the extracted fingerprint while taking into account

which bits are more likely to have flipped. Specifically, the

process flips bits at random with probability relative to the

likelihood that the bit has flipped, each time checking against

the secure hash. We simulated this approach and found that

about 90% of the time it will find the correct string within

10

6

guesses for the example distribution described above.

The benefits of this approach are that it is simple to

implement and provides no information to an attacker in

the form of error-correction bits. The main disadvantages

are that it does not scale well to longer bit sequences and

that the stochastic nature of the algorithm provides only

probabilistic guarantees of running time. Therefore, it would

likely be used only in conjunction with other approaches.

For example, an application might attempt this method for

offline verification and fall back to an online method in cases

when it fails.

14