Preface

Page 1

180/190/200 Horizon

Owners Manual

08/01

This manual will acquaint you with the use and maintenance of your new Four Winns® boat. This manual also

provides special information critical to the safety of the passengers, and longevity of the equipment. The

information on the following page lists the means used to increase the visibility of these important messages.

Also included in your owners packet is the Boating Basics, A Guide to Responsible Boating. This publication

covers the boating basics and should be read along with your Four Winns owners manual before operating your

boat. Review this information in detail.

Four Winns continually strives to improve its products. Unit specifications, including standard and optional

equipment are constantly being modified. Equipment availability is also subject to change. The most

current and accurate information available at the time of publication is included in this manual. Some

variation in equipment, description, location, and details can result.

The information in this manual focuses upon the equipment designed and manufactured by Four Winns on

specific models. When appropriate, please utilize the information pertinent to your specific boat model.

Equipment such as engines, and other accessories are manufactured by others. The information provided in

this manual is intended to be used in conjunction with the information provided by the manufacturers of this

equipment. All information available at the time of manufacture has been included with your owners packet.

Read this entire manual carefully before operating your new boat. Many instructions may require direct

performance of the activity to fully understand the correct method. If you choose to read this manual at home,

remember to take it to the boat with you.

Your Four Winns dealer knows your boat best and is interested in your complete satisfaction. Return to the

dealer for service or other assistance. If you find it necessary to contact Four Winns directly, please refer to the

address information listed below. Be sure to include the boat model, serial number, your daytime telephone

number, and specifics of the information desired.

This manual has been specifically developed for the 180 Horizon® (180H), 190 Horizon® (190H), and 200

Horizon® (200H) models. Please record the model and serial number information below.

Model Serial Number

________________________ __________________________

This manual should be considered part of the boat. Should you sell the boat, pass this manual on to the new

owner. Take special care of this manual. Certain information in this manual may not be available in a replace-

ment manual.

Thank you for joining the Four Winns family. We appreciate your purchase and welcome the opportunity to

demonstrate our commitment to you.

Four Winns Customer Service Department

925 Frisbie Street

Cadillac, Michigan 49601

231-775-1343 (Phone)

231-779-2345 (FAX)

E-Mail Address: [email protected]

© Four Winns, L.L.C. 2001. All Rights Reserved.

PREFACE

Preface

Page 2

180/190/200 Horizon

Owners Manual

08/01

SAFETY WARNINGS

This manual contains instructions critical to the safety of those aboard or the longevity of the equipment. Pay

close attention to all safety warnings. The following safety warnings and instructions are used throughout

the manual and at selected locations on your boat.

This safety symbol and this signal word indicate an imminently hazardous situation which, if not

avoided, WILL result in death or serious injury.

This safety symbol and this signal word indicate a potentially hazardous situation which, if not

avoided, CAN result in severe injury or death.

This safety symbol and this signal word indicate a potentially hazardous situation which, if not

avoided, MAY result in minor or moderate personal injury or property damage. It may also be used

to alert against unsafe practices.

NOTICE

This is used to notify people of installation, operation, or maintenance information which is important

but not hazard-related.

YOU are responsible for your own safety, as well as the safety of your passengers and fellow boaters.

You should fully understand and become familiar with the operating procedures and safety precau-

tions in this manual and any other information in the owners packet before you launch the boat.

Always operate your boat with consideration, courtesy, and common sense.

The warnings in this manual do not and can not address every conceivable situation. Always use common

sense! If you have any questions regarding your boat or its operation, contact your dealer.

The following page illustrates the locations of various warning labels, capacity label and other stickers on

your Four Winns® boat.

Preface

Page 3

180/190/200 Horizon

Owners Manual

08/01

LABEL LOCATIONS

The NMMA capacity label and various warning labels are placed at different locations on each model for your

safety. Additional warnings for fuel leakage, blower operation, and other important information will be im-

printed or located on the dash. Many of these stickers and labels are not required by the U.S. Coast Guard

but are important to ensure the safe operation of your Four Winns® boat. In addition, the Hull Identification

Number plate is permanently attached below the deck-hull joint on the starboard aft corner.

NOTICE

Not all of the warning label stickers are depicted in the following pages. Some of these labels

will be found on appliances i.e. microwave, one burner alcohol stove, dockside power cord.

Be sure to read and follow all manufacturers literature and warning label(s) relating to their

product(s). This literature is included in your owners packet.

Below are letters corresponding to the various locations for each item on the drawings. See pages 4 and 5

for the actual wording of each of the various warning labels found on your boat.

(A) Helm Boarding Ladder Warning (B) Boarding Ladder Warning

(C) Procedure Checklist (D) Equipment Checklist

(E) Capacity Label (F) Powered Ventilation for Gas Engines Label

(G) Ski Tow Warning (H) NMMA Certified

(I) Winning Edge Sticker (J) Armorcote Sticker

CD

IJ

H

F

B

E

A

G

Preface

Page 4

180/190/200 Horizon

Owners Manual

08/01

E. CAPACITY LABEL

NOTE:

WARNING

BEFORE STARTING ENGINE:

EQUIPMENT

DRAIN PLUG - SECURED?

MOVEABLE SEATS - SECURED?

LIFE JACKET - ONE FOR EACH PERSON?

OTHER EMERGENCY GEAR - ON BOARD?

PROCEDURES

EMERGENCY STOP SWITCH - TETHER

HOOKED UP?

EVERYBODY - SEATED IN BOAT? NEVER

ON SEAT BACKS, RAISED SEATS, OR

EDGES OF BOAT!

OPERATORS VISION - UNOBSTRUCTED?

WEATHER CONDITIONS - SAFE TO GO

OUT?

PASSENGERS - AWARE OF EMERGENCY

PROCEDURES?

C & D EQUIPMENT AND

PROCEDURES CHECKLIST

WARNING

DO NOT USE SKI TOW FITTING

FOR LIFTING OR PARASAILING.

FITTING COULD PULL OUT OF

DECK RESULTING IN SERIOUS

INJURY OR DEATH.

G. SKI TOW WARNING LABEL

A. HELM BOARDING LADDER WARNING LABEL

DANGER

SHUT OFF MOTOR WHEN NEAR

SWIMMERS. SEVERE INJURY OR

DEATH WILL RESULT FROM

CONTACT WITH A ROTATING

PROPELLER.

DANGER

NEVER APPROACH OR USE

LADDER WHEN MOTOR IS

RUNNING. SEVERE INJURY

OR DEATH WILL RESULT

FROM CONTACT WITH

ROTATING PROPELLER.

B. BOARDING LADDER WARNING LABEL

WARNINGS LABELS - LOCATIONS SHOWN ON PAGE 3.

WARNING

GASOLINE VAPORS CAN EXPLODE RESULTING

IN INJURY OR DEATH. BEFORE STARTING ENGINE

-CHECK ENGINE BILGE COMPARTMENT FOR

GASOLINE OR VAPORS, AND

-OPERATE BLOWER FOR FOUR MINUTES, AND

VERIFY BLOWER OPERATION.

RUN BLOWER WHEN VESSEL IS OPERATING BE-

LOW CRUISING SPEED.

F. POWERED VENTILATION FOR GAS ENGINES

H. NMMA CERTIFICATION STICKER

CAPACITY WILL VARY DEPENDING

UPON WHICH MODEL YOU HAVE.

Preface

Page 5

180/190/200 Horizon

Owners Manual

08/01

J. ARMORCOAT STICKER

I. WINNING EDGE STICKER

WARNING

NO VENTILATION IS PROVIDED.

FUEL VAPORS ARE A FIRE AND

EXPLOSION HAZARD. TO AVOID

INJURY OR DEATH, DO NOT STORE

FUEL OR FLAMMABLE LIQUIDS HERE.

L. NO VENTILATION WARNING LABEL

WARNING

CARBON MONOXIDE IS PRODUCED BY ALL

GASOLINE ENGINES AND GENERATOR SETS.

AVOID BRAIN DAMAGE OR DEATH FROM CARBON MONOXIDE.

KEEP COCKPIT AND CABIN AREAS WELL VENTILATED.

AVOID BLOCKAGE OF EXHAUST OUTLETS.

