1601 J. P. Hennessy Drive, LaVergne, TN USA 37086 615/641-7533 800/688-6359 www.coatsgarage.com

HENNESSY

INDUSTRIES INC. Manufacturer of AMMCO

®

, COATS

®

and BADA

®

Automotive Service Equipment and Tools.

Manual Part No.: 941413 04

Revision: 6/18

4000SP

Drum & Disc

BRAKE LATHE

®

Installation Instructions

Operating Instructions

Safety Instructions

Maintenance Instructions

with Parts Identification

READ these instructions before placing unit in

service. KEEP these and other materials delivered

with the unit in a binder near the machine for

ease of reference by supervisors and operators.

ii • AMMCO 4000SP Brake Lathe

AMMCO 4000SP Brake Lathe • iii

Table of Contents

Safety Notices and Decals . . . . . . . . . . . . .iv

Warning

Cautions and Dangers . . . . . . . . . . . . . . . . . . . . . .iv

Owner’s Responsibility . . . . . . . . . . . . . . . . .v

Definitions of Hazard Levels . . . . . . . . . . . . .v

General Safety Instructions . . . . . . . . . . . . .vi

Before You Begin

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Electrical Requirements . . . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Preparation for Use . . . . . . . . . . . . . . . . . . . . . . . .2

Operating Specifications . . . . . . . . . . . . . . . . . . . .2

Principle Operating Parts . . . . . . . . . . . . . . . . . . . .3

Operating Instructions

Arbor Installation . . . . . . . . . . . . . . . . . . . . . . . . . .4

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Basic Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Poly V-Belt Tension and Adjustment . . . . . . . . . . . .5

Basic Operation of Handwheels . . . . . . . . . . . . . .5

Reconditioning Brake Drums

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mounting Drums . . . . . . . . . . . . . . . . . . . . . . . . . .6

Reconditioning Disc Brake Rotors

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Twin Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

6950 Twin Cutter . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rotor Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Set Up and Reconditioning Rotors . . . . . . . . . . .10

Maintenance and Service

Oiling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Care of Arbors and Adapters . . . . . . . . . . . . . . . .12

Shear Gear Replacement . . . . . . . . . . . . . . . . . . .13

Parts Identification

Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-15

Motor Mount and Drive Shaft . . . . . . . . . . . . .16-17

Crossfeed Assembly . . . . . . . . . . . . . . . . . . . .18-19

Disc Brake Feed Mechanism, #7751 . . . . . . .20-21

Drum Feed Gearbox Assy. 3037 . . . . . . . . . . .22-23

6950 Twin Cutter . . . . . . . . . . . . . . . . . . . . . . . . .24

Electrical Panel Assembly . . . . . . . . . . . . . . . . . .25

Contents

iv • AMMCO 4000SP Brake Lathe

Safety

Safety Notices and

Decals

For your safety, and the safety of others, read and

understand all of the safety notices and decals includ-

ed here and on the unit.

Read entire manual

before installing,

operating, or servic-

ing this equipment.

Proper maintenance

and inspection is

necessary for safe

operation.

Do not operate a

damaged lathe.

Warning

This equipment incorporates parts such as snap

switches and power receptacles which tend to pro-

duce arcs or sparks. Therefore, when located in a serv-

ice facility, the unit should be in a room or enclosure

provided for the purpose, or should be at least 18” or

more above floor to minimize the risk of igniting fuel

vapors.

Cautions and Dangers

1. Eye and face protection requirements:

“Protective eye and face equipment is required

to be used where there is a reasonable

probability of injury that can be prevented by use

of such equipment.” OSHA 1910.133 (a).

Protective goggles, safety glasses, or a face

shield must be provided by the purchaser/user

and worn by the operator of the equipment.

Make sure all eye and face safety precautions are

followed by the operator(s). Keep bystanders out

of the area.

2. Do not remove any safety equipment, belt

guards, or shortcut controls or operations.

3. Make sure drums and rotors are properly and

squarely mounted before starting lathe, and that

all parts are secure.

4. Do not wear loose clothing, jewelry, or gloves

when operating or working around a lathe.

5. Do not overload the lathe. Read and understand

the lathe specifications. Overloading is poor

machine tool practice, shortens the life of the

lathe, and could cause a failure resulting in

personal injury.

Failure to follow danger, warning, and cau-

tion instructions may lead to serious per-

sonal injury or death to operator or

bystander or damage to property. Do not

operate this machine until you read and

understand all the dangers, warnings and

cautions in this manual. For additional

copies of either, or further information,

contact:

Henne

ssy Industries, Inc.

1601 J.P. Hennessy Drive

LaVergne, TN 37086

(615) 641-7533 or (800) 688-6359

www.coatsgarage.com

WARNING

AMMCO 4000SP Brake Lathe • v

Owner’s Responsibility

To maintain machine and user safety, the responsi-

bility of the owner is to read and follow these instruc-

tions:

• Follow all installation instructions.

• Make sure installation conforms to all applicable

Local, State, and Federal Codes, Rules, and

Regulations; such as State and Federal OSHA

Regulations and Electrical Codes.

• Carefully check the unit for correct initial function.

• Read and follow the safety instructions. Keep

them readily available for machine operators.

• Make certain all operators are properly trained,

know how to safely and correctly operate the

unit, and are properly supervised.

• Allow unit operation only with all parts in place

and operating safely.

• Carefully inspect the unit on a regular basis and

perform all maintenance as required.

• Service and maintain the unit only with

authorized or approved replacement parts.

• Keep all instructions permanently with the unit

and all decals/labels/notices on the unit clean and

visible.

• Do not override safety features.

Definitions of Hazard

Levels

Identify the hazard levels used in this manual with

the following definitions and signal words:

DANGER

Watch for this symbol:

It Means: Immediate hazards, which will result in

severe personal injury or death.

WARNING

Watch for this symbol:

It Means: Hazards or unsafe practices, which could

result in severe personal injury or death.

CAUTION

Watch for this symbol:

It Means: Hazards or unsafe practices, which may

result in minor personal injury or product or property

damage.

Watch for this symbol! It means BE ALERT! Your

safety, or the safety of others, is involved!

CAUTION

WARNING

DANGER

Safety

1. Read and follow instructions.

2. Always wear eye protection, avoid loose

clothing and jewelry.

3. Keep all guards, shields, and covers in place and

in working order.

4. Keep bystanders out of work area.

5. Unplug unit from power source before servicing

or adjusting.

6. Maintain unit properly, keep work surfaces and

work area clean.

CAUTION

Prevent accidents and injury, read and follow instructions.

vi • AMMCO 4000SP Brake Lathe

Safety

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches from the

tool before turning it on. Make this a habit.

3. Keep work area clean. Cluttered areas and

benches invite accidents.

4. Avoid dangerous operating environments. Do not

use power tools in areas where explosive vapors

are present or in damp or wet locations. Do not

expose them to rain. Keep the work area clean

and well lighted.

5. Keep children away. All bystanders should be

kept completely away from the work area.

