TDLS-A-001

http://www.yokogawa.com/us

Carbon Monoxide Measurement in Coal-Fired Power Boilers

Industry: Power Generation

Product: TDLS200 Tunable Diode Laser Spectroscopy

Background Information

There are currently 1470 generators at 617 facilities in the

United States alone that use coal as the major source of

energy to generate electricity. Of these facilities, 141 are

considered industrial, institutional or commercial sites that

consume most of the electricity produced on-site. The

remaining 476 sites are identified as “power plants” owned

by electric utilities and independent power producers that

generate and sell electricity as their primary business

1

. The

primary goals that drive these power plants are increasing

efficiency and throughput, reducing emissions of pollutants,

and maintaining a high level of safety. Obtaining these goals

ensures that the power plants generate the highest profits,

while complying with environmental regulations and assuring

workplace and community safety.

Introduction

An accurate measurement of the carbon monoxide (CO)

concentration in the boiler flue gas can be used to achieve

the goals of combustion efficiency, pollutant emissions

reduction, and safe operation. By measuring the

concentration of CO, power plants are able fine tune the air

to fuel ratio used on the burners to obtain the highest

combustion efficiency. Measuring the CO concentration

allows the power plants to reduce the amount combustion air

used while ensuring complete combustion, reducing the

production of the pollutant NOx. The concentration of CO in

the flue gas is also the most sensitive indicator of unburned

combustibles in the process and can indicate the emergence

of an unsafe situation.

Efficiency, Emissions, Safety

Given complete mixing, a precise or stoichiometric amount of

air is required to completely react with a given quantity of

fuel to produce complete combustion. In real world

applications, conditions are never ideal so additional or

“excess” air must be supplied to completely burn the fuel.

Too little excess air will result in a “fuel rich” situation

producing a flue gas containing unburned combustibles

(carbon monoxide, soot, smoke, coal). This situation results

in a loss of efficiency because not all of the potential energy

of the coal is captured in the combustion process resulting in

fuel wastes. Combustion processes that run fuel rich are

“running dirty” meaning an increase in pollutant emissions.

Also, this is not a safe situation as the unburnt fuel could

possibly come into contact with an ignition source further

down the process resulting in an uncontrolled explosion.

Too much excess air results in an “air rich” situation,

resulting in complete combustion and safety, but also

produces undesirable effects. Efficiency is lost in an air rich

process because the increased flue gas flow results in heat

loss. More fuel is required to generate the same amount of

heat, so fuel is wasted in this low “boiler fuel-to-steam”

efficiency situation. Since air is comprised of over 78%

nitrogen, increasing the air used for combustion significantly

increases the concentration of nitrogen. Nitrogen exposed to

temperatures above 1600°C (2912°F) may result in the

formation of “thermal NOx” (NO, NO

2

). These substances

are major contributors to the formation of acid rain and their

release into the atmosphere is heavily regulated by

environmental agencies.

The ideal situation is to provide just enough excess air to

produce complete combustion, but not any more than that.

This will produce the highest efficiency, lowest emissions of

pollutants, and maintain a high level of safety. The question

is: How is the excess air setpoint determined?