SIGNS IF EXPOSURE INCLUDE NAUSEA, DIZZINESS, AND DROWSINESS.

SEE BOAT OWNERS MANUAL FOR MORE DETAILS.

IF USING A CATALYTIC HEATER, PROVIDE VENTILATION.

DO NOT USE CATALYTIC HEATER WHILE SLEEPING.

M. CARBON MONOXIDE WARNING LABEL

WARNING

EXHAUST FUMES FROM ENGINES CONTAIN CARBON MONOXIDE.

BOATS WITH CANVAS DEPLOYED ARE MORE LIKELY TO COLLECT

EXHAUST FUMES. AVOID BRAIN DAMAGE OR DEATH FROM CARBON

MONOXIDE. KEEP COCKPIT AND CABIN AREAS WELL VENTILATED.

SIGNS OF EXPOSURE INCLUDE NAUSEA, DIZZINESS, AND DROWSINESS.

SEE BOAT OWNERS MANUAL FOR MORE DETAILS. IF USING A

CATALYTIC HEATER, PROVIDE VENTILATION. DO NOT USE CATALYTIC

HEATER WHILE SLEEPING.

N. CARBON MONOXIDE CANVAS WARNING LABEL

ADDITIONAL WARNINGS NOT SHOWN ON PAGE 3.

O. TRANSOM/SIDE DOOR WARNING LABEL

WARNING

PREVENT FALLS OVERBOARD.

CLOSE, LATCH, AND STAY

INSIDE GATE WHILE UNDERWAY.

WARNING

AVOID SERIOUS INJURY OR DEATH

FROM FIRE OR EXPLOSION RESULTING

FROM LEAKING FUEL. INSPECT SYSTEM

FOR LEAKS AT LEAST ONCE A YEAR.

