AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

1

Thank you for joining our live webinar today.

We will begin shortly. Please standby.

Thank you.

Need Help?

Call ReadyTalk Support: 800.843.9166

AISC Live Webinars

1

Today’s audio will be broadcast through the

internet.

Alternatively, to hear the audio through the phone,

dial 800 741 4871.

International callers, dial 00+1 212 231 2909.

For additional support, please press *0 and you will

be connected to a live operator.

AISC Live Webinars

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

2

Today’s live webinar will begin shortly.

Please standby.

As a reminder, all lines have been muted. Please type any

questions or comments through the Chat feature on the left

portion of your screen.

Today’s audio will be broadcast through the internet.

Alternatively, to hear the audio through the phone, dial

800 741 4871.

International callers, dial 00+1 212 231 2909.

For additional support, please press *0 and you will be

connected to a live operator.

AISC Live Webinars

AISC is a Registered Provider with The American Institute of

Architects Continuing Education Systems (AIA/CES). Credit(s)

earned on completion of this program will be reported to AIA/CES

for AIA members. Certificates of Completion for both AIA members

and non-AIA members are available upon request.

This program is registered with AIA/CES for continuing professional

education. As such, it does not include content that may be

deemed or construed to be an approval or endorsement by the AIA

of any material of construction or any method or manner of

handling, using, distributing, or dealing in any material or product.

Questions related to specific materials, methods, and services will

be addressed at the conclusion of this presentation

AISC Live Webinars

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

3

Copyright Materials

This presentation is protected by US and International

Copyright laws. Reproduction, distribution, display and

use of the presentation without written permission of

AISC is prohibited.

© The American Institute of Steel Construction 2014

AISC Live Webinars

Design of Reinforcement for Steel Members Part II

Presented by Bo Dowswell, Ph.D., P.E.

February 13, 2014

This presentation is a continuation of the AISC live webinar, Design of

Reinforcement for Steel Members. Several topics will be discussed which affect

the strength and serviceability of reinforced steel members. Deflection of

beams with pre-load will be discussed briefly, and further information will be

provided on the design of built-up columns. Other topics include: weld design,

including the calculation of weld strength for built-up columns; how intermittent

welds affect the section properties of a built-up member; local buckling,

including the effect of stitch welds on the local buckling of plates. An example

problem will be used to illustrate some of the design principles for a composite

beam with reinforcement at the tension flange.

Course Description

6

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

4

• To learn and understand the AISC Specification strength and

serviceability requirements for designing reinforced structural steel

members.

• To gain familiarity with the deflection of beams with pre-load when

safely reinforcing steel members for structural steel buildings.

• To learn and understand material and code requirements for welding

of built-up structural steel beams and columns.

• To learn and understand the design principles for reinforcing composite

beams through the presentation of a design example.

Learning Objectives

7

8

DESIGN OF

REINFORCEMENT FOR

STEEL MEMBERS-

PART 2

Bo Dowswell, P.E., Ph.D.

Principal

ARC International, LLC

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

5

• Reinforced Beam & Column Design

Reinforcement types

Pre-load

Partial-length reinforcement

• Course video and presentation slides are

available on the AISC Website:

www.aisc.org/content.aspx?id=37256

Part 1 Summary

9

• Beam Deflection

• Section Properties of Built-Up Members

• Weld Design

• Built-Up Columns: Additional Topics

• Flexural Plate Buckling (Plate Buckling

Between Intermittent Welds)

Course Description

10

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

6

BEAM DEFLECTION

11

Beam Deflection

Deflection of Beams with Pre-Load

• Structural analysis models are built with

reinforced member properties

• Deflection must be adjusted to account

for pre-load.

12

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

7

Pre-load deflection: deflection before

reinforcement is added.

Beam Deflection

ω

n

= proportion of load applied before the

13

Deflection of reinforced member: only

loads applied after reinforcement is added.

