February 1, 2008

Lit. No. 27366, Rev. 01

MECHANIC'S GUIDEMECHANIC'S GUIDE

MECHANIC'S GUIDEMECHANIC'S GUIDE

MECHANIC'S GUIDE

SNOSNO

SNOSNO

SNO

WPLWPL

WPLWPL

WPL

OO

OO

O

WSWS

WSWS

WS

Featuring the

FF

FF

F

loStaloSta

loStaloSta

loSta

tt

tt

t

®®

®®

®

MVP PL MVP PL

MVP PL MVP PL

MVP PL

US™ HyUS™ Hy

US™ HyUS™ Hy

US™ Hy

drdr

drdr

dr

aulic System &aulic System &

aulic System &aulic System &

aulic System &

IsolaIsola

IsolaIsola

Isola

tion Module Light Systemtion Module Light System

tion Module Light Systemtion Module Light System

tion Module Light System

SNOSNO

SNOSNO

SNO

WPLWPL

WPLWPL

WPL

OO

OO

O

WSWS

WSWS

WS

CAUTION

Read this manual before servicing the snowplow.

Lit. No. 27366, Rev. 01 February 15, 2008

3

TABLE OF CONTENTS

Introduction .................................................................................................... 4

Preface ...................................................................................................... 4

Recommended Tools ............................................................................... 4

Available Service Items ........................................................................... 4

Safety Information .......................................................................................... 5

System Overview............................................................................................ 8

Blade, T-Frame & Lift Assemblies .......................................................... 8

Snowplow Components .................................................................... 8

Securing Pivot Bar to T-Frame ......................................................... 8

Pivot Plates ........................................................................................ 9

Initial Stand Shoe Setup .................................................................. 10

Stand Shoe Adjustment .................................................................. 10

Cutting Edge Wear and Leveling Adjustment Procedure ............ 11

Blade Spring Replacement Tool (PN 20043) ................................. 12

Lift Arm and Lift Ram Installation................................................... 13

Headlamp Beam Aiming ................................................................. 14

Vehicle Lighting Check ................................................................... 15

Hydraulic ................................................................................................ 16

MVP PLUS™ FloStat

®

Hydraulic System Specifications .............. 16

Hydraulic Fitting and Hose Installation ......................................... 17

Hydraulic Unit Components ........................................................... 18

Hydraulic Component Installation ................................................. 19

Valve Location ................................................................................. 20

Cartridge Valves .............................................................................. 21

Check Valves ................................................................................... 22

Valve Lock Rings ............................................................................. 22

Relief Valves .................................................................................... 23

Electrical ................................................................................................. 24

Wiring ............................................................................................... 24

Electrical Assembly ......................................................................... 25

Cover and Final Assembly .............................................................. 26

Controls .................................................................................................. 27

General Information ........................................................................ 27

MVP PLUS CabCommand Hand-Held Control .............................. 28

MVP PLUS Joystick Control ........................................................... 30

Theory of Operation ..................................................................................... 32

Electrical & Hydraulic Schematics.............................................................. 33

Legend .................................................................................................... 33

Electrical Schematic .............................................................................. 34

Hydraulic Schematic .............................................................................. 35

Raise ....................................................................................................... 36

Lower ...................................................................................................... 38

Angle Right ............................................................................................. 40

Angle Left ............................................................................................... 42

Retract (Vee) ........................................................................................... 44

Scoop ...................................................................................................... 46

Right Extend ........................................................................................... 48

Right Retract .......................................................................................... 50

Left Extend ............................................................................................. 52

Left Retract ............................................................................................. 54

Hold in Raised Position ......................................................................... 56

Striking An Object While Plowing Forward ......................................... 57

Striking An Object While Back Dragging ............................................. 58

Low Beam Headlamps with Snowplow Connected to Vehicle ........... 59

High Beam Headlamps with Snowplow Connected to Vehicle .......... 60

Troubleshooting Guide Table of Contents ................................................. 61

Lit. No. 27366, Rev. 01 February 15, 2008

4

PREFACE

This guide has been prepared to

assist the trained mechanic in the

service of WESTERN

®

snowplows. It

also provides safety information and

recommendations. We urge all

mechanics to read this manual

carefully before attempting to service

the WESTERN snowplow equipment

covered by this guide.

INTRODUCTION

Service of your WESTERN

snowplow equipment is best

performed by your local Western

Products outlet. They know your

snowplow best and are interested in

your complete satisfaction.

RECOMMENDED TOOLS

• Long/Slender Needle-Nosed

Pliers

• Flat Screwdriver

• 12V Test Light

• Torque Wrench

• Allen Wrench Set

• Combination Wrench Set

• 1/4" Drive Ratchet Set w/6" ext.

• 3/8" Drive Ratchet Set

• Deep Socket: 7/8"

• 11/16" Tappet Wrench

• Angle Head Wrenches: 15° and

60°

• Digital Volt/Ohmmeter

• Ammeter

• Pressure Test Kit

• Flashlight

• Pick Set

• Hammer

• Pencil Magnet

• TORX

®

Drivers: T20 and T30

• Automotive Blade-Type Fuses:

7.5- and 15-Amp

• Mini Fuses: 4-Amp

• Vacuum Pump w/3/8" NPT

Barbed Fitting

• 3/8" NPT Plug

TORX

®

is a registered (

®

) trademark of Textron, Inc.

AVAILABLE SERVICE ITEMS

• Motor Bearing Sleeve Repair Kit: PN 64589

(Requires 3/8-24 x 4 Hex Cap Screw, not included.)

• Isolation Module Tester: PN 26470-2

• Pressure Test Kit: PN 56679

(Requires 90° elbow and adapter fittings, not included. See Pump Pressure Test .)

• Spring Removal Tool: PN 20043

• Test Harness: PN 28957

• Diagnostic Harness: PN 29290-1

• Pump Shaft Seal Repair Kit: PN 28856

(Requires 1/4-28 x 4-1/2 Hex Cap Screw, not included.)

Lit. No. 27366, Rev. 01 February 15, 2008

5

NOTE: Indicates a situation or

action that can lead to damage to

your snowplow and vehicle or

other property. Other useful

information can also be described.

SAFETY INFORMATION

INSTRUCTIONS

Pull and hold Lock Pin out; then rotate Handle DOWN

and release Lock Pin. It must lock into LOWER hole.

Push down top of Shoe; Shoe will be on the

ground. Repeat steps 2 and 3 on other side of plow.

Back vehicle away.

After lowering blade and

turning control off, disconnect

electrical connections.

STEP 3

STEP 2

STEP 1

After seating plow horns in receiver brackets,

pull Handle up; Shoe will lift off the ground.

Pull and hold Lock Pin out; then rotate Handle UP

and release Lock Pin. It must lock into UPPER

hole. Stand Hook must grip Receiver Pin.

Plug in electrical connections.

Repeat steps 1 and 2 on

other side of plow.

STEP 1

STEP 2

STEP 3

ON

OFF

OFF

ON

Receiver Pin

Stand Hook

Handle

(Pull)

Lock Pin

Shoe

Handle

MOUNTING PLOW (ON)

Read Owner's Manual for complete instructions.

REMOVING PLOW (OFF)

Read Owner's Manual for complete instructions.

Patents: US 4,999,935; 5,420,480; RE 35,700; 6,145,222; 6,209,231; 6,253,470; 6,526,677; CAN 2,060,425; patents pending.

67796

®

WARNING/CAUTION AND INSTRUCTION LABELS

Become familiar with and inform users about the warning and instruction labels

on the back of the blade.

NOTE: If labels are missing or cannot be read, see your sales outlet.

Warning and Caution Label

Instruction Label

CAUTION

Indicates a potentially

hazardous situation that, if not

avoided, may result in minor or

moderate injury. It may also be

used to alert against unsafe

practices.

WARNING

Indicates a potentially

hazardous situation that, if not

avoided, could result in death

or serious personal injury.

SAFETY DEFINITIONS

Lit. No. 27366, Rev. 01 February 15, 2008

6

SAFETY INFORMATION

SAFETY PRECAUTIONS

Improper installation and operation

could cause personal injury, and/or

equipment and property damage.

Read and understand labels and the

Owner's Manual before installing,

operating, or making adjustments.

WARNING

Lower blade when vehicle is

parked. Temperature changes

could change hydraulic

pressure, causing the blade to

drop unexpectedly or damaging

hydraulic components. Failure

to do this can result in serious

personal injury.

WARNING

Remove blade assembly before

placing vehicle on hoist.

WARNING

Keep 8' clear of the blade when

it is being raised, lowered or

angled. Do not stand between

the vehicle and blade or

directly in front of the blade. If

the blade hits or drops on you,

you could be seriously injured.

WARNING

Keep hands and feet clear of

the blade and T-frame when

mounting or removing the

snowplow. Moving or falling

assemblies could cause

personal injury.

WARNING

Do not exceed GVWR or GAWR

including blade and ballast. The

rating label is found on the

driver-side vehicle door

cornerpost.

CAUTION

Refer to the current Selection

List for minimum vehicle

recommendations and ballast

requirements.

WARNING

To prevent accidental

movement of the blade, always

turn the ON/OFF switch to OFF

whenever the snowplow is not

in use. The control indicator

light will turn off.

PERSONAL SAFETY

• Remove ignition key and put the

vehicle in park or in gear to

prevent others from starting the

vehicle during installation or

service.

• Wear only snug-fitting clothing

while working on your vehicle or

snowplow.

• Do not wear jewelry or a necktie,

and secure long hair.

• Wear safety goggles to protect

your eyes from battery acid,

gasoline, dirt and dust.

• Avoid touching hot surfaces such

as the engine, radiator, hoses

and exhaust pipes.

