METAKAOLIN STUDY

Pre-Feasibility Review of the Potential for

Developing Metakaolin from Oil Sands Operations

for Use in Concrete

Prepared for:

Action Plan 2000 on Climate Change – Minerals and Metals

Prepared by:

Michel de Spot, P.Eng.

Maggie Wojtarowicz, E.I.T.

November 2003

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport i

Table of Contents

1. Executive Summary......................................................................................................1

2. Introduction....................................................................................................................1

2.1. Study Objectives.........................................................................................................2

2.2. Scope of Report ..........................................................................................................2

2.3. About EcoSmart..........................................................................................................4

3. Background.....................................................................................................................4

3.1. Definitions...................................................................................................................5

3.2. Use of Metakaolin in Canada...................................................................................6

3.3. Use of Metakaolin in the World...............................................................................6

3.4. Investigations of Metakaolin Production from Oil Sands Operations...............6

3.5. Research into the Use of Metakaolin as an SCM..................................................7

4. Technical Evaluation ....................................................................................................7

4.1. Extraction and Calcination Process.........................................................................7

4.2. Performance in Concrete as an SCM ......................................................................9

5. Economic Evaluation..................................................................................................10

5.1. Cost of Production of CMFT..................................................................................10

5.1.1. Cost of Extraction of MFT...........................................................................10

5.2. Cost of Testing CMFT for Use as SCM ...............................................................10

5.3. Cost of Transportation.............................................................................................10

5.4. Demand vs. Cost vs. Price ......................................................................................11

6. Environmental Evaluation........................................................................................14

7. Summary of Findings.................................................................................................15

7.1. Properties of Various SCMs and PC.....................................................................15

7.2. Benefits of CMFT Production and Usage as SCM.............................................16

7.3. Drawbacks of CMFT Production and Usage as SCM........................................16

8. Conclusions....................................................................................................................16

8.1. General.......................................................................................................................16

8.2. Oil Sands Industry....................................................................................................17

8.3. Cement/Concrete Industry......................................................................................17

8.4. EcoSmart Concrete Project.....................................................................................17

9. Future Work .................................................................................................................18

9.1. EcoSmart....................................................................................................................18

9.2. Research Community...............................................................................................18

9.3. Oil Sands Industry....................................................................................................18

9.4. Concrete Industry.....................................................................................................18

10. References......................................................................................................................18

11. Appendices.....................................................................................................................19

List of Tables

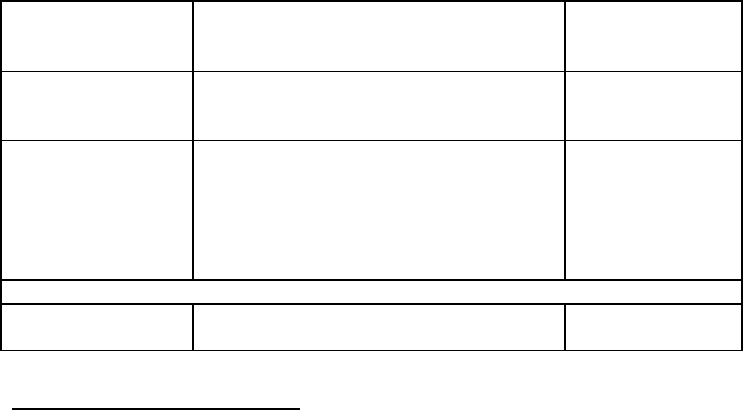

Table 1: Sample Calculation for Syncrude Kaolin Production Capability ...................4

Table 2: Relationship between Demand, Supply, Cost and Price of CMFT ...............12

Table 3: Comparison of the Properties of Various SCMs and PC.................................15

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport ii

List of Figures

Figure 1: Scope of the EcoSmart™ Metakaolin Study........................................................3

Figure 3: Tynebridge Extraction Process...............................................................................8

Figure 4: Distances between Production Site and Potential Market for CMFT........11

Figure 5: Relationship between Demand, Cost and Price of CMFT.............................11

Figure 6: Market Analysis Curve: Price vs. Demand........................................................13

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 1

1. Executive Summary

The following report evaluates the potential of metakaolin recuperated from oil sands

tailing ponds in North Alberta, as a supplementary cementing material (SCM) for

concrete.

Oil sands operations produce vast quantities of tailings containing extremely fine clays

that prevent the reuse of process water from the tailings ponds. Preliminary research has

indicated that this fine material can be processed into a product similar to metakaolin

(MK). Metakaolin is a valuable product with many commercial uses, including as a high

performance SCM. Extracting the fine clay from the ponds to produce SCM would have

two benefits: clarifying the process water for reuse in the operations while producing a

valuable product from a by-product.

The study finds however that, while it is technically feasible, the concept is uneconomical

for many reasons. The material that can be produced from the pond – called calcined

mature fine tailings or CMFT – while similar to MK, has lower quality and performance

than the products currently on the market. Another shortcoming is that CMFT is grey

while metakaolin from virgin kaolin is white. Therefore, in performance and appearance,

CMFT cannot compare to MK. Rather, it is more like fly ash (FA), another SCM

abundantly available in Alberta, but at a much lower price than MK. Furthermore, the oil

sand region is isolated, landlocked and far from the market for concrete. Because of the

cost of extracting, drying, calcining, and transporting the material, CMFT cannot

compete against FA, and the study concludes on the non-feasibility of the concept.

The oil sand industry still wants to resolve its water and pond issues, and continues to

investigate ways to process the fine tailing. If this research is successful and CMFT with

improved quality, color and cost can be produced, then it will be worthwhile to re-

examine the case and see if the product can be used in concrete.

2. Introduction

The use of Portland cement (PC) in concrete has significant greenhouse gas (GHG)

implications, where the manufacture of each tonne of PC generates approximately 0.9

tonnes of CO

2

emissions

1

. The “GHG signature” of concrete can be reduced by partial

replacement of PC with supplementary cementing materials (SCM). Typical SCMs

include fly ash, ground granulated blast furnace slag, and silica fume, ground limestone,

natural pozzolans and metakaolin.