Beam Deflection

ω

r

= proportion of load applied after the

14

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

8

Total Deflection: =

n

+

r

n

= deflection of non-reinforced member

using loads applied before the

r

= deflection of reinforced member using

loads applied after the member is

reinforced

Beam Deflection

15

The adjusted deflection can be calculated

using the value from a finite element model

m

= total deflection from the finite element

model using the reinforced member

properties

Beam Deflection

r

mr n

n

I

I

16

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

9

I

n

= moment of inertia of non-reinforced

member

I

r

= moment of inertia of reinforced

member

Beam Deflection

17

Deflection of Beams with Partial-Length

Reinforcement

Finite Element Model

18

Beam Deflection

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

10

SECTION PROPERTIES OF

BUILT-UP MEMBERS

19

AISC Specification Section F4

Equations F4-5 and F4-8 require the

calculation of J

2

2

2

1 0.078

bb

cr

xc o t

bt

CE L

J

F

Sh r

Lr

AISC Specification

20

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

11

Torsion Constant

The torsion constant, J, can be calculated

based on individual element behavior or

integral element behavior

individual behavior integral behavior

21

Torsion Constant

Individual Element Behavior (1 Plate)

J

s

= J

w

+ J

p

J

w

= torsion constant of the W shape

J

p

= torsion constant of the plate

t

p

= plate thickness

b

p

= plate width

3

1

3

ppp

Jbt

22

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

12

Torsion Constant

Individual Element Behavior (2 Plates)

J

s

= J

w

+ J

p1

+ J

p2

J

p1

= torsion constant of Plate 1

J

p2

= torsion constant of Plate 2

23

Torsion Constant

Integral Element Behavior (1 Plate)

b = minimum of b

f

and b

p

t

f

= flange thickness

b

f

= flange width

iwp pfpf

JJ Jbtttt

24

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

13

Torsion Constant

Integral Element Behavior (2 Plates)

b

1

= minimum of b

f

and b

p1

b

2

= minimum of b

f

and b

p2

t

p1

= thickness of Plate 1

t

p2

= thickness of Plate 2

12111

22 2

iwp p pfpf

pf p f

JJ J J bttt t

bt t t t

25

Effective torsion constant for members with

intermittent welds, J

eff

J

s

< J

eff

< J

i

J

eff

= effective torsion constant

J

s

= torsion constant for independent

behavior

J

i

= torsion constant for integral behavior

Torsion Constant

26

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

14

• Generally, commercial software

packages provide J

i

• J

s

can be used as a conservative

estimate of J

eff

, but this can be extremely

conservative

• See Chang and Johnston (1952) for a

more accurate solution

Torsion Constant

27

WELD DESIGN

28

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

15

Intermittent Welds

• Lower cost

• Less weld shrinkage distortion

• Greater corrosion potential

Intermittent Welds

29

Intermittent Welds

AISC Specification Section J2.2b

• L ≥ 4w

• L ≥ 1.5 in.

L = segment length

w = weld size

30

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

16

Maximum weld spacing for intermittent welds

in AISC Specification Sections D.4 and J3.5

Intermittent Welds

1. Ensure close fit-up

over entire faying

surface

2. Prevent corrosion

between connected

elements

31

AISC Specification Sections D.4 and J3.5

(a) P

max

= 24t ≤ 12 in.

(b) Unpainted Weathering Steel:

P

max

= 14t ≤ 7 in.

P

max

= weld spacing

t = thickness of the thinner part

Intermittent Welds

32

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

17

Members Welded Under Load

Elevated temperatures near the weld cause

a reduction in material properties of the

base material

33

Welding to Loaded Members

General Recommendations

• Use small diameter electrodes and low

welding current

• Use stringer beads only (not weave

beads)

• Specify intermittent welding in short

lengths

Welding to Loaded Members

34

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

18

General Recommendations (continued)

• Where appropriate, specify a maximum

interpass temperature of 300 °F

• Allow time for welds to cool between

passes

• Use temperature crayons or other

suitable means to monitor the

temperature of the base metal near the

weld

Welding to Loaded Members

35

Welding to Loaded Members

600 °F

800 °F

1,600 °F

1,100 °F

Concept of Inactive Areas

Standard Weld Temperature Field

36

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

19

Welding to Loaded Members

600 °F

800 °F

1,600 °F

1,100 °F

Section Normal to Arc Travel

Standard Weld Temperature Field

37

Example Temperature Curve for Low Heat

Input Weld

Welding to Loaded Members

Section Through

Weld Normal to

Arc Travel

38

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

20

Example Yield Strength Curve for Low

Heat Input Weld

Welding to Loaded Members

yy

FF

Section Through

Weld Normal to

Arc Travel

39

Inactive Area Normal to Arc Travel

Conservative Values:

w

y

=1 in. for SMAW

w

y

=2 in. for FCAW

See Huenersen et al. (1990)

for a more rigorous solution

Welding to Loaded Members

40

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

21

Inactive Area Parallel to Arc Travel

Conservative Estimate:

Full flange width plus

the portion of the web

defined by w

y

See Huenersen et al. (1990)

for a more rigorous solution

Welding to Loaded Members

41

BUILT-UP COLUMNS:

ADDITIONAL TOPICS

42

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

22

How can we design the

reinforcement welds for

columns?