• Always have a fire extinguisher

rated BC handy, for flammable

liquids and electrical fires.

FIRE AND EXPLOSION

Be careful when using gasoline. Do

not use gasoline to clean parts. Store

only in approved containers away

from sources of heat or flame.

HYDRAULIC SAFETY

• Always inspect hydraulic

components and hoses before

using. Replace any damaged or

worn parts immediately.

• If you suspect a hose leak, DO

NOT use your hand to locate it.

Use a piece of cardboard or

wood.

FUSES

The WESTERN

®

electrical and

hydraulic systems contain several

blade-style automotive fuses. If a

problem should occur and fuse

replacement is necessary, the

replacement fuse must be of the

same type and amperage rating as

the original. Installing a fuse with a

higher rating can damage the system

and could start a fire. Fuse

Replacement, including fuse ratings

and locations, is located in the

Maintenance section of the Owner's

Manual.

WARNING

Hydraulic fluid under pressure

can cause skin injection injury.

If you are injured by hydraulic

fluid, get medical attention

immediately.

WARNING

Gasoline is highly flammable

and gasoline vapor is explosive.

Never smoke while working on

vehicle. Keep all open flames

away from gasoline tank and

lines. Wipe up any spilled

gasoline immediately.

Lit. No. 27366, Rev. 01 February 15, 2008

7

SAFETY INFORMATION

TORQUE CHART

CAUTION

Read instructions before

assembling. Fasteners should

be finger tight until instructed

to tighten according to torque

chart. Use standard methods

and practices when attaching

snowplow including proper

personal protective safety

equipment.

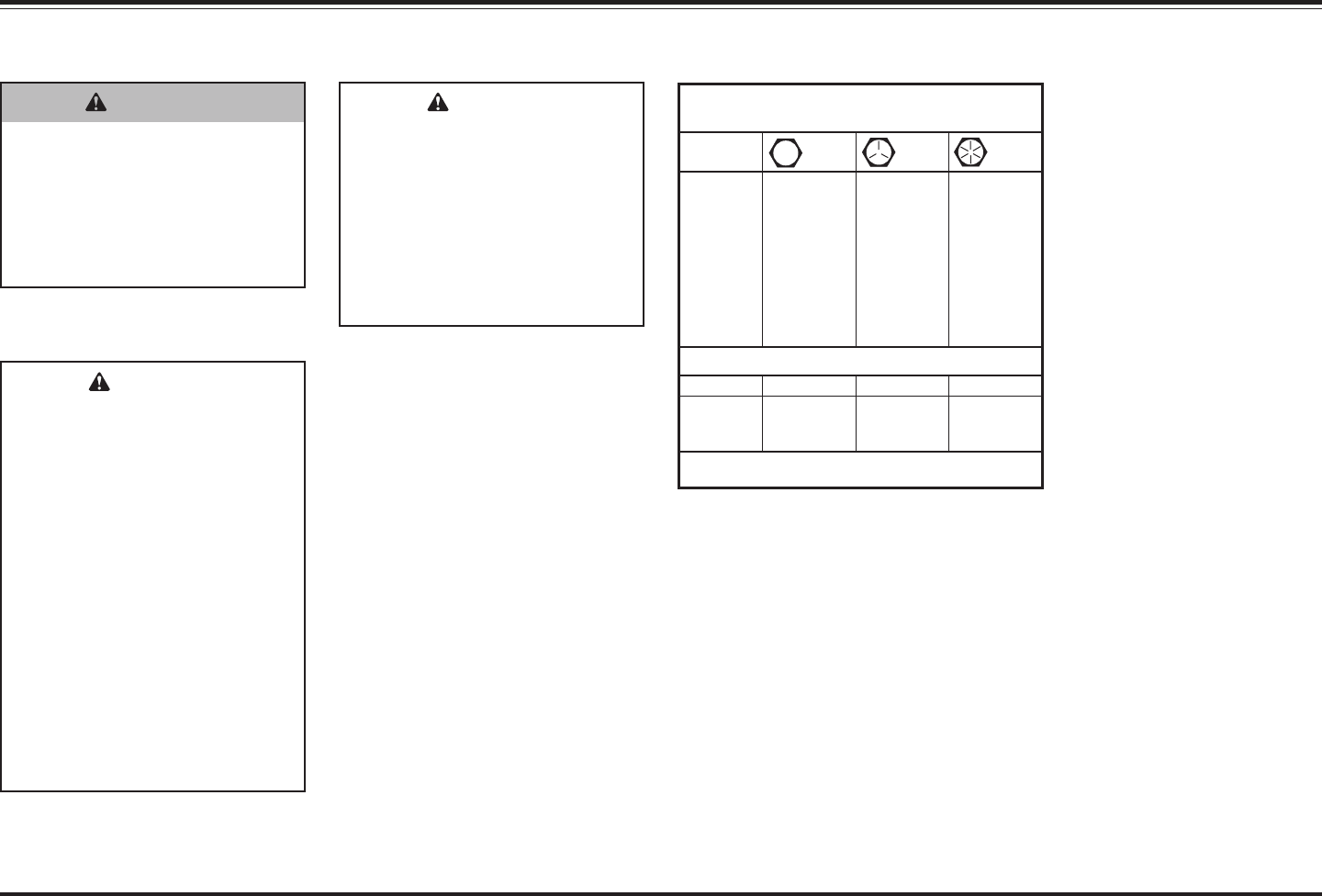

Recommended Fastener Torque

Chart (Ft.-Lb.)

Size

SAE

Grade 2

SAE

Grade 5

SAE

Grade 8

1/4-20

5/16-18

3/8-16

3/8-24

7/16-14

1/2-13

9/16-12

5/8-11

3/4-10

7/8-9

1-8

6

11

19

24

30

45

66

93

150

150

220

9

18

31

46

50

75

110

150

250

378

583

13

28

46

68

75

115

165

225

370

591

893

Metric Grade 8.8 (Ft.-Lb.)

Size TorqueSize

Torque

M 6

M 8

M 10

M 12

M 14

M 16

7

17

35

60

95

155

These torque values apply to fasteners

except those noted in the instruction.

VENTILATION

BATTERY SAFETY

WARNING

Vehicle exhaust contains lethal

fumes. Breathing these fumes,

even in low concentrations,

can cause death. Never

operate a vehicle in an

enclosed area without venting

exhaust to the outside.

CAUTION

Batteries normally produce

explosive gases which can

cause personal injury.

Therefore, do not allow flames,

sparks or lit tobacco to come

near the battery. When

charging or working near a

battery, always cover your face

and protect your eyes, and

also provide ventilation.

Batteries contain sulfuric acid

which burns skin, eyes and

clothing.

Disconnect the battery before

removing or replacing any

electrical components.

Lit. No. 27366, Rev. 01 February 15, 2008

8

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

SNOWPLOW COMPONENTS

Stacking

Stop

Shoe

Handle

T-Frame

Assembly

Upper Lift Frame

Lower Lift

Frame

Lock Pin

Stand

Plow

Horn

Lift Arm

1. Install a 1" jam nut and tighten to

25 ft-lb, then loosen 1/16 turn.

2. Hold 1" cap screw and jam nut to

prevent rotation, and install

1" locknut. Tighten locknut

securely against jam nut.

NOTE: When properly adjusted,

pivot bar should pivot freely

without any looseness.

1" Locknut

1" Jam Nut

Pivot Bar

Pivot

Bushing

1" x 7"

Cap Screw

SECURING PIVOT BAR TO T-FRAME

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

9

Configuration 3

Configuration 4

Pivot Pin

Pivot Pin

Pivot Plate A

(Flat Side Up)

Pivot Plate B

(Flat Side Up)

PIVOT PLATES

1. Measure the distance "d" from

the ground to the top edge of the

receiver bracket. Measure both

sides and determine average

value "d".

2. Use dimension "d" from Step 1,

and the following chart to

determine the proper pivot plate

mounting position and pivot hole

selection.

d

Top Edge of

Receiver

Pivot Plate A

(Bevel Side Up)

Pivot Pin

Pivot Pin

Pivot Plate B

(Bevel Side Up)

Configuration 1

Configuration 2

Pivot Plate Mounting and Hole Positions

for Configurations 1 & 2

Pivot Plate Mounting and Hole Positions

for Configurations 3 & 4

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

Pivot Plate Configuration Chart

Dimension

"d" Configuration

Stacking

Stop

13.0" – 14.5" 1 No

14.5" – 16.0" 2 No

16.0" – 17.5" 3 No

17.5" – 19.0" 4 Yes

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

10

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

Config. 1

Config. 2

Config. 3

Config. 4

INITIAL STAND SHOE SETUP

The illustration below shows the

recommended starting positions for

configuring your stand shoes.

9-3/4" to 11-1/4"

1-3/8" to 2-1/8"

Roll Pin

STAND SHOE ADJUSTMENT

1. Attach snowplow to the vehicle

mount. With snowplow lowered

to the ground and on level

pavement, measure the

dimension from the ground to the

center of the pivot bar cap screw.

This dimension must be 9-3/4" to

11-1/4".

2. With the snowplow attached and

on the ground, place the stand

arm in the lower position with the

lock pin engaged and with the

stand shoe fully retracted in the

"up" position. Measure the

distance from the ground to the

bottom of the stand shoe. This

distance should be 1-3/8" to

2-1/8". The stand can be

adjusted to achieve this

dimension by removing the roll

pin and selecting the proper hole

in the stand stem. When the

stand height is correct, cut and

remove the spring tie.

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

11

After the snowplow has been

installed on the vehicle in the correct

configuration, a fine adjustment can

be made to bring the cutting edges of

the snowplow in full contact with the

ground across the entire cutting

edge. This adjustment feature should

be used as the cutting edges begin

to wear in order to maintain an even

wear pattern across both cutting

edges and provide good scraping

action.