6. Make the workshop kid-proof. Use padlocks and

master switches, and remove starter keys.

7. Don’t force a tool. It will do the job better and

safer at the rate for which it was designed.

8. Use the right tool. Don’t force a tool or an

attachment to do a job for which it was not

designed.

9. Dress properly. Loose clothing, gloves, neckties,

shop rags or jewelry may get caught in moving

parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair.

10. Wear eye protection. Safety glasses, goggles, or

a face shield will help protect the operator from

injury. Use a face shield and dust mask during

dusty operations.

11. Secure the work properly to the unit for setup

and tool bit positioning. Do not attempt to hold a

drum or rotor steady on the arbor with your

hands. Both hands must be free to operate unit.

12. Don’t overreach. Keep proper footing and balance

at all times when lathe is in operation or when

working around the unit.

13. Maintain tools with care. Keep tools sharp and

clean for best and safest performance. Follow

instructions for lubricating and changing

accessories.

14. Remove power from the unit and disconnect

tools before servicing and when changing

accessories such as blades, bits, cutters, etc.

Follow lockout and tag-out procedures as

required.

15. Avoid unintentional starting. Make sure the

switch is in the OFF (O) position before plugging

the machine in or performing any maintenance or

service work.

16. Use recommended accessories. Consult the

manufacturer’s catalogs for recommended

accessories. Use of improper accessories may

cause risk of injury to operator or bystanders.

17. Never stand or lean on a lathe. Serious injury

could occur if the lathe is tipped or if the cutting

tool is unintentionally contacted.

18. Check damaged parts carefully. Before further

use of the lathe, a guard or other part that is

damaged should be carefully checked.

Immediately replace all damaged, missing, or

non-functional parts. Check for alignment of

moving parts, binding of moving parts, breakage

of parts, mounting, and any other conditions that

may affect operation. Guards and other parts that

are damaged should be properly repaired or

replaced before lathe is used again.

19. Always feed the work into a blade or cutter and

against the direction of rotation. Cutters and tool

bits are designed to cut from the inside of a drum

or rotor to the outer edge. Do not attempt to cut

from the outside edge in to the center.

20. Never leave tools running unattended. Turn the

power off. Don’t leave the tool until it comes to a

complete stop.

21. Never use compressed air to blow the tool clean.

Chips and dust may be driven between machined

parts and into bearings, causing undue wear.

They may also contact persons in the area

causing personal injury.

22. Operate the lathe in the proper environment. The

lathe incorporates parts such as snap switches

and power receptacles, which tend to produce

arcs or sparks. Therefore, when located in a

garage the unit should be in a room or enclosure

provided for the purpose, or should be at least

18” or more above the floor to minimize the risk

of igniting fuel vapors.

General Safety Instructions

Before operating the lathe, review the warning information on the lathe and the cautions, warnings and dangers

in this manual. Also review the following general safety instructions. Failure to follow safety instructions could

result in personal injury to operator or bystanders and damage to the lathe or personal property.

Before You Begin

Receiving

The shipment should be thoroughly inspected as soon as it is

received. The signed bill of lading is acknowledgement by the

carrier of receipt in good condition of shipment covered by our

invoice.

If any of the goods called for on this bill of lading are shorted

or damaged, do not accept them until the carrier makes a nota-

tion on the freight bill of the shorted or damaged goods. Do this

for your own protection.

NOTIFY THE CARRIER AT ONCE if any hidden loss or damage

is discovered after receipt and request the carrier to make an

inspection. If the carrier will not do so, prepare a signed state-

ment to the effect that you have notified the carrier (on a spe-

cific date) and that the carrier has failed to comply with your

request.

IT IS DIFFICULT TO COLLECT FOR LOSS OR DAMAGE AFTER

YOU HAVE GIVEN THE CARRIER A CLEAR RECEIPT.

File your claim with the carrier promptly. Support your claim

with copies of the bill of lading, freight bill, invoice, and photo-

graphs, if available.

Although AMMCO’s responsibility ceases upon delivery of the

shipment to the carrier, we will gladly assist in tracing lost ship-

ments. Our willingness to assist in every possible manner does

not make AMMCO responsible for collection of claims or

replacement of lost or damaged materials. Shipping damage

claims will not be handled under warranty.

Installation

1. Assemble bench according to the instructions provided.

Tighten all fasteners securely.

2. After assembly, the bench should be leveled and may be

bolted down with 3⁄8 or 7⁄16 inch bolts or lag screws.

3. Unbolt the lathe from the shipping pallet. Lift the lathe onto

the bench.

4. Bolt the lathe to the bench with the hardware provided.

Tighten fasteners securely.

5. Remove any packing materials and protective wrapping

from the lathe and components.

6. Make sure lathe is turned off. Plug lathe into a properly

installed and grounded outlet that matches the lathe plug.

7. Remove the shipping plug, insert the oil dipstick, and check

oil level. The lathe is shipped with the correct amount and type

of oil. Add oil as necessary to reach the correct mark on the dip-

stick. Use only EP-80-90 gear oil. Oil level should be checked

often. See figure 2.

8. Clear the area and turn lathe on. Check for proper operation

(motor and spindle rotation).

AMMCO 4000SP Brake Lathe • 1

Figure 1 - Power cord plug and receptacle types

Figure 2 - Check oil level

Electrical Requirements

The lathe must be properly grounded to pro-

tect the operator from shock. The lathe is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding-type receptacle. Should an

extension cord be required, use 3-conductor

cords with 3-prong grounding plug and 3-

prong grounding receptacle properly rated to

handle this electrical power tool only. Do not

modify a cord or plug to match a receptacle;

have a qualified electrician install an appropri-

ate outlet to match the lathe requirements.

Repair or replace any worn or damaged power

cords immediately.

Verify that the lathe plug and grounding-type

receptacle match as shown in Figure 1.

115 VAC

220 VAC

2 • AMMCO 4000SP Brake Lathe

Operating Specifications 4000

Overall Lathe Height . . . . . . . . . . . . . . . . . . . .17.25” (438 mm)

Lathe Shipping Weight . . . . . . . . . . . . . . . . . .385 lbs. (175 kg)

Floor Space Requirements - Width . . . . . . .48” (1219.20 mm)

Floor Space Requirements - Depth . . . . . . .34.5” (901.70 mm)

Spindle to Floor . . . . . . . . . . . . . . . . . . . . .39.375” (1000 mm)

(mounted on optional bench)

Electrical requirements

Standard: 115 VAC, 60 Hz, single-phase, fused at 20 amps

Optional: 220 VAC, 60 Hz, single-phase, fused at 15 amps

Spindle Motor . . . . . . . . . . . . . . . . . .1 HP, 60 Hz, 115/220 VAC

Spindle Travel . . . . . . . . . . . . . . . . . . . . . . . . .6.875” (175 mm)

Spindle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 RPM

Spindle Feed Speed-Drum . . . . . . . . . . . . . . . . . . .0.005 in/rev

Cross Feed Speed-Rotor . . . . . . . . . . . . . . . . . . . .0.002 in/rev

Handwheel Graduations . . . . . . . . . .0.002 inches (0.050 mm)

Maximum Rotor Diameter* . . . . . . . . .14.5 inches (368.3 mm)

Maximum Rotor Thickness . . . . . . . . .1.875 inches (47.63 mm)

Brake Drum Diameter

Minimum: 6 inches

Maximum: 28 inches

Maximum drum depth . . . . . . . . . . . . . . . . . .6.875” (175 mm)

Maximum load

Standard: 1” Arbor . . . . . . . . . . . . . . . .100 lbs. (45.36 kg)

Optional: 1.875” Arbor . . . . . . . . . . . . .200 lbs. (90.72 kg)

* The optional No. 6936 Cross Feed Extension increases the

maximum rotor diameter to 19 inches (483 mm).