K. LEAKING FUEL WARNING LABEL

Preface

Page 6

180/190/200 Horizon

Owners Manual

08/01

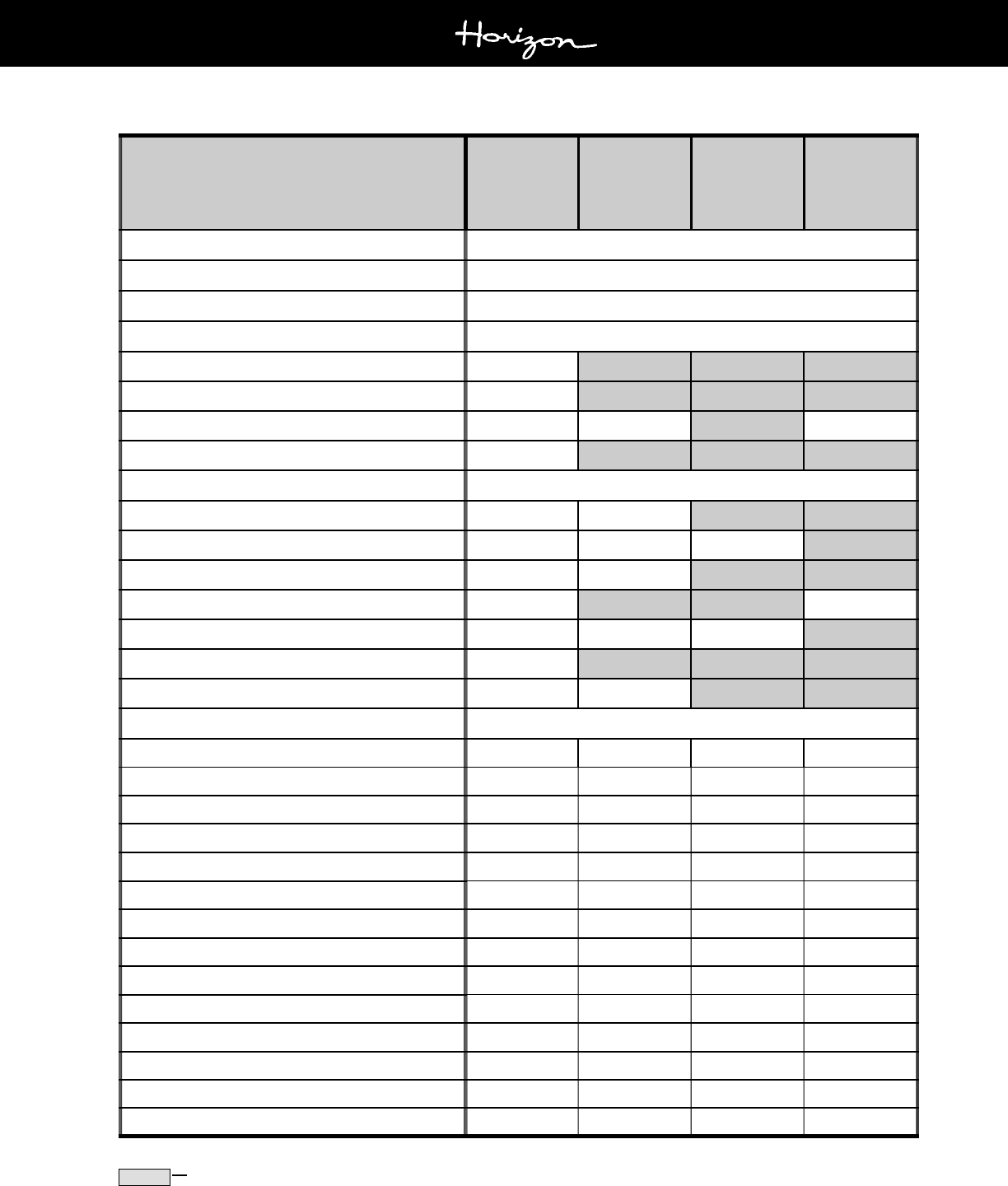

A. LOA

B. BEAM

C. KEEL TO W/S SHELF

D. TOTAL HEIGHT

E. TRANSOM ANGLE

F. DEAD RISE

G. OB TRANSOM HEIGHT

H. BRIDGE CLEARANCE

I. COCKPIT STERN HEIGHT

J. COCKPIT HEIGHT HELM

K. FREEBOARD

L. DRAFT

180 HORIZON SPECIFICATIONS

180 HORIZON

SPECIFICATIONS: US METRIC

LOA : 18’ 6" 5.64 m

LOA w/Extended Swim Platform 20’ 2" 6.15 m

Storage Length: 21’ 0" 6.40 m

Beam: 8’ 1" 2.46 m

Keel to Windshield Shelf: 45" 1.14 cm

Total Height: 4’ 10" 1.52 m

Total Height on Trailer 6’ 7" 1.96 m

Transom Angle: 15

o

15

o

Deadrise: 19

o

19

o

OB Transom Height 25" 64 cm

Bridge Clearance: 3’ 9" 1.14 m

Cockpit Height (Stern): 27" 69 cm

Cockpit Height (Helm): 29" 74 cm

Freeboard (Min): 26" 66 cm

Draft (Drive Down): 31" 79 cm

Draft (Drive Up): 14" 36 cm

Fuel: 38 gal 144 l

Passengers: 8 8

Maximum Capacity: 1300 lbs 590 kg

POWER RATINGS & WEIGHTS

Engine Type

Propshaft Power

HP KW

Boat & Engine Weights

LBS KG

4.3 GL/SX 190 142 2690 1220

5.0GL/SX 220 164 2790 1270

5.0GI/SX 250 187 2800 1270

Trailer Weight 780(S) / 880(T) LBS 354(S) / 399(T) KG

®

Preface

Page 7

180/190/200 Horizon

Owners Manual

08/01

A. LOA

B. BEAM

C. KEEL TO W/S SHELF

D. TOTAL HEIGHT

E. TRANSOM ANGLE

F. DEAD RISE

G. OB TRANSOM HEIGHT

H. BRIDGE CLEARANCE

I. COCKPIT STERN HEIGHT

J. COCKPIT HEIGHT HELM

K. FREEBOARD

L. DRAFT

190 HORIZON SPECIFICATIONS

190 HORIZON

SPECIFICATIONS: US METRIC

LOA : 19’ 6" 5.94 m

LOA w/Extended Swim Platform 21’ 2" 6.45 m

Storage Length: 21’ 9" 6.63 m

Beam: 8’ 5" 2.57 m

Keel to Windshield Shelf: 46" 1.17 cm

Total Height: 4’ 11" 1.50 m

Total Height on Trailer 6’ 7" 2.01 m

Transom Angle: 15

o

15

o

Deadrise: 19

o

19

o

Bridge Clearance: 3’ 9" 1.14 m

Cockpit Height (Stern): 28" 71 cm

Cockpit Height (Helm): 29" 74 cm

Freeboard (Min): 26" 66 cm

Draft (Drive Down): 32" 81 cm

Draft (Drive Up): 15" 38 cm

Fuel: 42 gal 159 l

Passengers: 9 9

Maximum Capacity: 1450 lbs 658 kg

POWER RATINGS & WEIGHTS

Engine Type

Propshaft Power

HP KW

Boat & Engine Weights

LBS KG

4.3 GL/SX 190 142 2860 1300

5.0GL/SX 220 164 2960 1340

5.0GI/SX 250 187 2970 1350

Trailer Weight 780(S) / 990(T) LBS 354(S) / 408(T) KG

®

Preface

Page 8

180/190/200 Horizon

Owners Manual

08/01

A. LOA

B. BEAM

C. KEEL TO W/S SHELF

D. TOTAL HEIGHT

E. TRANSOM ANGLE

F. DEAD RISE

G. OB TRANSOM HEIGHT

H. BRIDGE CLEARANCE

I. COCKPIT STERN HEIGHT

J. COCKPIT HEIGHT HELM

K. FREEBOARD

L. DRAFT

200 HORIZON SPECIFICATIONS

200 HORIZON

SP EC IFIC ATION S : U S M E TR IC

LOA : 20’ 6" 6.25 m

LOA w/Extended Swim Platform 22’ 3" 6.78 m

Storage Length: 22’ 2" 6.76 m

Beam: 8’ 6" 2.59 m

Keel to Windshield Shelf: 52" 1.32 cm

Total Height: 5’ 6" 1.68 m

Total Height on Trailer 7’ 0" 2.13 m

Transom Angle: 15

o

15

o

Deadrise: 19

o

19

o

Bridge Clearance: 4’ 3" 1.30 m

Cockpit Height (Stern): 30" 76 cm

Cockpit Height (Helm): 32" 81 cm

Freeboard (Min): 29" 74 cm

Draft (Drive Down): 34" 86 cm

Draft (Drive Up): 17" 43 cm

Fuel: 45 gal 170 l

Passengers: 11 11

Maximum Capacity: 1600 lbs 730 kg

POWER RATINGS & WEIGHTS

Engine Type

Propshaft Power

HP KW

Boat & Engine Weights

LBS KG

5.0GL/SX 220 164 3090 1400

5.0GL/DP 220 164 3110 1410

5.0GI/SX 250 187 3100 1410

5.0GI/DP 250 187 3120 1420

5.7GS/SX 250 187 3090 1400

5.7GS/DP 250 187 3110 1410

5.7SI/SX 280 209 3100 1410

5.7SI/DP 280 209 3120 1420

Trailer Weight 780(S) / 900(T) LBS 354(S) / 408(T) KG

®

Page 1

Table of Contents180/190/200 Horizon

Owners Manual

08/01

OPERATION ............................................................................................................................................. 1

A - 1 GENERAL .................................................................................................................. 1

A - 2 COMPONENT SYSTEMS ........................................................................................... 1

A - 3 SAFETY EQUIPMENT ................................................................................................ 1

A - 4 PASSENGER SAFETY ............................................................................................... 1

A - 5 RULES OF THE ROAD ............................................................................................. 1

A - 6 LIGHTNING ................................................................................................................. 1

A - 7 DRUGS AND ALCOHOL ............................................................................................. 2

A - 8 PRE-CRUISE SYSTEM CHECK .................................................................................. 2

A. Before Starting The Engines .............................................................................. 2

B. After Starting The Engine .................................................................................. 2

A - 9 ENGINE OPERATIONAL PROCEDURES ...................................................................... 2

A. Before Starting .................................................................................................. 2

B. Cold Engine Start (Carbureted Engines) ............................................................ 3

C. Warm Engine Starting ....................................................................................... 3

D. Shifting and Control Speed ............................................................................... 4

E. Stopping Engine ................................................................................................ 4

A - 10 GROUNDING AND TOWING ....................................................................................... 4

A - 11 BOATING EDUCATION ................................................................................................ 5

A. Boating Courses ................................................................................................ 5

B. Boating Manuals and Literature .......................................................................... 5

C. Charts and Maps ................................................................................................ 5

SAFETY EQUIPMENT .............................................................................................................................. 1

B - 1 GENERAL .................................................................................................................... 1

A. Required Safety Equipment .............................................................................. 1

B. Personal Floatation Devices (PFDs) ................................................................... 1

C. PFD Types ......................................................................................................... 1

D. PFD Pointers ..................................................................................................... 2

E. Emergency Stop Switch ..................................................................................... 2

F. Fire Extinguisher ................................................................................................ 3

G. Visual Distress Signal Devices ........................................................................... 3

H. Sound Signaling Devices .................................................................................... 4

I. Navigation Lights ................................................................................................ 4

J. Additional Recommended Equipment ................................................................. 4

B - 2 CARBON MONOXIDE ................................................................................................. 4

A. Properties and Characteristics of Carbon Monoxide ........................................... 5

B. What Makes Carbon Monoxide ......................................................................... 5

C. How a Person is Affected by Carbon Monoxide .................................................. 5

D. Effects of Carbon Monoxide .............................................................................. 5

E. Symptoms ....................................................................................................... 5

F. Treatment (Evacuate, Ventilate, Investigate, Take Corrective Action) ................... 6

G. Inspection ........................................................................................................ 6

H. Operation ......................................................................................................... 6

I. Boathouses, Sea Walls and Other Boats .......................................................... 6

J. Backdrafting (Station Wagon Effect) .................................................................. 7

TABLE OF CONTENTS

Table of Contents

Page 2

180/190/200 Horizon

Owners Manual

08/01

K. Cabin Appliances .............................................................................................. 8

L. Ventilation of Accommodation Spaces ................................................................ 8

M. Running of Engine in Idle .................................................................................... 8

N. Altitude and Sea Conditions .............................................................................. 8

O. Portable Generator Sets ................................................................................... 8

P. Maintenance - Engine Performance ................................................................... 8

Q. Maintenance - External Conditions .................................................................... 8

B - 3 SAFE BOATING PRACTICES ...................................................................................... 9

A. Drugs and Alcohol .............................................................................................. 9

B. Safe Operation ................................................................................................... 9

C. Passenger Safety ............................................................................................... 9

D. Propeller ............................................................................................................ 9

E. First Aid ............................................................................................................10

F. Operation By Minors .........................................................................................10

G. Rules of the Road ...........................................................................................10

H. Voluntary Inspection .........................................................................................10

I. Safe Boating Courses .......................................................................................10

B - 4 WATER SPORTS ........................................................................................................10

A. Water Sport Guidelines .........................................................................................10

B. Water Skiing ......................................................................................................... 11

BASIC SEAMANSHIP ................................................................................................................................ 1

C - 1 GENERAL ................................................................................................................... 1

A. Boating Regulations .......................................................................................... 1

B. Rules of Seamanship ........................................................................................ 1

C - 2 NAVIGATIONAL AIDS .................................................................................................. 3

A. International Association of Lighthouse Authorities System B (IALA-B) ............. 3

B. Lateral Markers .................................................................................................. 3

C. Safe Water Markers ........................................................................................... 3

D. The Uniform State Waterway Marking System ................................................... 4

E. A Special Sign .................................................................................................... 4

F. Noise ................................................................................................................. 4

C - 3 RECOMMENDED READING ....................................................................................... 4

C - 4 CONTACTS .................................................................................................................. 4

C - 5 OWNERS LOGS AND RECORDS .............................................................................. 5

C - 6 NAVIGATIONAL AIDS CHART ...................................................................................... 5

WARRANTY AND SERVICE ...................................................................................................................... 1

