Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

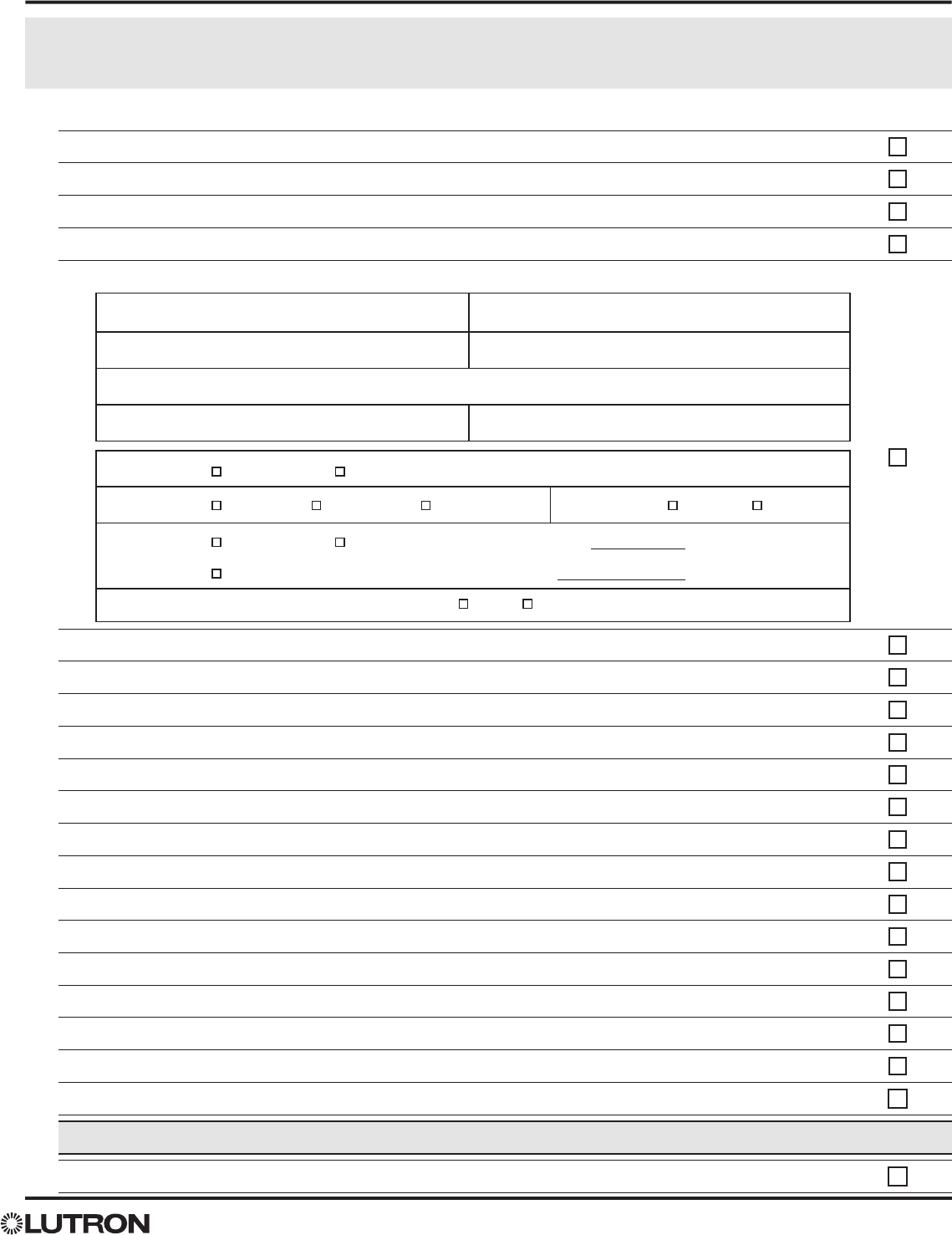

Lutron Custom Curved Drapery Track Worksheet

IMPORTANT: All steps must be complete prior to sending in your template. Failure to complete any of the noted

steps in this document will result in your template being rejected. Templates that are rejected will be sent back to the

dealer for correction and must be resubmitted successfully before the quoted lead time begins.