1. Snowplow must be installed on a

properly ballasted vehicle, in the

correct configuration.

2. Vehicle and snowplow must be

on a level surface.

3. If the optional shoe kit has been

installed on the blade, remove

the shoes during this adjustment

procedure.

4. Place blade wings in scoop

position on the ground with no

tension on lift chains.

Rear Fasteners

Front Fasteners

Pushbeam

T-Frame

5. Remove the rear pushbeam to

T-frame fasteners. Loosen the

front fasteners, and allow the

blade to find a level position.

6. Select the hole in the rear of the

T-frame that is best aligned with

the rear hole in the pushbeam,

and reinstall the rear fasteners.

Tighten all four fasteners to

250 ft-lb.

7. Raise and lower the blade

several times. The cutting edge

should be contacting the level

surface across the full length of

the cutting edge.

8. Verify that the cutting edges

remain in full contact with the

ground while the wings are

shifted from the scoop position to

a fully retracted (vee) position.

9. Reinstall blade shoes if removed

in Step 3.

Complete this procedure as often as

required to provide even cutting edge

wear. Replace the cutting edge(s)

when worn to within 1" of the

carriage bolts.

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

Select the hole

best aligned with

rear hole in

pushbeam.

CUTTING EDGE WEAR AND LEVELING ADJUSTMENT PROCEDURE

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

12

1. Insert the threaded rod in

through the hole in the channel

weldment. Be sure the threaded

hole in the tab on the rod is

nearest to the channel.

CAUTION

Servicing the trip springs

without special tools and

knowledge could result in

personal injury.

2. Place the assembly on to the top

anchor above the spring as

illustrated. Be sure to place the

spring bar in between the tabs on

the rod. Insert the 1/2" x 1-1/2"

Gr. 5 cap screw through the

outside tab, through the hole in

the spring bar, and tighten into

the threaded hole.

3. Drop the 1/2" flat washer Gr. 8

over the threaded rod and fasten

the nut to the threaded rod.

Tighten the nut until the spring

bar is raised enough to insert the

pin through the pin hole. Center

the pin within the hole.

4. Loosen the nut to lower the

spring bar. Remove the spring

tool assembly by removing the

1/2" cap screw.

5. Remove the spring from the

blade by removing the bolt from

the bottom of the spring bar.

6. Insert the new spring with the

spring bar up through the top

anchor on the blade. Fasten the

bottom of the spring bar to the

anchor on the trip edge with the

previously removed fasteners.

Tighten.

7. Repeat Steps 1 and 2 above.

8. Repeat Step 3 above, except

remove the pin from the spring bar.

9. Repeat Step 4 above.

Channel

Rod

1/2" x 1-1/2"

Cap Screw Gr. 5

1/2" Coupling

Nut

1/2" Flat Washer Gr. 8

1/4" x 1-1/4"

Pin

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

BLADE SPRING REPLACEMENT TOOL (PN 20043)

Excerpts taken from Removable Spring Tool Installation Instructions (Lit. No. 6486, Rev. 02).

Lit. No. 27366, Rev. 01 February 15, 2008

13

LIFT ARM AND LIFT RAM INSTALLATION

Lift Arm

3/4" Flat

Washer

Cotter Pin

Lift

Arm

Lift Frame

Vertical

Support

3/4" Plastic

Washer

3/4" x 3-1/4"

Clevis Pin

3/4" x 3-1/4" Clevis Pin

3/4" x 3"

Heat Treated (HT) Pin

3/4"

Washer

Lift Ram

Cotter Pin

Cotter Pin

3/4"

Washer

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

Lit. No. 27366, Rev. 01 February 15, 2008

14

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

HEADLAMP BEAM AIMING

Torque headlamp fasteners to 45 ft-lb

once correct visual aim is achieved.

1. Place vehicle on a level surface

25 feet in front of a matte-white

screen, such as a garage door.

The screen should be

perpendicular both to the ground

and to the vehicle centerline.

2. The vehicle should be equipped

for normal operation. The

snowplow blade should be in

place and in raised position. Below

are steps listed by the Society of

Automotive Engineers (SAE)

pertinent to headlamp aiming in

specification #SAE J599d.

3. Prepare vehicle for headlamp

aim or inspection. Before

checking beam aim, the

inspector will:

a. Remove ice or mud from

under fenders.

b. Set tire inflation pressures to

the values specified on

vehicle information label.

c. Check springs for sag or

broken leaves.

d. See that there is no load in

the vehicle other than the

driver and ballast as specified

in the Selection List.

e. Check functioning of any

automatic vehicle leveling

systems and specific

manufacturer's instructions

pertaining to vehicle

preparation for headlamp

aiming.

f. Clean lenses.

g. Check for bulb burnout and

proper beam switching.

h. Stabilize suspension by

rocking vehicle sideways.

4. Mark (or tape) the vertical

centerline of the snowplow

headlamps and the vertical

centerline of the vehicle on the

screen. Mark the horizontal

centerline of the snowplow

headlamps on the screen

(distance from ground to

snowplow headlamp centers).

5. Align the top edge of the high

intensity zone of the snowplow

lower beam below the horizontal

centerline and the left edge of

the high intensity zone on the

vertical centerline for each

snowplow headlamp. (Refer to

diagram.)

Vertical

Centerline

ahead of DS

Snowplow

Headlamp

Align with

vehicle

centerline.

Vertical

Centerline

ahead of PS

Snowplow

Headlamp

Screen

Located

25 Feet from

Snowplow

Headlamps

Horizontal

Centerline

of Snowplow

Headlamps

High Intensity Zones

of Snowplow Headlamps

on Low Beam

Excerpts taken from Snowplow Headlamp Beam Aiming Instructions (Lit. No. 27769, Rev. 02).

Lit. No. 27366, Rev. 01 February 15, 2008

15

SYSTEM OVERVIEW – BLADE, T-FRAME & LIFT ASSEMBLIES

VEHICLE LIGHTING CHECK

1. Check the operation of vehicle

lights and then snowplow lights

with snowplow mounted to

vehicle and all harnesses

connected.

Turn signals and parking lamps

Parking lamps ON

• Both vehicle and snowplow

parking lamps should be ON at

the same time.

Driver-side turn signal ON

• Both vehicle and snowplow

driver-side turn signal lamps

should flash at the same time.

Passenger-side turn signal ON

• Both vehicle and snowplow

passenger-side turn signal

lamps should flash at the same

time.

Headlamps

Move vehicle headlamp switch to

the "ON" position. Connecting

and disconnecting the headlamp

harness plug should switch

between vehicle and snowplow

headlamps as follows:

Headlamp harness plug

DISCONNECTED

• Vehicle headlamps should be

ON.

• Snowplow headlamps should

be OFF.

Headlamp harness plug

CONNECTED

• Snowplow headlamps should

be ON.

• Vehicle headlamps should be

OFF.

Dimmer switch should dim

whichever headlamps are

operating. The high beam

indicator on the dash should light

when either set of headlamps is

on high beam.

Daytime Running Lamps (DRLs)

With headlamp switch OFF,

activate the DRLs.

Headlamp harness plug

DISCONNECTED

• Vehicle DRLs should be ON.

• Snowplow headlamps should be

OFF.

Headlamp harness plug

CONNECTED AND vehicle uses

the headlamp bulbs for DRLs:

• Snowplow headlamps should

be ON in DRL mode (with

reduced intensity compared to

high or low beam).

• Vehicle DRLs should be OFF.

Headlamp harness plug

CONNECTED AND vehicle uses

lamps other than the headlamp

bulbs for DRLs:

• Snowplow headlamps should

be ON in DRL mode (with

reduced intensity compared to

high or low beam).

• Vehicle DRLs should be ON.

• Vehicle headlamps should be

OFF.

Joystick Control or

CabCommand Control

The control indicator light should

light whenever the control

ON/OFF switch and the ignition

(key) switches are both in the

"ON" position. The snowplow

plugs do need to be connected to

the vehicle harness connectors.

2. Connect all snowplow and

vehicle harnesses. Raise the

snowplow and aim snowplow

headlamps according to the

Snowplow Headlamp Beam

Aiming instructions included with

the headlamps and any state or

local regulations.

3. Check aim of vehicle headlamps

with snowplow removed.

4. When the snowplow is removed

from the vehicle, install plug

covers on the vehicle battery

cable and lighting harness. Insert

the snowplow battery cable and

lighting harness into the cable

boot on the snowplow.

CAUTION

On 2-plug electrical systems,

plug covers shall be used

whenever snowplow is

disconnected. Vehicle Battery

Cable is 12-volt unfused source.

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

16

Breather

Quill

Reservoi

r

Valve

Manifold

Motor

Drain

Cap

Fill

Plug

SYSTEM OVERVIEW – HYDRAULIC

Western Products' FloStat hydraulic

system delivers fast and uniform

speed for lifting and angling. The

system raises the blade in two

seconds, and all angling functions

are less than five seconds.

Relief Valve Settings

• Pump Relief Valve (1)

2250 psi

2-1/2 turns CCW from fully seated

• Base-End Relief Valves (4)

4600 psi

1-1/4 turns CCW from fully seated

• Rod-End Relief Valves (2) 3700 psi

1-1/4 turns CCW from fully seated

CAUTION

Do not mix different types of

hydraulic fluid. Some fluids are

not compatible and may cause

performance problems and

product damage.