Preparation for Use

1. Inspect all adapters and accessories for

burrs, nicks, or other damage.

2. Clean accessories with a vaporizing solvent.

3. Apply a light film of oil to all adapters to pro-

tect their machined surfaces from rust. Refer to

the maintenance section for more information.

There is a circuit breaker located on the

electrical panel to prevent damage to

the lathe in the event the motor is

overloaded. Move the switch to the off

position and correct overloading situa-

tion before re-setting circuit breaker.

Serious personal injury could result if

circuit breaker is re-set while lathe is

still on.

WARNING

AMMCO 4000SP Brake Lathe • 3

Work Light

1” Arbor

Shield

Twin Cutter

Boring Bar and

Boring Bar Clamp

Cross Feed Lock

Cross Feed

Handwheel

Power Cord

Spindle Feed Handwheel

Spindle Feed

Engaging Lever

Spindle Lock

Oil Dipstick

Grease Fitting

Cross Feed

Engaging Lever

Cross Feed

Gearbox

V-Belt

Adjusting Lever

Belt Tension

Adjusting Nut

ON/OFF Switch

Draw Bar

Drive Motor

Pulley Guard

Principle Operating Parts

Operating Instructions

Arbor Installation

The 1” arbor shipped with the lathe has been carefully

matched to the lathe during final assembly and testing. Witness

marks have been etched onto the arbor and the spindle for pre-

cise, repeatable alignment.

The witness marks must be carefully aligned when installing

the arbor (Figure 3). A true-running arbor is essential to profes-

sional quality brake drum and rotor reconditioning.

1. Locate the witness marks on the arbor and the spindle.

2. Insert the arbor into the spindle making sure the witness

marks are aligned.

3. Tighten the drawbar (located at the rear of the spindle) to

pull the hardened and ground tapers of the arbor into the match-

ing seats in the spindle.

Adapters

Although the adapters, arbor, and spindle are made

of top grade steel and are turned, hardened, and pre-

cision ground to close tolerances, great care should

be taken in their use, handling, and storage. Even

the smallest nick, scratch, or loose chip on the

machined mating surfaces can cause incorrect rotor

mounting alignment. This will cause inaccurate

machining.

Always inspect the surface, face, and seating tapers of each

part before use (figure 4). Wipe each part clean before and after

using it. Carefully correct any flaw with a fine stone. If damage

cannot be corrected, replace the part.

Basic Operation

To completely understand drum and rotor turning you must

have knowledge of the lathe itself.

Spindle — The spindle is a motor driven shaft that turns the

arbor upon which the brake drum or rotor is mounted. By turn-

ing the drum and holding a cutting tool against the inner braking

surface, metal can be removed.

Do not try to move any feed levers or dials without

the drive motor running. Damage may occur to the

gear trains.

Spindle Feed — By operating the spindle feed lever, the spin-

dle will move the mounted brake drum to the left. This feeds the

braking surface across the cutting tool as the drum moves away

from the tool. Spindle feed may also be done manually using the

spindle feed handwheel.

CAUTION

CAUTION

4 • AMMCO 4000SP Brake Lathe

Figure 3 - Align witness marks during arbor

installation

Figure 4 - Use care to avoid damaging mating

surfaces

Arbor

Keep the arbor tapers and seats clean

Witness Marks

Typical Inner & Outer Adapters

Seating Tapers

Machined Surfaces

Figure 5 - Engage lever and loosen nut

Figure 6 - Clockwise rotation of handwheels

Figure 7 - Counterclockwise rotation of handwheels

Figure 8 - Measure drum diameter

Spindle feed refers to the distance the spindle is pulled per

revolution.

Spindle Speed — Spindle speed is measured in RPM’s. Refer

to the specifications listed on page 2 for the RPM rating.

Cross Feed — The cross feed draws the tool bit across the

face of a brake rotor or flywheel when the cross feed drive is

engaged. The cross feed may also be operated manually using

the cross feed handwheel.

Feed Speed — Feed speed refers to the thousands of an inch

the cutting tools move per revolution of the spindle.

Poly V-Belt Tension and Adjustment

A loose belt can cause slippage when taking heavy cuts. A belt

that is too tight can cause vibration and possible sub-standard

finishes on machined drums and rotors. Check and adjust belt

monthly.

1. Position the poly v-belt speed-adjusting lever to the left

(counterclockwise) to the fully engaged position.

2. Loosen the adjustment nut. See figure 5.

3. The poly v-belt should be adjusted to deflect 3/32” with a

5-pound push on the belt. The ideal tension is the lowest tension

at which the belt will not slip under the highest load.

4. Retighten the adjusting nut.

Check and adjust as required the tension during the first day of

operation. Do not overtighten.

Basic Operation of Handwheels

Clockwise rotation of the spindle feed handwheel retracts the

spindle in towards the lathe.

Clockwise rotation of the cross feed handwheel moves the

cutting tool in towards the lathe. Refer to figure 6.

Counterclockwise rotation of the spindle feed handwheel

extends the spindle out away from the lathe.

Counterclockwise rotation of the cross feed handwheel moves

the cutting tool out away from the lathe. Refer to figure 7.

Reconditioning Brake Drums

Preparation

1. Measure the diameter of the brake drum with a brake drum

micrometer (figure 8).

2. Determine if the drum will be within maximum rebore lim-

its after reconditioning.

NOTE: Most often, the DISCARD diameter is cast into the

brake drum, not the maximum machining diameter.

3. Inspect brake drum. Do not attempt to machine a drum that

is damaged or in poor condition.

AMMCO 4000SP Brake Lathe • 5

Poly V-belt

Adjustment Nut

Belt Adjusting Lever

Spindle Feed

Handwheel

Cross Feed

Handwheel

Spindle rotates when

motor is turned on.

Spindle Feed

Handwheel

Cross Feed

Handwheel

A

C

B

L

K

D

F

Hubbed Brake Drums

Hubbed Brake Drums — Tapered cone adapters fit

in the bearing seats, making contact near the middle

of the bearing race whenever possible rather than near

an edge. Various adapters and spacers may be used to

fill out the shaft of the arbor.