INSTRUCTIONS

COMPLETE

1. Determine and confirm whether a custom order is needed

Page 1, Sec 1

2. Review the general guidelines and limitations for custom curved drapery tracks

Page 1, Sec 2.1

3. Verify, if necessary, that the required curve radius is at least 20 in (508 mm)

Appendix (Page 5)

4. Submit your quote to obtain a COM number and coded shipping label

Page 1, Sec 2.2

5. After completing step 4, enter details below:

COM Number: Quote Number:

Dealer Name: Job Name:

Dealer Address:

Phone Number: Email Address:

Choose one: Single Track Dual Track Spacing between tracks: _______ in mm (circle one)

Choose one:

Left Draw Right Draw Center Draw Choose one: Splice No Splice

Choose one:

Pocket Mount Pocket Width: _________________ in mm (circle one)

Choose one: Drive side (viewed facing window)

Left Right

6. Construct the custom curve template according to the attached instructions

Page 2, Sec 3

7. Mark the correct orientation (A or B) on the template

Page 2, Sec 3.2

8. Verify clearance to the wall and other obstacles is 3½ in (89 mm) or more

Page 3, Sec 3.3

9. Write or affix your contact info on the template

Page 3, Sec 3.4

10. Mark the drapery track centerline on the template

Page 3, Sec 3.4

11. Mark drive location(s) on the template

Page 3, Sec 3.4

12. Mark the ends of the track(s) on the template

Page 3, Sec 3.4

13. Mark the extents of the pocket, if applicable, on the template

Page 3, Sec 3.4

14. For a tandem or center-draw system, mark the track center on the template

Page 3, Sec 3.4

15. Mark the wall or pocket position on the template

Page 3, Sec 3.4

16. Mark the splice location, if applicable, on the template

Page 3, Sec 3.4

17. Write the COM number directly on the template

Page 4, Sec 4.1

18. Complete this page and affix a copy of it to the template

Page 4, Sec 4.1

19. Verify the track length on the template matches the track length listed on the quote

Page 4, Sec 4.1

20. Make a photo record of the finished template in place, on site

Page 4, Sec 4.2

21. IMPORTANT: Process your custom curved drapery track quote as an order in MyProjects before submitting the template

22. Pack and mail the template

Page 5, Sec 5

Customer Service & Ordering

USA & Canada; 08.00 - 19.00 EST: 1.800.446.1503

U.K.; 09.00 - 18.00 GMT: +44.(0)20.7702.0657

commercialshadeest@lutron.com (commercial)

[email protected] (residential)

Technical Support & Services

USA and Canada; 24 hrs / 7 days: 1.800.523.9466

U.K.; 08.00 - 18.00 GMT: +44.(0)20.7680.4481

forums.lutron.com

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Please complete all steps of this procedure before submitting your order

Making the Custom Curved Drapery Track Template

Page 1

1

About Standard Curved Drapery Tracks

Lutron provides standard curved drapery tracks to fit inside or outside a 90 degree

corner. These tracks have a bend radius of 20 inches. This solution does not require the

creation of a template (you do not need this document), and can be found as a drapery

track option in myProjects. To specify in myProjects, select Add Product, then choose

Drapery. In the Product Details field, select Standard Curved Track. (Drive and

communication selections vary depending on need.) Standard curved drapery tracks are

available in single and tandem configurations only. All dual curved drapery tracks are

custom, and require a template.

If you need a Custom Curved Drapery Track, proceed to section 2.

2

Before You Begin the Template

2 .1 General guidelines and limitations

a. Lutron drapery track can be custom-curved to fit a curved wall, bay window, and many

other special applications. Constant radius is recommended.

b. A paper template is the only way to ensure accurate curving of the drapery track.

c. The finished track may vary ±3/4 in (19 mm) from the template.

d. Allow 1 in (25 mm) clearance between ends of drapery tracks and walls.

e. Curves must have a minimum radius of 20 inches. If you are unsure whether your curved

wall or window meets this requirement, see the Appendix on page 5.

f. 90° is the tightest inside angle possible. Smaller angles are not allowed. See figure 2.1F

g. “S” bends and other multiple-bend shapes can only be achieved by splicing two curved

tracks together.

h. Splices can only be made in straight sections of drapery track. Splice must occur on a

straight length of track at least 16 in (406 mm) long. See figure 2.1G/H

i. Maximum 1-piece track length is 216 in (548.6 cm)

j. Maximum 2-piece (spliced) track length is 360 in (914.4 cm)

k. Minimum spacing for dual tracks is 5½ in (140 mm) center-to-center. See figure 2.2K

l. Pockets must allow ample space for the track(s) and drapery stackback.

See table 2.1L for minimum pocket dimension.

Minimum

Dimension

Wall or Ceiling

Mount

Dual Track

P 6 in (152 mm) 11.5 in (292 mm)

Tabl e 2.1L

2.2 Submit your quote to obtain a COM number and coded shipping label

Before making your curved track template, you must submit a drapery track quote* to

the Lutron Shading Quotes Department. Upon receipt of your quote, the Shading Quotes

team will send you a COM number to identify materials associated with your order, along

with a bar-coded address label you’ll use to ship your template. If you submit a template

without a COM number and Lutron-issued shipping label, it will be rejected.

*Your quote must be calculated based on the straight-length equivalent of the curved

track(s) to be ordered, and must be submitted via email to [email protected].