Electrical System (Approximate)

• Solenoid Coil Resistance =

7 ohm at room temperature

• Solenoid Coil Amp Draw =

1.5 Amps

• Motor Relay Coil Resistance =

13.5 ohm @ 25° C

• Motor Relay Amp Draw = 0.7 Amp

• Maximum Motor Amp Draw =

250 Amps over relief at 2250 psi

• Switch Accessory Lead Draw =

0.75 Amp

Fastener Torque

System Capacity

• Unit Reservoir = 1-3/4 Quarts

• System Total = 2-3/8–2-3/4 Quarts

Hydraulic Fluid

Use WESTERN

®

High Performance

Fluid to –40°F (–40°C) or other fluid

conforming to military specification

MIL-H-5606A, such as Mobil Aero

HFA or Shell AeroShell

®

Fluid 4. Use

of other than these recommended

fluids may cause poor hydraulic

system performance and damage to

internal components.

Pump Motor

AeroShell

®

is a registered (

®

) trademark of Shell Oil Company.

MVP PLUS™ FloStat

®

HYDRAULIC SYSTEM SPECIFICATIONS

12V DC with +/– connection

2200–2300 psi pump relief valve

4550–4650 psi base-end relief valves

3650–3750 psi rod-end relief valves

4.5" dia 1.5 kW motor

.000652 GAL/REV pump

Hydraulic Hose 1/4 SAE 100R1 and

3/8 SAE 100R17

Vehicle Control Harness Fuses

(Automotive Blade-Type)

• Park/Turn = 15 Amp

• Control = 7.5 Amp

Hydraulic Unit Harness Fuses

(Mini)

• 4 Amp

Pump Cap Screws 5/16-18 x 2-1/2 150-160 in-lb

Motor Terminals (+ and –) 5/16-18 Nut 50-60 in-lb

Motor to Manifold Cap Screws 1/4-20 x 6-1/4 30-40 in-lb

Reservoir Screws #10-24 x 5/16 30-35 in-lb

Solenoid Valves 7/8 Hex Head 19-21 ft-lb

Coil Nuts 3/4 Hex-Head Jam Nut 40-60 in-lb

Cover Screws 1/4-20 x 1/2 Shoulder Screw 60-80 in-lb

SAE O-Ring Plugs 1/8 or 5/32 Internal Hex 55-65 in-lb

Hydraulic Unit Mount Bolts 3/8-16 x 1 25-33 ft-lb

Check Valves 7/8 Hex Head 19-21 ft-lb

Secondary to Primary Manifolds 1/4-20 x 3 10-13 ft-lb

Motor Relay Small Terminals 10-32 Nut 15 in-lb max

Motor Relay Large Terminals 5/16-24 Nut 35 in-lb max

Motor Relay Mount Screws 1/4-20 x 1/4 90-100 in-lb

Plow Module Mount Screws 1/4-20 x 5/8 60-70 in-lb

Angle Ram Piston Locknuts 100-120 ft-lb

Angle Ram Gland Nuts 150-180 ft-lb

Lit. No. 27366, Rev. 01 February 15, 2008

17

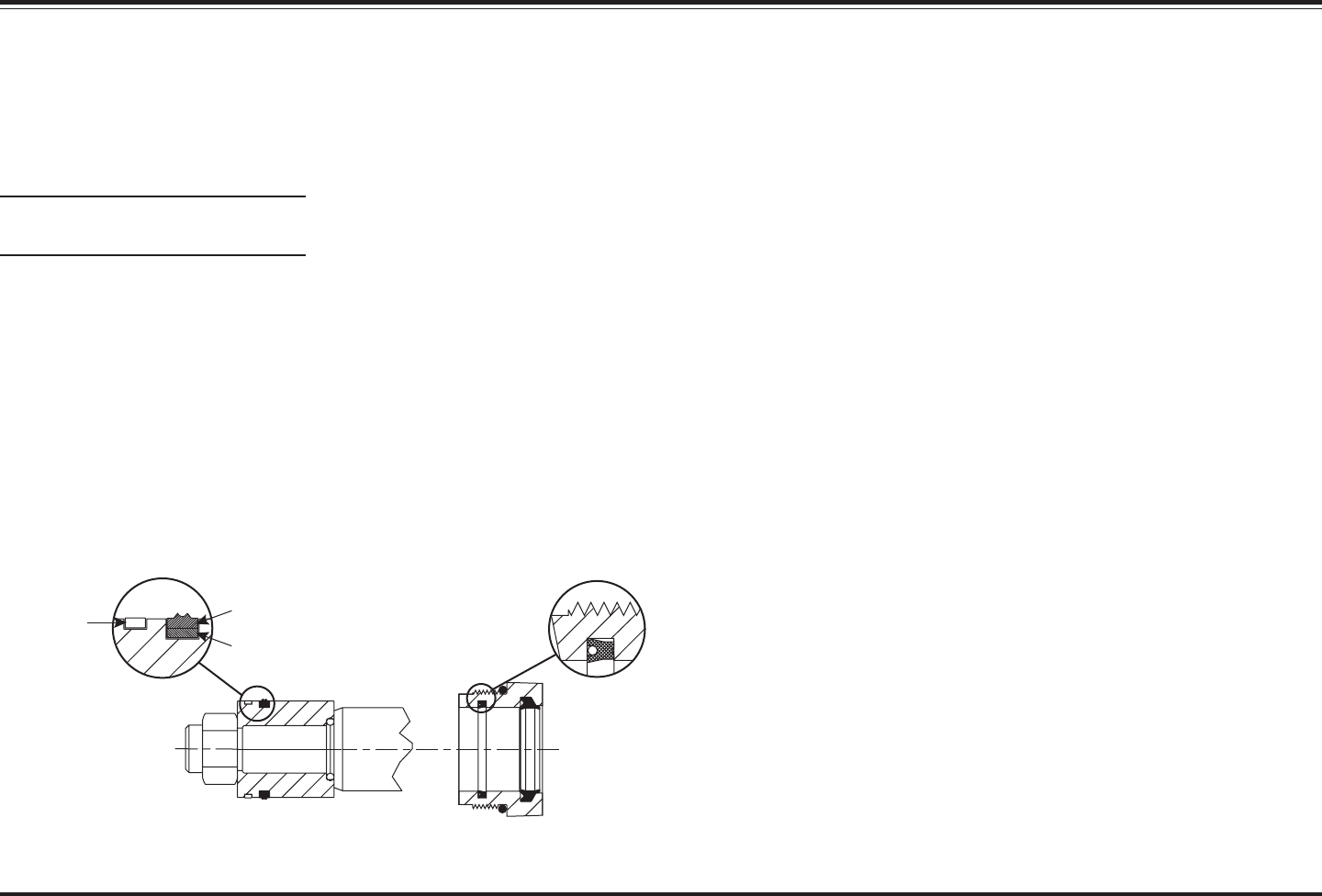

SYSTEM OVERVIEW – HYDRAULIC

NOTE: Overtightening JIC hose

fitting ends will result in a

fractured fitting.

Do not use thread sealant or tape on

hoses and fittings. This could

damage product.

Use the following procedure and

fitting orientation illustrations to

install SAE O-ring fittings in valve

block and rams.

1. Remove plug from ram or

manifold port. Use a rag to catch

residual fluid when removing

manifold plugs.

2. Turn jam nut on fitting as far back

as possible.

3. Lubricate O-ring with clean

hydraulic fluid.

4. Screw fitting into port by hand as

far as it will go. The washer

should contact port face and

shoulder of jam nut threads.

5. Unscrew fitting to proper position,

no more than one full turn.

6. Use one wrench to hold fitting

body in position and tighten the

jam nut with another wrench until

the washer again contacts port

face. Tighten 1/8–1/4 turn to lock

fitting in place.

HYDRAULIC FITTING AND HOSE INSTALLATION

PS Rod End

PS Base End

DS Rod End

Lift Ram

45°

90°

Elbow

10°10°

90°

Elbow

45°

DS Base End

45°

90°

Elbow

Angle Rams

Hydraulic Unit

Long 90°

Elbows

90° Elbow

and Cap

Long 90°

Elbows

90°

Elbow

10°

45°

45°

30°

30°

10°

Use the following procedure and

illustrations to install hydraulic

hoses.

1. Attach all hoses to fittings,

routing hoses as shown. Leave

hoses finger tight at this time.

1/4" x 36" Hose

To Passenger-

Side Rod (Front)

3/8" x 45" Hose

To Driver-Side

Base (Rear)

3/8" x 38" Hose

To Passenger-

Side Base (Rear)

1/4" x 12" Hose

To Lift Ram

1/4" x 42" Hose

To Driver-Side

Rod (Front)

2. Wrap angle ram hoses with

protective hose wrap as shown.

Start wrap on base end hose so

wrap covers diagonal brace.

Group hoses away from brace

and continue wrapping, forming a

smooth outward loop to the

hydraulic unit.

3. Using a wrench to hold the hose

end in position, tighten all hose

fittings 1/8–1/4 turn past finger

tight.

Excerpts taken from MVP PLUS™ Snowplow Installation Instructions (Lit. No. 44229, Rev. 05).