Hubless Brake Drums — A cone fits into the center

hole of the drum from the inside to center the drum on

the arbor. Select a hubless adapter which will fit inside

the drum, against the flat lug hole surface and either

straddle the boltholes to avoid mounting against a burr,

or remove the burrs. Slip the hubless adapter onto the

arbor followed by a spring, the cone, the drum, and

another hubless adapter. Fill out the shaft with spacers

as needed.

Key to Mounting Adapters, Cones, and Related Parts

A. 1” Arbor

B. Flange Plate

C. Spring

D. Centering Cone

E. Rotor, Drum or Flywheel

F. Flange Plate

G. Spacer(s)

H. Self-Aligning Spacer (AMMCO)

I. Arbor Nut

Note: The self-aligning spacer should always be used

next to the arbor nut when tightening. To avoid over-

tightening, wrench tighten the arbor nut counterclock-

wise until the drum and adapters begin to turn on the

arbor, then continue to advance the wrench 1/16 of a

turn. DO NOT overtighten the arbor nut.

Mounting Drums

1. Loosen the boring bar clamp nut and push the boring bar all

the way into the clamp.

2. Mount the drum on the arbor using the proper adapters,

cones, and spacers. Use examples in Figure 10 for guidance.

3. Wrap the drum silencer band snugly around the drum. Be

sure it covers up to the right-hand edge (figure 9).

IMPORTANT: The spindle feed handwheel will not operate

unless the spindle feed engagement lever is in the OFF posi-

tion. Feed should only be adjusted when the spindle is turning.

4. Position the cross slide and spindle by turning their respec-

tive handwheels to their maximum clockwise (in) position. Then

back off the cross feed handwheel 2 complete turns and the

spindle handwheel 4 complete turns.

6 • AMMCO 4000SP Brake Lathe

Figure 9 - Attach silencer band

Figure 10 - Typical drum mounting configurations

Buckle Finger

Silencer Band for Drums

A

C

B

E

H

D

F

I

G

Hubless Brake Drums

Figure 12 - First scratch cut

Figure 11 - Positioning the boring bar

Figure 13 - Set drum diameter measurement

Figure 14 - Second scratch cut

5. Position the boring bar by loosening the boring bar clamp

nut and sliding the boring bar inward toward the drum until the

tool bit is close to the drum (figure 11).

The boring bar position is changed whenever a drum of differ-

ent diameter is machined.

The entire boring bar clamp may also be swiveled to achieve

the best cutting position.

6. Turn the drum by hand to make sure that everything is clear.

7. Turn the lathe ON.

8. Advance the tool bit manually until it just contacts the drum

surface momentarily and makes a scratch cut (figure 12).

9. Loosen the dial lock screw on the cross feed handwheel

and set the dial to the diameter of the drum as measured with

the micrometer (figure 13). Tighten the lock screw.

This setting will be the reference used to help determine the

drum recondition diameter.

10. Back the tool bit off and turn the lathe OFF.

11. Loosen the arbor nut, rotate the drum 1⁄2 turn (180°) on

the arbor and inner adapter, and retighten the nut.

12. Turn the lathe ON.

13. Turn the spindle feed handwheel 1⁄2 turn in either direc-

tion and make a second scratch cut (figure 14).

14. Turn the lathe OFF.

15. Examine the scratch cuts.

If the first and second cuts are opposite one another (180°

apart), remove the drum from the arbor, check the mounting

adapters and arbor for nicks, burrs, or chips, remount the drum,

and repeat scratch cut process.

If the scratches are side by side, proceed to step 16.

16. Turn the spindle feed handwheel until the deepest worn

groove of the drum lines up with the point of the tool bit.

17. Advance the tool bit into the bottom of the groove by

rotating the cross feed handwheel counterclockwise.

NOTE: These operations may be done with the lathe running.

The depth of cut dial will show the approximate reconditioned

diameter of the drum. This measurement must be compared

with:

A. The maximum rebore limits cast into the drum.

B. The measured diameter to determine the best amount

of material to be removed in one pass.

18. Determine the depth-of-cut by these general guidelines:

• Roughing cuts should be no deeper than 0.020”.

• Finish cuts should be no shallower than 0.004” deep.

AMMCO 4000SP Brake Lathe • 7

First

Scratch

Cut

Dial Lock

Screw

Second

Scratch

Cut

19. With the lathe running, set the depth-of-cut dial to the

depth desired and lock the cross feed by tightening the lock

knob (figure 15).

20. Set the feed shut-off by sliding it on the shaft to a point

that approximately equals the depth of the drum and tightening

it in place (figure 16). The feed will stop when it reaches this

point.

21. Engage the feed lever to begin drum reconditioning.

Reconditioning Disc Brake

Rotors

Preparation

1. Inspect the rotor carefully for scoring, rust ridges (at the

inner and outer circumference of the rotor), and hard spots. Any

excessive wear or deformity should be noted and, if not within

acceptable limits, the rotor should be replaced.

2. Use a micrometer to check the thickness of the rotor (fig-

ure 17) at no less than 3 points around the circumference about

1” (2.54 mm) in from the outer diameter.

If the rotor thickness varies between readings, it should be

reconditioned. However, if the thickness is less than the mini-

mum established by the manufacturer, or if it will be less after

reconditioning, the rotor should be replaced.

NOTE: Most often the DISCARD thickness dimension is cast

or stamped into the rotor, not the minimum machine-to thick-

ness.

Twin Cutter

A twin cutter tool is used to recondition both surfaces of a

brake rotor at the same time. The twin cutter replaces the bor-

ing bar on top of the cross feed after removing the upper and

lower tool bar clamps.

Model 6950 Twin Cutter

1. Mount the twin cutter on the cross feed with the stud bolt

extending through the cast slot (see figure 18). The slot helps

center the twin cutter to the rotor.

2. Secure the twin cutter to the cross feed with self-aligning

nut and washer assembly. Tighten the nut firmly.

8 • AMMCO 4000SP Brake Lathe

Figure 15 - Lock cross feed

Figure 16 - Set spindle feed shut-off

Figure 17 - Measure rotor thickness

Figure 18 - Install the twin cutter

Cross Feed Lock Knob

Feed shut-off

Spindle feed lever

Upper and lower boring

bar clamps

Cross slide self-aligning nut/washer

Twin

cutter

Cross slide self-aligning

nut/washer

AMMCO 4000SP Brake Lathe • 9

Rotor Mounting

Review the descriptions of mounting a brake drum

on page 6. The same directions apply when mounting

a brake rotor. Hubbed rotors are mounted on adapters

that fit into the bearing races. Hubless rotors use a

cone in the center hole and a hubless adapter on each

side of the rotor. Spacers are used to fill out the arbor

shaft so that the arbor nut can be tightened. The

setups illustrated in Figure 19 are typical of the many

mounting configurations necessary to meet the

requirements of brake rotor reconditioning. The

adapters, cones, and spacers supplied with the lathe

will allow reconditioning of the majority of the rotors

found on current production vehicles. Optional

adapters, cones, and spacers are available to meet

special needs.

NOTE: Adapters may also be used as spacers to fill

out the arbor shaft if care is taken to prevent damage

to their machined surfaces.