Please be sure to include all relevant measurements and curved track details, including

constant/variable radius, single/dual/tandem configuration, and splice/no-splice. These

details will be used by the Shading Quotes team to finalize the Lutron quote.

Min. 16 in (406 mm)

Splice

Splice

Figure 2.1G/H

LESS

THAN 90°

MORE

THAN 90°

90°

Figure 2.1F

Min. 5.5 in (140 mm)

Figure 2.1K

Contents

1 About Standard Curved Drapery Tracks ........ 1

2 Before You Begin the Template ..................... 1

2.1 General guidelines and limitations ......1

2.2 Submit your quote .............................1

3 Making the Template ..................................... 2

3.1 Tools and materials ............................2

3.2 Build the paper layout ........................2

3.3 Trace the curvature ............................3

3.4 Add vital information ..........................3

4 Finishing the Template .................................. 4

4.1 Final preparations for submittal ..........4

4.2 Make a photo record ..........................4

5 Pack and Ship the Completed Template ....... 5

APPENDIX: Qualifying the Minimum Radius ...... 5

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Please complete all steps of this procedure before submitting your order

Making the Custom Curved Drapery Track Template

Page 2

3

Constructing the Template

3.1 Tools and materials for constructing a durable template and submitting it to Lutron

3.2 Build the paper layout

a. Begin by taping contractor paper together close to wall. Use the ceiling or the floor (floor shown), whichever follows the curvature best.

Contractor Paper* Mailing Tube

Compass

(optional; recommended)

*NOTE: Anything other than contractor paper or poster paper may be rejected.

Please use the most durable material available.

Figure 3.2a

b. If making the template on the ceiling, mark the template “Orientation A.”

If making the template on the floor, mark the template “Orientation B.”

Figure 3.2b

Digital Camera

or Camera-Equipped

Smartphone

Masking Tape (2-inch or wider;

please do not use painter’s tape)

Black Marker Scissors Tape Measure

Minimum

12 in (305 mm)

Tape all edges securely

Contractor Paper

Ceiling

Floor

Orientation

A

Orientation

B

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Please complete all steps of this procedure before submitting your order

Making the Custom Curved Drapery Track Template

Page 3

Paper

Drapery Track

Centerline

Wall

3

Making the Template (continued)

3.3 Trace the curvature

a. Using a compass or similar tool to maintain a constant spacing to the wall, follow the wall profile to trace the track centerline onto paper.

b. After completing the trace, darken the pencil line with the black marker.

The typical distance for wall

mounted track is 3½ in (89 mm)

from the wall, however, your

distance may be greater for the

curtain to clear items like handles,

window sills, columns, vents, etc.

Figure 3.3

3.4 Add vital information

Figure 3.4

Mark the

Drapery Track

Centerline

Mark ends of track

(and extents of pocket if applicable)

Mark drive

location(s)

Mark wall

location

(if applicable)

Mark contact info

or attach business card

Mark center draw location

(if applicable)

Mark template

orientation

A = Ceiling

B = Floor

Orientation

B

SPLICE

CENTER

DRAW

CENTERLINE

WALL

DRIVE

END OF

TRACK

END OF

TRACK

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Please complete all steps of this procedure before submitting your order

Making the Custom Curved Drapery Track Template

Page 4

IMPORTANT: All steps must be complete prior to sending in your template. Failure to complete any of the noted

steps in this document will result in your template being rejected. Templates that are rejected will be sent back

to the dealer for correction and must be resubmitted successfully before the quoted lead time begins.

4

Finishing the Template

4.1 Final preparations for submittal

a. Complete the form and checklist on the Custom Curved Drapery Track Worksheet, then attach a copy of that page to the template as

shown below.

b. Verify the length of the track centerline on the template matches the track length listed on the quote.

NOTE: The length of the track centerline and the track length listed on the quote must match.

c. Be sure that the template is taped together in one piece. Mark an “X” over each taped seam so the Lutron Manufacturing team will have a

reference as to where to rejoin those pieces in the event they become separated.

NOTE: Templates shipped on separate sheets will be rejected. Each curved track must have its own template. The only exception is dual

tracks, which can be on the same template.

4.2 Make a photo record

a. Take a digital photo of the finished template in place.

b. Take several photos of the surface where the drapery track will be mounted, and the surroundings.

NOTE: Lutron may request copies of your photos if clarification of installation site features is needed.