It has been discovered that the by-product of oil sands operations, namely the clay from

tailings ponds, can be processed into a material with similar properties to metakaolin for

use in paper making, ceramics, concrete, and other industrial applications. The oil sands

operations in northern Alberta produce vast quantities of tailings, which are stored in

gigantic tailings ponds. Fine clay, which represents a significant part of these tailings,

takes a long time to settle, and therefore makes it very difficult to recycle the process

water. Extraction and processing of this clay is a promising means of turning the by-

product into a value-added product and clarifying the process water for reuse in the

operations.

Starting from existing scientific and technical information produced by the oil sands

industry and the research community, this study investigates the validity and feasibility of

the concept of reclaiming and processing the tailings into a product that can be used as an

SCM in concrete. In the study, the EcoSmart™ Concrete Project has reviewed the

1

Malhotra, 1999.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 2

existing research and technical studies, has commissioned an independent pre-feasibility

study, and engaged the various stakeholders in the process and decision-making.

2.1. Study Objectives

The objectives of this study are:

1. to assess the potential for developing metakaolin from oil sands operations for

use as an SCM in concrete (on technical, economic, and environmental basis);

and

2. to determine whether further exploration of this technology is justified.

2.2. Scope of Report

This study was conducted as the first phase of a two-phase feasibility study for

developing this SCM technology, as indicated on Figure 1. This report reviews the

existing information and updates the technical, economic, and environmental

assumptions for calcination of the oil sands clay. The extraction process proposed in a

previous study by Syncrude

2

, one of the oil sands operators, was assumed technically

viable and was not re-examined. This report also includes the input of the cement and

concrete industry as well as the oil sands industry in terms of the current market for this

material and willingness to develop the product, and thus, the market. Finally, the role of

the Federal Government was also taken into account in developing this technology. The

outcome of the study is a compilation and summary of the existing and EcoSmart-

commissioned information, and a clear overview of the potential and the challenges of

the concept.

2

Tynebridge, 1998.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 3

Figure 1: Scope of the EcoSmart™ Metakaolin Study

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 4

2.3. About EcoSmart

The objective of the EcoSmart™ Concrete Project (EcoSmart) is to minimize the GHG

signature of concrete by maximizing the replacement of Portland cement in the concrete

mixtures with SCMs while maintaining or improving cost, performance, and

constructability. EcoSmart is an industry-government partnership generating and

transferring knowledge on reducing the CO

2

emissions from the construction industry.

3. Background

Numerous research and technical studies have pointed to the great potential of metakaolin

(MK) as a supplementary cementing material with performance similar although slightly

inferior to silica fume (SF) (see Table 3 in Section 7.1).

MK is produced by thermally processing pure kaolinite. Main sources of kaolinite as

well as the key MK producers are located in clay deposits in Georgia, U.S. and Cornwall,

U.K. The price of MK in Canada is about the same as SF and ranges between $400 and

$600 per tonne depending on the location

3

. Besides concrete, other markets for kaolin

and MK include the paper, ceramics, and fibre-cement boards industries.

Oil sands operations produce vast quantities of fine tailings collected in gigantic tailings

ponds. Fine tailings comprise mainly of kaolinite, illite, and quarts. The details of the

composition of fine tailings are provided in Section 3.1. Currently, the oil sand fields

have a total of 400 million cubic meters of tailings, which contain up to 60 million tonnes

of kaolin

4

. According to one of the oil sands companies in Alberta, their operations could

produce up to 6 million tonnes of Calcined Mature Fine Tailing (CMFT) annually

5

, a

material similar but not equal in performance to MK.

Based on rough calculations by Syncrude alone, this oil sands operator could produce 3.3

million tonnes of kaolin during their 2003 production of 85 barrels of oil, as indicated in

Table 1.

Table 1: Sample Calculation for Syncrude Kaolin Production Capability

6

Product Conversion Factors Potential for

Kaolin

Production

1m

3

of MFT 1m

3

(1280kg) of MFT containing 30%

solids (clay) produces 384kg of clay

containing 40% kaolin

153.6 kg of kaolin

per m3 MFT

1 barrel (bbl) of oil It requires 1 m

3

of oil sand to produce 1

barrel of oil.

Removal of that oil produces 1.1 m

3

of

sand containing 0.25m

3

of MFT

[(1280kg MFT x 0.25) x 0.3 solids x 0.4

kaolin]

38.4 kg of kaolin

per bbl oil

2003 Production

85 M bbl oil per

year

85 M x 38.4 kg of kaolin per year 3.3 M tonnes of

kaolin per year

3

Personal Communication, Brad Pope, Pozzolanic, July 18, 2003.

4

Wong et.al., 2002, p.1.

5

NLK, 2002, p. 4-3.

6

Personal Communication, Ted Lord, Syncrude Research, August 29, 2003.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 5

3.1. Definitions

Portland cement (PC) is a hydraulic cement produced by pulverizing Portland cement

clinker, usually in combination with calcium sulphate (gypsum). Portland cement clinker

is a partially fused ceramic material consisting primarily of hydraulic calcium silicates

and calcium aluminates.

7

Supplementary cementing material (SCM) is a pozzolanic material that contains high

proportions of silica and in some SCMs, alumina. When used in concrete as partial

replacement of PC, it reacts with unreacted calcium hydroxide from the hydration of PC

to form calcium silicate hydrates – the desired end product of PC hydration. SCMs

include fly ash (FA), ground granulated blast furnace slag (GGBFS), silica fume (SF),

natural pozzolans (NP), and metakaolin (MK).

Metakaolin (MK) is produced by calcining virgin kaolin.

Kaolin is a clay mineral consisting of the mineral kaolinite with admixtures of quartz and

feldspar

8

.

Tailings are the by-product of the oil sands operations, namely a mixture of water and the

solid matter remaining after nearly all the oil is removed. Tailings include sand, clay,

silt, residual bitumen and water.

Fine tailings (FT) are the small particles in suspension (10% solids) in the tailings pond,

comprised mainly of clay and silt

9

suspended in water.