Lit. No. 27366, Rev. 01 February 15, 2008

18

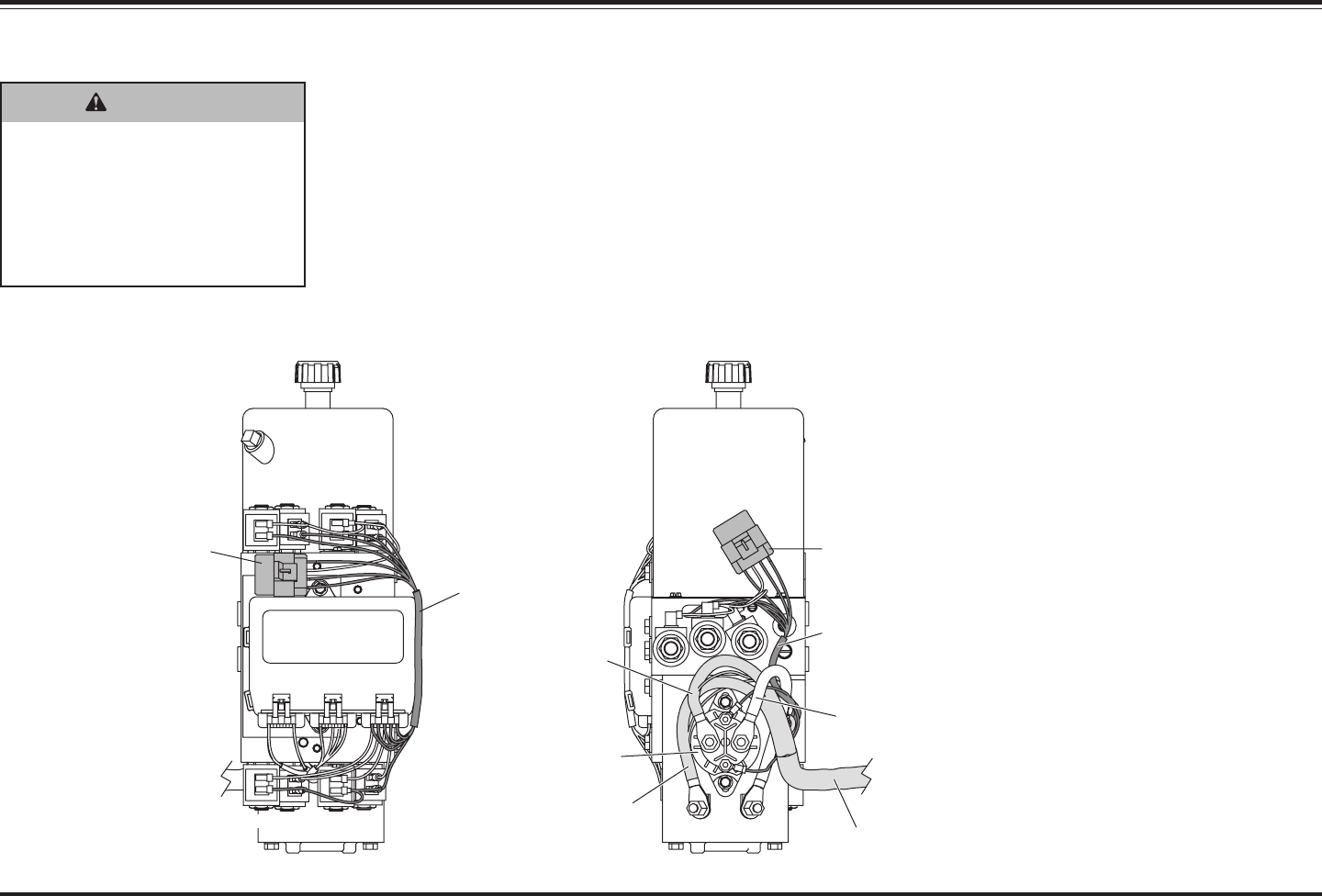

HYDRAULIC UNIT COMPONENTS

SYSTEM OVERVIEW – HYDRAULIC

Magnet

Fill/Fluid Level Plug

Breather

Reservoir

O-Ring

Pump

Pump

O-Ring

Quill

O-Ring

Boss Plug

Pump

Shaft

Seal

Filter

DS

Base-End Relief

Valves

DS Rod-End

Relief Valve

PS Rod-End

Relief Valve

PS

Base-End

Relief

Valves

Coil

Solenoid

Cartridge

Valve

Valve

Lock Ring

Check

Valve

Pump

Relief Valve

Primary to

Secondary

Block O-Rings

Motor

Lit. No. 27366, Rev. 01 February 15, 2008

19

HYDRAULIC COMPONENT INSTALLATION

SYSTEM OVERVIEW – HYDRAULIC

Ram Seal Installation

1. Lubricate the seals and O-rings

with hydraulic fluid.

NOTE: Placing the part in warm

fluid will facilitate installation.

2. Install the seals and O-rings in

the exact orientation as shown.

3. For single-acting (lift) rams:

Slide the gland nut over the split

bearing end of the rod to prevent

damaging the seals.

For double-acting (angle)

rams: Remove the piston, and

slide the gland nut over the

threaded end of the rod to

prevent damaging the seals.

It is possible to remove cartridges

and check valves from a hydraulic

unit without draining the hydraulic

fluid from the reservoir.

1. Install the Diagnostic Harness

(PN 29290-1) following the

instructions included with the kit.

2. Cycle through the control

functions twice to remove the

pressure in the hydraulic unit.

3. Slowly remove the breather from

the top of the hydraulic unit.

4. Either (a) completely drain

reservoir and skip to Step 9 or

(b) proceed for instructions on

removing hydraulic components

without completely draining

reservoir.

4. For double-acting (angle) rams

only: Install the piston in the

orientation shown. Tighten piston

locknut to 100–120 ft-lb.

5. Carefully reassemble the ram.

6. Insert a 0.012" feeler gauge

between the front surface of the

cylinder tube face and the hex of

the gland nut. Tighten the gland

nut until it is snug against the

feeler gauge.

7. Remove the feeler gauge, and

tighten the gland nut an

additional 1/4 turn. This

adjustment procedure will

provide a torque of 150–180 ft-lb.

Outer Seal

Inner Backing

Ring

Double-Acting

Rams Only

Single- and

Double-Acting

Rams

Split Wear

Ring (If Used)

Cartridge & Check Valve Removal

5. Install a 3/8" barb fitting into the

top of the reservoir tank.

6. Attach a hand-operated vacuum

pump to the barb fitting.

7. Using the vacuum pump, pull a

vacuum of approximately

5"–10" Hg.

8. You should now be able to

remove cartridges and check

valves from the hydraulic unit

with minimal fluid loss. Maintain

the vacuum until the replacement

cartridge/check valve has been

installed. Once the replacement

part has been installed, release

the vacuum and remove the

3/8" barb fitting.

9. Reinstall the breather and

remove the 29290-1 Diagnostic

Harness according to the

instructions included with the kit.

Excerpts taken from Gland Nut Ram Seal Kits Service Literature (Lit. No. 28944, Rev. 01).

Lit. No. 27366, Rev. 01 February 15, 2008

20

SYSTEM OVERVIEW – HYDRAULIC

VALVE LOCATION

S4

S5

S6

S7

DS Base-End

Relief Valves

PS Base-End

Relief Valves

DS

Rod-End

Relief

Valve

PS

Rod-End

Relief

Valve

Pump Relief

Valve

Pump Pressure

Test Port

Quill

DS

Rod-End

Check

Valve

DS Base-End

Check Valve

PS

Rod-End

Check

Valve

PS Base-End

Check Valve

S8

S9

S10

S11

S1

S2

S3

Valve Type

Wire

Colors

S1

SV08-2004 White & Red

S2

SVCV08-20 Green & Red

S3

SV08-2004 Blue & Red

S4

SVCV08-20 Tan & Red

S5

SV08-2004 Black & Red

S6

SF08-2015 Yellow & Red

S7

SVCV08-20 Brown & Red

S8

SVCV08-20 Grey & Red

S9

SV08-2004 White & Red

S10

SF08-2015 Green & Red

S11

SVCV08-20 Orange & Red

Lit. No. 27366, Rev. 01 February 15, 2008

21

CARTRIDGE VALVES

The MVP PLUS™ snowplow

FloStat

®

hydraulic system performs

10 blade movement functions.

All functions require the vehicle

ignition (key) switch to be in the

"RUN" or "ACCESSORY" position

and the power to be activated on the

snowplow cab control.

Nine of the ten hydraulic functions

require energizing the electric motor

and opening solenoid cartridge

valves. The LOWER function does

not energize the motor but requires

opening of one valve.

NOTE: Cartridges S6 and S10 have

the letter "F" stamped on the end

of the stem. These cartridges have

a higher pressure rating than the

"SV" cartridges. Cartridges and

their lock rings must be installed

in the correct locations for proper

system performance.

SYSTEM OVERVIEW – HYDRAULIC

SV08-2004 S3 ON

SV08-2004 S1

MOVEMENT

BLADE

RAISE LOWER SCOOPVEE

SF08-2015 S6

EXTEND

LEFT

S4SVCV08-20 ON ON

SVCV08-20 S2 ON

SV08-2004

SVCV08-20

SVCV08-20

SV08-2004

SVCV08-20

SF08-2015

S5

S8

S11

S9

S7

S10

ON

MOTOR M ONON

ON

ON

ON

ON

ON ON

ON

ONON

ONONON

ON

ON

ONON

ONON

ANGLE

RIGHT

ANGLE

LEFT

RIGHT

RETRACT

ON

ON

ON

ON

RIGHT

EXTEND

ON

ON

ON

LEFT

RETRACT

ON

ON

ON

ON

Lit. No. 27366, Rev. 01 February 15, 2008

22

SYSTEM OVERVIEW – HYDRAULIC

CHECK VALVES

The check valves supply make-up

fluid to the low-pressure side of a

ram that is extending or retracting

through a relief valve due to impact

on one or both wings.

Tighten check valves to 19–21 ft-lb.

VALVE LOCK RINGS

Install valve lock rings over the

base-end check valves only (not

rod-end check valves). Also install

valve lock rings over cartridge valves

S6 and S10 only (not any other

cartridges).

After tightening check valve or

cartridge, place valve lock ring over

hex and tighten screw to 45–55 in-lb.