The patented self-aligning spacer prevents diagonal

thrust on the adapters. The self-aligning spacer should

always be used adjacent to the arbor nut.

- 1" Arbor

- Arbor Nut

- Self-Aligning Spacer

- Spacer

- Spring

- Flange Plate

- Flange Plate

- Centering Cone

- Small Double Taper Adapter

- Large Double Taper Adapter

- Adapter, Used as Spacer

Figure 19 - Typical rotor mounting configurations

Set Up and Reconditioning Rotors

1. Install a silencer band on the mounted rotor. Stretch the band

around the rotor and hook the metal loop over a lead weight. Refer

to figure 20.

2. Center the twin cutter to the rotor (figure 21). Loosen the stud

nut and adjust the twin cutter so that the rotor is centered between

the tool bits. The slot of the twin cutter should be approximately

parallel to the lathe spindle. Tighten the stud nut firmly.

3. Install the safety shield as shown in figure 22. Review the cau-

tions and dangers section and the general safety information at the

beginning of this manual. The safety shield is easily screwed onto

the twin cutter in the threaded mounting hole provided.

Always wear safety glasses or a face shield. Cutting or

grinding on an exposed surface such as a rotor will pro-

duce flying chips and debris.

4. Attach the optional 7075 Pad Silencer and the Clip-on Silencer

as needed for composite rotors.

5. Make sure that the tool bits clear the rotor surfaces and the

silencer band. Give the rotor a full turn by hand and watch for clear-

ance all the way around.

6. Turn the lathe ON.

7. Turn each tool bit control (the outer knurled knobs, figure 23)

clockwise until the tool bits just contact the rotor surfaces.

8. When the tool bits make contact, rotate each of the inner

depth-of-cut collars to zero and back the tool bits away from the

rotor.

From this point on, all tool adjustments will be made with the tool

bit controls. Then inner depth-of-cut collars will be the reference

and should not be moved.

9. Turn the cross feed handwheel until the tool bits are at mid-

point of the rotor face.

WARNING

Figure 20 - Attach silencer band

Figure 21 - Center the twin cutter

Figure 22 - Attach the safety shield

Figure 23 - Tool bit controls

10 • AMMCO 4000SP Brake Lathe

Silencer band

Twin cutter

Stud nut

Tool bits

Safety shield

Twin cutter

Inner depth-

of-cut collars

Tool bit controls

Hold knob with one

hand – turn collar

Each increment =

0.002” english,

0.05 mm metric

Figure 24 - First scratch cut

10. Turn the left-hand tool bit control until the tool bit contacts

the rotor surface and makes a scratch cut (figure 24). After the cut

is made, back the tool bits off and turn the lathe OFF.

The scratch will usually appear as an incomplete circle. This is

caused by runout or wobble due to rotor condition, or by the way

the rotor is mounted on the arbor (figure 25).

11. Check rotor mounting by loosening the arbor nut and turning

the rotor 180° by hand on the arbor. Make sure the inside adapter

does not rotate along with the rotor. Then retighten the arbor nut,

turn the cross feed handwheel back 1/2 turn, turn the lathe ON, and

repeat step 10 to make a second scratch cut (figure 26).

12. If the scratch cuts are side-by-side, the runout or wobble is

caused by rotor condition. A dial indicator may be used to compare

rotor runout with manufacturer’s specifications. See figure 27.

13. If the scratch cuts are opposite one another (180°), the rotor

may not be properly mounted on the arbor. Remove the rotor and

examine the arbor and all adapters for nicks, burrs, chips, dirt, or

rust. Inspect the rotor hub for loose or damaged bearing cups.

Clean, repair, remount, or replace as necessary.

14. Recheck the setting of the depth-of-cut collars, which were

set to zero earlier by moving the tool bits inward until they just con-

tact the surfaces of the rotor. The collars should be at zero. Reset

the collars if necessary.

15. Turn the cross feed handwheel clockwise until the tool bits

are near the rotor hub.

16. Turn the lathe ON.

17. Turn both tool bit controls to the desired depth-of-cut and lock

them in position by tightening the red lock knobs above the tool

bits.

18. Engage the automatic cross feed (figure 28) by moving the

lever to the rear of the lathe. The cross feed will stop automatically

when the cutting tools have moved all the way across the face of

the rotor.

19. Exert light pressure inward on cross feed while turning cross

feed handwheel slowly clockwise until the leadscrew is engaged.

AMMCO 4000SP Brake Lathe • 11

Figure 25 - Rotate rotor 180°

Figure 26 - Second scratch cut

Figure 27 - Using a dial indicator

Figure 28 - Engage automatic

cross feed

First scratch cut

Rotate rotor only 180°

Loosen arbor

nut, do not turn

inside adapter

Second

scratch cut

Scratch cuts

opposite each

other

Dial indicator

ON

OFF

Double Chuck Adapter

Mounting drums or rotors using the Ammco double

chuck adapter.

Figure 6 – Double Chuck Adapter

1. Thoroughly clean the surface of the rotor or drum

that will be mounted on the double chuck.

2. Place the hubless rotor or drum on a flat clean sur-

face. Install the double chuck by positioning the appro-

priate jaws in the center hole. Tighten the jaws by

inserting the key into one of the key slots in the side of

the chuck turning counterclockwise. The double chuck

will automatically self center the rotor or drum.

Note: Make sure that the chuck jaws are tight.

Do not leave the key in the key slot when

starting the brake lathe.

3. Install the backing plate onto the brake lathe arbor

with offset facing outward.

4. Ins all the double chuck, with rotor or drum

installed, onto the 1-inch arbor. Use the spacers sup-

plied with the brake lathe so that it extends out to the

arbor threads.

5. Use the arbor nut supplied with the machine and

tighten the nut against the spacers.

6. After tightening the double chuck, turn on the

brake lathe to check for runout of the rotor or brake

drum. Machine the rotor or drum.

Note: Always use the backing plate to help eliminate

rotor or drum vibration during turning. If necessary, use

a small spacer before the installation of the backing

plate.

CAUTION

12 • AMMCO 4000SP Brake Lathe

Maintenance and Service

Oiling

The lathe is shipped from the factory with the correct amount

and type of oil. Check oil level frequently as shown in figure 29,

and refill as necessary with EP-80-90 gear oil.

After every 500 hours of use, drain the oil and refill to the

appropriate level on the dipstick with clean EP-80-90 gear oil.

Use the oil drain plug on the front of the lathe to drain the old

oil. See figure 30.

The drum feed gearbox and the disc brake feed mechanism

assemblies are filled with a special lubricant and need no further

internal lubrication.

Lubricate the cross feed once each month with automotive

chassis grease. Pump the grease into the fitting until clean

grease comes out the relief slot at the base of the fitting as

shown in figure 31.

Use a hand pump grease gun only. A high-pressure gun can

burst the lathe casting.

Grease the lead screw drive monthly (figure 32). Locate the

lead screw drive by pulling the protective boot back.

Oil exposed metal parts periodically to prevent rust.