Mature fine tailings (MFT) are a gel-like substance (30% solids) composed of very

slowly settling fine clay particles, and is made up mostly of water

10

. MFT contains the

clay and silt particles remaining in suspension after 2-3 years of settlement

11

. The typical

mineral composition of MFT includes approximately 23% kaolin, 17% illite (mica), 30%

quartz, and small quantities of other minerals, including iron and titanium, as well as

some organics. The iron and titanium in the MFT contribute to the unwanted dark colour

in the material. The minerals in MFT comprise mainly of silica and alumina (at a ratio of

approximately 2:1 to 3:1)

12

. Kaolinitic component in MFT can be concentrated up to

65% by weight.

13

MFT is near or at its terminal density and will not densify further

under its own self-weight in the tailings pond.

Calcined mature fine tailings (CMFT) are produced by first separating out the finer

fraction (primarily kaolin) from MFT and then heating this fraction to drive off the

hydroxyl groups (

-

OH) from the component oxides, i.e., thermal decomposition

14

.

Unlike other SCMs, MK and CMFT are unregulated products. In addition, although MK

and CMFT have similar properties, CMFT is inferior to MK because of impurities such

as silica, illite, iron, and titanium. Research indicates that the effectiveness of MK from

MFT as an SCM is approximately 85-90% that of pure MK

15

.

7

ACI Manual of Concrete Practice, 2003, ACI 116R-12-14.

8

http://www.a-m.de/englisch/lexikon/kaolinit.htm, viewed on September 4, 2003.

9

Personal Communication, Ted Lord, Syncrude Research, August 29, 2003.

10

http://www.syncrude.com/research/04_03.html, viewed July 18, 2003.

11

Personal Communication, Ted Lord, Syncrude Research, August 29, 2003.

12

Omotoso, D. et.al., 2001 Presentation and Tynebridge, 1998, p. 1.

13

Omotoso, D. et.al., 2001 Presentation.

14

INSA, 2002 and Omotoso, D. et.al., 2001 Presentation.

15

University of Calgary and Syncrude, October 2001.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 6

3.2. Use of Metakaolin in Canada

Currently in Canada, metakaolin is only used in small quantities in British Columbia. It

is imported from the U.S. and is used primarily in architectural and specialty concretes.

The price of metakaolin in B.C. is approximately five times the price of Type 10 Portland

cement.

16

3.3. Use of Metakaolin in the World

The NLK study indicates that MK use in the concrete industry is very limited. In North

America, it is commercially available as MetaMax®, and is produced in Georgia, USA

by Engelhard Corporation. There is also a smaller source of MK in south-eastern USA.

In the USA, the Departments of Transportation of New York, Illinois, Florida, and

California approve the use of MK in concrete. There has also been some use of MK in

concrete in New Zealand and in the Amazon Basin.

17

3.4. Investigations of Metakaolin Production from Oil Sands Operations

In 1998, Syncrude Canada commissioned a study on clay recovery from MFT generated

in its oil sands operations. The study was carried out by Tynebridge Technologies

Limited. The study described a possible extraction process, the costs of production in a

pilot plant, and scale up factors based on a pilot plant configuration that would use the

smallest equipment available. The study defined the technology required to produce

CMFT, and provided a simplified cash flow analysis indicating that the economics were

reasonable, based on a selling price of $600/tonne

18

. However, the oil sands operators,

including Syncrude, were not interested in pursuing this business venture themselves, but

were receptive to making this opportunity available to an interested independent third

party.

During 2001 and early 2002, following preliminary investigations and discussions with

the oil sands industry, EcoSmart undertook as part of its mandate to follow up and further

investigate the technical, economic and environmental potential and challenges of

developing this source of metakaolin. Through this process, EcoSmart was to serve as a

means to identify the interested third party. Stakeholder meetings were held in Alberta

with representatives of three oil sands companies, the cement and concrete industry, the

Federal Government and the research community. The meeting minutes may be found in

the Appendices. As a result, it was decided to review, as part of a pre-feasibility study,

the Tynebridge study in order to refine the numbers with more accurate information.

In 2002, following further consultations to determine the scope, EcoSmart commissioned

a pre-feasibility study. NLK Consultants Inc. was retained to complete this work. The

study involved a market analysis, desktop research and industry interviews. The

technical aspects of production and use of CMFT as an SCM were investigated, updating

the economic analysis of the Tynebridge study, and incorporating environmental

considerations. The NLK study halved the price of the MK product from the selling price

identified in the Tynebridge study by refining the process costs, assuming that the

extraction technology proposed was feasible, and assuming that a partial replacement of

Portland cement by MK could reduce the total cementitious amount in a unit of concrete.

Following the completion of the report and into 2003, EcoSmart continued consultations

with industry and the research community, concluding with a second stakeholder meeting

in Alberta to identify the next steps in the technology exploration process. The minutes

16

Bouzoubaâ and Fournier, 2003, p. 5-6, 22-23.

17

NLK, 2002, p. 4-8.

18

Tynebridge, 1998, p. 8.

Figure 2: Fort McMurray,

Alberta Oil Sands

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 7

from this meeting are included in the Appendices. This report presents the outcome of

the entire EcoSmart undertaking regarding this alternative SCM material.

The following sections of the report provide more details of the findings from the

EcoSmart initiative.

3.5. Research into the Use of Metakaolin as an SCM

The NLK report summarizes the findings on the use of metakaolin as an SCM available

from research literature. Overall, based on this literature review, the SCM potential of

this material is promising. As a follow-up to the NLK report, EcoSmart engaged the

world-renowned expertise of the Institut National des Sciences Appliqués de Lyon

(INSA) and the materials expertise of AMEC Earth & Environmental, Burnaby, B.C., to

provide additional insights into the technical potential of CMFT as an SCM.

ICON/CANMET in Ottawa, ON, has been engaged in assessing the requirements of a

concrete testing program for CMFT and has conducted a study into the current situation

of SCMs in Canada.