Rod-End

Check Valves

(No Lock Rings)

Base-End

Check Valves

Valve Lock

Rings

Valve Lock Ring

S6 Cartridge

S10 Cartridge

Valve Lock Ring

DS Rod-End

Check Valve

DS

Base-End

Check Valve

PS Rod-End

Check Valve

PS

Base-End

Check Valve

NOTE: Cartridges S6 and S10 have

the letter "F" stamped on the end

of the stem. These cartridges have

a higher rating than the "SV"

cartridges. Cartridges and their

lock rings must be installed in the

correct locations for proper

system performance.

Lit. No. 27366, Rev. 01 February 15, 2008

23

RELIEF VALVES

When all cartridge valves are closed,

hydraulic fluid is trapped in the ram

by the solenoid cartridge valves,

check valves, base-end relief valves

and rod-end relief valves.

When the snowplow contacts an

object while plowing, force of the

impact increases hydraulic pressure

in the base end of the ram. When

pressure exceeds 4600 psi, the ram's

base-end relief valves open, allowing

hydraulic fluid back to the reservoir.

The rod-end check valve allows fluid

to fill the rod end of the ram.

SYSTEM OVERVIEW – HYDRAULIC

PS

B

Base-End

Relief Valves

C

Pump Relief Valve

Pressure

Test Port

DS

A

Rod-End

Relief Valves

PS

DS

A (Qty 2)

B (Qty 4)

C (Qty 1)

1-1/4

1-1/4

2-1/2

3700

4600

2250*

Relief

Valve

Approx.

Pressure

(psi)

# of Turns

Out (ccw)

from

Fully Seated

* See the Pump Pressure Test

Section for details.

When the snowplow contacts an

object while back dragging, force of

the impact increases hydraulic

pressure in the rod end of the ram.

When pressure exceeds 3700 psi,

the ram's rod-end relief valve opens,

allowing hydraulic fluid into the

reservoir passage. The base-end

check valve allows fluid to fill the

base end of the ram. Because of

differential area on either side of the

ram's piston, fluid flows from the

reservoir to the base end.

NOTE: Relief valves B and

components are not interchangeable

with A and C. See Relief Valve

Inspection and Adjustment Section

for service.

NOTE: See "Striking an Object

While Plowing" Schematics for

Details.

Lit. No. 27366, Rev. 01 February 15, 2008

24

Battery

RED

BLK

4321

Vehicle

Headlamps

Park/Turn

Lamps

Vehicle

Headlamps

Park/Turn

Lamps

Factory Vehicle Harness

Factory Vehicle Harness

Vehicle Battery Cable

To Snowplow

Control

To Switched

Accessory

Fire Wall

RED

Vehicle Lighting Harness (11-Pin)

Vehicle Control Harness

Adapter

Long Plug-In Harness

Short Plug-In Harness

15-Amp Fuse (Park/Turn)

7.5-Amp Fuse (Control)

Isolation Module

BAT

WIRING

SYSTEM OVERVIEW – ELECTRICAL

CAUTION

On 2-plug electrical systems, plug

covers shall be used whenever

snowplow is disconnected.

Vehicle Battery Cable is 12-volt

unfused source.

NOTE: The Isolation Module and short plug-in harness, containing the

park and DRL lamp wire, are shown on the driver side for illustration

purposes only. Location may be different for the vehicle.

Lit. No. 27366, Rev. 01 February 15, 2008

25

ELECTRICAL ASSEMBLY

SYSTEM OVERVIEW – ELECTRICAL

C

8-Solenoid

Harness

C

B

A

Fuse

Holder

Plow Module

C

B

A

S5S4 S6 S7

S9

S8 S10 S11

A

Plow Battery Cable

B

3-Solenoid

Harness

8" Red Cable

Fuse Holder

Black

Red

S1 S2 S3

1/4-20 x 1/4

Tapping Screw (2)

90-100 in-lb

5/16-18 Nut (2)

50-60 in-lb

5/16-24 Nut (2)

Max. 35 in-lb

+

-

10-32 Nut (2)

Max. 15 in-lb

1/4-20 x 5/8

Tapping Screw (2)

60-70 in-lb

Harness Valve Type

Wire

Colors

S1

SV08-2004 White & Red

S2

SVCV08-20 Green & Red

B

S3

SV08-2004 Blue & Red

S4

SVCV08-20 Tan & Red

S5

SV08-2004 Black & Red

S6

SF08-2015 Yellow & Red

S7

SVCV08-20 Brown & Red

S8

SVCV08-20 Grey & Red

S9

SV08-2004 White & Red

S10

SF08-2015 Green & Red

C

S11

SVCV08-20 Orange & Red

Torque Specifications

All Solenoid Valves 19–21 ft-lb

All Solenoid Coil Nuts 48–60 in-lb

Motor Relay Terminals

Small 10–15 in-lb

Large

25–35 in-lb

Motor Terminals 50–60 in-lb

Lit. No. 27366, Rev. 01 February 15, 2008

26

COVER AND FINAL ASSEMBLY

SYSTEM OVERVIEW – ELECTRICAL

Before any service, remove breather slowly

to relieve reservoir pressure.

Use long cable tie to secure cable

in original position.

Apply dielectric grease to terminals.

Fit top retainer ring

over cover ridges.

Breather must be installed

before operating snowplow.

1/4-20 x 1/2 Round Washer-Head

Shoulder Screw (5) – 60-80 in-lb.

3/8-16 x 1 Hex Cap Screw (3)

25-33 ft-lb.

Short cable tie holds

cable in cover slot.

Fit bottom retainer ring

into cover ridges.

Lit. No. 27366, Rev. 01 February 15, 2008

27

SYSTEM OVERVIEW – CONTROLS

GENERAL INFORMATION

The MVP PLUS™ snowplow is

operated by with one of two special

controls—the CabCommand 9-button

hand-held control or a joystick-style

control. The controls allow you to go

from a vee, to a scoop, to a standard

straight-blade snowplow, all at the

touch of a button or single-lever

movement.

Each control has its own ON/OFF

switch with an indicator light to show

WARNING

To prevent accidental

movement of the blade, always

turn the ON/OFF switch to OFF

whenever the snowplow is not

in use. The control indicator

light will turn off.

when the control is powered up. Your

vehicle ignition (key) switch controls

a fused circuit that powers your cab

control directly from the battery.

The ON/OFF switch on the cab

control allows you to turn OFF the

control and prevent blade movement

even when the ignition switch is ON.

The control ON/OFF switch serves

as an emergency stop if required.

All controls are protected by a

replaceable fuse located in the under

hood snowplow electrical system.

See Fuse Replacement in the

Maintenance section of the Owner's

Manual.

The control is able to sense a lack of

communication with the electrical

system. Should the indicator light

start to flash, refer to the

Control/Cable/Plow Module Test.

MVP PLUS™

Joystick Control

MVP PLUS™

Hand-Held Control

Indicator Light

Indicator Light

ON/OFF Switch

(Emergency Stop)

Lit. No. 27366, Rev. 01 February 15, 2008

28

1. Turn the vehicle ignition switch to

the "ON" or "ACCESSORY"

position.

2. Press the ON/OFF button on the

control. The power indicator light

glows red, indicating the control

is ON. The indicator light glows

red whenever the control and the

vehicle ignition switch are both

ON and the electrical

connections to the snowplow are

completed.

The ON/OFF button operates as

an emergency stop if required.

Function Time-Outs

All control functions, except

LOWER/FLOAT, time out (stop)

automatically after a period of time.

This is to limit the amount of

electrical energy required from the

vehicle.

NOTE: If control function times out

before desired blade movement is

complete, release button and

press again.

Automatic Shutdown

The control will automatically turn

OFF after being idle for 20 minutes.

SYSTEM OVERVIEW – CONTROLS

MVP PLUS™ CabCommand HAND-HELD CONTROL

WARNING

To prevent accidental

movement of the blade, always

push button to switch the

control OFF whenever the

snowplow is not in use. The

control indicator light will turn

off.

Smooth Stop

The control automatically allows the

blade to coast to a stop when the

button is released. This results in

smoother operation, reduces the

shock to the hydraulic system and

increases hose and valve life.

RAISE

LOWER

R

L

ON/OFF

FLOAT

SCOOP

WING

VEE

WING

Power Indicator

Light (red)

ON/OFF

Button

(Emergency

Stop)

Float Light

(green)

Excerpts taken from UltraMount

®

Owner's Manual (Lit. No. 44230, Rev. 06).

Lit. No. 27366, Rev. 01 February 15, 2008

29

Scoop/Retract (Vee) Blade

Position

The two round buttons located to the

left and right of the RAISE button

move both wings at the same time

into the blade positions described in

the following table:

Function Description of Operation

SCOOP

Press this button to extend both wings forward into the scoop position.

Function times out after 5.0 seconds.

RETRACT

(VEE)

Press this button to draw both wings into the fully retracted (vee) position.

Function times out after 3.0 seconds.

Function Description of Operation

L WING

Press the round WING button on the left side of the control to move the

left wing. The first time the button is pressed after the control is turned ON

or another function is used, the wing will extend. Repeated use of the

same button, without using another function, results in movement in the

opposite direction from the previous movement. Function times out after

3.0 seconds.

R WING

Press the round WING button on the right side of the control to move the

right wing. The first time the button is pressed after the control is turned

ON or another function is used, the wing will extend. Repeated use of the

same button, without using another function, results in movement in the

opposite direction from the previous movement. Function times out after

3.0 seconds.