Attach a

completed

copy of the

Custom Curved

Drapery Track Worksheet

Mark an “X” across each seam

Write the COM

number directly

on the template

Orientation

B

WALL

CENTER

DRAW

COM #

123456789

END OF

TRACK

END OF

TRACK

DRIVE

INSTRUCTIONS

COMPLETE

1. Determine and confirm whether a custom order is needed

Page 1, Sec 1

2. Review the general guidelines and limitations for custom curved drapery tracks

Page 1, Sec 2.1

3. Verify, if necessary, that the required curve radius is at least 20 in (508 mm)

Appendix (Page 5)

4. Submit your quote to obtain a COM number and coded shipping label

Page 1, Sec 2.2

5. After completing step 4, enter details below:

COM Number:

123587469

Quote Number:

Q776F

Dealer Name:

Smith & Doe

Job Name:

Lillian House

Dealer Address:

2121 Fieldhouse Road, Taylor, OH 44711

Phone Number:

302-897-5551

Email Address:

Choose one:

Single Track

Dual Track Spacing between tracks: _______ in mm (circle one)

Left Draw

Right Draw

Center Draw

Splice

No Splice

Choose one:

Ceiling Mount

Wall Mount

Distance from wall: ____________ in mm (circle one)

Pocket Mount

Pocket Width: _________________ in mm (circle one)

Choose one: Drive side (viewed facing window)

Left

Right

6. Construct the custom curve template according to the attached instructions

Page 2, Sec 3

7. Mark the correct orientation (A or B) on the template

Page 2, Sec 3.2

8. Verify clearance to the wall and other obstacles is 3½ in (89 mm) or more

Page 3, Sec 3.3

9. Write or affix your contact info on the template

Page 3, Sec 3.4

10. Mark the drapery track centerline on the template

Page 3, Sec 3.4

11. Mark drive location(s) on the template

Page 3, Sec 3.4

12. Mark the ends of the track(s) on the template

Page 3, Sec 3.4

13. Mark the extents of the pocket, if applicable, on the template

Page 3, Sec 3.4

14. For a tandem or center-draw system, mark the track center on the template

Page 3, Sec 3.4

15. Mark the wall or pocket position on the template

Page 3, Sec 3.4

16. Mark the splice location, if applicable, on the template

Page 3, Sec 3.4

17. Write the COM number directly on the template

Page 4, Sec 4.1

18. Complete this page and affix a copy of it to the template

Page 4, Sec 4.1

19. Make a photo record of the finished template in place, on site

Page 4, Sec 4.2

20. IMPORTANT: Process your custom curved drapery track quote as an order in MyProjects before submitting the template

21. Pack and mail the template

Page 5, Sec 5

TO ENSURE A SUCCESSFUL CUSTOM CURVED DRAPERY TRACK ORDER,

FOLLOW THESE STEPS (detailed instructions attached):

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. C 11/2021

|

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Lutron Custom Curved Drapery Track Worksheet

CENTERLINE

CENTERLINE

Lutron Electronics Co., Inc.

Coopersburg, PA 18036-1299, U.S.A.

P/N 368-4025 Rev. D 03/2023 |

Lutron and the Lutron logo are trademarks of Lutron Electronics Co., Inc., registered in the US and other countries

Making the Custom Curved Drapery Track Template

Page 5

IMPORTANT: ALL INSTRUCTIONS MUST BE FOLLOWED. A Production Engineer will review your template and will

determine if it is approved or if additional information is required. If the template meets the necessary requirements,

your curved track layout will be approved for manufacture. Failure to complete any of the noted steps in this document

will result in your template being rejected. Templates that are rejected will be sent back to the dealer for correction

and must be resubmitted successfully before the quoted lead time begins.

5

Pack and Ship the Completed Template

APPENDIX:

Qualifying the Minimum Radius (optional; see page 1, section 2.1, item d.)

a. Carefully roll the template and slide it into a sturdy mailing tube.

NOTE: Do not fold the template. Folding makes it difficult to lay flat, which may distort the true size and shape of curve.

b. Apply the addressed COM label supplied with your quote to the outside of the tube and ship via the carrier of your choice.

COM Label

Mailing Tube

Template

(rolled up)

Use the method shown here to

determine whether the curvature

of your installation site meets the

20-inch minimum radius requirement.

a. Using a chalk line or string, mark a

reference line (a.) connecting the two

ends of the curved wall section.

b. Find the midpoint of reference line a.,

and mark a second reference line (b.)

at a 90° angle to the first, extending

to the curved wall. See figure A.1

c. Measuring from the wall along

reference line b., make a reference

mark (c.) 20 inches from the wall.

d. Anchor a piece of string at reference

mark c., then extend it along

reference line b., to the curved wall.

Cut the string where it reaches

the curved wall (a 20-inch length).

See figure A.2

e. Swing the end of the string in an arc

to establish a 20-inch radius and

observe its proximity to the curved

wall. See figure A.3

If the string’s arc is smaller than the

curvature of the wall, the wall’s radius

is larger than 20 inches, and the site

qualifies for a curved drapery track.

Midpoint of Line a.

a.

b.

90°

Figure A.1

20 in

radius

c.

Larger than

20 in radius

20 in

string

Figure A.3

c.

b.

Wall

String

Figure A.2