4. Technical Evaluation

4.1. Extraction and Calcination Process

The extraction process described in the Tynebridge study and illustrated in Figure 3

involves the addition of sodium silicate as a dispersant (attrition mill) and removal of

residual bitumen (primary clarifier) before further thickening (secondary thickener). The

silt from the thickener is returned to the tailings ponds, while the kaolin-rich overflow is

dewatered and spray dried. The clay (containing kaolinite, illite, iron, titanium, and

traces of bitumen) is then calcined (hydroxyl groups removed at temperatures in the order

of 600-800

o

C).

19,

20

19

Tynebridge, 1998, p. 5.

20

Wong et.al., 2002, p. 6.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 8

Figure 3: Tynebridge Extraction Process

INSA suggests that MFT be calcined without prior removal of the 2% bitumen typically

contained in the raw tailings. This would reduce the requirement for additional fuel for

the calcining process. In addition, INSA studies have shown that a benefit of this method

in the material’s performance in concrete.

21

The MFT needs to be dried and calcined, a process that generates approximately 0.43

tonnes of CMFT per tonne of MFT

22

.

INSA suggests that an existing multi-hearth furnace at Portland cement manufacturing

plants could be used to calcine MFT on a pilot scale. A pilot-scale test of this nature will

provide more realistic information for the commercial scale production than is currently

available from laboratory scale operations.

23

The optimum calcination temperature that produces the most reactive MK is in the range

of 600-800

o

C. One study found that calcination at 700

o

C produced a MK that resulted in

the highest concrete strengths. However, little difference in concrete strength was

noticed when using MK calcined at temperatures up to 790

o

C. Reactivity of the MK did

reduce at a calcination temperature of 850

o

C

24

. It is not clear whether these findings

apply directly to CMFT, although another study has shown that MFT calcined at 1000

o

C

had very little pozzolanic activity

25

.

21

INSA, 2002.

22

NKL, 2002, p. 5-3.

23

INSA, 2002.

24

Wong et.al., 2002, p. 6.

25

Wong et.al., 2002, p. 8.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 9

The oil and sands industry suggests that the advantages of producing CMFT for use in

concrete instead of MK include: elimination of mining costs, availability of partially

processed product, and use of vast quantities of waste product. This industry foresees

transportation costs, capital investment, and market forces to be the main hurdles.

26

4.2. Performance in Concrete as an SCM

Generally, MK improves most mechanical and durability properties of concrete, and thus,

CMFT is expected to exhibit similar benefits. However, the properties of both MK and

CMFT, and their performance in concrete, will be affected by the calcination temperature

(see section 4.1).

27,

28

To achieve the full benefits of using MK as an SCM in terms of improved concrete

properties, INSA experience shows that MK must replace at least 15-20% of the cement,

particularly when the material is not pure, as is the case with CMFT

29

. Wong et.al., 2002,

suggest that replacement levels in excess of 15% for both MK and CMFT would be

required for full removal of the calcium hydroxide formed during the hydration of

cement

30

.

The high specific area of MK relative to that of both Portland cement and fly ash

increases the rate of concrete strength development. This property may be beneficial in a

ternary blend of Portland cement, FA and MK, where the use of FA typically results in

lower rates of strength development. The drawback of this feature of MK is that it also

increases the water demand and the consumption of air-entraining agent, and reduces the

workability of concrete

31,

32

. Furthermore, to counteract the detrimental effects of

increased water demand, chemical admixtures (water reducing admixtures and/or

superplasticizers) may need to be introduced, thereby increasing the costs of a concrete

mix

33

. Additional work is required to ascertain these properties for CMFT, since it is a

somewhat different material from pure MK. For example, one study showed that the

specific surface of CMFT was nearly 2.5 times that of pure MK

34

.

MK has historically been used in similar concrete applications with similar performance

results as silica fume (SF). CANMET study has shown that MK concrete may require

less superplasticizer and have slightly better constructability characteristics (e.g.,

finishability) than SF concrete

35

. However, Wong et.al., 2002, indicate that research into

CMFT usage as a pozzolan is still in its infancy

36

.

The NLK study suggests that by replacing a portion of the cement in a concrete mix with

MK, the total cementitious material content can be reduced, thereby reducing the

economic impact of using this high-priced SCM on the price of the concrete mix

37

.

While this may be a feasible option for pure MK, which has a pozzolanic reactivity of

26

Ted Lord, Syncrude, January2003.

27

Benoit Fournier, CANMET October 2001 presentation of Zhang and Malhotra, 1995

results.

28

University of Calgary and Syncrude, October 2001.

29

INSA, 2002.

30

Wong et.al., 2002, p. 3.

31

NLK, 2002, p. 4-5 to 4-6, and 4-8.

32

Wong et.al., 2002, p. 2.

33

AMEC, 2003.

34

University of Calgary and Syncrude, October 2001.

35

Benoit Fournier, CANMET presentation of Zhang and Malhotra, 1995 results.

36

Wong et.al., 2002, p. 9.

37

NLK, 2002, p. 4-9

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 10

1.15 compared to Portland cement

38

, INSA does not recommend this approach, especially

without concrete trial tests

39

. Furthermore, as indicated in Section 3.1, CMFT are only

85-90% as efficient as pure MK, bringing their pozzolanic reactivity down to the Portland

cement level.

Colour is also an issue: unlike pure MK, which is almost white, CMFT is medium to dark

grey, depending on the extent of carbonation, since the material becomes lighter with the

increasing calcination temperature

40

. The whiter the MK, the more valuable it is, and the

easier its introduction in the concrete industry

41

.

Other properties that tend to improve when MK is used include: resistance to sulphate

attack and alkali-silica reaction (ASR)

42

, durability under freezing and thawing

conditions, and resistance to cracking and surface deterioration

43

.

5. Economic Evaluation

5.1. Cost of Production of CMFT

5.1.1. Cost of Extraction of MFT

Syncrude is currently involved in a consortium conducting a three-year research study

between the oil sands operators, the University of Alberta and CANMET in Devon,

Alberta. This research is focused on the extraction of commercial grades of MFT-kaolin

as a value added resource. The study, which will demonstrate the technical and economic

feasibility of this process, will cost approximately $250,000.