Cleaning

Keep the lathe as clean as possible for trouble-free operation,

as well as safety and longer lathe life. Use a brush to sweep

metal chips and dust off the lathe.

Do not use compressed air to blow the lathe clean. Chips and

dust may be driven between machined parts and into bearings,

causing undue wear.

Care of Arbors and Adapters

Although the adapters, arbors, and spindle are made of top

grade steel and are turned, hardened, and precision ground to

close tolerances, great care should be taken in their use, han-

dling, and storage. Even the smallest nick, scratch, or loose chip

can cause incorrect rotor or drum alignment, resulting in inac-

curate reconditioning.

Remove all adapters from the arbor after reconditioning a drum

or rotor and wipe them clean - especially the inboard adapter.

When a finished drum or rotor is removed from the arbor, the

inboard adapter may move slightly away from the face of the

arbor and allow metal chips to fall into the opening, causing a

poor mounting for the next drum or rotor.

Regularly inspect the faces and seating tapers of the adapters

for nicks and scratches, correct any flaw with a fine stone. If the

damage cannot be corrected, replace the adapter. Handle the

adapters and arbors with care and store them on individual

hooks. Do not throw them into a box. The adapters are designed

for mounting drums and rotors only. Do not misuse the

adapters.

Figure 29 - Oiling

Figure 30 - Drain plug location

Figure 31 - Cross feed grease fitting

Figure 32 - Lead screw drive

Grease fitting

for cross feed

Dipstick

Oil level

Oil drain plug

Relief slot

Feed mechanism lead screw

AMMCO 4000SP Brake Lathe • 13

Shear Gear Replacement

The shear gear is located in the drive housing under the dot

plug cover. It is designed to “strip out” and prevent gearbox

damage should a tool accidentally jam.

Remove the dot plug button. Remove the C-clip. Remove the

shear gear. Remove any stripped teeth from the drive housing.

Install the new gear. The concave side of the C-clip faces the

gear to maintain pressure. Replace the dot plug button.

Parts Identification

The following pages illustrate and identify the component

parts of the 4000 lathe. Complete parts breakdowns with

exploded view illustrations are provided to facilitate the ordering

of spare or replacement parts. Assemblies are outlined where it

is recommended the individual parts not be ordered separately.

These assemblies are furnished because some parts are

staked, pinned, or press fitted, then drilled, machined, or bored.

Accuracy must be maintained.

14 • AMMCO 4000SP Brake Lathe

AMMCO 4000SP Brake Lathe • 15

Spindle

PART

ITEM NO. Qty. DESCRIPTION

1 903102 1 Nut, arbor

2 903101 1 Arbor

3 903159 1 Ring, retaining

4 923682 1 Ring, adapter

5 903085 2 Boot

6 940720 1 Seal, oil, double-lip

7 903089 2 Ring, oil seal adapter

8 903164 1 Seal, oil

9 903033 2 Washer, thrust

10 903153 1 Spindle body, 3000/4000

11 909831 1 Key, drive

12 906486 1 Screw, cup point set

14 909830 1 Quill, drive, 3000/4000

15 900283 1 Washer, lock, 3000/4000

16 901602 1 Screw, hex hd. cap, 3000/4000

17 910216 1 Quill, drive, 4100/7700

18 906868 1 Screw, flat hd., 4100/7700

19 910737 1 Block, keyway, 4100/7700

20 903032 * Shim (0.005 THK)

921322 * Shim (0.0075 THK)

21 904670 1 Nut, lead screw, 4000/7000

22 907344R 1 Rear flange assembly, 4000

23 900209 4 Screw, skt. hd. cap, 4000, 4100

24 904671 1 Nut, take up

25 903338 1 Screw, skt. hd. set

26 904435 1 Ring, boot, 4000/4100

27 909592 1 Clamp, front

28 903142 1 Plug, brass

29 906854 1 Knob

30 903319 2 Screw, skt. hd. cap, 4000

31 909645 1 Rod, lock, 4000

32 909998 1 Clamp, rear, lower

33 909999 1 Clamp, rear, upper

34 906825 2 Screw, skt. hd. cap

35 900213 1 Screw, set

36 907005 1 Drawbar & nut assy, 3000/4000

37 903086 1 Boot & spring, 3000/4000

38 903037 1 Feed mechanism, 4000

16 • AMMCO 4000SP Brake Lathe

AMMCO 4000SP Brake Lathe • 17

Motor Mount and Drive Shaft

PART

ITEM NO. Qty. DESCRIPTION

1 906766 1 O-ring

2 906101 2 Screw, hex hd. cap

3 921557 2 Washer, lock

4 902165 1

Motor/bracket assembly

115/230V,

60Hz, 1Ph

6 940538 1

Pulley, drive, 4000SP

7 900220 2 Set screw, 3000/4000

8 903023 1 Shaft, motor mount

9 903015 1 Lever, belt tension

10 903035 1 Pin, eccentric belt release

11 907348 1 Lever belt release assembly

12 903088 1 Handle, belt release

13 900320 1 Knob, ball

14 903180 1 Screw, socket hd.

15 902364 * Washer, wave

16 903223 1 Bushing, motor mount shaft

17 903377 1 Nut, hex

18 903166 1 Plug, Welch

19 903172 1 Ring, retaining I.D.

20 903394 2 Cup, bearing

21 903393 2 Bearing, Cone

22 903372 1 Plug, allen pipe

23 922006 1 Fitting, grease

24 909847-C 1 Shaft, worm w/square key

PART

ITEM NO. Qty. DESCRIPTION

25 903169 * Shim, 0.005”

(*Quantity as required)

903170 * Shim, 0.007”

(*Quantity as required)

903171 * Shim, 0.020”

(*Quantity as required)

26 903186 1 Cap and seal assembly

27 903010 1 Cap, bearing seal

28 903163 1 Seal, oil

29 940581 1

Pulley w/pin and tube, 4000SP

30 924239 1 Pin, groove, 4000/4100

31 925588 1 Tube, rubber, 4000/4100

32 940141 1 Poly V-belt

33 900236 1 Screw, hex hd. cap

34 940139 1 Key, square

35 903215 1 Sleeve, oil filler

36 903148 1 Dipstick

37

8301035

1 Nut, self-locking

39 907788 1 Guard, belt

40 910352 1 Panel assembly, electrical

41 900220 2 Screw, set

42 925454 1 Key, square

921743

1

Motor/bracket assembly

230V, 50Hz, 1Ph

18 • AMMCO 4000SP Brake Lathe

AMMCO 4000SP Brake Lathe • 19

Cross Feed Assembly

PART

ITEM NO. Qty. DESCRIPTION

1 907345 1 Cross feed assembly

2 911227 1 Nut/washer, hex, self-align, assy.

3 911221 1 Nut, locking

4 911225 1 Retainer

5 911224 1 Washer

6 903017 1 Clamp, boring bar, upper

7 920666 1 Clamp, boring bar, lower

8 903031 1 Stud, boring bar

9 909835 1 Cross feed

10 906874 3 Race

11 909626 1 Cross feed handwheel assy.