D - 1 FOUR WINNS WARRANTY POLICY .......................................................................... 1

D - 2 HULL STRUCTURE WARRANTY ................................................................................ 1

D - 3 WARRANTY REGISTRATION ..................................................................................... 1

D - 4 TRANSFER OF WARRANTY ...................................................................................... 1

D - 5 PRE-OWNED UNIT REGISTRATION ........................................................................... 1

D - 6 INSURANCE COVERAGE .......................................................................................... 2

D - 7 SERIAL NUMBER RECORD ....................................................................................... 2

D - 8 PRE-DELIVERY SERVICE ......................................................................................... 2

D - 9 REPLACEMENT PARTS ............................................................................................. 2

D - 10 WINNGEAR ............................................................................................................ 2

Page 3

Table of Contents180/190/200 Horizon

Owners Manual

08/01

ENGINES AND INSTRUMENTATION ......................................................................................................... 1

E - 1 GENERAL .............................................................................................................................. 1

E - 2 ENGINE EXHAUST ................................................................................................................ 1

E - 3 ENGINES ............................................................................................................................... 2

E - 4 PROPELLERS ....................................................................................................................... 2

A. Diameter .......................................................................................................................... 2

B. Pitch ................................................................................................................................ 2

C. Prop Slip ......................................................................................................................... 2

E - 5 RUNNING ANGLE & POWER TRIM/TILT ................................................................................. 3

A. Power Trim ...................................................................................................................... 3

B. Power Tilt ........................................................................................................................ 3

E - 6 ENGINE INSTRUMENTATION ................................................................................................. 3

A. Tachometer ...................................................................................................................... 4

B. Speedometer ................................................................................................................... 4

C. Temperature Gauge .......................................................................................................... 4

D. Oil Pressure Gauge ......................................................................................................... 5

E. Voltmeter ......................................................................................................................... 5

F. Fuel Gauge ...................................................................................................................... 5

G. Power Trim Gauge ........................................................................................................... 5

H. Four Winns/VDO Module Display Settings ........................................................................ 5

I. Ignition Switch ................................................................................................................. 7

J.. Emergency Stop Switch ................................................................................................... 7

K. Engine Hour Meter ........................................................................................................... 8

L. Alarm Systems ................................................................................................................ 8

M. Instrument Maintenance ................................................................................................... 8

N. VDO Module Quick Start Card ........................................................................................... 9

CONTROL SYSTEMS ............................................................................................................................... 1

F - 1 GENERAL .............................................................................................................................. 1

F - 2 CONTROL OPERATION ......................................................................................................... 1

A. Carbureted Engines .......................................................................................................... 1

B. Fuel Injected Engines (EFI) ............................................................................................... 2

F - 3 NEUTRAL SAFETY SWITCH .................................................................................................. 2

F - 4 CONTROL SYSTEM MAINTENANCE ..................................................................................... 2

STEERING SYSTEMS ............................................................................................................................... 1

G - 1 GENERAL .............................................................................................................................. 1

A. Rotary Steering ................................................................................................................ 1

B. Tilt Steering ...................................................................................................................... 1

C. Power Steering ................................................................................................................. 1

G - 2 PROPELLER TORQUE .......................................................................................................... 2

G - 3 STEERING SYSTEM MAINTENANCE .................................................................................... 2

A. General Maintenance ....................................................................................................... 2

B. Rotary System Maintenance ............................................................................................ 2

C. Winter Storage ................................................................................................................. 3

Table of Contents

Page 4

180/190/200 Horizon

Owners Manual

08/01

ELECTRICAL SYSTEMS ........................................................................................................................... 1

H - 1 GENERAL .............................................................................................................................. 1

H - 2 BATTERY SYSTEM ............................................................................................................... 1

A. Single Battery System ..................................................................................................... 1

H - 3 12 VOLT ELECTRICAL EQUIPMENT ...................................................................................... 1

A. Helm Equipment .............................................................................................................. 1

B. Installation of Additional 12 Volt Equipment ....................................................................... 2

C. Interior Equipment ............................................................................................................ 2

H - 4 ELECTRICAL SYSTEM MAINTENANCE ................................................................................. 3

A. Battery Maintenance ........................................................................................................ 3

B. Electrical Wiring Maintenance .......................................................................................... 3

H - 5 STRAY CURRENT CORROSION ............................................................................................ 4

A. General ............................................................................................................................ 4

B. Galvanic Corrosion ........................................................................................................... 5

C. Corrosion Prevention ........................................................................................................ 5

FUEL SYSTEMS ....................................................................................................................................... 1

I - 1 GASOLINE FUEL SYSTEMS ................................................................................................. 1

A. System Testing ................................................................................................................ 1

B. Fuel Fills ......................................................................................................................... 1

C. Anti-Syphon Valves .......................................................................................................... 2

D. Fuel Gauge ...................................................................................................................... 2

E. Fuel Senders ................................................................................................................... 2

F. Fuel Filters ...................................................................................................................... 3

G. Use and Maintenance ...................................................................................................... 3

I - 2 FUEL STANDARDS ................................................................................................................ 3

A. Problems With Alcohol in Gasoline ................................................................................... 3

B. Recommendations ........................................................................................................... 4

I - 3 FUELING INSTRUCTIONS ...................................................................................................... 4

VENTILATION AND DRAINAGE SYSTEMS .............................................................................................. 1

J - 1 ENGINE COMPARTMENT VENTILATION ............................................................................... 1

A. Gravity Ventilation System ............................................................................................... 1

B. Forced Air Ventilation ....................................................................................................... 1

C. Engine Ventilation System Maintenance ........................................................................... 1

J -2 HULL DRAINAGE SYSTEMS ................................................................................................. 1

A. Transom Drain ................................................................................................................. 1

B. Bilge Pumps .................................................................................................................... 1

C. Liner Drains ..................................................................................................................... 2

D. Bilge Compartment Drainage ............................................................................................ 2

INTERIOR EQUIPMENT ............................................................................................................................ 1

K - 1 GLOVE BOX .......................................................................................................................... 1

K - 2 BUILT-IN COOLER ................................................................................................................. 1

K - 3 STEREO ................................................................................................................................ 1

K - 4 CHERRY HELM ENHANCEMENTS ....................................................................................... 1

K - 5 ANCHOR LOCKER STORAGE .............................................................................................. 2

K - 6 SKI STORAGE LOCKER ....................................................................................................... 2