5.2. Cost of Testing CMFT for Use as SCM

CANMET is often involved in testing of new materials for use in concrete. They

estimate that a study to optimize the MK content in concrete with respect to strength and

cost of concrete would cost in the order of $30,000. A performance-testing program at

CANMET of CMFT as an SCM in concrete was estimated to last approximately a year

and a half and cost in the order of $200,000.

44

5.3. Cost of Transportation

Remoteness of the Alberta oil sands is another major challenge for developing the CMFT

as an SCM for use in concrete. The NLK study indicates that transportation costs from

the production site at Fort McMurray to the market may range from $90 to $120 per

tonne of CMFT, depending on the size of production, total transport distance, and

availability of bulk transport

45

. This alone represents a major disadvantage for CMFT

compared to PC, which is typically produced near the market, or FA, which is produced

in the Edmonton region. FA also has a developed market, which allows the users to take

advantage of bulk transport. The distances between Fort McMurray and potential

38

AMEC, 2003.

39

INSA, 2002.

40

Figure in January 22, 2001 letter from George Jones

41

INSA, 2002.

42

Wong et.al., 2002, p.1

43

NLK, 2002, p. 4-6 and 4-7.

44

Personal Communication, Nabil Bouzoubaâ, CANMET, July 10, 2003.

45

NLK, 2002, p. 3-4.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 11

markets (including off shore markets) for CMFT as an SCM in concrete are illustrated on

Figure 4.

Figure 4: Distances between Production Site and Potential Market for CMFT

5.4. Demand vs. Cost vs. Price

The EcoSmart initiative on this source of MK has furthered the understanding of the

circular relationship between the demand, the cost and the price of CMFT. This point is

best illustrated by Figure 5 and Table 2.

Figure 5: Relationship between Demand, Cost and Price of CMFT

Vancouver

Prince

Rupert

Calgary

Fort McMurray

VancouverVancouver

Prince

Rupert

Prince

Rupert

CalgaryCalgary

Fort McMurrayFort McMurray

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 12

Figure 5 demonstrates that Production Size (Supply) determines the Cost; the Cost of

production with the desired rate of return on investment plus transportation cost

determine the Price; and the Price of the product determines the size of the market, or the

Demand. However, in the end, the Demand drives the Supply, sets the Price, and

ultimately determines the Cost. If the Cost relative to the Price returns a favourable

interest on the investment, the feasibility of a venture is determined. The producer (in

this case either the oil sands industry or a third party) then decides if the rate of return

meets their expectations. Indeed, the ultimate variable in this “equation” – whether to

proceed with the venture or not – is the producer’s willingness and desire to take the risk

of making the initial investment. Table 2 presents several options for CMFT production

based on the NLK and Tynebridge studies.

Table 2: Relationship between Demand, Supply, Cost and Price of CMFT

Relative Size of

CMFT Production

Plant

Demand

(tonnes / year)

Supply

(tonnes / year)

Cost

($ / tonne)

Price*

($ / tonne)

N/A 0 N/A N/A 650-680

(current

price of

MK)

Smallest

(Tynebridge)

0 22,000 167 600

Smallest (NLK) 20-24,000 37,000 114 303

Medium 39,000 74,000 72 282

Large (based on a

given Price that sets

the Demand)

200,000 N/A N/A 130

Large (based on a

given Supply that

determines the

Price)

N/A 1,000,000 29 142

* Includes transportation costs, assuming delivery within Western Canada and North-

Western States

In summary, at the current price of MK ($650-680/tonne, which is comparable to the

price of silica fume) the demand for CMFT is virtually nil. There are four main reasons

for this:

1. the product is inferior to MK in its properties as an SCM, including its colour,

2. the demand for high-performance, white MK as an SCM is presently small and

the supply of pure MK is sufficient to meet the current demand,

3. the price in the best case scenario would be similar to Portland cement and

higher than FA, and

4. if CMFT aims to supply the demand for lower grade SCM, it cannot compete

against FA, which can be produced at near zero cost, without additional

processing, closer to the market, and with negligible environmental impact

associated only with its transportation.

At the $600/tonne price level as determined by the Tynebridge study for 22,000 tonnes of

CMFT supply annually, the demand can be assumed to be nil as well (for the same

reasons as above).

The NLK study calculates the price of $303/tonne for the production of 37,000

tonnes/year. The demand at this price within Western Canada by the concrete industry is

estimated at 20-24,000 tonnes. At the slightly lower price of $282/tonne when

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 13

production is doubled to 74,000 tonnes/year, the demand is estimated to increase to only

39,000 tonnes/year. The balance of the supply would need to find other markets (e.g.,

paper, tires, etc.) or the geographical market would have to be expanded (but this carries

additional transportation cost implications).

A production level of 1,000,000 tonnes/year lowers the price of CMFT to $142/tonne.

This production level assumes an extensive market for CMFT, both in the type of

application and geographical extent.

Since MK is currently used only in specialty concrete products, such as ultra strength

concrete, the price of MK is relatively very high and the market for MK is relatively

small. To create a large enough demand to keep the cost down and make the venture

profitable for a producer, the price of CMFT for use in concrete will have to be at most at

the level of Portland cement, if not lower. In Western Canada, the price of CMFT would

have to be at most $130/tonne. Therefore, based on a market analysis curve provided by

the NLK study in Figure 6, this price is expected to generate a demand for 200,000

tonnes/year. Detailed assumptions for these numbers may be found directly in the two

studies referenced.

Figure 6: Market Analysis Curve: Price vs. Demand

46

In the best case scenario, with the demand for CMFT at 220,000 tonnes/year at the

$130/tonne price comparable to PC in Western Canada, extraction of the corresponding

amount of MFT from the tailings ponds (approximately 11 million tonnes of tailings,

assuming tailings contain 10% clay, of which about 20% could be converted to CMFT

47

)

would not satisfy the need of the oil sand operators to clean up their tailings ponds. As

indicated in Section 3, there is potential to produce 6 million tonnes of CMFT per year.