What are the loads?

Weld Design for Columns

43

The load in the cover plate

must be transferred to the non-

reinforced section at the

theoretical cutoff point.

Welds must develop the cover

plate’s portion of the required

axial load in the column

44

Weld Design for Columns

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

23

The load in each plate, based on equal axial

stress over the cross sectional area, is

A

p

= area of the reinforcing plate

A

r

= total area of the reinforced section

p

p

r

A

FP

A

45

Weld Design for Columns

Shear Flow

A

p

= area of the reinforcing plate

I

rx

= strong-axis moment of inertia of the

built-up member

V

r

= required shear force

v = shear force per unit length

r

rx

VQ

v

I

p

QAy

46

Weld Design for Columns

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

24

Anchor Force

rc

A

rx

M

Q

F

I

rc

M

rc

M

47

Weld Design for Columns

48

Weld Design for Columns

How can we determine V

r

and M

rc

?

Apply a uniform notional load to develop a

bending moment equal to that caused by

the initial out-of-straightness. For δ

0

=

L/1,000

P

r

= required axial load

125

r

n

P

w

L

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

25

49

Weld Design for Columns

Apply w

n

in the proper direction

The first-order moment,

M

c

, is calculated at the

theoretical cutoff point.

If the column is subjected

to axial load only, the

maximum shear, V

r

, is at

the theoretical cutoff

point.

Weld Design for Columns

50

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

26

AISC Manual Table 3-23,

Case 1.

51

2

x

wx

M

lx

2

x

l

Vw x

Weld Design for Columns

The required moment, M

rc

, can be determined

with a second order analysis or calculated using

multiplier, B

1

from AISC Specification

Appendix 8, Section 8.2.

1

1

1 α

m

r

e

C

B

P

P

1rc c

M

BM

Weld Design for Columns

52

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

27

P

e1

= elastic lateral buckling load of the

column

P

r

= required axial strength

C

m

= 1.0

= 1.00

for LRFD

= 1.60 for ASD

Weld Design for Columns

53

p

p

r

A

FP

A

The total load in the plate at the theoretical

cutoff point is the anchor force for the

moment plus the plate’s portion of the axial

load.

54

Weld Design for Columns

rc

A

rx

M

Q

F

I

rpA

F

FF

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

28

F

r

must be developed

over distance,

d

rt

The shear force per unit

length,

v, must me

developed between the

theoretical cutoff points

Weld Design for Columns

55

FLEXURAL PLATE

BUCKLING

56

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

29

Column Local Buckling

b

t

140

r

y

E

F

.

Column Flange Plates

Specification Table B4.1a, Case 7

57

Beam Local Buckling

b

t

140

r

y

E

F

.

112

p

y

E

F

.

Beam Compression Flange Plates

Specification Table B4.1b, Case 18

58

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

30

Flexural Plate Buckling

Flexural Buckling Between Intermittent

Welds

Local Buckling Flexural Buckling

59

AISC Specification Section E6.2

Non-Staggered:

t = plate thickness

075 12in.

max

y

E

Pt

F

.

Flexural Plate Buckling

60

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

31

The buckled shape of the plate changes

when staggered welds are used

Flexural Plate Buckling

61

AISC Specification Section E6.2

Staggered:

50% increase in

P

max

when staggered

1 12 18 in.

max

y

E

Pt

F

.

Flexural Plate Buckling

62

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

32

Norris et al. (1951) found critical C/b ratios,

where local buckling will be the controlling

limit state If

C/b < (C/b)

cr

.

Flexural Plate Buckling

C = clear distance

between fasteners

b = plate width

63

For Stiffened Elements,

For Unstiffened Elements,

Flexural Plate Buckling

050

cr

C

b

.

14

cr

C

b

.

64

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

33

140

r

y

bE

tF

.

05 05 070

rr r

y

E

Cbt t

F

.. .

Beam Compression Flange Plates

050

cr

C

b

.