SCOOP

FLOAT ON / OFF

VEE

RAISE

LOWER

WING

LR

WING

Control Functions

Raise, Lower, Float, Angle

The four diamond-shaped buttons in

the center of the control face, when

pressed, will result in the movements

described in the table:

SYSTEM OVERVIEW – CONTROLS

Wing Positions

The two round buttons located to the

left and right of the LOWER button

move either wing independently of

the other as described in the

following table:

Float Light

(green)

LOWER

WING

SCOOP

LR

FLOAT ON / OFF

VEE

WING

RAISE

Function Description of Operation

RAISE

Press this button to raise the snowplow and cancel the FLOAT mode.

Function times out after 4.0 seconds.

LOWER

Press this button to lower the snowplow. Release the button to stop blade

at desired height.

FLOAT

Press the LOWER button and hold 3/4 second to activate this mode. The

FLOAT indicator light in the upper left corner of the control face will

illuminate. The blade will lower to the ground surface and follow the

contour of the surface as it dips or raises. Function does not time out, but

control will shut down after 20 minutes of nonuse.

Press RAISE button momentarily to cancel FLOAT. Angling left or right will

interrupt (stop) the FLOAT function while the blade angles. FLOAT will

resume when angling is complete.

L

(Angle

Left)

With wings in a straight line, press the L button to move both wings to the

angle left position to cast snow to the driver's left side. The left wing

retracts while the right wing extends. Function times out after 3.0 seconds.

R

(Angle

Right)

With wings in a straight line, press the R button to move both wings to the

angle right position to cast snow to the driver's right side. The right wing

retracts while the left wing extends. Function times out after 3.0 seconds.

Excerpts taken from UltraMount

®

Owner's Manual (Lit. No. 44230, Rev. 06).

Lit. No. 27366, Rev. 01 February 15, 2008

30

WARNING

To prevent accidental

movement of the blade, always

move the ON/OFF switch to

OFF whenever the snowplow

is not in use. The control

indicator light will turn off.

1. Turn the vehicle ignition switch to

the "ON" or the "ACCESSORY"

position.

2. Move the slide switch on the side

of the control to the "ON"

position. The power indicator

light glows red, indicating the

control is ON. The indicator light

glows red whenever the control

and the vehicle ignition switch

are both ON and the electrical

connections to the snowplow are

completed.

The ON/OFF switch operates as

an emergency stop if required.

Function Time-Outs

All control functions, except LOWER/

FLOAT, time out (stop) automatically

after a period of time. This is to limit

the amount of electrical energy

required from the vehicle.

NOTE: If control function times out

before desired blade movement is

complete, release the lever to the

center position, then move back

into the desired function.

Automatic Shutdown

The control will automatically turn

OFF after being idle for 20 minutes.

To reactivate the control after a shut

down, move the ON/OFF switch to

OFF, then back to ON.

Smooth Stop

The control automatically allows the

blade to coast to a stop when the

lever returns to center position. This

results in smoother operation,

reduces the shock to the hydraulic

system and increases hose and

valve life.

Control Lever Movement

From the center position, the control

lever can be moved in one of eight

(8) directions to control various

movements of the snowplow blade.

To change from one movement of the

blade to another, the control lever

must be moved back to the center

position before selecting the desired

function. Whenever the lever is

released, it should spring back into

the center position to stop any blade

movement.

SYSTEM OVERVIEW – CONTROLS

MVP PLUS™ JOYSTICK CONTROL

LOWER

RAISE

VEE

FLOATON / OFF

WINGWING

SCOOP

R

L

Power Indicator

Light (red)

Float Light

(green)

ON/OFF

Switch

(Emergency

Stop)

Excerpts taken from UltraMount

®

Owner's Manual (Lit. No. 44230, Rev. 06).

Lit. No. 27366, Rev. 01 February 15, 2008

31

Function Description of Operation

SCOOP

Move the control lever toward the word SCOOP on the control face to

extend both wings forward into the scoop position. Function times out

after 5.0 seconds.

RETRACT

(VEE)

Move the control lever toward the word RETRACT (VEE) on the control

face to draw both wings into the fully retracted (vee) position. Function

times out after 3.0 seconds.

Function Description of Operation

L WING

Move the control lever toward the left side of LOWER on the control face

to move the left wing. The first time the lever is moved into the slot after

the control is turned ON or another function is used, the wing will extend.

Repeated use of lever in the same slot, without using another function,

results in movement in the opposite direction from the previous

movement. Function times out after 3.0 seconds.

R WING

Move the control lever toward the right side of LOWER on the control

face to move the right wing. The first time the lever is moved into the slot

after the control is turned ON or another function is used, the wing will

extend. Repeated use of lever in the same slot, without using another

function, results in movement in the opposite direction from the previous

movement. Function times out after 3.0 seconds.

Function Description of Operation

RAISE

Move the control lever toward the top of the control body to raise the

snowplow and cancel the FLOAT mode. Function times out after 3.0

seconds.

LOWER

Move the control lever toward the bottom of the control body to lower the

snowplow. Release the lever to stop blade at desired height.

FLOAT

Move the control lever to the LOWER position and hold 3/4 second to

activate this mode. The FLOAT indicator light in the upper right corner of

the control face will illuminate. The blade will lower to the ground surface

and follow the contour of the surface as it dips or raises. Function does

not time out; however, control will shut down after 20 minutes of nonuse.

Move lever to the RAISE position momentarily to cancel FLOAT. Angling

left or right will interrupt (stop) the FLOAT function while the blade angles.

FLOAT will resume when angling is complete.

L

(Angle

Left)

With wings in a straight line, move the control lever straight to the left to

move both wings to the angle left position to cast snow to the driver's left

side. The left wing retracts while the right wing extends. Function times

out after 3.0 seconds.

R

(Angle

Right)

With wings in a straight line, move the control lever straight to the right to

move both wings to the angle right position to cast snow to the driver's

right side. The right wing retracts while the left wing extends. Function

times out after 3.0 seconds.

LOWER

RAISE

VEE

FLOATON / OFF

WINGWING

SCOOP

R

L

Float Light

(green)

Control Functions

Raise, Lower, Float, Angle

Movement of the control lever in

straight lines up and down or from

side to side on the control body will

result in the blade movements as

described in the following table:

SYSTEM OVERVIEW – CONTROLS

Excerpts taken from UltraMount

®

Owner's Manual (Lit. No. 44230, Rev. 06).

Scoop/Retract (Vee) Blade Position

Moving the control lever from the

center position toward the word

SCOOP or RETRACT (VEE) on the

face of the control body will cause

both wings to move at the same time

into the blade positions described in

the following table:

Wing Positions

Move the control lever from the

center position toward the word,

WING, on either side of the face of

the control body. The use of either of

these slots will allow movement of

either wing independently of the

other as described in the following

table:

Lit. No. 27366, Rev. 01 February 15, 2008

32

THEORY OF OPERATION

SNOWPLOW HEADLAMPS

The Isolation Module acts as an

electrical hub, automatically directing

vehicle power to the appropriate

vehicle or snowplow lighting devices,

while also supplying battery power to

the snowplow control.

The vehicle high and low beams

enter and exit the Isolation Module

through positions 3 (left-side lighting)

and position 4 (right-side lighting).

Park, turn and DRL signals also enter

through positions 3 and 4. The output

of the vehicle dimmer switch is

directed to the Isolation Module via

the long and short plug-in harnesses.

All snowplow lighting exits the

Isolation Module through position 2.

When the snowplow is not attached

to the vehicle, the signal passes

through the normally closed relay

contacts to the vehicle headlamps.

During this time, the Isolation Module

is inactive, placing no current draw

on the vehicle's electrical system.

With the snowplow attached, the

Isolation Module is still inactive until

either of the two following conditions

are met: The vehicle parking lights

are turned ON or the vehicle ignition

switch is turned ON.

Turning ON the vehicle parking lights

activates a series of relays,

automatically transferring the vehicle

high and low beams to the snowplow

while supplying battery power directly

to the snowplow parking lights.

Turning ON the vehicle ignition

switch energizes a snowplow control

relay, supplying vehicle battery power

directly to the control via the vehicle

control harness. The vehicle ignition

switch also supplies power to the

vehicle turn signals. Activating the

vehicle turn signals energizes turn

signal relays, which supply vehicle

battery power directly to the

snowplow turn signals.

SNOWPLOW DAYTIME

RUNNING LIGHTS

Because Daytime Running Lamps

(DRLs) are controlled differently on

some vehicles, two Isolation Modules

have been developed.

The standard Isolation Module

transfers the DRL output from the

vehicle headlamps to the snowplow

headlamps when the vehicle ignition

switch is turned ON and the

snowplow is attached.

The second Isolation Module,

designed for vehicles with dedicated

DRL bulbs, senses the vehicle in the

DRL mode and a series of relays

energize, placing the snowplow low

beams in series. This Isolation

Module does not turn OFF the

vehicle's dedicated DRLs.

SNOWPLOW HYDRAULICS

The MVP PLUS™ snowplow

hydraulic system performs ten blade

movements.

All movements require the vehicle

ignition (key) switch to be in the

"RUN" or "ACCESSORY" position

and the power to be activated on the

snowplow cab control.

Nine of the ten hydraulic movements

require energizing the electric motor

and appropriate solenoid cartridge

valves. The tenth function, lower,

does not energize the motor but

requires activating a cartridge valve.

Power from the vehicle battery is

supplied to the solenoid coils and the

snowplow control via the Isolation

Module. The solenoid cartridge

valves operate in various

combinations, directed by the cab

control, to send hydraulic fluid to the

snowplow lift and angle rams or back

to the reservoir.

MOVEMENT

BLADE

RAISE

LOWER

ANGLE

RIGHT

ANGLE

LEFT SCOOPVEE

EXTEND

LEFT

LEFT

RETRACT

RIGHT

EXTEND

RIGHT

RETRACT

Lit. No. 27366, Rev. 01 February 15, 2008

33

ELECTRICAL & HYDRAULIC SCHEMATICS

The following section contains

hydraulic and electrical schematics to

help explain how the hydraulic unit

performs the different functions. A

schematic is an abstract drawing

showing the purpose of each of the

components in the system. Each

component is represented by a

graphical symbol. The hydraulic and

electrical legends describe each of

the symbols used in the schematics

for this guide.