The current SCM market could absorb a maximum of 220,000 tonnes of CMFT per year,

much less than the 6 million tonnes that could be produced.

The lower reactivity and darker colour of CMFT than of MK makes the value of CMFT

more comparable with that of FA. However, CMFT cannot compete with FA for the

following reasons:

• the production of FA in Alberta already exceeds the demand,

• the price of FA (FOB) at a power plant in Alberta is low (from $8 - $12 / tonne),

• FA does not require additional processing,

• FA is closer to the market, and

• the GHG benefit in concrete is greater with FA.

46

NLK, 2002, p. 2-9.

47

NLK, 2002, p. 4-3.

0

200

400

600

0 50,000 100,000 150,000 200,000

MK Demand (tonnes/year)

MK Price ($/t)

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 14

The use of yet another SCM by the ready-mixed concrete supplier requires additional

cost for a separate silo for CMFT.

Therefore, unless drastic change occurs in the current price or quality of FA, CMFT will

have difficulty penetrating the SCM market.

6. Environmental Evaluation

The NLK report calculated the CO

2

impact of using CMFT as an additional SCM in a

concrete mixture containing 300 kg/m

3

total cementitious materials content and 25% fly

ash (by weight), i.e., Portland cement at 225 kg/m

3

and fly ash at 75 kg/m

3

. NLK

suggested that by using CMFT as an additional SCM, the total cementitious materials

content could be reduced by up to 10%. However, the validity of this approach is

questioned by INSA

48

.

As an example, the CO

2

signature of concrete would be decreased by amounts in the

order of 0.08-0.20 tonnes/m

3

of concrete as a result of using 10% CMFT (by weight) in

the concrete mixture, for total cementitious materials contents reductions of 0-10%,

respectively

49

. This reduction may be compared with the CO

2

signature reduction of 0.13

tonnes per cubic meter of concrete when cement is replaced by an additional 10% fly ash

(i.e., in addition to the 25% already replaced in the baseline mix). Therefore, it is evident

that unless the total cementitious materials content is reduced (by at least 6%, according

to these calculations), there is no CO

2

advantage to using CMFT.

The NLK analysis assumes that 0.9 tonnes of CO

2

are generated per tonne of Portland

cement produced, and that the CO

2

emissions associated with the production of fly ash

are accounted for by the power generation sector, thus, only transportation-related CO

2

emissions need to be considered. The study calculated that 0.37 tonnes of CO

2

would be

generated per tonne of CMFT produced, and that transportation-related CO

2

emissions

would be in the order of 0.02 tonnes per tonne of CMFT delivered to the Vancouver

market

50

. The transportation emissions can be assumed to be roughly the same for

CMFT and FA transported from northern Alberta to south-western British Columbia.

Other environmental benefits of developing CMFT from the oil sands industry include:

• reduction of the volume of the tailings ponds;

• improved settling properties of tailings ponds for process water recovery; and

• improved oil recovery efficiency from the tar sands (if the 2% residual bitumen

is recovered from the tailings)

51

.

Some of the detrimental environmental impacts of this initiative include:

• additional natural gas requirements for the calcination and drying processes

(note: CO

2

emissions from the burning of this fuel have already been

incorporated in the calculations of the CO

2

signature of concrete containing

CMFT);

• some additional emissions of other contaminants from the calcination and drying

processes, e.g., CO, NO

x

, N

2

O, SO

2

, CH

4

, PM (filterable);

• emissions from transportation of CMFT from source to user (note: CO

2

emissions from the transportation of this material have also already been

included in the CO

2

signature of CMFT concrete)

52

.

48

INSA, 2002.

49

NLK, 2002, based on data used to generated graph on p. 5-9.

50

NLK, 2002, p. 5-10.

51

NLK, 2002, p. 5-9 and 5-10.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 15

7. Summary of Findings

7.1. Properties of Various SCMs and PC

Examination of the various aspects of CMFT extraction, processing, and potential use as

an SCM in concrete can be summarized and the properties compared with those of other

SCMs and PC. Table 3 presents a summary of the main aspects that can be used for

comparison.

Table 3: Comparison of the Properties of Various SCMs and PC

Property CMFT MK SF FA PC

Performance Factor

(approximate

PC)

(a)

1.10 1.15 1.25 0.85 1.00

Colour Medium to

Dark

White Dark Light to

Medium

Medium

Cost in BC (on the

market) ($ / tonne of

product)

(unknown) $400 -

$600

$400 -

$600

$8 (at the

Alberta

plant)

$75 (with

transport)

$130-$150

Availability (in

Canada)

(tonnes/year)

Potentially: 6

million

53

Currently: for

small

laboratory

tests only

(unknown,

but

abundant)

20,000

54

2,200,000

55

14,000,000

capacity

CO

2

Generated by

Production (tonnes

CO

2

/ tonne of

product)

0.37 0

(b)

0 0 0.9

CO

2

Saved by

Partial Replacement

of PC (tonnes CO

2

/

tonne of product)

0.53

(0.37-0.9)

0.9 0.9 0.9 N/A

CO

2

Saved by

Partial Replacement

of PC (tonnes CO

2

/

m

3

of concrete)

0.08-0.20

(c)

0.13 0.13 0.13

(d)

N/A

(a)

Factors used in the work by Popovic

56

(b)

Emissions attributed to mining industry

(c)

10% CMFT in addition to 25% FA, total cementitious material content reductions by

0-10%

57

(d)

Additional 10% FA in addition to 25% FA

52

NLK, 2002, p. 5-10.

53

NLK, 2002, p. 4-3.

54

Bouzoubaâ and Fournier, 2003, p. 31.

55

Bouzoubaâ and Fournier, 2003, p. 31.

56

AMEC, 2003.

57

NLK, 2002, based on data used to generated graph on p. 5-9.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 16

7.2. Benefits of CMFT Production and Usage as SCM

It has been shown that it is technically feasible to produce CMFT from the oil sands

tailings ponds. The benefits associated with the production of CMFT and its use as an

SCM in concrete include:

• extracting MFT from tailing ponds would allow oil sands operators to recover

the limited process water, reduce the size of the tailings ponds, increase the

capacity of the tailings ponds for future operations, and reduce the risk of a

breach in the banks containing the tailings ponds;

• the use of this by-product would displace the need for mining virgin material;

• there are huge reserves of this by-product in Canada; and

• use of CMFT as an SCM in concrete has GHG reduction potential.