For Stiffened Elements

Specification Table

B4.1b, Case 18

Flexural Plate Buckling

65

112

p

y

bE

tF

.

05 05 056

pp p

y

E

Cbt t

F

.. .

Beam Compression Flange Plates

Specification Table

B4.1b, Case 18

Flexural Plate Buckling

66

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

34

14

cr

C

b

.

For Unstiffened

Elements

14

rr

Ct.

14

p

p

Ct.

Select

r

and

p

from AISC

Specification Table B4.1a or

B4.1b.

Flexural Plate Buckling

67

COMPOSITE BEAM

EXAMPLE

68

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

35

An existing composite beam must carry an

additional live load of 40 psf. This example

shows calculations for the required

reinforcement using LRFD.

For the existing beam calculations, see

Example I.1 in the AISC Design Examples,

Version 14.1.

69

70

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

36

71

72

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

37

Given:

The live load increased from 100 psf to 140

psf.

The existing live load will be removed

before the beam is reinforced.

The existing beam is A992.

73

For the existing beam:

The available flexural strength,

b

M

n

= 769 kip-ft

The lower bound moment of inertia,

I

LB

= 2,520 in.

4

74

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

38

The concrete is normal weight with a

specified compressive strength,

f

c

= 4 ksi.

There are 46 ¾-in.-diameter headed stud

anchors symmetrically placed about the

midspan.

The existing dead load is 0.900 kip/ft

75

Solution:

Existing Beam Material Properties

A992

F

y

= 50 ksi

F

u

= 65 ksi

76

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

39

Applied Loads

Estimated weight of reinforcement:

20 lbs/ft = 0.02 kip/ft

Dead load:

w

D

= 0.900 kip/ft + 0.02 kip/ft = 0.920 kip/ft

77

Live load:

w

L

= (10.0 ft)(140 psf)(0.001 kip/lb)

= 1.40 kips/ft

Required load:

w

u

= (1.2)(0.920 kip/ft) + (1.6)(1.40 kip/ft)

= 3.34 kips/ft

78

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

40

Required Flexural Strength

AISC Manual Table 3-23, Case 1.

79

2

2

8

3.34 kip/ft 45.0 ft

8

845 kip-ft

u

u

wL

M

80

Preliminary Analysis Conclusions

For the existing beam,

b

M

n

= 769 kip-ft

769 kip-ft < 845 kip-ft

(Utilization Ratio = 1.10)

> L/360 (18% Over)

The beam must be reinforced

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

41

Reinforcement Selection Issues

• Flexural reinforcement is most efficient

when located farthest from the neutral

axis

• Partial-length reinforcement is more

economical than full-length

reinforcement

81

Horizontal Overhead

Reinforcement Selection Issues (continued)

• Productivity for horizontal welding is

about 4 times that of overhead welding

82

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

42

Reinforcement Selection Issues (continued)

• An adequate shelf dimension must be

provided for fillet welds

• For this example, the bottom of the beam

must remain clear of obstructions

83

Two L 2 ½ 2 ½ 3/8 will be added to the

top of the bottom flange. The material will

be A36 (

F

y

= 36 ksi, F

u

= 58 ksi).

84

L 2 ½ 2 ½ 3/8 :

A

a

= 1.73 in.

2

I

xa

= 0.972 in.

4

y = 0.758 in.

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

43

The total weight of the reinforcement is

(2)(5.90 lb/ft) = 11.8 lb/ft = 0.0118 kip/ft

The revised load is

w

u

= 1.2(0.912 kip/ft) + 1.6(1.40 kip/ft)

= 3.33 kips/ft

The revised moment, M

u

= 844 kip-ft.

85

Available Flexural Strength

AISC Specification Section I3.2a: Plastic

stress distribution shall be used when

The stabilizing effect of the reinforcing

angles will be neglected.

86

3.76

wy

hE

tF

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

44

From AISC Manual Table 1-1, h/t

w

for a

W21

50 is 49.4.

49.4 < 90.6; therefore, the plastic stress

distribution will be used.

87

29,000 ksi

3.76 3.76 90.6

50 ksi

y

E

F

Concrete Strength

A

c

= (120 in.)(4.5 in.)

= 540 in.

2

C = 0.85f

c

A

c

= (0.85)(4 ksi)(540 in.