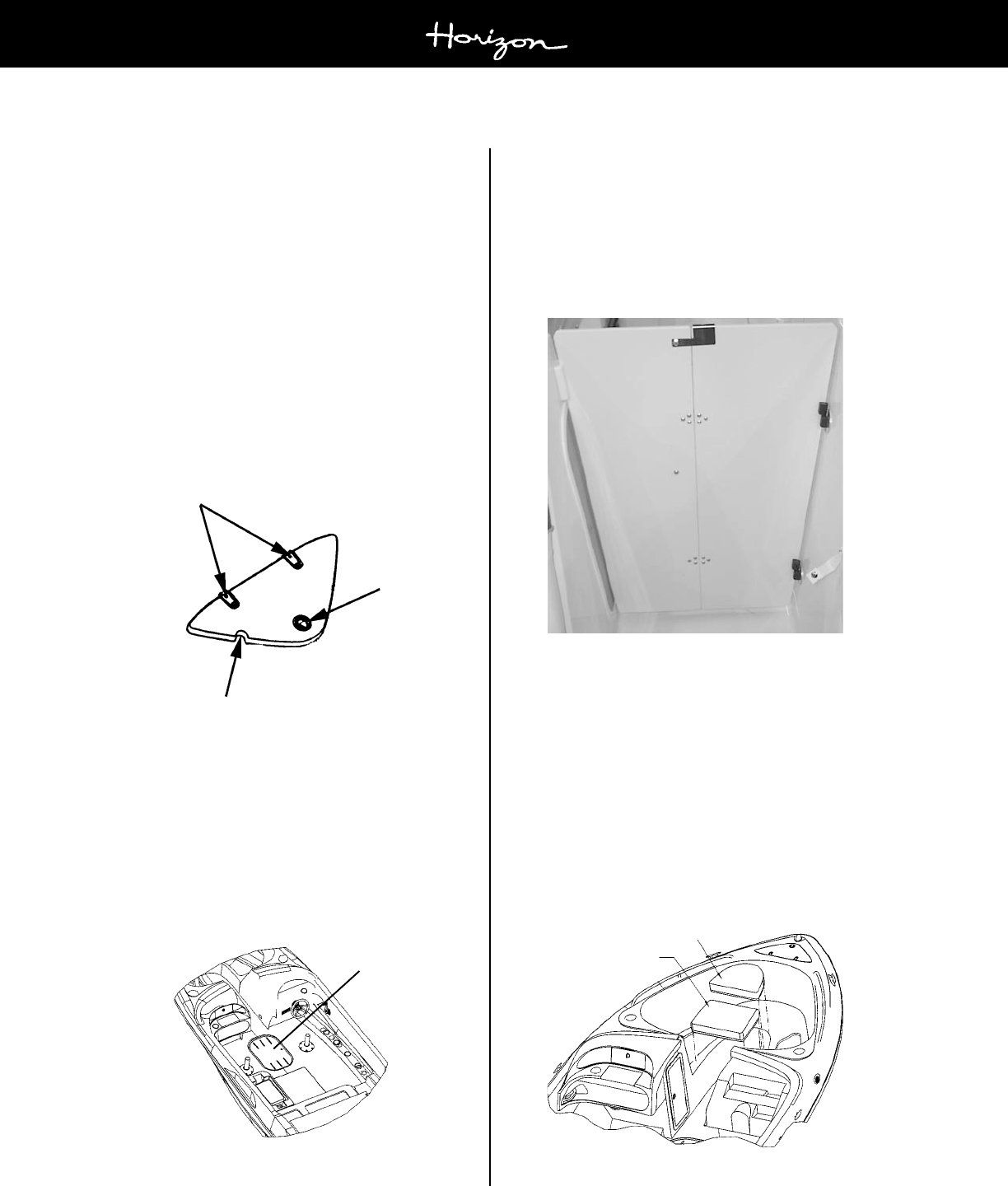

K - 7 WALK-THRU DOORS ............................................................................................................ 2

Page 5

Table of Contents180/190/200 Horizon

Owners Manual

08/01

K - 8 BOW FILL-IN CUSHIONS ...................................................................................................... 2

K - 9 WALK-THRU STORAGE LOCKERS ...................................................................................... 3

EXTERIOR EQUIPMENT ........................................................................................................................... 1

L - 1 RAILS & DECK HARDWARE ................................................................................................. 1

A. Rails ................................................................................................................................ 1

B. Cleats .............................................................................................................................. 1

C. Stern Rail with Tow Ring .................................................................................................. 1

D. Maintenance ...................................................................................................................... 1

L - 2 WINDSHIELDS ...................................................................................................................... 1

L - 3 SWIM PLATFORM - STERN LADDER ................................................................................... 2

L - 4 ADD-ON SWIM PLATFORM OPTION .................................................................................... 2

L - 5 ANCHOR & ANCHORING ...................................................................................................... 3

L - 6 DEPTHSOUNDER ................................................................................................................... 4

L - 7 WAKE BOARD TOWER OPTION ............................................................................................ 4

UPHOLSTERY .......................................................................................................................................... 1

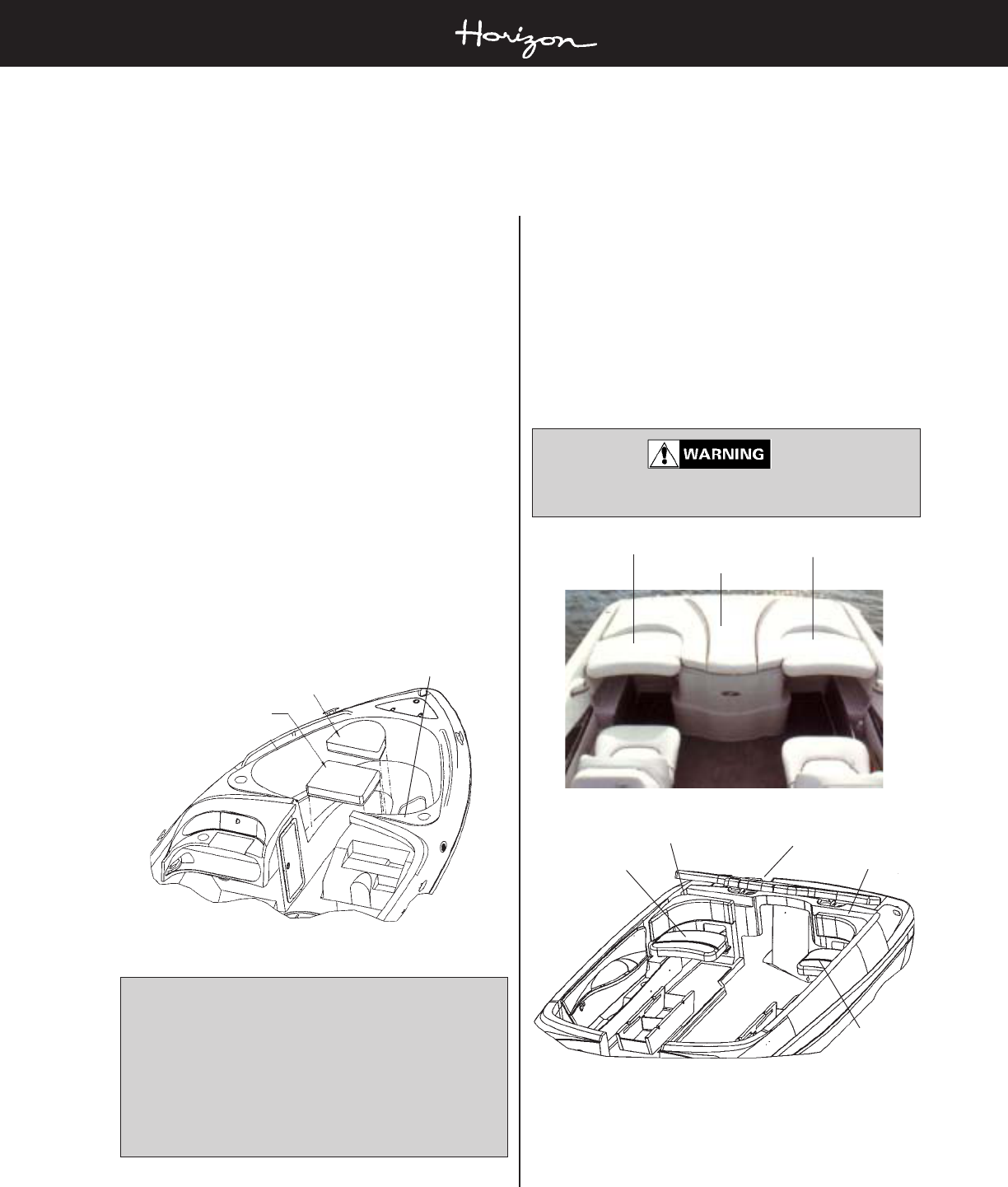

M - 1 EXTERIOR SEATING ............................................................................................................. 1

A. Cockpit Tables ................................................................................................................. 1

B. Bow Seating .................................................................................................................... 1

C. Jump Seats ..................................................................................................................... 1

D. Lounger ........................................................................................................................... 2

E. Top Storage ....................................................................................................................... 2

F. Bucket Seats (Sunsport Seating Option) ......................................................................... 3

G. Sundeck (Sunsport Seating Option)................................................................................... 4

I. Sunsport Couch ................................................................................................................. 4

M - 2 EXTERIOR UPHOLSTERY CARE ........................................................................................... 4

M - 3 REPLACEMENT UPHOLSTERY ............................................................................................ 5

M - 4 CARPET CARE ..................................................................................................................... 5

A. Interior and Exterior Carpet ............................................................................................... 5

B. Cleaning and Maintenance ............................................................................................... 5

C. Stain Removal Testing ...................................................................................................... 6

D. Stain Removal Procedures ............................................................................................... 6

WEATHER COVERS ................................................................................................................................. 1

N - 1 GENERAL INFORMATION ..................................................................................................... 1

A. Convertible Top (Suntop) .................................................................................................. 1

B. Side Curtains ................................................................................................................... 2

C. Aft Curtains ..................................................................................................................... 2

D. Forward Cover .................................................................................................................. 2

E. Bimini Top (Southwest) ...................................................................................................... 2

F. Cockpit Cover .................................................................................................................... 3