7.3. Drawbacks of CMFT Production and Usage as SCM

The drawbacks associated with the production of CMFT from oil sands operations and its

use as an SCM in concrete include:

• CMFT is not the same as MK;

• the performance of CMFT as an SCM is inferior to that of MK, rather, it is more

comparable to FA;

• CMFT is a low-value product due to its dark colour;

• the transportation costs are high;

• capital investment is needed to initiate commercial production;

• the resistance of the construction industry needs to be overcome;

• CMFT cannot compete against fly ash; and

• the current SCM market is not large enough to generate the economies of scale

required to keep the price down.

8. Conclusions

8.1. General

Calcined mature fine tailings (CMFT) are a material with similar but inferior properties

to pure metakaolin (MK).

CMFT is dark in colour, which makes it a low-value product in most of the potential

markets identified to date (e.g., white concrete products, paper). It is less reactive than

pure MK (85-90% effectiveness), approximately as reactive as Portland cement, and only

somewhat more reactive than fly ash (FA) (18% more reactive). It is more energy and

labour intensive to produce than FA, where both materials are by-products of industrial

processes. Its energy intensity also makes CMFT less environmentally beneficial than

FA. Finally, under current market conditions, CMFT is at least four times more

expensive than FA.

The demand for MK, particularly CMFT, in Western Canada is not sufficient to justify

the capital expense of developing this SCM. However, the worldwide demand for SF and

the insufficient supply may provide the market needed to economically develop CMFT.

58

Additional research into the use of MK, and more specifically CMFT, is required to

determine the optimum temperature for calcination, the long-term performance in

58

Personal Communication, Phil Seabrook, Levelton, September 19, 2001. Comments

on NLK, 2002 report.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 17

concrete, and quality control requirements and procedures

59

. Also, more information is

needed for the ready-mixed concrete producer as the user of CMFT, such as the price,

availability, additional testing requirements, risk management options, etc.

60

8.2. Oil Sands Industry

The oil sands industry is not interested in going into this venture if there is no identifiable

market for the CMFT product

61

. Their main interest presently lies in recovering the

process water for reuse in the operations. If the water recovery process generates a

concentrated and practical MFT as a by-product, it would be made available for further

processing by an interested third party. They consider production of CMFT as a

synergistic approach to fine tailings management, water recovery, environmental

protection, and waste product commercialization

62

.

The oil sands industry is interested in producing a new batch of MFT (uncalcined,

calcined, or partially calcined) for testing at a laboratory, such as CANMET, and for

experimenting at an interested ready-mixed plant.

8.3. Cement/Concrete Industry

The cement and concrete industry are not presently interested in taking on the

development of CMFT as an SCM. They would be willing to consider using CMFT if

the oil sands industry can provide the product at no cost at their plants. This industry also

raised the concern that presently there is no market for this material in concrete

applications or the ready-mixed concrete industry, and that the investments required to

make MK a viable SCM could be better spent elsewhere to reduce the CO

2

footprint of

concrete

63,

64,

65

. In addition, as was the experience with developing FA as an SCM,

specifiers and end users would have to be persuaded of the benefits of CMFT and would

have to be willing to accept any associated risks. As a rule, most Canadian industry

specifiers defer to CSA specifications when designing their projects. As such, there may

be a further hesitance to use MFT-based metakaolin, as it is not derived from a pure

natural kaolinite clay source

66

.

8.4. EcoSmart Concrete Project

The EcoSmart Concrete Project has ascertained that producing CMFT from the oil sands

industry is feasible, provided that all MK markets can absorb this product, including the

concrete, paper, tire, etc. markets. However, based on its mandate, EcoSmart’s focus is

only on the SCM application, and EcoSmart may revisit this application pending the

outcome of the investigation of the oil sands industry into other applications.

59

University of Calgary and Syncrude, October 2001.

60

Personal Communication, Phil Seabrook, Levelton, September 19, 2001. Comments

on NLK, 2002 report.

61

John Oxenford, Syncrude, January 14,2003.

62

Ted Lord, Syncrude, January 2003.

63

Personal Communication, Jim Caruth, Pozzolanic, October 11, 2001. Comments on

NLK, 2002 report.

64

Personal Communication, Ron Sills, Lehigh Inland Cement, October 11, 2001.

Comments on NLK, 2002 report.

65

Personal Communication, Tom Gibson, Lehigh Northwest Cement, September 23,

2001. Comments on NLK, 2002 report.

66

Personal Communication, Paul Masson, Lafarge Canada, January 14, 2003.

Metakaolin meeting.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 18

9. Future Work

9.1. EcoSmart

Based on the findings in this study, it is recommended that no further work be done by

the EcoSmart™ Concrete Project on developing CMFT as an SCM at this time. When an

improved and feasible product is developed by the oils sands industry and research

community, it is recommended that EcoSmart initiate a case study project using this

material.

9.2. Research Community

CANMET, the University of Alberta, the University of Calgary, and other interested

parties are continuing their research work on the extraction of this source of kaolin. It is

also recommended that research be continued on the use of CMFT in concrete, to bring

the knowledge about the performance of CMFT to the level of other SCMs such as FA,

SF and MK. The oil sands industry should provide samples as required.

9.3. Oil Sands Industry

The oil sands industry is continuing to investigate economical ways to clean up the

tailings ponds, and conducting research into the extraction of quality kaolin that could be

used to produce quality CMFT, comparable to pure MK. Other uses for the MFT and

CMFT will be investigated, along with continuation of investigations into other third

party groups interested in producing CMFT. The oil sands industry will also try to find a

way to reuse the process water from the tailings ponds instead of continually drawing on

fresh water and increasing the size of the tailings ponds. This study will be completed by

2005.