2

)

= 1,840 kips

88

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

45

Steel Strength

T = A

s

F

y

= (50 ksi)(14.7 in.

2

) + (2) (36 ksi)(1.73

in.

2

)

= 860 kips

89

Steel Anchor Strength

AISC Manual Table 3-21

Assume all anchors are placed in the weak

position

1 anchor per rib:

Q

n

= 17.2 kips/anchor

2 anchors per rib: Q

n

= 14.6 kips/anchor

90

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

46

Q

n

= (2)(14.6 kips/anchor)

+ (21)(17.2 kips/anchor)

= 390 kips

The compression load in the concrete is

C = MIN(1,840, 860, 390) = 390 kips

Shear transfer for composite action is

controlled by the anchor strength.

91

AISC Specification Section I3.1a

The effective width of the concrete slab is

the minimum of

(1) One eighth of the beam span

b

e1

= (45 ft.)(2 sides)/8 = 11.3 ft

92

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

47

(2) One-half the distance to the centerline

of the adjacent beam

b

e2

= (10 ft.)(2 sides)/2 = 10.0 ft

(3) Distance to the Edge of the slab

Not Applicable

93

The effective width of slab is

b

e

= b

e2

= 10.0 ft = 120 in.

94

b

e

= 10.0 ft

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

48

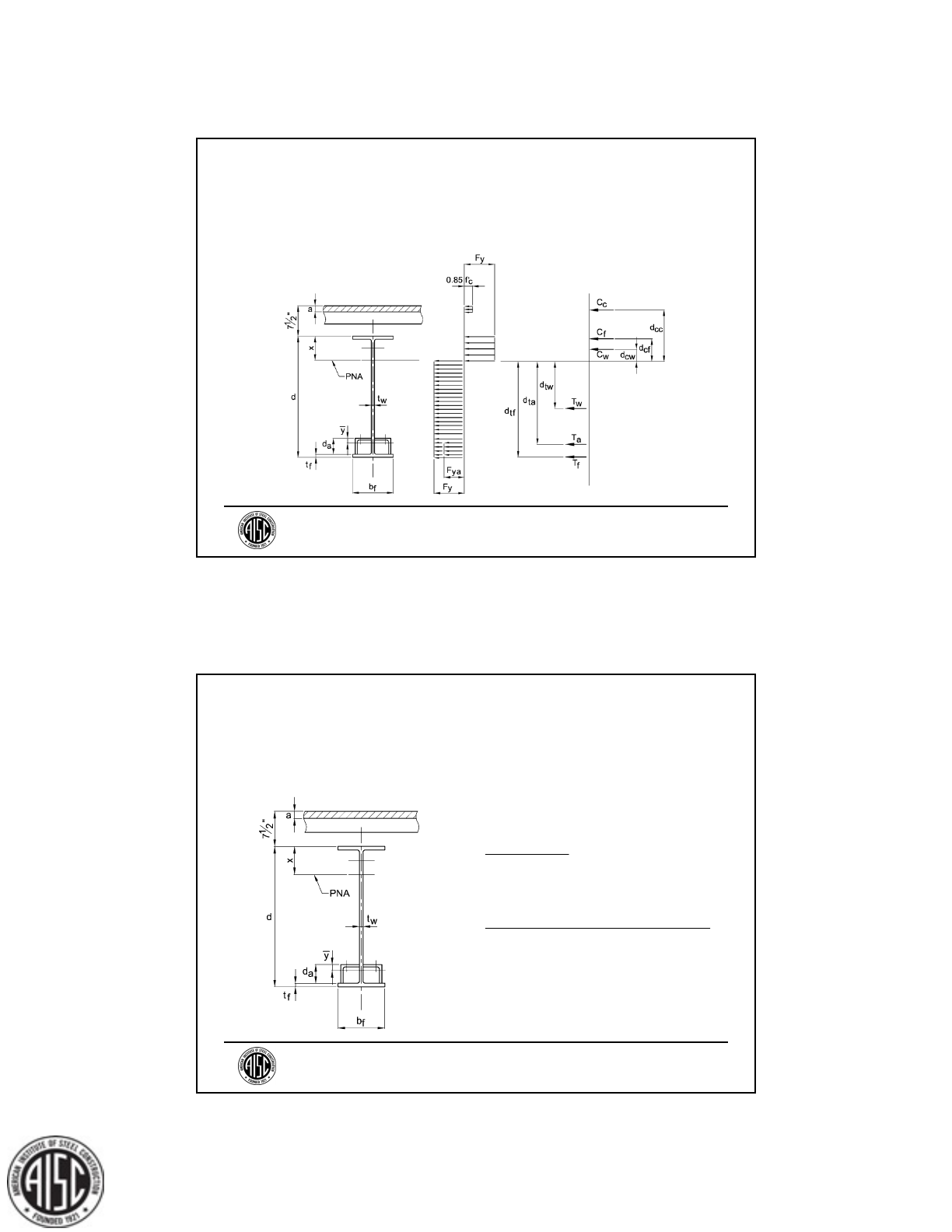

Plastic Analysis of Cross Section

95

Compression Block Depth

96

0.85

390 kips

0.85 4 ksi 120 in.

0.956 in.

c

C

a

fb

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

49

C

c

= 390 kips

C

f

= (50 ksi)(0.535 in.)(6.53 in.) = 210 kips