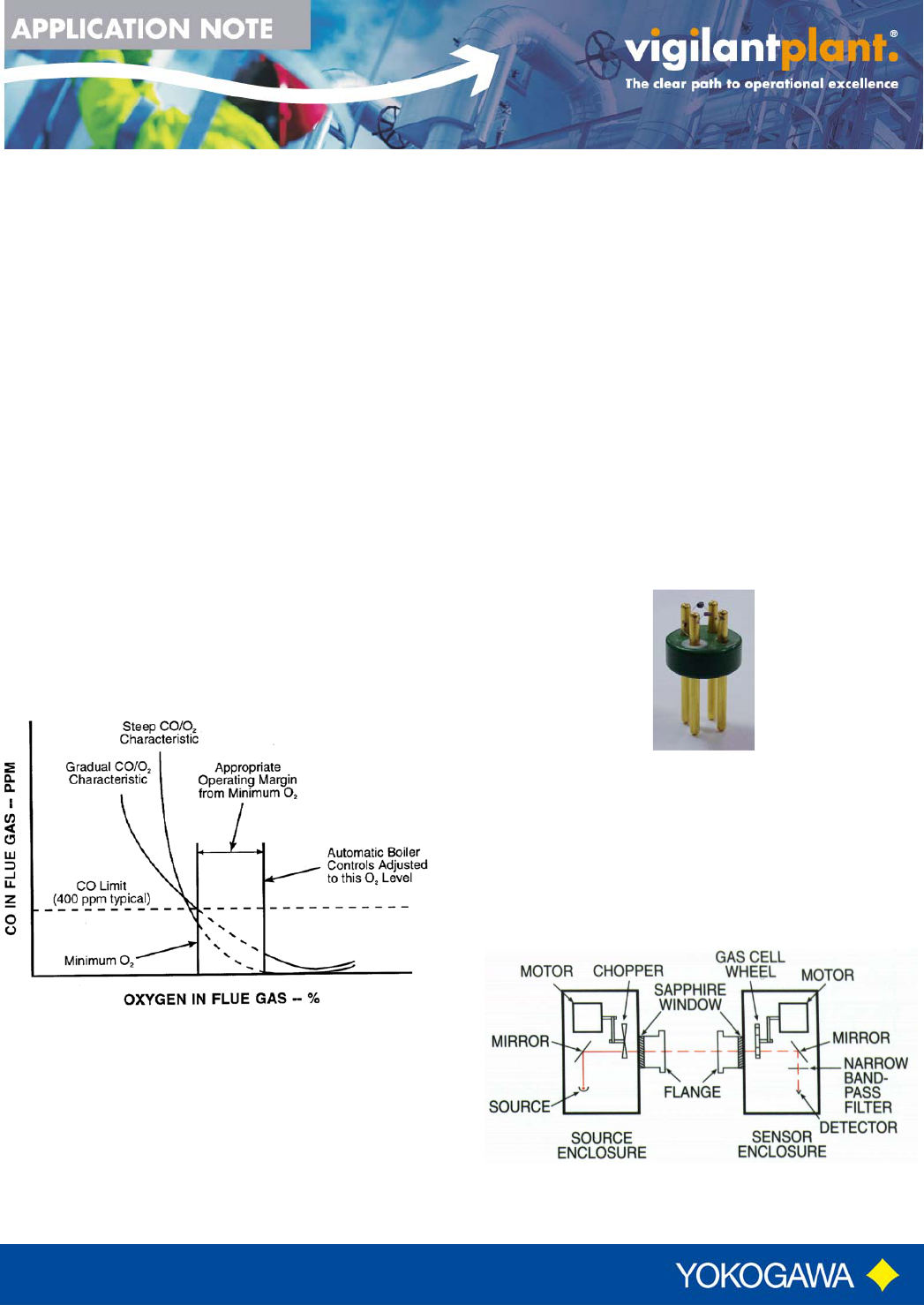

Using CO to trim excess O

2

The amount of excess air in the flue gas is determined by

measuring the concentration of oxygen (O

2

). The ideal

excess O

2

level (the lowest possible that allows complete

combustion) depends on several factors: the fuel type, the

burner type, humidity changes in the air, moisture content

changes in the fuel, varying boiler loads, fouling of the burner

system, and mechanical wear of combustion equipment.

Since many of these factors are continuously changing, the

ideal amount of excess oxygen continuously changes as

well. Measuring carbon monoxide (CO) can help to

determine the excess oxygen setpoint.

CO is the most sensitive indicator of incomplete combustion.

As the amount of excess O

2

is reduced, the emergence of

CO will occur before other combustibles appear (unburnt

fuel). When the concentration of CO reaches the desired

setpoint (typically around 400 ppm), the excess O

2

concentration is at the desired level and becomes the new

excess O

2

setpoint. As the concentration of CO increases or

decreases, the excess O

2

setpoint can be trimmed

accordingly. CO trim control of excess O

2

concentration

assures minimal energy loss, maximum efficiency, and

reduced NOx emissions independent of boiler load, fuel type,

humidity, moisture content of fuel and other variables that

make excess O

2

control difficult. The key to obtaining these

benefits is an accurate and reliable measurement of CO in

low ppm levels.

All Rights Reserved, Copyright © 2008, Yokogawa Corporation of America

Obstacles to Measuring CO in

Coal Fired Boilers

Measuring CO accurately and reliably in coal fired

applications has traditionally been extremely challenging.

Some of the obstacles that must be overcome:

- Flue gas laden with fly ash particulate

- High temperature in the optimal measuring location

- Stratification of gas concentrations

- Presence of SO

2

in the flue gas

- Speed of response in non-insitu installations

Current measuring technologies that are employed to

measure CO (or combustibles in general) are Catalytic Bead

sensors, Thick/Thin Film thermistors, and IR spectroscopy.