G. Mooring Cover ................................................................................................................... 3

N - 2 TRAILERING .......................................................................................................................... 4

N - 3 WINTER STORAGE ............................................................................................................... 4

N - 4 MAINTENANCE ..................................................................................................................... 4

N - 5 USE OF WEATHER COVERS AND CARBON MONOXIDE .................................................... 5

Table of Contents

Page 6

180/190/200 Horizon

Owners Manual

08/01

FIBERGLASS AND HULL INFORMATION ................................................................................................ 1

O - 1 HULL DESIGN INFORMATION ................................................................................................ 1

O - 2 FIBERGLASS CONSTRUCTION ............................................................................................. 1

O - 3 EQUIPMENT INSTALLATION .................................................................................................. 1

O - 4 FIBERGLASS CARE & MAINTENANCE ................................................................................. 2

A. General Maintenance ....................................................................................................... 2

B. Weathering Effects on Gel Coat ....................................................................................... 2

C. Stains .............................................................................................................................. 3

O - 5 FIBERGLASS REPAIRS ........................................................................................................ 3

A. Scratches ........................................................................................................................ 4

B. Gouges & Cracks ............................................................................................................ 4

C. Osmotic Blistering ........................................................................................................... 5

O - 6 ANTIFOULING PAINT ............................................................................................................. 5

O - 7 HULL SUPPORT .................................................................................................................... 5

WOODWORK AND COMPOSITES ........................................................................................................... 1

P - 1 HIGH-PRESSURE LAMINATE CARE ..................................................................................... 1

P - 2 STAR BOARD ........................................................................................................................ 1

P - 3 CHERRY ENHANCEMENTS ................................................................................................. 1

GENERAL MAINTENANCE ....................................................................................................................... 1

Q - 1 WINTERIZATION .................................................................................................................... 1

A. Prior to Lifting for Winter Lay-up ....................................................................................... 1

B. After Lifting ....................................................................................................................... 1

C. Prior to Winter Storage ..................................................................................................... 1

Q - 2 ENGINE FLUSH OUT ............................................................................................................. 2

Q - 3 GENERAL MAINTENANCE SCHEDULE ................................................................................. 3

TRAILERS ................................................................................................................................................ 1

R - 1 GENERAL TRAILER INFORMATION ...................................................................................... 1

A. Regulations ...................................................................................................................... 1

B. Load Carrying Capacity ..................................................................................................... 1

C. Hitches ............................................................................................................................. 2

R - 2 TRAILER COMPONENTS ....................................................................................................... 2

A. Bunk Supports .................................................................................................................. 2

B. Tongue .............................................................................................................................. 2

C. Swivel Jack ....................................................................................................................... 3

D. Coupling Assembly ........................................................................................................... 4

E. Surge Disc Brakes ............................................................................................................ 4

F. Winch ............................................................................................................................... 5

G. Wheels ............................................................................................................................. 6

H. Spare Tire Carrier ............................................................................................................. 6

I. Lights .............................................................................................................................. 7

J. Tie-downs ......................................................................................................................... 7

R - 3 OPERATION .......................................................................................................................... 8

A. Hitching Trailers ............................................................................................................... 8

B. Backing Up With Surge Disc Brakes ................................................................................ 9

Page 7

Table of Contents180/190/200 Horizon

Owners Manual

08/01

R - 4 TRAILERING ........................................................................................................................ 10

A. Checklist ....................................................................................................................... 10

B. Tactics ........................................................................................................................... 10

R - 5 MAINTENANCE .................................................................................................................... 11

A. Care of Exterior Finish .................................................................................................... 11

B. Bunks ............................................................................................................................. 11

C. Swivel Jack ..................................................................................................................... 11

D. Brake Actuator & Coupling Assembly .............................................................................. 11

E. Winch ............................................................................................................................. 11

F. Lights ............................................................................................................................. 11

G. Tie-downs ....................................................................................................................... 12

H. Wheels ........................................................................................................................... 12

I. Brakes ............................................................................................................................ 12

J. Bearings ......................................................................................................................... 12

R - 6 AXLE INSPECTION & REPAIRS ............................................................................................ 12

A. Removal of Hub .............................................................................................................. 13

B. Bearing/Seal Inspection and Replacement ...................................................................... 13

C. Hub Reinstallation .......................................................................................................... 13

GLOSSARY ......................................................................................................................................... 1

FLOAT PLAN ........................................................................................................................................... 1

FUEL LOG ................................................................................................................................................ 1

SERVICE LOG .......................................................................................................................................... 1

SERVICE INFORMATION ......................................................................................................................... 1

ELECTRICAL SCHEMATICS ..................................................................................................................... 1

Section A

Page 1

180/190/200 Horizon

Owner’s Manual

08/01

A - 1 GENERAL

Before starting the boat, become familiar with all of the

various systems and related operations. Be sure all

necessary safety equipment is on-board. Know the “Rules

of the Road”. Have an experienced operator brief you on

the general operation of your new boat. Perform a “Pre--

Cruise Systems Check”. This manual is a part of your

boat’s equipment. Always keep it on board.

A - 2 COMPONENT SYSTEMS

Before you can really enjoy your boat, a thorough under-

standing of its systems and their operation is essential.

This manual and the associated manufacturers informa-

tion are included in the owner’s packet. This informa-

tion is provided to enhance your knowledge of the boat.

Read this information carefully.

After becoming familiar with the boat and its systems,

reread this manual. Maintenance and service tips are

included to help keep the boat in like-new condition.

A - 3 SAFETY EQUIPMENT

Besides the equipment installed on the boat by

Four Winns, L.L.C., certain other equipment is required

for passenger safety. A brochure listing the Federal equip-

ment requirements is included in the owner’s packet or

is available through your local U.S. Coast Guard Sta-

tion. Remember that these laws are for your protection

and are minimum requirements. Check your local and

state regulations, also.

Items like a sea anchor, working anchor, extra dock lines,

flare pistol, a line permanently secured to your ring buoy,

etc. could at some time save your passengers lives, or

save your boat from damage.

The Coast Guard Auxiliary offers a “Courtesy Examina-

tion.” This inspection will confirm the boat is equipped

with all of the necessary safety equipment.

A - 4 PASSENGER SAFETY

You are responsible for the safety of your passengers as

well as for their behavior while aboard. Make sure:

1. Each passenger is properly instructed in Personal

Flotation Device (PFD) use and keeps one within

reach in case of emergency. All nonswimmers and

children should wear a PFD at all times when under-

way.

2. Passengers do not sit on gunwales, open decks, el-

evated pedestal seats or on seat backs when the

boat is underway. This could cause them to be thrown

overboard during a sudden maneuver.

3. At least one other person knows how to operate the

boat in case of an emergency.

A - 5 “RULES OF THE ROAD”

As in driving an automobile, there are a few rules that

must be known if safe boating operation is to be main-

tained. The Coast Guard, Coast Guard Auxiliary, Depart-

ment of Natural Resources or your local boat club spon-

sor courses in boat handling, including “rules of the road”.

Such courses are strongly recommended. Books on this

subject are also available from local libraries.

A - 6 LIGHTNING

When boating, it is important to be aware of the weather

around you. When the weather changes for the worse,

DO NOT jeopardize your safety by trying to “ride out the

storm”. If possible, return to safe harbor and dock your

vessel immediately.

If caught in a storm, seek shelter inside the cabin and

wait for the storm to pass. With open bow models, suntops

and campers will provide some protection, but should not

be relied on if you are able to return to shore. Exercise

care when high winds are present!

OPERATION

Section A

Page 2

180/190/200 Horizon

Owner’s Manual

08/01

DO NOT swim or dangle legs or arms into the

water during a lightning storm. Stay out of the

water!

Lightning will seek a ground when it strikes. Avoid con-

tact with metal parts such as bow rails, control handle, or

windshield.

A - 7 DRUGS AND ALCOHOL

Please keep in mind that along with the fun of boating

comes responsibility. As the owner or operator of a plea-

sure boat, you are obligated (morally and legally) to use

good judgement while underway in providing for the safety

and well-being of your passengers and other boaters

around you.

A common and flagrant violation of good judgement and

the law by mariners involves the use of alcohol or drugs.

Each year, about half of all accidents involving fatalities

involve the use of alcohol or drugs.