T

f

= (50 ksi)(0.535 in.)(6.53 in.) = 210 kips

T

a

= (2 angles)(36 ksi)(1.73 in.

2

) = 125 kips

C

w

= (50 ksi)(0.380 in.)(x 0.535 in.)

T

w

= (50 ksi)(0.380 in.)(20.8 in. 0.535 in. x)

97

The plastic neutral axis (PNA) is located by

force equilibrium

C = T

C

c

+ C

f

+ C

w

= T

f

+ T

a

+ T

w

Solve for x = 3.44 in.

Also: C

w

= 55.3 kips

T

w

= 320 kips

98

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

50

d

cc

= 3.44 in. + 7.50 in. 0.956 in./2 = 10.5 in.

d

cf

= 3.44 in. 0.535 in./2 = 3.17 in.

d

cw

= (3.44 in. 0.535 in.)/2 = 1.45 in.

d

tf

= 20.8 in. 3.44 in. 0.535 in./2 = 17.1 in.

99

d

ta

= 20.8 in. 3.44 in. 0.535 in. 2.50

+ 0.758 in.

= 15.1 in.

d

tw

= (20.8 in. 3.44 in. 0.535 in.)/2 = 8.41 in.

100

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

51

M

n

= (390 kips)(10.5 in.)

+ (210 kips)(3.17 in.)

+ (55.3 kips)(1.45 in.)

+ (320 kips)(8.41 in.)

+ (125 kips)(15.1 in.)

+ (210 kips)(17.1 in.)

= 13,010 kip-in.

= 1,080 kip-ft.

101

b

M

n

= (0.90)(1,080 kip-ft)

= 972 kip-ft

M

u

= 844 kip-ft. < 972 kip-ft o.k.

102

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

52

Required Shear Strength

AISC Manual Table 3-23, Case 1.

103

2

3.33 kips/ft 45.0 ft

2

74.9 kips

u

u

wL

V

Available Shear Strength

AISC Specification Section I4.2

The available shear strength is based on

the properties of the steel section alone

AISC Manual Table 3-2

v

V

n

= 237 kips > 74.9 o.k.