9.4. Concrete Industry

Once successful results from the oils sands industry are established, the ready-mixed

concrete producers should experiment with CMFT in concrete and gain confidence in the

use of this SCM. The oil sands industry should provide sufficient samples to the ready-

mixed concrete producers for testing. It is further recommended that the concrete

industry adopt this material as an alternate SCM once the oil sands industry and the

research community have advanced the knowledge and quality of this material.

10. References

ACI Manual of Concrete Practice. ACI International. 2003.

AMEC Earth & Environmental Limited (Rusty Morgan). “Metakaolin Review Meeting

Edmonton – January 14, 2003: Summary of Presentation.”

Bouzoubaâ, N. Research Scientist, ICON/CANMET. [email protected]

Bouzoubaâ, N. and Fournier, B. "Current Situation of Supplementary Cementitious

Materials (SCMs) in Canada." CANMET Report MTL 2003-4 (TR), Natural

Resources Canada, Ottawa, April 2003.

Caruth, Jim. Formerly Fly Ash Manager, Pozzolanic International Limited (presently

with Lehigh Northwest Cement Limited). [email protected]

Fournier, B. Program Manager, Concrete Technology Program, CANADA.

“Presentation of Zhang and Malhotra, 1995 Results”, EcoSmart™ Metakaolin

Meeting, Edmonton – October 16, 2001.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 19

INSA (Pera, Jean). “Analysis of the NLK Project EA 2860 – EcoSmart™ Concrete

Project Metakaolin Pre-Feasibility Study.” December 2002.

Lord, Ted. Syncrude Canada. Presentation on “Kaolin Clay Derived from Oil Sands

Fine Tailings – The Syncrude Perspective” to EcoSmart at Metakaolin

Stakeholder Meeting in Edmonton, Alberta, January 14, 2003.

Lord, Ted. Syncrude Research. (780) 970-6907, [email protected]

Malhotra, V.M. May 1999. “Making Concrete ‘Greener’ with Fly Ash.” Concrete

International, Vol. 21, no. 5, pp. 61-66.

Masson, Paul. Lafarge Canada Inc. (403) 225-5424, paul.masson@lafarge-na.com

NLK Consultants Inc. “EcoSmart Concrete Project Metakaolin Pre-Feasibility Study.”

September 2002.

Pope, Brad. Manager of Marketing and Technical Services, Pozzolanic International

Limited. (604) 946-3842, [email protected]

Omotoso, D., Hamza, H., Oliver, J. and Lord, T. Presentation by CANMET AST,

Devon, Alberta Research Council, and Syncrude Research on “Kaolin in Oil

Sand Tailings” to EcoSmart at Metakaolin Stakeholder Meeting in Edmonton,

Alberta, October 16, 2001.

Oxenford, John. Manager, Research Programs, Edmonton Research Centre, Syncrude

Canada. (780) 970-6810, [email protected]

Sills, Ron. Regional Marketing Manager, Lehigh Inland Cement.

Tynebridge Technologies Limited. “Syncrude Kaolin Recovery Project.” September

1998.

University of Calgary and Syncrude Canada. Research Update Presentation on “Potential

Use of Metakaolin from Oil Sand Tailing in Concrete.” October 16, 2001.

Wong, R.C.K., Gillott, J.E., Thomas, M.J., and Poon, C.S. “Calcined Oil Sands Tailings

as a Pozzolanic Admixture for Concrete.” Submitted to Cement and Concrete

Research for publication in November 2002.

11. Appendices

The appendices to this report are prepared separately from this document, and are

available at www.ecosmart.ca.

Appendix 1: AMEC Earth & Environmental Limited (Rusty Morgan). “Metakaolin

Review Meeting Edmonton – January 14, 2003: Summary of Presentation.”

Appendix 2: Bouzoubaâ, N. and Fournier, B. "Current Situation of Supplementary

Cementitious Materials (SCMs) in Canada." CANMET Report MTL 2003-4 (TR),

Natural Resources Canada, Ottawa, April 2003.

Appendix 3: EcoSmart Concrete Project, Minutes of Metakaolin Meeting in

Edmonton, October 16, 2001.

Appendix 4: EcoSmart Concrete Project. Minutes of Metakaolin Meeting in

Edmonton, January 14, 2003

Appendix 5: Fournier, B. Program Manager, Concrete Technology Program,

CANADA. “Presentation of Zhang and Malhotra, 1995 Results”, EcoSmart™

Metakaolin Meeting, Edmonton – October 16, 2001.

EcoSmart™ Metakaolin Study – Report for Action Plan 2000

EcoSmartMKReport 20

Appendix 6: INSA (Pera, Jean). “Analysis of the NLK Project EA 2860 –

EcoSmart™ Concrete Project Metakaolin Pre-Feasibility Study.” December 2002.

Appendix 7: Lord, Ted. Syncrude Canada. Presentation on “Kaolin Clay Derived

from Oil Sands Fine Tailings – The Syncrude Perspective” to EcoSmart at

Metakaolin Stakeholder Meeting in Edmonton, Alberta, January 14, 2003.

Appendix 8: NLK Consultants Inc. “EcoSmart Concrete Project Metakaolin Pre-

Feasibility Study.” September 2002.

Appendix 9: Omotoso, D., Hamza, H., Oliver, J. and Lord, T. Presentation by

CANMET AST, Devon, Alberta Research Council, and Syncrude Research on

“Kaolin in Oil Sand Tailings” to EcoSmart at Metakaolin Stakeholder Meeting in

Edmonton, Alberta, October 16, 2001.

Appendix 10: Tynebridge Technologies Limited. “Syncrude Kaolin Recovery

Project.” September 1998.

Appendix 11: University of Calgary and Syncrude Canada. Research Update

Presentation on “Potential Use of Metakaolin from Oil Sand Tailing in Concrete.”

October 16, 2001.

Appendix 12: Wong, R.C.K., Gillott, J.E., Thomas, M.J., and Poon, C.S. “Calcined

Oil Sands Tailings as a Pozzolanic Admixture for Concrete.” Submitted to Cement

and Concrete Research for publication in November 2002.