It is a federal offense to operate a boat while intoxicated.

Criminal penalties may include the termination of operat-

ing privileges for up to one year. Many states have passed

similar laws.

Alcohol or drugs have an inhibiting effect on the judge-

ment and reaction time of the boat operator and his/her

passengers. Heed the advice of experts and statisti-

cians...DO NOT drink or use drugs when operating a boat.

NEVER allow an obviously intoxicated person to take the

helm.

Have fun in your Four Winns® boat, but also have the

good sense to be mentally alert and physically capable

of operating the boat in a safe manner.

A - 8 PRE-CRUISE SYSTEM CHECK

Before leaving the dock, the following items should be

checked:

A. Before Starting The Engine

1. Check the weather forecast. Determine if the cruise

planned can be made safely.

2. Be sure all necessary safety equipment is on board

and operative. This includes items such as the run-

ning lights, horn, spotlight, life saving devices, etc.

3. Check the bilge water level and bilge pump opera-

tion. Check the engine and drive fluid levels. Look

for other signs of potential problems. Check for the

scent of fuel fumes.

4. Activate the Bilge Blower. Check the blower output.

Gasoline vapors can explode resulting in injury

or death. Before starting the engine, check

engine compartment bilge for gasoline or vapors.

Operate blower for four minutes, and verify blower

operation. ALWAYS run the blower when the

vessel is operating below cruising speed.

5. Ensure an adequate amount of fuel is on board.

6. Be sure you have sufficient water and other provi-

sions on board for the cruise planned.

7. Leave a written message listing details of the planned

cruise with a close friend ashore.

B. After Starting The Engine

1. Visibly check the engine to be sure there are no ap-

parent water or oil leaks.

2. Check the gauges. Make sure the oil pressure, wa-

ter temperature, voltmeter, etc. are reading normally.

3. Have a safe cruise and enjoy yourself.

Always be sure to raise and secure the anchor

prior to operating your boat. Failure to raise

and secure anchor before getting underway

could result in damage to boat and even severe

injury or death from a rebounding anchor.

A - 9 ENGINE OPERATIONAL PROCEDURES

A. Before Starting

1. Check the engine compartment for water, gas, and/

or oil leaks of any kind. Keep the bilge in a clean

condition to prevent blower and bilge pump damage,

and fire hazards.

Section A

Page 3

180/190/200 Horizon

Owner’s Manual

08/01

2. Check the fluid levels of the engine oil and power

steering system daily. Fill oil or steering fluid as re-

quired by the indications on the dip sticks. Refer to

the Table 1: “SAE Viscosity Chart” and your engine

manual included in the owner’s packet. DO NOT

USE MULTIGRADE OIL. Power steering and power

trim use automatic transmission fluid. Check the

fluid levels in the vertical drive units or transmission

as often as practical.

Table 1: SAE Viscosity Chart

3. Start and operate the bilge blower system for at least

four (4) minutes before start-up.

4. Lower the vertical outdrive units (on applicable mod-

els) making sure the water intakes are under the water.

B. Cold Engine Start (Carbureted Engines)

1. The engine may require priming prior to starting. To

prime the engine, proceed as follows:

a. Place ignition switch in the OFF position.

b. Disengage shift mechanism.

c. Move control handle to the full throttle position;

this operates accelerator pump and primes the

engine.

d. Repeat priming, if necessary.

e. Return the control handle to fast idle position.

2. Turn key switch to START position and hold until

engine starts. DO NOT hold in START position for

more than ten seconds. In colder weather, more prim-

ing may be necessary. However, too much priming

may flood engine.

IF THE LOWEST

ANTICIPATED

TEMPERATURE IS*

THE FOLLOWING

SAE VISCOSITY OILS

ARE RECOMMENDED

32

O

F (0

o

C) and above

SAE 30

0

O

F (-18

O

C) to 32

O

F (0

O

C)

SAE 20W-20

Below 0

O

F (-18

O

C)

SAE 10W

*Temperature range you expect to operate.

Note: Use only single viscosity oils.

If engine floods:

• Disengage shift. Move handle to full throttle position.

• Turn key switch to the START position.

• Immediately move the control handle to the idle posi-

tion when the engine starts.

NOTICE

Failure to move the control handle to the idle

position immediately when engine starts will al-

low engine to “over-rev” and engine damage could

result. “Over-revving” engine after off-season stor-

age could also damage the water pump impeller.

When starting engine for the first time after

off-season storage, always idle engine for

one minute to allow the water pump to

prime.

3. As soon as engine starts:

a. Release key to the ON or RUN position.

b. Move control handle to the fast idle position to

warm up engine. DO NOT exceed 1000 RPM.

NOTICE

Cold engine starting procedures are different for

EFI engines. Priming is not necessary. Refer to

the engine owner’s manual for additional informa-

tion.

C. Warm Engine Starting

1. Move control handle to the neutral detent position.

2. Turn key switch to START position and hold until

engine starts, but DO NOT hold in start position for

more than ten seconds. If engine does not start, let

go momentarily, then try again.

3. As soon as engine starts, release key to the ON or

RUN position.

NOTICE

NEVER turn key to START position when en-

gine is running.

NOTICE

Warm engine starting procedures are different

for EFI engines. Refer to the engine owner’s

manual for additional information.

Section A

Page 4

180/190/200 Horizon

Owner’s Manual

08/01

D. Shifting and Control Speed

NOTICE

If your boat is equipped with a non-OEM remote

control system, ask your dealer how to properly

operate it.

1. Move control handle to the neutral detent (idle) posi-

tion. This will engage neutral start switch and allow

engine to start.

DO NOT shift into FORWARD or REVERSE un-

less engine is running. Damage to the shift sys-

tem could result from trying to shift without the

engine running. Carefully check function of all

control and engine systems before leaving the

dock.

2. To go FORWARD - actuate the neutral lock mecha-

nism and briskly move the shift handle forward. Throttle

movement will begin after forward gear engagement.

3. To go in REVERSE - actuate the neutral lock mecha-

nism and briskly move the shift handle rearward.

Throttle movement will begin after reverse gear en-

gagement.

DO NOT shift from forward to reverse when the

boat is planing.

NOTICE

DO NOT shift if engine speed is above 800 RPM.

4. To go from FORWARD to REVERSE, or REVERSE

to FORWARD; always pause at NEUTRAL and allow

engine speed to return to idle.

5. After shifting is completed, continue to move the con-

trol handle slowly in the desired direction to increase

speed.

Any time the boat is operated, be aware of

changes in shift system operation. A sudden

increase in shift effort at the remote control

handle, or other abnormal operation, indicates

a possible problem in the shift system. If this

occurs, the following precautions must be taken:

• With engine running and boat securely tied

to the dock, shift drive into forward and re-

verse to ensure there is gear engagement.

• When docking the boat, all docking maneu-

vers must be performed at slow speed. Pay

special attention to other boaters. Passen-

gers should be informed of potential prob-

lems and precautions taken.

If you suspect there is a problem, see your engine

manufacturer’s certified service dealer or Four Winns

dealer as soon as possible for proper diagnosis and re-

quired service or adjustment. Continued operation could

result in damage to the shift mechanism and loss of con-

trol.

E. Stopping Engine

1. Move control handle to the NEUTRAL position.

2. Turn ignition key to the OFF position.

NOTICE

DO NOT stop engine at speeds above idle or

“speed up” engine while turning off ignition.

Engine damage could result.

A - 10 GROUNDING AND TOWING

If the boat should become disabled, or if assist-

ing another craft that is disabled, great care must

be taken. The stress applied to a boat during

towing may become excessive. Excessive

stress can damage the structure of the boat and

create a safety hazard for those aboard.

Section A

Page 5

180/190/200 Horizon

Owner’s Manual

08/01

Four Winns® boats are not designed nor intended to be

used as a towing vessel. The mooring cleats on

Four Winns® boats are not designed or intended to be

used for towing purposes. These cleats are specifically

designed as mooring cleats for securing the boat to a

dock, pier, etc. DO NOT use these fittings for towing or

attempting to free a grounded vessel.

Freeing a grounded vessel or towing a boat that is dis-

abled requires specialized equipment and knowledge.