104

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

53

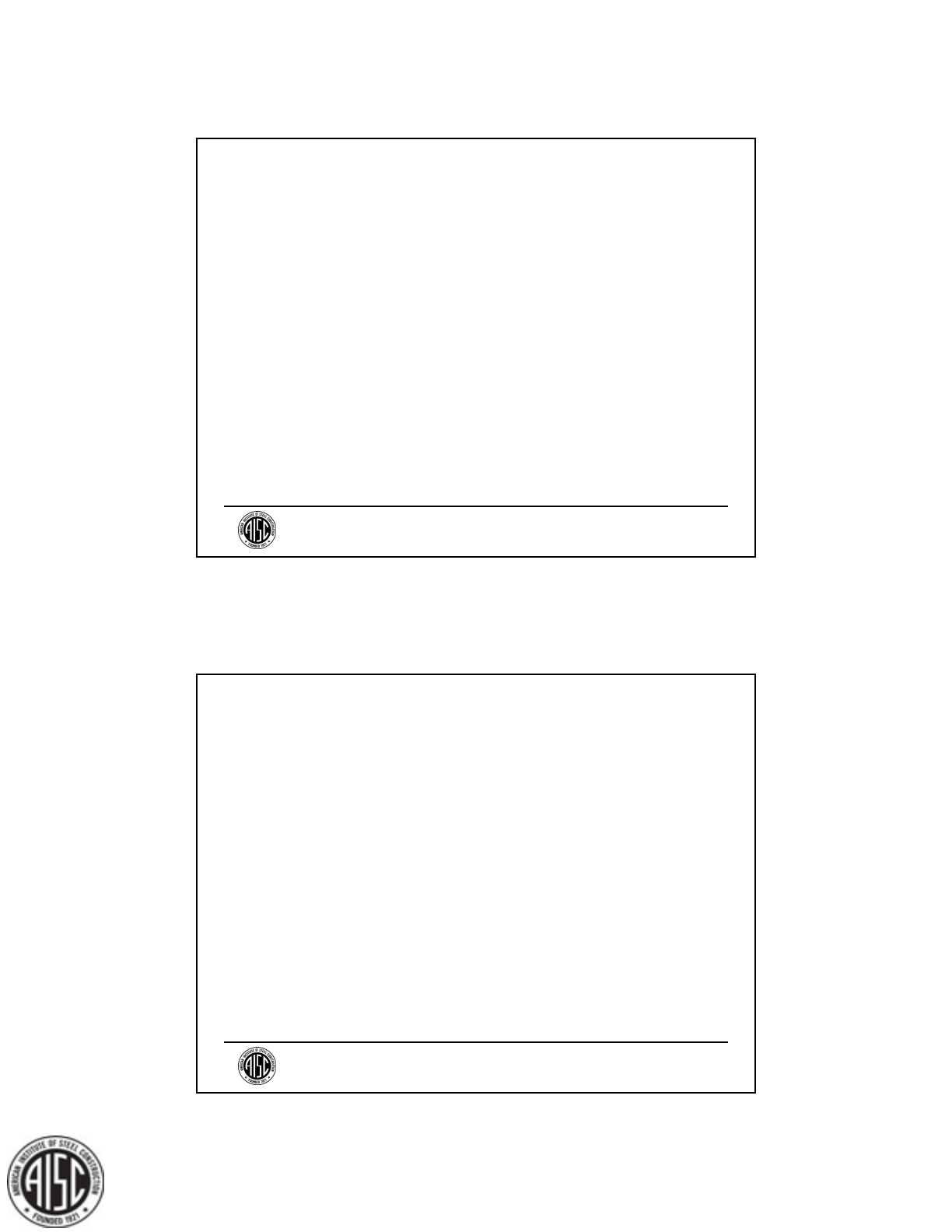

Location of the Theoretical Cutoff Point

Only partial-length reinforcement will be

provided. The location of the theoretical

cutoff point must be determined so the

flexural strength of the non-reinforced

segments will be adequate.

105

AISC Manual Table 3-23, Case 1.

For the existing beam,

b

M

n

= 769 kip-ft.

l= 45 ft

w

u

= 3.33 kips/ft

106

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

54

Solve for x = 15.5 ft

Use a preliminary distance from the end of

the beam to the theoretical cutoff point of

14 ft.

107

2

3.33 kips/ft

769 kip-ft 45.0 ft

2

x

wx

Mlx

x

x

Live Load Deflection

Live load deflection will be limited to:

1. For 100% of the design live load:

a

= L/360 = (45 ft)(12 in./ft)/360 = 1.50

in.

2. For 50% of the design live load:

a

= 1.0 in.

108

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

55

109

n

equiv s tr s

f

Q

IIII

C

Deflection will be calculated using I

eff

AISC Specification Commentary Section I3.2

I

eff

= 0.75I

equiv

AISC Specification Commentary Equation C-

I3-4

Transformed Moment of Inertia

= E

s

/E

c

= (29,000 ksi)/(3,490 ksi)

= 8.31

b

tr

= (10 ft)(12 in./ft)/8.31

= 14.4 in.

I

tr

= 5,500 in.

4

110

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

56

The moment of inertia of the structural

steel section, including the reinforcing

angles,

I

s

= 1,170 in.

4

111

Q

n

= 390 kips

T = A

s

F

y

= 860 kips

C = 0.85f

c

A

c

= 1,840 kips

C

f

= compression force in slab for fully

composite beam

= minimum of T and C

= 860 kips

112

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

57

113

444

4

in. 5 500 i

390 kips

1 170 1 1n. in.70

860 kip

i

s

4 090 n.

n

equiv s tr s

f

Q

IIII

C

,,

,

,

AISC Specification Commentary Equation

C-I3-4

AISC Specification Commentary Section

I3.2

I

eff

= 0.75I

equiv

= (0.75)(4,090 in.