12 906839 1 Screw, set

13 909634 1 Dial

14 909611 1 Spring, dial

15 909633 1 Handwheel

16 903026 1 Crank, handwheel

17 902309 1 Nut, handwheel

18 903214 1 Washer, flat

19 903176 1 Key, woodruff

20 900220 1 Screw, set

21 902064 1 Spring

22 909836 1 Plug

23 906854 1 Knob, locking

24 903142 1 Plug, brass

25 906873 1 Bearing, needle thrust

26 903211-1 1 Lead screw assy.

27 929240 1 Boring bar and screw assy.

28 903087 1 Boot and spring assy.

29 910346 1 Bar, guide

30 901680 2 Screw, hex hd. set

31 907751 1 Gearbox assy., 4000

32 900237 4 Screw, cap, 4000/4100/7500

36 940558 1 Tool bit holder assembly, drum

907681 1 Carbide insert, positive rake

20 • AMMCO 4000SP Brake Lathe

**

**

AMMCO 4000SP Brake Lathe • 21

Disc Brake Feed Mechanism, #7751

PART

ITEM NO. Qty. DESCRIPTION

1 910870 1 Gear case assy.

2 903221 4 Screw, socket head

3 903910 2 Washer, lock

5 907790 1 Case, gear

6 940718 1 Coupling assy.

7 940719 1 Universal coupling assy.

10 940403 1 Pin, roll

11 940717 1 Coupling

14 910340 1 Rod, drive

15 906937 2 Pin, dowel

16 906973 2 Washer, thrust

17 907775 1 Trap

18 907778 1 Gear, drive

20 906350 1 Washer, bone shim

21 909814 1 Shifter shaft assy.

22 907994 1 Gear, helix

23 904006 1 Pin, roll

24 905613 2 Ring, retaining

25 907764 1 Shaft, clutch

26 906138 1 Ring, Retaining

27 903176 5 Key, woodruff

28 909816 1 Gear, fine feed

29 909813 1 Clutch

30 909812 1 Gear, coarse feed

34 907748 1 Shaft, shift

35 907902 1 Gear case cover and tube assy.

36 907783 1 Tube

37 903221 2 Screw, socket hd. cap

39 904789 1 Washer

40 906254 1 Screw, socket hd. cap

41 906974 1 Cap, tube

42 906392 2 Screw, hex hd. machine

43 906391 2 Screw, hex hd. machine

44 940521 1 Plate, index

45 904508 2 Screw, round hd. machine

46 907742 1 Shifter handle assy.

47 907746 1 Pin, shifter handle

48 906451 1 Washer

49 907699 1 Spring

50 907744 1 Body, shifter handle

51 900320 1 Knob, ball

52 900220 1 Screw, set

**53 909815 1 Driven assembly.

PART

ITEM NO. Qty. DESCRIPTION

54 924241 1 Worm drive assy.

57 906872 4 Washer, travel

58 906871 2 Bearing, needle thrust

59 907998 1 Housing and Bushing assy.

61 907992 1 Worm drive assy.

62 906834 2 Screw, cone point set

**63 907996 1 Shear gear and ring assy.

64 906446 1 Plug, dot

65 909821 1 Coupling assy.

66 903174 1 Ring, retaining

67 909825 1 Spacer and bushing assy.

68 909822 1 Coupling and gear assy.

69 904096 1 Pin, roll

70 907908 2 Shim, 0.005”

907903 2 Shim, 0.010”

907904 2 Shim, 0.020”

907905 2 Shim, 0.030”

71 924516 1 Shifter & intermediate gear assy.

72 928367 2 Screw, cap

73 928529 1 Lead screw nut kit

74 905639 2 Ring, retaining

75 940529 1 Decal

** The 940907 metal face gear can only be

used in conjunction with lathes equipped

with a circuit breaker located on the elec-

trical panel.

The plastic 907996 shear gear can be used

on lathes with or without the circuit break-

er. Failure to follow these instructions may

lead to minor personal injury or product or

property damage.

CAUTION

22 • AMMCO 4000SP Brake Lathe

AMMCO 4000SP Brake Lathe • 23

Drum Feed Gearbox Assy. 3037

PART

ITEM NO. Qty. DESCRIPTION

1 902308 1 Screw, allen set

3 903097 1 Ring, retaining

4 909930 1 Bearing, thrust

5 940533 1 Screw, feed adjusting

6 903715 1 Gear case assy.

8 925182 1 Gear case

9 903392 1 Cup, bearing

10 907007 1 Spindle extension assy.

11 903391 1 Bearing, taper roller

12 903154 1 Spindle extension

13 903092 1 Pin, groove

14 903040 1 Shut-off assy.., 3000/4000

15 903039 1 Collar, stop

16 903084 1 Screw, knurled

17 903141 2 Plug, brass

18 903058 1* Clutch shifter assy.

19 900212 1 Screw, allen set

20 904449 2 Key, Hy-Pro

21 903042 1* Clutch handle and shaft assy.

22 907343 1* Feed control lever and differen-

tial assy.

23 903036 1 Roller

24 907338 1 Pinion bushing assy.

25 903081 1* Driven friction disc & bearing

assy.

26 903098 1 Screw, dog point set

27 903069 1 Gear, miter

28

8114379

4 Screw, socket hd. cap

29 903324 4 Washer

30 906155 1 Washer, wave

31 903184 1 Nut, stop

32 900213 1 Screw, allen set

33 909443 1 Nut, bearing lock

34 909444 1 Washer, spherical

35 909498 1 Gear case cover assy.

36 903038 2 Pin, dowel

37 904641 1 Washer, bone fiber

38 903054 1 Shaft

39 900220 1 Screw, set

40 903090 1* Handwheel assy.

41 903026 1 Handle, crank

42 908235 1 Lead screw & clutch assy.

3000/4000

43 900311 2 Ball, steel

44 909918 1* Lead screw/miter gear assy.

3000/4000

PART

ITEM NO. Qty. DESCRIPTION

45 903060 1 Spring, clutch

46 903047 1 Gear, sliding clutch

47 906163 1 Ring, retaining

48 907264 1 Clutch jaw

49 907263 1 Spring, coil

50 903061 1 Cup, spring loading

51 903082 1 Friction disc assy.