The Catalytic Bead and Thick/Thin Film thermistors utilize

the thermal properties of combustion to change the

resistance of an active element compared to that of an

inactive reference element. The active element is coated

with metal that acts as a catalyst for combustion when

exposed to air and a hydrocarbon. The other element is left

in a natural state without a coating to act as a reference

against background changes that would affect both elements

(i.e. process temp, gas thermal conductivity etc).

Combustion on the surface of the active bead increases the

temperature of the bead in effect raising its resistance. The

difference between the reference and active resistance

values is proportional to the concentration of combustibles in

the process gas.

Catalytic Bead Sensor

Infra-red Analyzers use an infrared source mounted directly

on the flue gas duct or stack on the side opposite from the

receiver. Infrared energy is radiated by the source, through

the flue gas, to the receiver. The receiver employs gas filter

correlation and narrow band pass optical filtration with a solid

state detector to determine the absorption of radiation by CO

in the flue gas. The magnitude of the absorption is

proportional to the concentration of CO in the flue gas.

Infrared Analyzer

These measuring technologies are prone to the following

problems:

- The catalytic sensors require sample extraction (not insitu)

installations. These sample extraction systems are prone to

plugging and fouling with fly ash in coal fired applications.

They require frequent preventative maintenance and the

filters they require cause slow response times.

All Rights Reserved, Copyright © 2008, Yokogawa Corporation of America

- The catalytic sensors are discreet or point measurements.

They do not provide a path or average measurement across

the firebox. They are subject to stratification errors, may not

detect isolated areas of CO breakthrough, and require

multiple points of installation to provide adequate coverage.

Flue Gas Stratification

- IR analyzers cannot make the measurement in particulate

laden (fly ash) flue gas. This combined with temperature

limitations prevents IR installation directly across the fire box.

They must be installed further down the process, at lower

temperatures after particulate removal (precipitators). This

introduces more lag time in detecting CO breakthrough.

Also CO that reacts after the fire box will not be detected

(CO quenching).

- IR analyzers are subject to interference from CO

2

and

water. Catalytic sensors are subject to interference from

NO

2

and water, and quickly deteriorate in the presence of

SO

2

. This mandates frequent calibrations, replacements,

and suspect accuracy.

These problems prevent these traditional measurement

technologies from providing an accurate and reliable CO

measurement.

Solution to Measuring CO in Coal

Fired Boilers

Tunable Diode Laser Spectroscopy (TDLS) manufactured by

Yokogawa Corporation of America has been proven in the

field to be a solution for this difficult measurement. Tunable

Diode Laser measurements are based on absorption

spectroscopy. The TruePeak Analyzer (TDLS200) is a TDLS

system and operates by measuring the amount of laser light

that is absorbed (lost) as it travels through the gas being

measured. In the simplest form a TDL analyzer consists of a

laser that produces infrared light, optical lenses to focus the

laser light through the gas to be measured and then on to a

detector. The detector and electronics that control the laser

then translate the detector signal into a signal representing

the CO concentration.

The TruePeak Analyzer utilizes powerful lasers that are

highly sensitive and selective for CO. This results in many

benefits over traditional IR analyzers and catalytic sensors:

- The TruePeak Analyzer measures CO directly in the fire

box. This means no lag time in detecting CO breakthrough

and no false low reading due to CO quenching after the fire

box.

- The TruePeak Analyzer measures CO insitu. There is no

extractive sample system induced maintenance or lag time.

- The TruePeak Analyzer is a path (across the fire box)

measurement. This provides an average reading that

ensures isolated areas of CO breakthrough are detected.

Multiple installations are not required.

- The powerful, selectable laser of the TruePeak Analyzer

penetrates fly ash and is sensitive to low ppm levels of CO.

Summary

Coal fired power plants can achieve the highest efficiency,

lowest emission levels, and ensure safety by using CO

concentration measurements to fine tune their excess O

2

setpoint. These benefits are achievable only if the CO

measurement is accurate and reliable. Using TDLS, the

TruePeak Analyzer from Yokogawa can provide that

accurate, reliable CO measurement in coal fired power

plants.

Product Recommendations

The TruePeak Analyzer- Model TDLS200

1. Source: Department of Energy Website (www.energy.gov)