Line failure and structural damage caused by improper

towing have resulted in fatal injuries. Because of this,

Four Winns strongly suggests that these activities be

left to those who have the equipment and knowledge,

such as the U.S. Coast Guard or Sea Tow, to safely

accomplish the towing task.

Running aground can cause serious damage to

a boat and associated underwater gear. If the

boat should become grounded, distribute per-

sonal flotation devices and inspect the boat for

possible damage. Thoroughly inspect the bilge

area for signs of leakage. An experienced ser-

vice facility should check the hull and underwater

gear at the first opportunity. DO NOT continue

to use the boat if the condition of the hull or un-

derwater equipment is questionable.

If towing or being towed is absolutely necessary, use the

strongest lines available, and attach them to the bow

eyes or stern eyes only. Have all passengers slip on life

jackets and take a seat in the cabin or other protected

area.

Lines can snap or other hardware can be loos-

ened or broken while towing. Under certain con-

ditions, this can cause severe injury or fatality.

A - 11 BOATING EDUCATION

A. Boating Courses

Boating education classes are offered throughout the

country. The United States Coast Guard Auxiliary offers

free courses on different topics usually during the off-

season. The most popular course is the “Boating Skills

& Seamanship Course,” and information can be obtained

by calling 1-800-336-BOAT.

The United States Power Squadron also offers free courses

ranging from basic seamanship to celestial navigation.

For information, contact your local Power Squadron, or

write: U.S.P.S., P.O. Box 30423, Raleigh, NC 27622.

The Red Cross offers power boating and canoeing classes.

Contact: Director of Water Safety, American National Red

Cross, 17th & D Streets N.W., Washington, DC 20006.

The Canadian Power and Sail Squadron offers seaman-

ship courses. Information can be obtained by calling

1-800-268-3579 (Canada only).

B. Boating Manuals and Literature

A good source of information is the U.S. Coast Guard’s

home study book called “The Skipper’s Course”. This

book may be purchased through: Superintendent of Docu-

ments, U.S. Government Printing Office, Washington, DC

20402, Stock # 050-012-00159-6.

Another good source of boating information is Chapman’s

“Piloting, Seamanship and Small Boat Handling”. Also,

check the local library or bookstore for additional informa-

tion on boating.

C. Charts and Maps

U.S. nautical charts are sold throughout the country at

Governmental Printing Office stores and other agents. A

chart catalog is available by writing to: National Oceanic

and Atmospheric Administration, National Ocean Survey,

Rockville, MD 20852.

In addition, many federal agencies publish recreational

maps, including the U.S. Army Corp. of Engineers, the

Forest Service, the National Park Service, and the Ten-

nessee Valley Authority.

Addresses of all state boating agencies are listed in “A

Boater’s Guide”. For a free copy, write to: National Ma-

rine Manufacturers Association, 401 N. Michigan Avenue,

Chicago, IL 60611.

Section B

Page 1

180/190/200 Horizon

Owner’s Manual

08/01

B - 1 GENERAL

As the owner/operator of the boat, you are responsible

for assuring that all required safety equipment is aboard.

You should also consider supplying additional equipment

as needed for your safety and that of your passengers.

Check state and local regulations and call the U.S. Coast

Guard Boating Safety Hotline at 1-800-368-5647 for in-

formation about required safety for information about

required safety equipment.

A. Required Safety Equipment

Most of the safety equipment required by federal regu-

lations is provided as standard equipment. Personal

Floatation Devices (life jackets) must fit the person wear-

ing it. If local regulations require additional equipment,

it must be approved by the U.S. Coast Guard (USCG).

Minimum requirements include the following:

• Personal Floatation Devices

• Visual Distress Signal

• Bell or Whistle

• Fire Extinguisher

• Navigation Lights

NOTICE

As the owner/operator of the boat, you are re-

sponsible for assuring that all required safety

equipment is aboard and meets the boating

regulations as prescribed by both federal and

local authorities in your area.

B. Personal Floatation Devices (PFDs)

Federal regulations require that you have at least one

Coast Guard approved personal floatation device (PFD)

for each person in a recreational boat. You should not

use your boat unless all PDFs are in serviceable condi-

tion, readily accessible, legibly marked with the Coast

Guard approval number, of an appropriate size (within

the weight range and chest size marked on the PDF)

for each person aboard.

A PFD provides buoyancy to help keep your head above

the water and to help you remain in a satisfactory posi-

tion while in the water. Body weight and age should be

considered when selecting a PFD. The buoyancy pro-

vided by the PFD should support your weight in water.

The size of the PFD should be appropriate for the

wearer. Body weight or chest size are common meth-

ods used to size PFDs. It is your responsibility to en-

sure that you have the proper number and types of

PFDs on board and that your passengers know where

and how to use them.

C. PFD Types

Five types of PFDs have been approved by the U.S.

Coast Guard. The PFDs are described as follows:

PFD Type 1, Wearable (Figure B1) has the greatest

required buoyancy. Its design allows for turning most

unconscious persons in the water from face down po-

sition to a vertical or slightly backward, face-up posi-

tion. It can greatly increase the chances of survival.

Type 1 is most effective for all waters, especially off-

shore when rescue may be delayed. It is also the most

effective in rough waters.

Figure B1: Type I, Wearable

PFD Type II, Wearable (Figure B2) turns its wearer in

the same way as Type I, but not as effectively. The

Type II does not turn as many persons under the same

conditions as a Type I. You may prefer to use this PFD

where there is a probability of quick rescue such as in

areas where other people are commonly involved in

water activities.

Figure B2: Type II, Wearable

SAFETY EQUIPMENT

Section B

Page 2

180/190/200 Horizon

Owner’s Manual

08/01

D. PFD Pointers

The purpose of a PFD is to help save your life. If you

want it to support you when you are in the water, it needs

to fit, float, and be in good condition.

1. Try the PFD on and adjust it until it fits comfortably

in and out of the water. Mark your PFD if you are

the only wearer.

2. To make sure the PFD works, wear it in the water.

This will show you how it works and give you confi-

dence when you use it.

3. Teach children how to put a PFD on and allow them

to try it in the water. That way, they know what the

PFD is for and how it works. They will feel more

comfortable with it if they suddenly find themselves

in the water.

4. If the PFD is wet, allow it to dry thoroughly before

storing it. Do not dry it in front of a radiator or heater.

Store it in a well ventilated area.

5. Keep PFDs away from sharp objects which can

tear the fabric or puncture the floatation pads.

6. For their own safety and the safety of others, all

nonswimmers, poor swimmers, and small children

should wear PFD’s at all times, whether the boat is

stationary or moving.

7. Check the PFD frequently to make sure that it is

not torn, that floatation pads have no leaks, and

that all seams and joints are securely sewn.

8. If a PFD contains kapok, the kapok fibers may be-

come waterlogged and lose their buoyancy after

the vinyl inserts are punctured. If the kapok be-

comes hard or if it is soaked with water replace it,

otherwise, it may not work when you need it.

E. Emergency Stop Switch

This safety device automatically stops the engine if the

lanyard is attached to the operator and the operator

falls from his work station. Refer to the engine manual

for detailed information about using this switch.

The emergency stop switch (Figure B6) incorporates a

shutoff switch, switch clip, lanyard, and lanyard clip. The

lanyard clip must be securely attached to the operator’s

PFD, clothing, arm, or leg. Be sure to attach the lan-

PFD Type III, Wearable (Figure B3) allows the wearer

to place themselves in a vertical or slightly backward

position. It does not turn the wearer. It maintains the

wearer in a vertical or slightly backward position and

has no tendency to turn the wearer face down. It has

the same buoyancy as a Type II PFD and may be ap-

propriate in areas where other people are commonly

involved in water activities.

Figure B3: Type III, Wearable

PFD Type IV, Throwable (Figure B4) is required in ad-

dition to the PFDs previously discussed. The most com-

mon Type IV PFD is a buoyant cushion or ring buoy. It

is designed to be thrown to a person in the water,

grasped and held by the user until he or she is res-

cued. A Type IV PFD should always be in serviceable

condition and immediately available for use. Grasping

this PFD may be difficult if the rescue is delayed or if

the user is overcome by hypothermia (loss of body heat).

Figure B4: Type IV, Throwable

PFD Type V, Wearable (Figure B5) when inflated, it