The first two schematics show a

general overview of the complete

hydraulic and electrical systems.

Other schematics highlight the flow

of hydraulic fluid and electrical

current for each function the

hydraulic unit performs as well as the

flow of electrical current for the

snowplow and vehicle lights.

• Bold lines represent the circuit

being activated only.

• Shaded components are either

activated or shifted from their

normal position.

CROSSING WIRE

WIRE SPLICE

FUSE

SOLENOID COIL

CIRCUIT GROUND

MOTOR RELAY

BATTERY

MOTOR

IN LINE CONNECTOR

PARK/TURN LAMP

COMPONENT ENCLOSURE

PRINTED CIRCUIT BOARD

L

H

HEADLAMP

CHECK VALVE

ELECTRICAL LEGEND HYDRAULIC LEGEND

COMPONENT ENCLOSURE

FILTER, STRAINER,

DIFFUSER

ELECTRIC MOTOR

RAM

HYDRAULIC PUMP

FIXED DISPLACEMENT

LINE, TO RESERVOIR

BELOW FLUID LEVEL

FLOW, DIRECTION OF

HYDRAULIC FLUID

LINE, WORKING (MAIN)

LINES JOINING

LINES CROSSING

SPRING

SOLENOID, SINGLE WINDING

VALVE, ADJUSTABLE

PRESSURE RELIEF

VALVE, FLOW CONTROL,

ADJUSTABLE-

NON-COMPENSATED

VALVE, TWO POSITION,

TWO CONNECTION

(TWO WAY)

VALVE, TWO POSITION,

TWO CONNECTION

(TWO WAY) WITH INTEGRAL

CHECK VALVE

Lit. No. 27366, Rev. 01 February 15, 2008

34

ELECTRICAL SCHEMATIC

3

2

1

4

3

2

1

4

4-Pin Plug

(Under Dash)

RED

RED

BLK

BLK

GRN

RED

WHT

BLK

Control

RED

RED/GRN

To Switched Accessory Lead

Vehicle Control Harness, 4 Wire

1 – Red

2 – Green

3 – White

4 – Black

1 – Red (Control Power)

2 – Red (Twisted with #3)

3 – Black (Twisted with #2)

4 – Black (Control Ground)

4

2

3

1

4

2

3

1

(connector face view)

ADCB

Vehicle Battery Cable, 4 Receptacle

BLK

BLK

RED

BACD

WHT

RED

RED

CC

A

B

A

B

D

D

BLK

TAN

A

B

C

D

E

F

G

H

J

K

* HB-1(9004) A=BLUE, J=YELLOW)

** 99 DODGE RAM W/SPORT PACKAGE

PS LOW BEAM NO.2 OUT

**

PS HIGH BEAM NO.2 IN

**

DS HIGH BEAM NO.2 IN

**

DS LOW BEAM NO.2 OUT

**

PARK LAMP IN

PS TURN IN

PS COMMON OUT

PS LOW BEAM OUT

PS HIGH BEAM OUT

PS COMMON IN

PS HIGH BEAM IN

PS LOW BEAM IN

DS TURN IN

DS COMMON OUT

DS LOW BEAM OUT

DS HIGH BEAM OUT

DS COMMON IN

DS HIGH BEAM IN

DS LOW BEAM IN

A

B

C

D

E

F

G

H

J

K

Vehicle

Lighting

Harness,

11 Pin

For All

Headlamps

Except

HB-3/HB-4:

To Vehicle

Headlamps,

Park/Turn

and Factory

Vehicle

Harnesses

PS COMMON OUT

PS COMMON IN

PS HIGH BEAM OUT

PS LOW BEAM OUT

PS TURN IN

BLU

LTBLU

RED

ORG

PUR

A

B

C

D

E

F

G

H

J

K

DS COMMON IN

DS COMMON OUT

PS LOW BEAM IN

PS HIGH BEAM IN

DS HIGH BEAM OUT

DS LOW BEAM OUT

DS TURN IN

PARK LAMP IN

DRL SIGNAL IN

LTBLU

YEL

BLU

GRN

BRN

PUR

ORG

RED

PNK

DS LOW BEAM IN

DS HIGH BEAM IN

YEL

GRN

A

B

C

D

E

F

G

H

J

K

WHT/YEL

PUR

LTBLU

ORG

RED

BLU

*

Isolation Module

A

B

C

D

E

F

G

H

J

K

WHT

GRN

WHT/YEL

GRN

YEL

*

BLU

*

RED

ORG

LTBLU

PUR

BRN

YEL

*

GRN

BLU/ORN

LTBLU

BRN

PUR

GRY

BLK/WHT

WHT/YEL

BLK/ORN

BLK

From Vehicle

Control

Harness

From Vehicle

Lighting

Harness

From DS

Vehicle

Headlamps

From PS

Vehicle

Headlamps

DKBLU/WHT

WHT

RED/WHT

RED/BLK

DKBLU/RED

RED/YEL

BLU

RED

A

B

C

D

E

F

G

H

J

K

Plow

Lighting

Harness,

11 Pin

TURN

PARK

COM

HIGH

LOW

BEAM

PARK

TURN

HIGH

LOW

BEAM

LOW-6A

TURN-8B

COM-11B

PARK

HIGH-4C

C

A

BB

C

A

BB

C

A

B

C

A

B

COM-5B

LOW-1A

HIGH-3C

TURN-9B

PARK

COM

TURN-9B

COM-11B

PARK

LOW-6A

TURN-8B

COM-5B

COM

HIGH-4C

LOW-1A

HIGH-3C

COM

8

11

10

9

7

5

6

3

4

1

2

8

9

10

11

4

6

5

7

2

3

1

BLK/WHT

BLK/ORN

WHT/YEL

WHT

BLU/ORN

BLK

BLK/ORN

GRY

PUR

BRN

LTBLU

A

C

B

BLK/ORN

Plow Module

WHT

TAN

BLK

BLK

RED

4 Amp Fuse: S1, S2, S3

4 Amp Fuse: Motor Relay

4 Amp Fuse: S4, S5, S6, S7

4 Amp Fuse: S8, S9, S10, S11

–

Pump

Motor

RED

RED

Motor

Relay

S1

S2

S3

BLK

RED

RED

WHT

GRN

BLU

RED

A

G

A

B

C

D

E

F

K

H

J

G

A

B

C

D

E

F

K

H

J

G

A

B

C

D

E

F

K

H

J

G

A

B

C

D

E

F

K

H

J

B

S10

S9

S8

S11

S7

S6

GRY

RED

WHT

GRN

ORN

RED

BRN

YEL

S4

S5

BLK

TAN

BB

A

C

A

HH

D

C

F

G

EE

D

C

F

G

K

J

K

J

B

C

A

Configuration

Plug or

Dust Cover

15 Amp

Park/Turn

Fuse

7.5 Amp

Control

Fuse

Battery

Port #1 Adapter

4

3

4

3

2

1

+

+

–

For HB-3/HB-4

Headlamps:

To Vehicle

Headlamps,

Park/Turn, DRL

and Factory

Vehicle

Harnesses

RED

BLK

RED

Located at Front of Vehicle

Snowplow Assembly

Passenger-Side Plow Lamp

Driver-Side Plow Lamp

CAUTION

On 2-plug electrical systems, plug covers shall

be used whenever snowplow is disconnected.

Vehicle Battery Cable is 12-volt unfused source.

Lit. No. 27366, Rev. 01 February 15, 2008

35

HYDRAULIC SCHEMATIC

Relief Valve Settings

Pump

Ram, Base-End

Ram, Rod-End

2250 psi

3700 psi

4600 psi

SV08-2004 S3 ON

SV08-2004 S1

MOVEMENT

BLADE

RAISE LOWER SCOOPVEE

SF08-2015 S6

EXTEND

LEFT

S4SVCV08-20 ON ON

SVCV08-20 S2 ON

SV08-2004

SVCV08-20

SVCV08-20

SV08-2004

SVCV08-20

SF08-2015

S5

S8

S11

S9

S7

S10

ON

MOTOR M ONON

ON

ON

ON

ON

ON ON

ON

ONON

ONONON

ON

ON

ONON

ONON

ANGLE

RIGHT

ANGLE

LEFT

RIGHT

RETRACT

ON

ON

ON

ON

RIGHT

EXTEND

ON

ON

ON

LEFT

RETRACT

ON

ON

ON

ON

PRESSURE TEST PORT

DRAIN

QUILL

PUMP

RELIEF

VALVE

S10S5

S6

S4

S11

S8

S9

S3

S2

S1

RELIEF

VALVES

DS BASE

RELIEF

VALVES

PS BASE

CHECK

VALVE

DS BASE

RELIEF

VALVE

DS ROD

RELIEF

VALVE

PS ROD

CHECK

VALVE

PS BASE

CHECK

VALVE

DS ROD

CHECK

VALVE

PS ROD

DS

PS LIFT

M

S7

SECONDARY BLOCK ASSEMBLY

PRIMARY BLOCK ASSEMBLY

Lit. No. 27366, Rev. 01 February 15, 2008

36

RAISE – ELECTRICAL

Plow Module

4 Amp Fuse: Motor

Relay

4 Amp Fuse: S1, S2, S3

Pump

Motor

Motor

Relay

GG

A

A

A

B

C

E

D

F

B

C

D

E

F

H

KK

H

JJ

A

B

A

GG

B

D

C

F

E

D

B

C

F