52 903093 1 Ring, retaining

53 903064 2 Washer

54 903062 10 Spring, Belville

55 903078 1 Disc, sliding friction

56 903077 1 Clutch, fixed friction

57 940530 1 Decal

*Sold as assy. only

24 • AMMCO 4000SP Brake Lathe

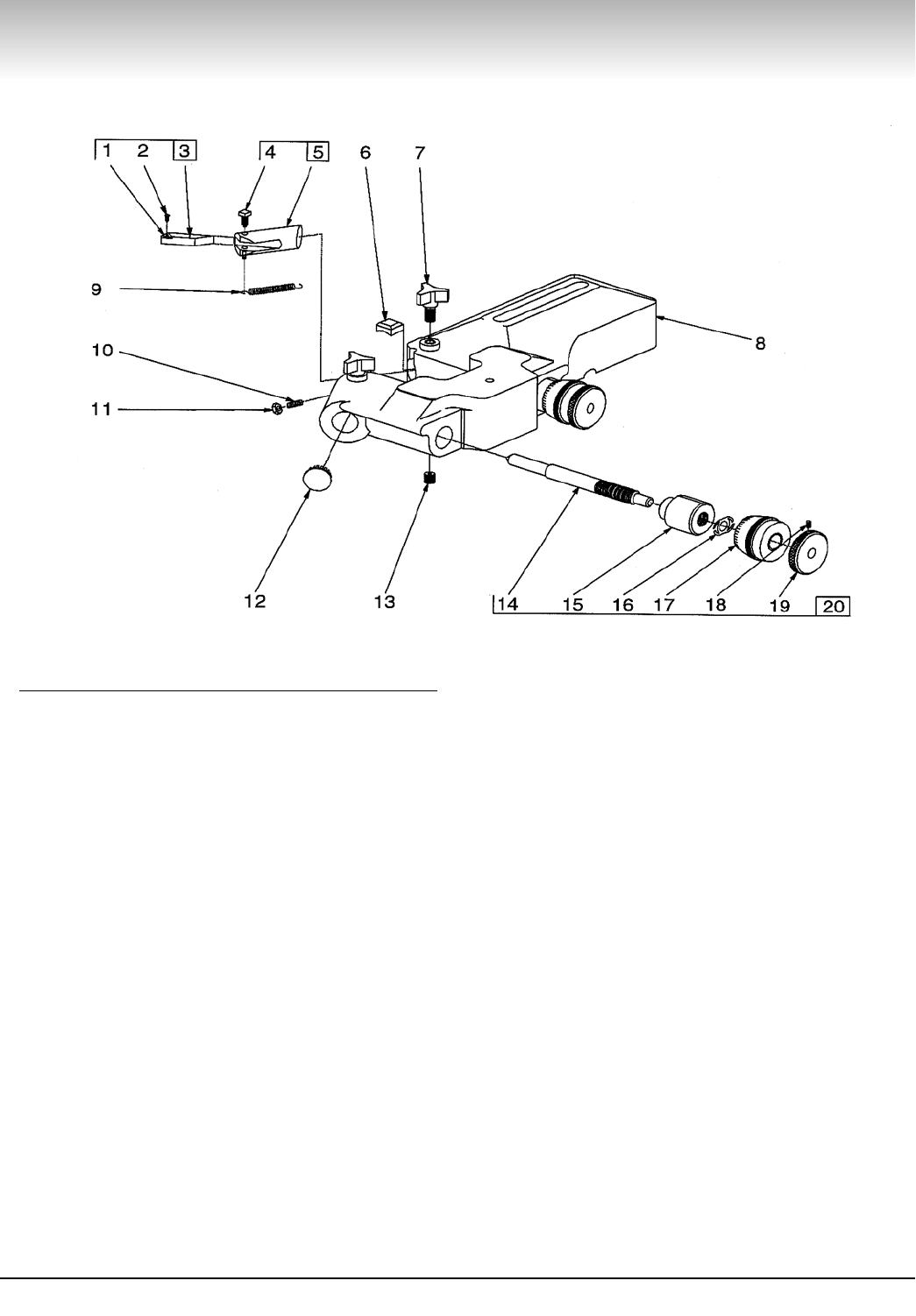

6950 Twin Cutter

PART

ITEM NO. Qty. DESCRIPTION

1 907681 2 Carbide Insert, Positive Rake

2 906499 2 Screw, #4-40 x .25 Oval Head

3 940559 1 Holder, Tool Bit, Right Hand,

Positive Rake

940560 1 Holder, Tool Bit, Left Hand,

Positive Rake

4 909249 2 Screw, Square Head Set

5 910650 1 Tool Holder, Left Hand

910651 1 Tool Holder, Right Hand

6 928584 2 Gib, Brass, Tool Holder

7 906854 1 Screw, Lock

8 928572 1 Twin Cutter Housing

9 906905 1 Spring

10 909879 2 Screw, Locating

11 903528 2 Nut, Hex

12 906977 2 Plug, Dot

13 906109 2 Screw, 3/8-16 Set

14 906908 2 Rod, Dial

15 906906 2 Plug, Dial

16 906929 2 Washer, Spring

17 906907 2 Dial, Micrometer

18 903338 2 Screw, Set

19 906923 2 Knob, Dial Rod

20 906901 1 Dial Assy.

AMMCO 4000SP Brake Lathe • 25

Electrical Panel Assembly

Ground

Green

(Austrialian Only)

Motor Cord & A-5637

Wire Nut Ref. From

Main Assy

11

12

Wrap With Electrical

Tape 2 Turns Min.

WIRING SCHEMATIC

Green

Green

ON

OFF

R

15

9

Black

Green

(Green/Yellow-Aust.)

8 / 7

5

Black

(Brown-Aust.)

White

(Blue-Aust.)

White

Black

White

6

13

1

14

4

10

17

18

22

11

12 / 20

3

19

2

6

A

A

CAUTION

SHUT OFF LATHE BEFORE

RESETTING BREAKER.

VOLTS

PHASE

H.P.:

MOTOR SPECS

Hz:

MTR AMPS:

LISTED

927L

GARAGE

COMPONENT

IF CONNECTED TO A CIRCUIT PRO-

TECTED BY FUSES. USE TIME-DELAY

FUSES WITH THE APPLICANCE.

Motor

Power Cord

12

21

12

White

White

Black

Black

White

Black

Black

(Green/Yellow)

Australian Only

(Brown) Australian Only

(Blue) Australian Only

15 AMP

Circuit

Breaker

Main

Switch

Black

Motor

WARNING

Part

Item Qty No. Description

1 1 910348 Electrical Panel

2 1 907963 Lamp Assembly

1 929225 Lamp Assembly (Austrialian Only)

3 1 907209 Cord Set, 110 V

1 907210 Cord Set, 220 V

1 929507 Cord Set (Austrialian Only)

4 1 940388 Clamp Strap

5 2 940441 Tinnerman Nut

6 1 940868 15 AMP Circuit Breaker

7 1 921972 Selt-Tapping, #6 Screw

8 1 901926 Lock Washer

9 1 906889 Bushing

10 2 903183 Round Head Machine Screw

11 1 900220 Set Screw

12 1 906058 Cord Grip, 110 V

1 906077 Cord Grip, 220 V

1 929643 Cord Grip,(Austrialian Only)

13 1 906893 Switch, 110 V

1 921464 Switch, 220 V

14 1 901185 Switch Plate

15 1 940988 Black Wire Assembly

17 1 920463 Electrical Caution Tag

18 8 900306 Screw, Drive

20 1 929642 Knock-out Adapter

22 1 941103 Reset Decal

220 V

110 V

1

95000257 Cord Set (UK)

941413 04 06/2018

© Copyright 1999 Hennessy Industries and COATS All Rights Reserved Printed in USA