4

)

=3,070 in.

4

114

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

58

For 100% live load

Using a three-member stepped beam finite

element model with:

w

L

= 1.40 kips/ft

L

r

= 18.3 ft

d

r

= 13.3 ft

E = 29,000 ksi

115

I

1

= 3,070 in.

4

I

2

= 2,520 in.

4

c

= 1.58 in. > 1.50 n.g.

116

I

1

I

2

I

2

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

59

Options to Limit Deflection

•Calculate

I using a more rigorous

approach

• Increase

I

1

by changing the angle size

• Increase the length of reinforcement,

L

r

117

Using the three-member stepped beam

finite element model with:

L

r

= 39 ft

d

r

= 3 ft

c

= 1.48 in. < 1.50 o.k.

118

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

60

For 50% live load

Using the three-member stepped beam

finite element model with:

w

L

= 0.70 kips/ft

L

r

= 39 ft

d

r

= 3 ft

c

= 0.73 in. < 1.0 o.k.

119

Welds at the End of the Reinforcement

120

rc

M

rc

M

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

61

The anchor force is

However, this equation is valid only in the

elastic range, where

M

r

≤ M

y

M

y

= F

y

S

x

rc

A

rx

M

Q

F

I

121

Due to the approximate nature of the

moment of inertia calculations, the weld

will be designed to develop the available

strength of the angles.

122

2

0 9 36 ksi 1 73 in. 56 0 kips

bn

P ...

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

62

Use two 3/16 in. fillet welds extending 8 in.

beyond the theoretical cutoff point. For

concentrically loaded weld groups, AISC

Manual Equation 8-2a is applicable.

w

R

n

= 1.39Dl

= (1.39)(3)[(2 welds)(8 in.)]

= 66.7 kips > 56.0 kips

o.k.

123

The beam web bust be thick enough to

transmit the load from the angles from the

beam. AISC Manual Equation 9-3 is

applicable.

0.286 in. < 0.380 in. o.k.

124

619 3

619

0 286 in.

65 ksi

min

u

D

t

F

.

.

.

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

63

Final Weld Design

125

Questions?

Bo Dowswell, P.E., Ph.D.

Principal

ARC International, LLC

126

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

64

References

Chang, F.K. and Johnston, B.G. (1952), “Torsion of Plate Girders,”

Transactions, American Society of Civil Engineers, April.

Huenersen, G., Haensch, H. and Augustyn, J. (1990), “Repair Welding

Under Load,” Welding in the World, Vol. 28, No. 9/10, pp. 174-182.

Norris, C.H., Polychrome, D.A. and Capozzoli, L.J. (1951), “Buckling

of Intermittently Supported Rectangular Plates,” Welding Research

Supplement, American Welding Society, November, pp. 546-s through

556-s.

127

Within 1 business day…

• You will receive an email on how to report attendance

from: [email protected]

• Be on the lookout: Check your spam filter! Check

your junk folder!

• Completely fill out online form. Don’t forget to check

the boxes next to each attendee’s name!

OR…

CEU Certificates

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

65

Access available in 24 hours…

• Go to:

http://www.wynjade.com/aisc14/webinarceu

Username: Your Attendee ID (found on your reg. receipt)

Password: Your Last Name

• Completely fill out online form. Don’t forget to check

the boxes next to each attendee’s name!

• Questions? Please email us at [email protected].

CEU Certificates

March 13 and 20, 2014:

2-part Webinar: Structural Stainless Steel

www.aisc.org/webinars

AISC Webinars

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

66

Spring 2014 Schedule has been released!

Seismic Design Manual and Application of the 2010 Seismic

Provisions

24 cities this spring

www.aisc.org/seminars

AISC Seminars

Fundamentals of Earthquake Engineering for Building Structures

Presented by Rafael Sabelli, Walter P Moore

Class begins February 24, 2014!

www.aisc.org/nightschool

AISC Night School

AISC Live Webinar Design of Reinforcement for Steel Members

Part II

Copyright © 2014

67

Thank You

Please fill out a brief survey at the conclusion of the webinar.

Your feedback is greatly appreciated.